Discontinuous bamboo hat shape fuel oil spray forming device

A fuel and hat technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of easy penetration to the bottom wall of the combustion chamber or the bottom surface of the cylinder head, easy mutual interference of sprays, etc. The effect of reasonable distribution and large diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

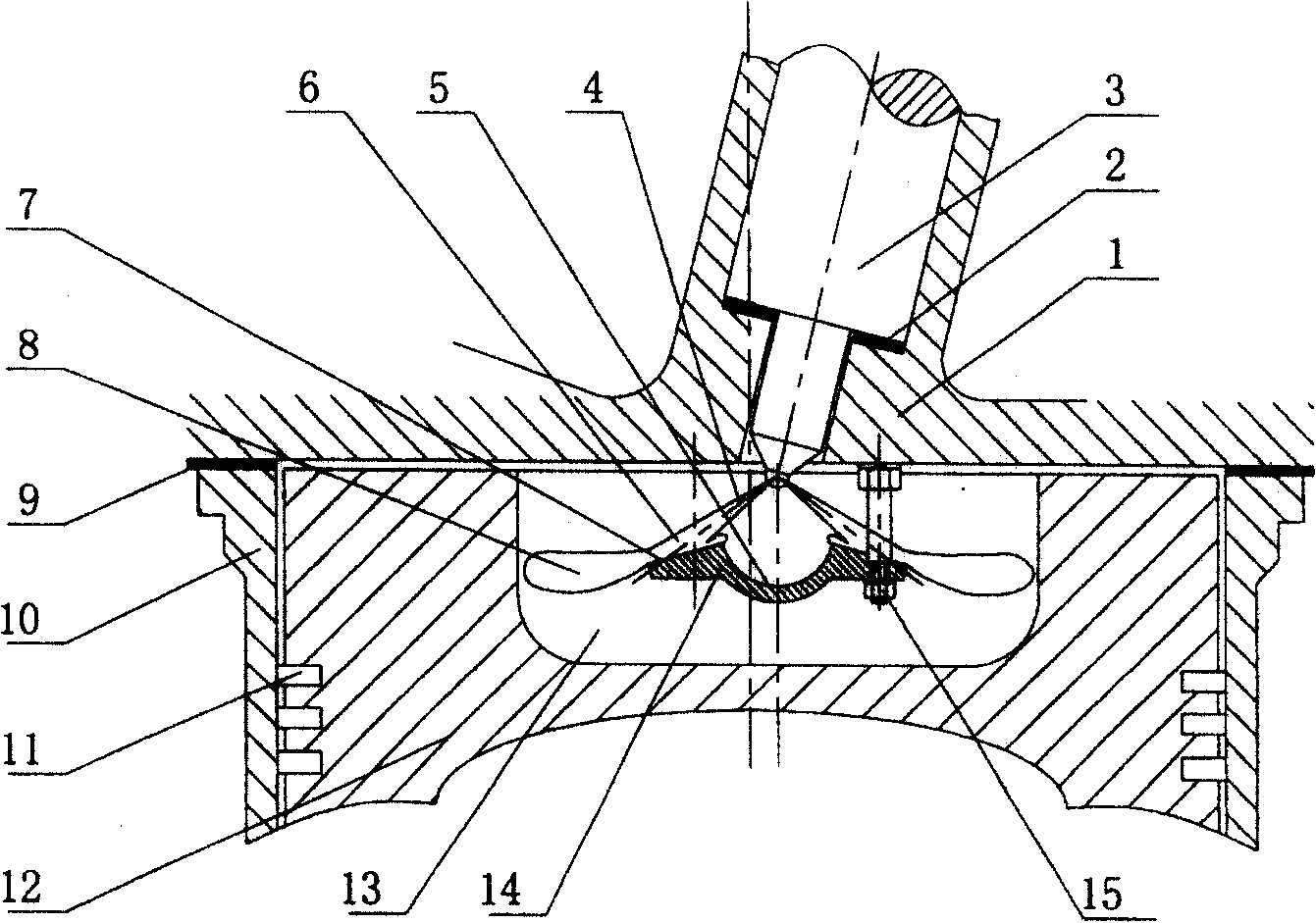

[0007] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0008] Such as figure 1 As shown, the device of the present invention includes a cylinder head 1, a sealing gasket 2, a porous injector 3, a copper sealing gasket 9, a cylinder 10, a piston ring 11, a piston 12, a combustion chamber 13, a collision body 14, and a bolt 15. The multi-hole fuel injector 3 is a traditional diesel engine fuel injector, its nozzle hole cone angle is 90-140 degrees, and the number of nozzle holes is 4-8. The multi-hole injector 3 is fixed in the cylinder head 1, and a sealing gasket 2 is installed between the two. The nozzle cone angle is the apex angle of the cone surface (nozzle cone) formed by the centerlines of all the nozzle holes of the multi-hole injector. The collision body 14 is a body of revolution formed by the wall surface 5 of the top pit and the side surface 7 of the cone. The top angle of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com