Diaphragm filter fabric clamp

A technology of filter cloth clamp and diaphragm clamp, which is applied in the field of filter press parts, which can solve the problems of laborious clamping, scrapping of quick clamping parts, and failure to realize, and achieve the effect of strengthening connection strength, fast loading and unloading, and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

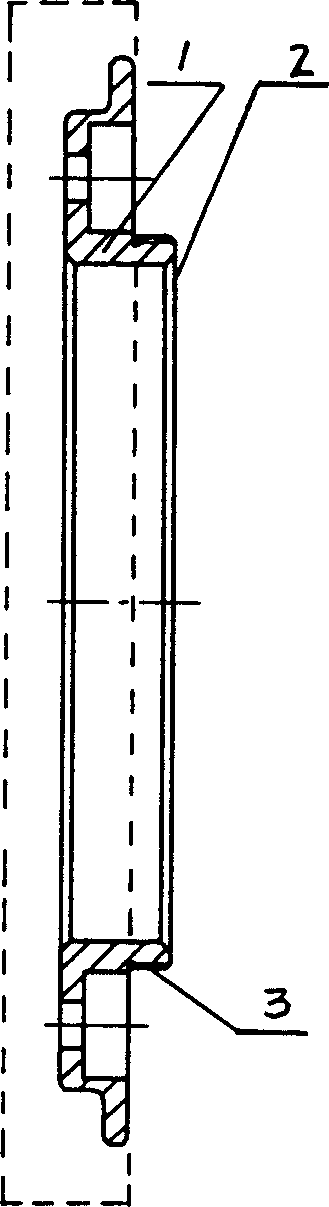

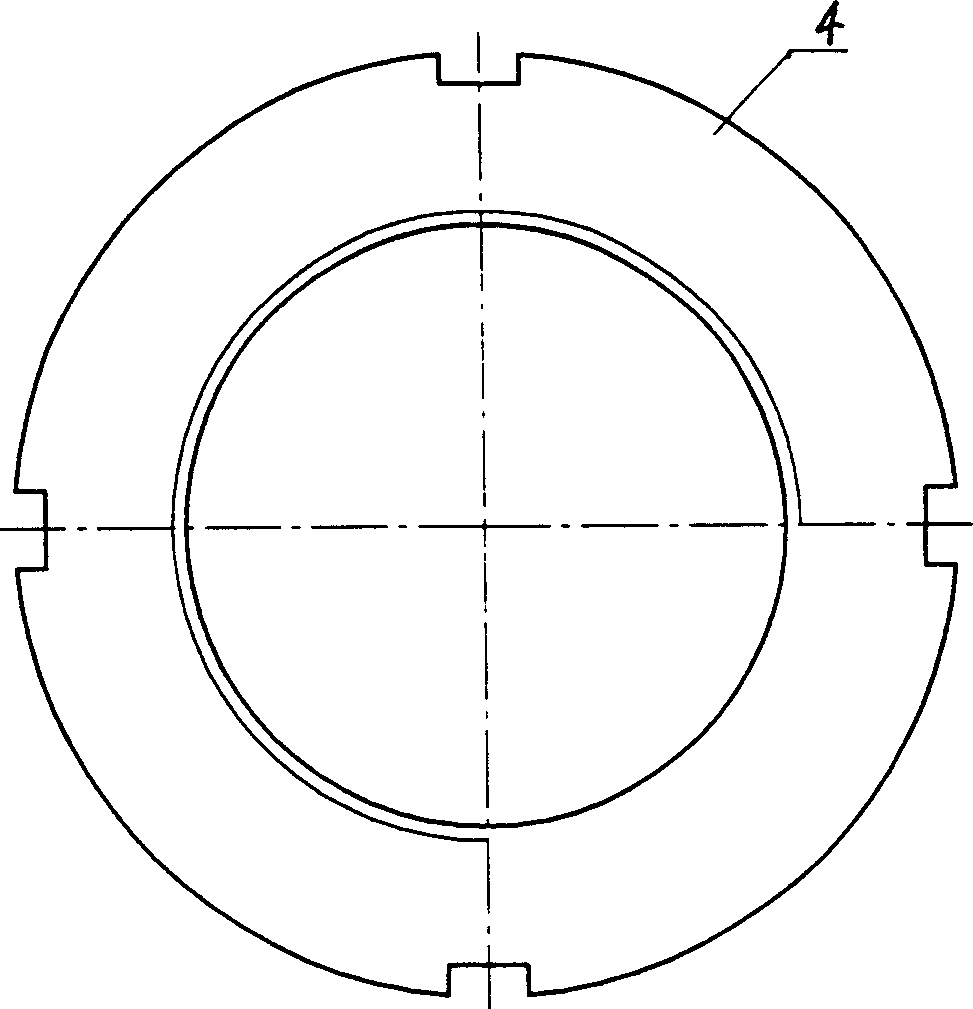

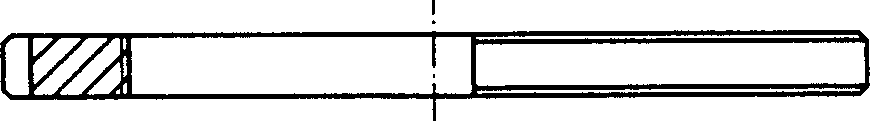

[0012] Embodiment 1: with reference to attached Figure 1~3 . The diaphragm filter cloth clip includes a diaphragm clip (1), the feed port of the diaphragm clip (1) is a filter cloth clip (2) and is integrated with the diaphragm clip (1). The filter cloth clamp (2) is a threaded screw connection type, which is composed of an external thread filter cloth collar (3) and an internal thread filter cloth chuck (4), and the internal thread filter cloth chuck (4) is screwed on the external thread filter cloth onto the collar (3) and press the filter cloth onto the clamping surface of the diaphragm clamp (1).

Embodiment 2

[0013] Embodiment 2: with reference to accompanying drawing 4~6. On the basis of Example 1, the filter cloth clip (2) is a snap-in type, consisting of an inner clip of the filter cloth clip and an outer clip (5) of the filter cloth clip, and the outer clip (5) of the filter cloth clip is clipped on the filter cloth clip Insert the inner clip and press the filter cloth tightly on the clamp surface of the diaphragm clamp (1). The outer wall of the filter cloth clip (5) is provided with planar convex-concave connecting grooves (6) at intervals on the circumference, and the circumference of the inner wall is provided with convex-table reinforcing ribs (7) at intervals. The inner clip of the filter cloth clip is integrated with the feeding port of the diaphragm clip (1), and the outer clip of the filter cloth clip (5) is composed of a collar and a chuck and adopts plastic (such as ABS) and mold injection molding or compression molding. 3 or 4 or 5 or 6 boss type reinforcing ribs (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com