Method for controlling novel open-head pinch roll and apparatus thereof

A control method and technology of pinch rollers, which are applied in the directions of transportation and packaging, coiling strips, and thin material handling, etc., can solve the problems of large unit equipment and complicated control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is the calculation of the motor torque for six different operating states of the pinch roller at the beginning.

[0046] 1. When the unit adopts tension uncoiling, the upper and lower pinch rollers are driven by hydraulic cylinders and pressed as pinch rollers. In order to achieve smooth unwinding, the pinch roller must generate a pinch tension of 6KN.

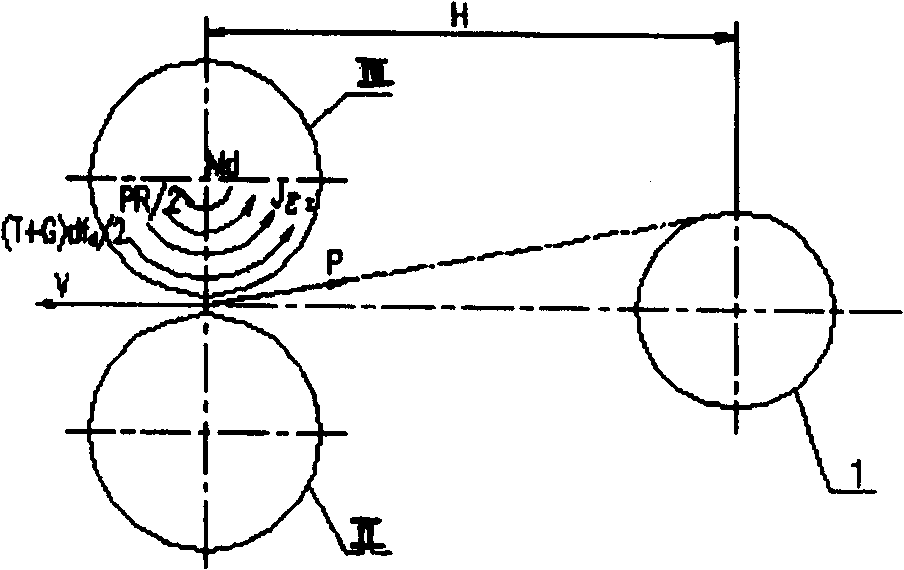

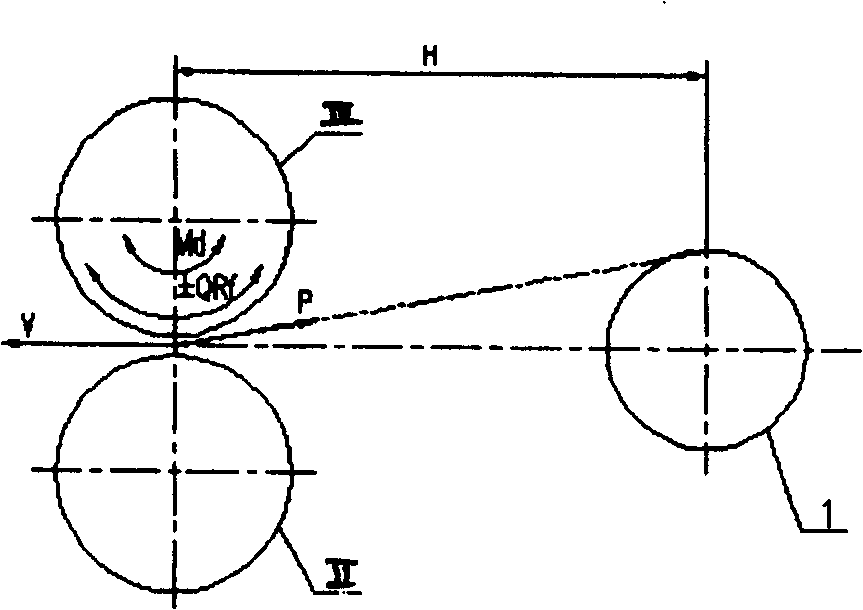

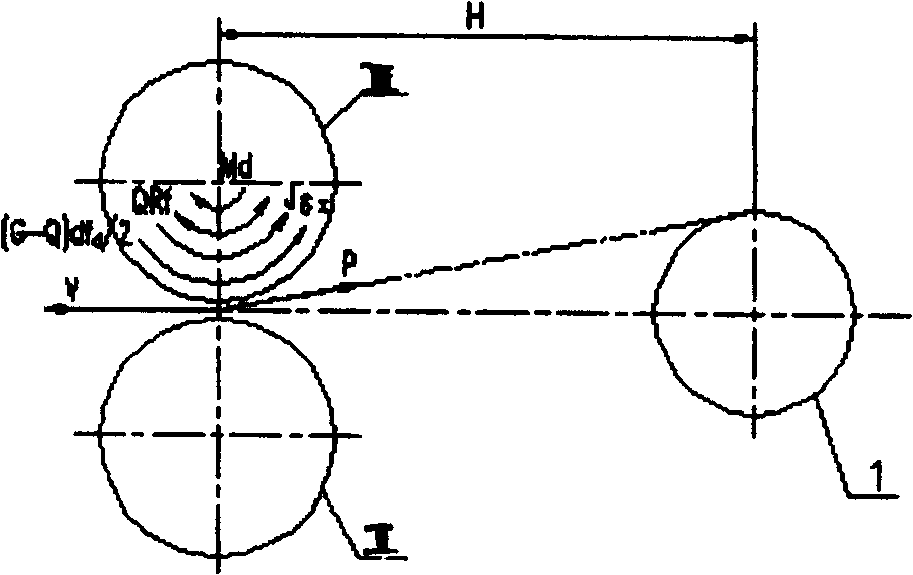

[0047] figure 1 is an analysis diagram of the torque applied to the roller in this case.

[0048] In the figure: I. Strip on uncoiler reel; II. Lower pinch roll; III. Upper pinch roll.

[0049] As shown in the figure, when the unit is threading the belt, the electric torque M on one roller d for:

[0050] m d ≥PR / 2+Jε z +(T+G)df d / 2(1)

[0051] In the formula: M d - electric torque on one roller, N m;

[0052] T-the pressing force applied by the oil cylinder between the upper and lower rollers, N;

[0053] G-the gravity of the upper roller, N;

[0054] d-the equivalent diameter of the bearing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com