Heat release structure of direct cooling refrigerator

A refrigerator and cold-type technology, which is applied in the field of heat release structure of direct cooling refrigerators, can solve the problems that the heat release area of the condenser 400 cannot be fully ensured, and the heat release efficiency of the condenser 400 is low, so as to improve the heat release efficiency and discharge The effect of increased thermal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

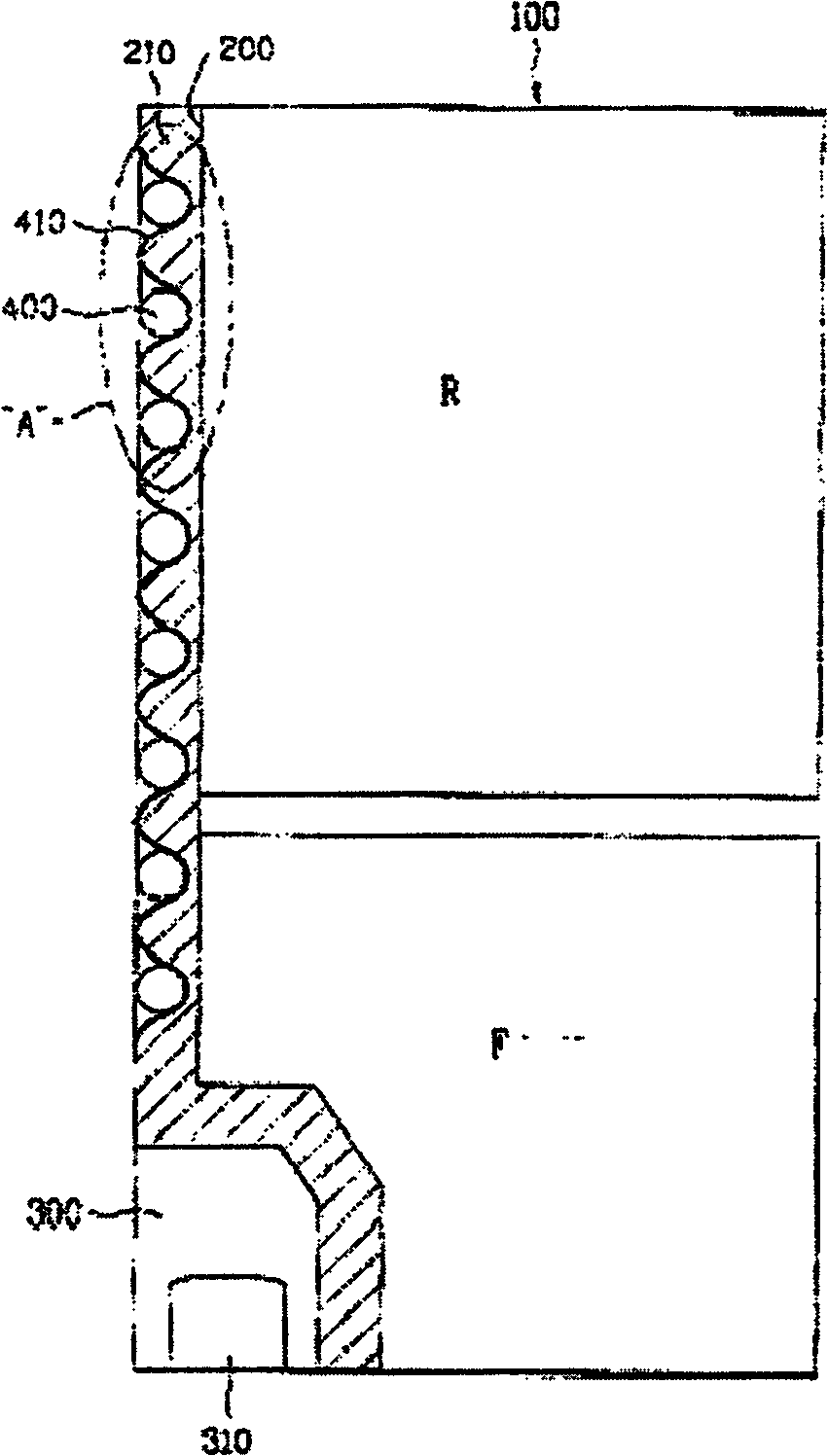

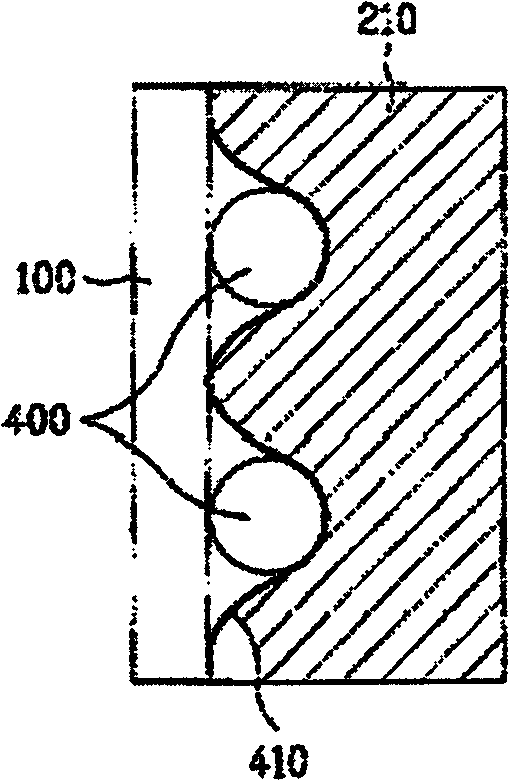

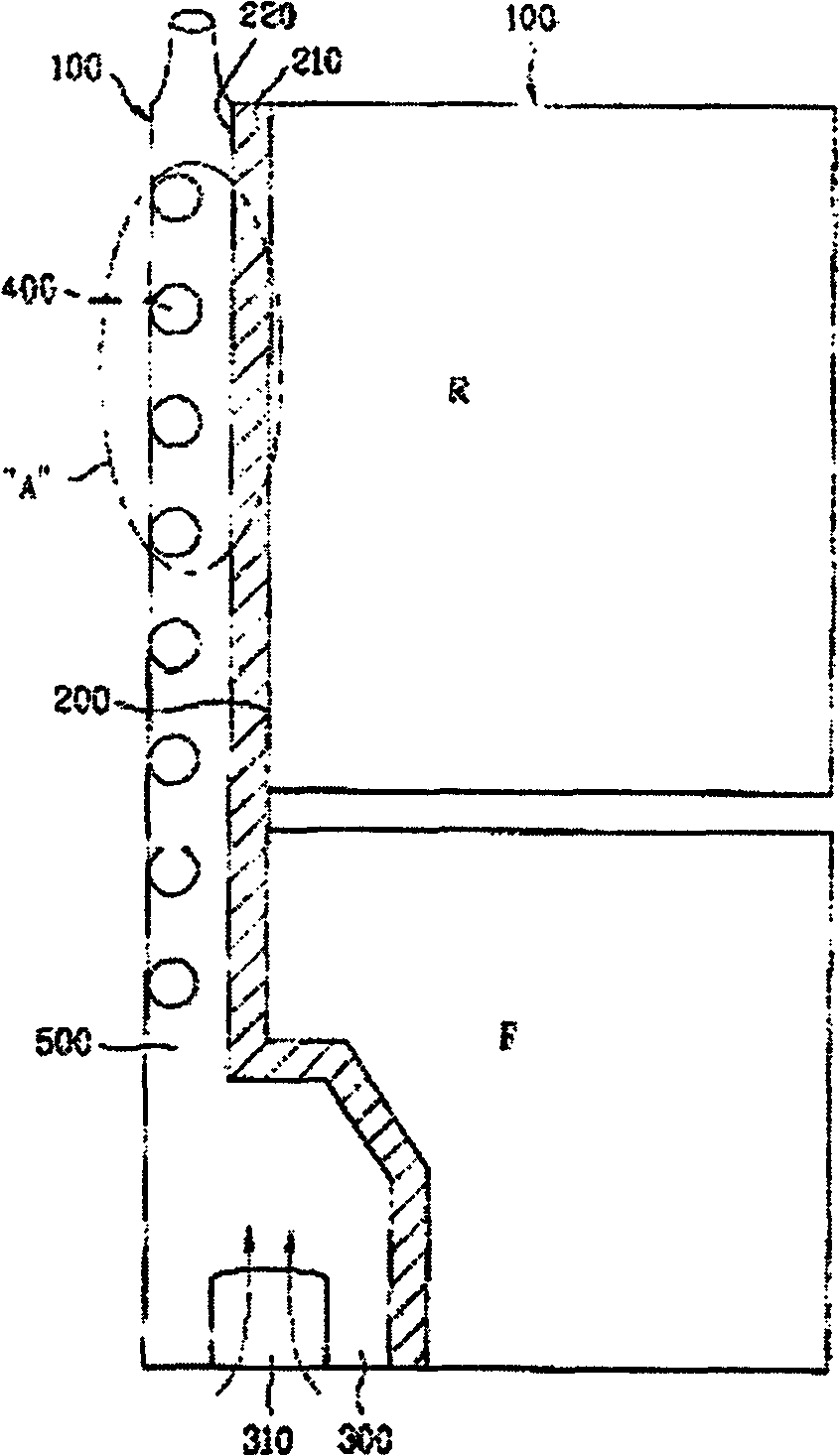

[0025] Such as image 3 As shown, the main components of the direct cooling refrigerator according to the embodiment of the present invention include an outer shell 100 , an inner shell 200 , a freezer room R and a refrigerator room F, a mechanical room 300 , a heat insulating material 210 , and a condenser 400 . Wherein, the outer shell 100 forms the appearance of the refrigerator; the inner shell 200 is located inside the outer shell 100, and the rear side is separated from the rear side of the outer shell 100 to form an air flow channel 500; the freezing room R and the refrigerating room F are respectively located inside the inner shell 200 The upper and lower sides of the upper and lower sides of the casing; the mechanical room 300 is located in a certain space at the bottom of the rear wall inside the casing 100, and can be equipped with ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com