Back light source device

A technology of backlight source and discharge tube, which is applied in the field of multi-lamp backlight source devices, can solve problems such as difficulty in improving brightness, and achieve the effects of realizing cost and suppressing uneven brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

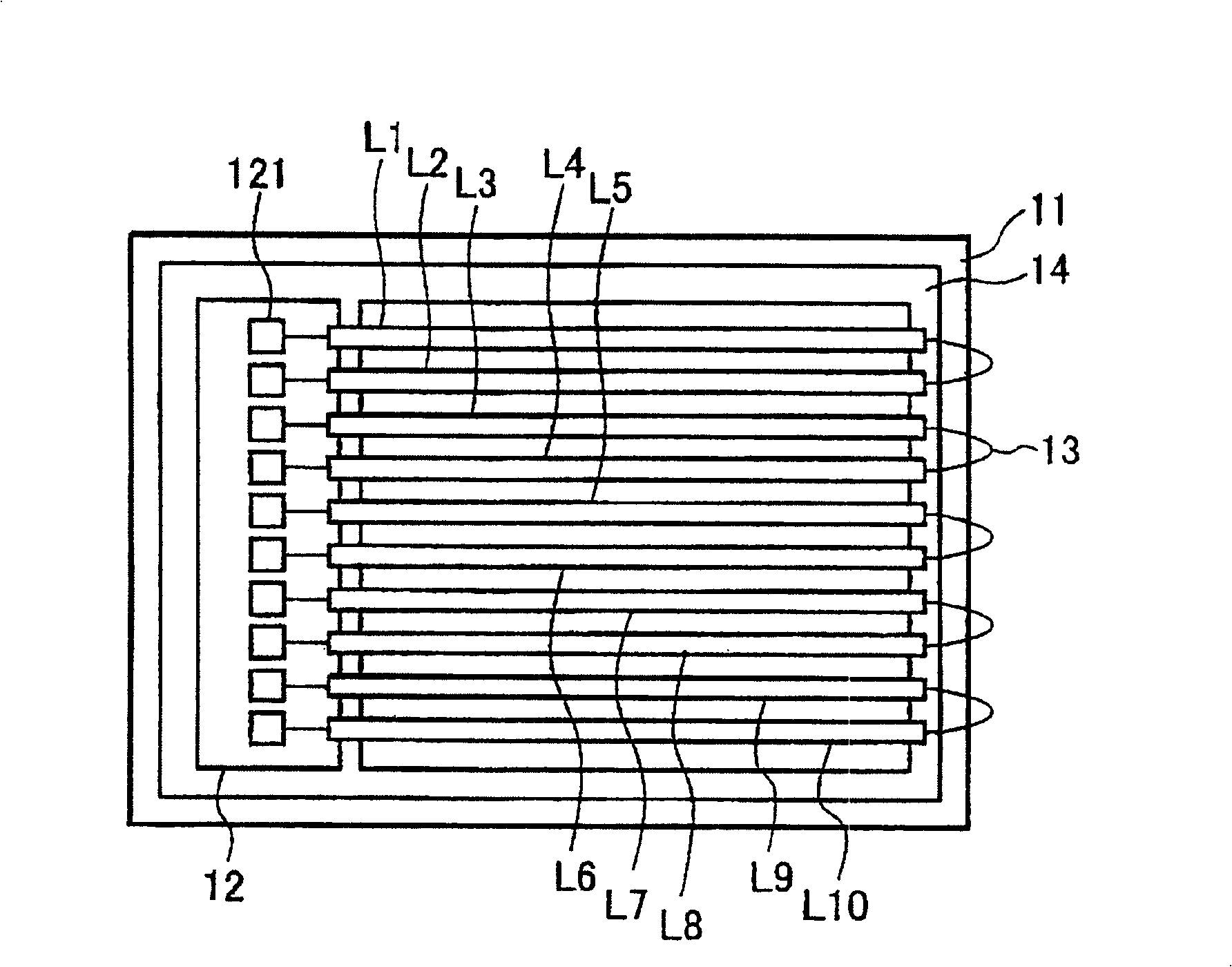

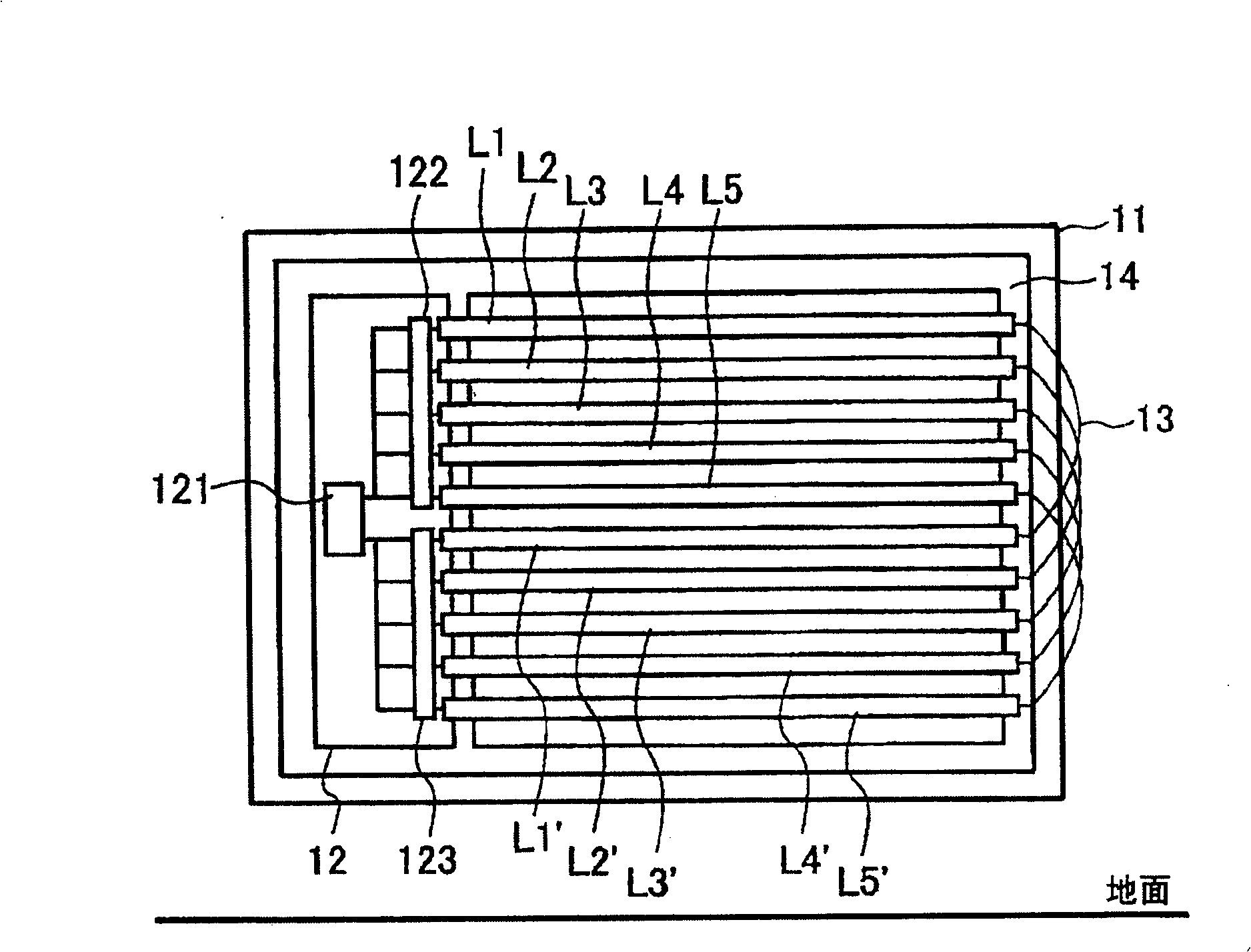

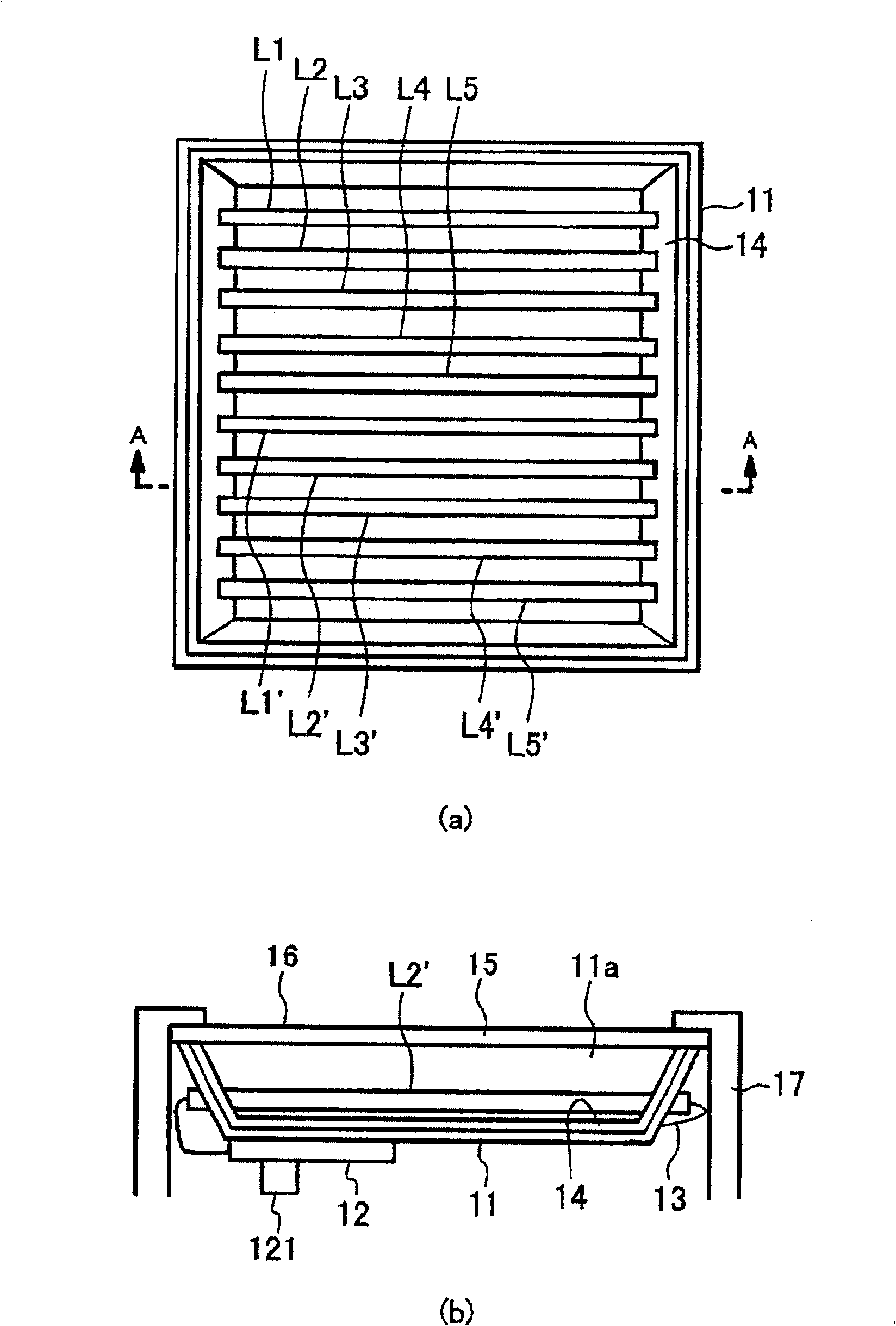

[0022] figure 2 It is a schematic diagram showing the relationship between the discharge tube and the inverter circuit in the backlight unit according to the first embodiment of the present invention. image 3 (a) is a plan view of the backlight unit according to Embodiment 1 of the present invention viewed from the display surface side. image 3 (b) is based on image 3 (a) Cross-sectional view of A-A after cutting. Such as Figure 2 ~ Figure 4 As shown, the backlight device according to Embodiment 1 of the present invention includes: a casing 11 , an even number of discharge tubes L1-L5 and L1'-L5', and an inverter circuit 12 . also, Figure 2 ~ Figure 3 This is an example when ten discharge tubes are used.

[0023] exist figure 2 Among them, the discharge tubes L1 to L5 and L1' to L5' are straight discharge tubes having a pair of electrodes, and are constituted by, for example, cold cathode tubes. The discharge tubes L1 to L5 and L1' to L5' are arranged in parallel...

Deformed example 1

[0040] Figure 5 It is a block diagram showing a modified example of the backlight unit according to Embodiment 1 of the present invention. Such as Figure 5 As shown, the backlight device of Embodiment 1 constitutes an inverter circuit 12a through two transformers. That is, in inverter circuit 12 a of Modification 1 of Embodiment 1, transformer 125 is provided in parallel with transformer 121 .

[0041] The electrode at one end of the discharge tube L1 arranged at the top of the first discharge tube group is connected to the electrode at one end of the discharge tube L1' arranged at the top of the second discharge tube group, and the analog U is formed by the discharge tube L1 and the discharge tube L1'. shaped tube. Similarly, the electrode arranged at one end of the second discharge tube L2 on the first discharge tube group is connected to the electrode arranged at one end of the second discharge tube L2' on the second discharge tube group. An electrode at one end of th...

Deformed example 2

[0045] Figure 6 It is a block diagram showing another modified example of the backlight unit according to Embodiment 1 of the present invention. Such as Figure 6 As shown, the backlight device of Modification 2 of Embodiment 1 consists of two transformers to form an inverter circuit 12b, and an even number (six or more) of discharge tubes are divided into four into a first discharge tube group composed of discharge tubes L1-Ln. , the second discharge tube group consisting of discharge tubes L1'-Ln', the third discharge tube group consisting of discharge tubes L1a-Lna, and the fourth discharge tube group consisting of discharge tubes L1a'-Lna'. In addition, in the inverter circuit 12 b of the modification 2 of the first embodiment, the transformer 125 is provided in parallel with the transformer 121 .

[0046] In addition, two of the first to fourth discharge tube groups are selected in order each time, the first group is composed of the first discharge tube group and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com