Method for X ray detection adopting multi-element exposure parameter formula

A technology of exposure parameters and X-rays, which is applied in the field of exposure, can solve the problems that empirical formulas cannot meet the conditions, change the X-ray exposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] For a new ray machine, it must be "trained" according to the requirements of the instrument manual before use. At the end of the "training", a wall thickness T 1 For a plate of 10mm to 12mm, set the "transillumination current I 1 " = tube rated current, "exposure time t 1 " = 1 minute, "focal length f 1 "=600mm and "tube voltage V 1 " = 120kV This set of parameters is transilluminated; and then a plate with a thickness of T 2 = 36 ~ 40mm (or overlap several plates), and then set the "transillumination current I 2 " = tube rated current, "exposure time t 2 " = 2 minutes, "focal length f 2 "=600mm and "Tube voltage"=(80%~100%) the highest tube voltage; then transilluminate the latter group of plates according to this set of parameters.

[0096] The thickness of the transilluminated plate is T 1 and T 2 Test the blackness of the negative film, and record the blackness values as D 1 and D 2 , and other conditions remain unchanged, then according to the measured ...

example 2

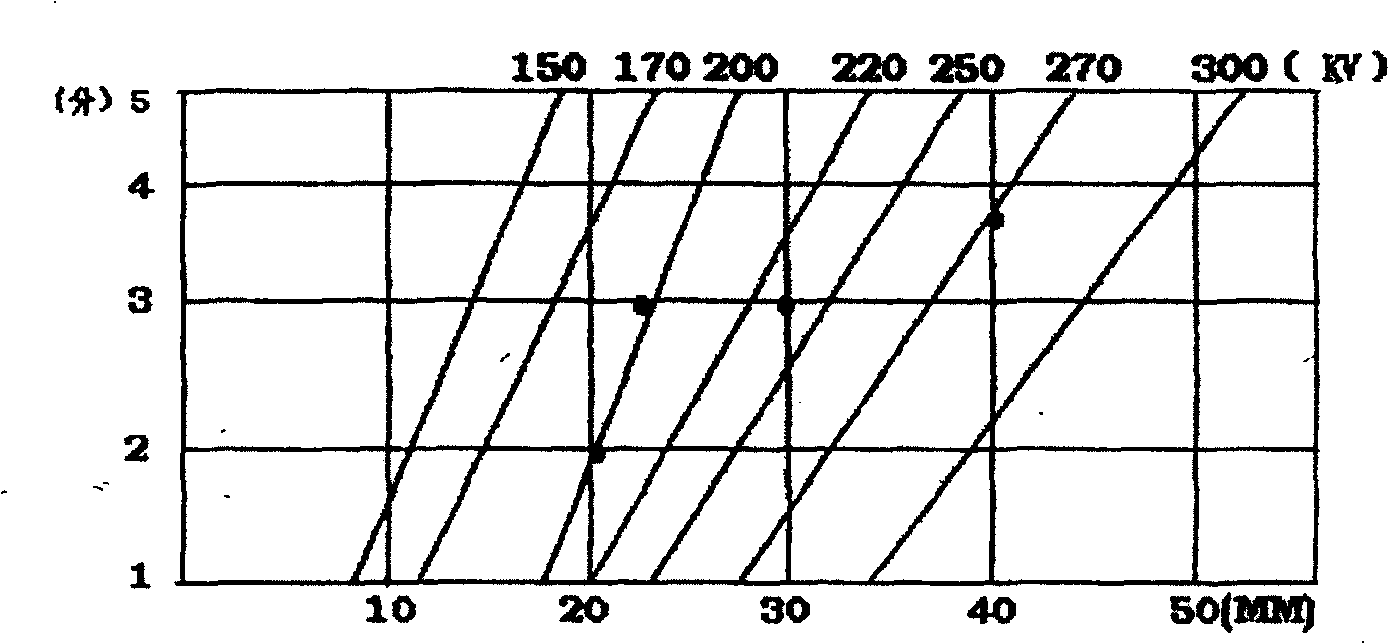

[0106] Example 2: For the reference exposure curve of a certain Dandong X3005 series machine, see figure 1

[0107] Take the value corresponding to the two red dots with the larger span of the two plate thickness ranges;

[0108] Select two red dots as the initial exposure point and its parameters are shown in Table 3:

[0109] Table three

[0110] plate thickness

mm

focal length mm

Tube current

(mA)

when exposed

Between (minutes

bell)

Tube voltage

kV

theoretical calculation

Voltage kV

ΔV

20

600

5

2

200

123.7

76.3

40

600

5

3.7

270

179.9

90.1

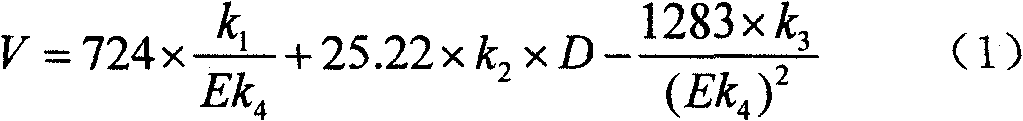

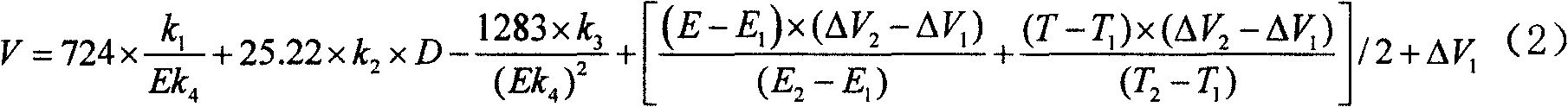

[0111] Substituting the values in Table 3 into the formula (1) can be obtained respectively

[0112] V 1 ’=123.7kV; ΔV 1 =76.3kV;

[0113] V 2 ’=179.9kV; ΔV 2 =90.1kV

[0114] ΔV 1 and ΔV 2 Substituting them into formula (2) resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com