Non-continuous bamboo hat shaped spray burning system

A spray combustion, internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of easy mutual interference of wall-blocking sprays, easy penetration of wall-blocking sprays, etc., achieve reasonable radial distribution, improve comprehensive performance, and spread area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

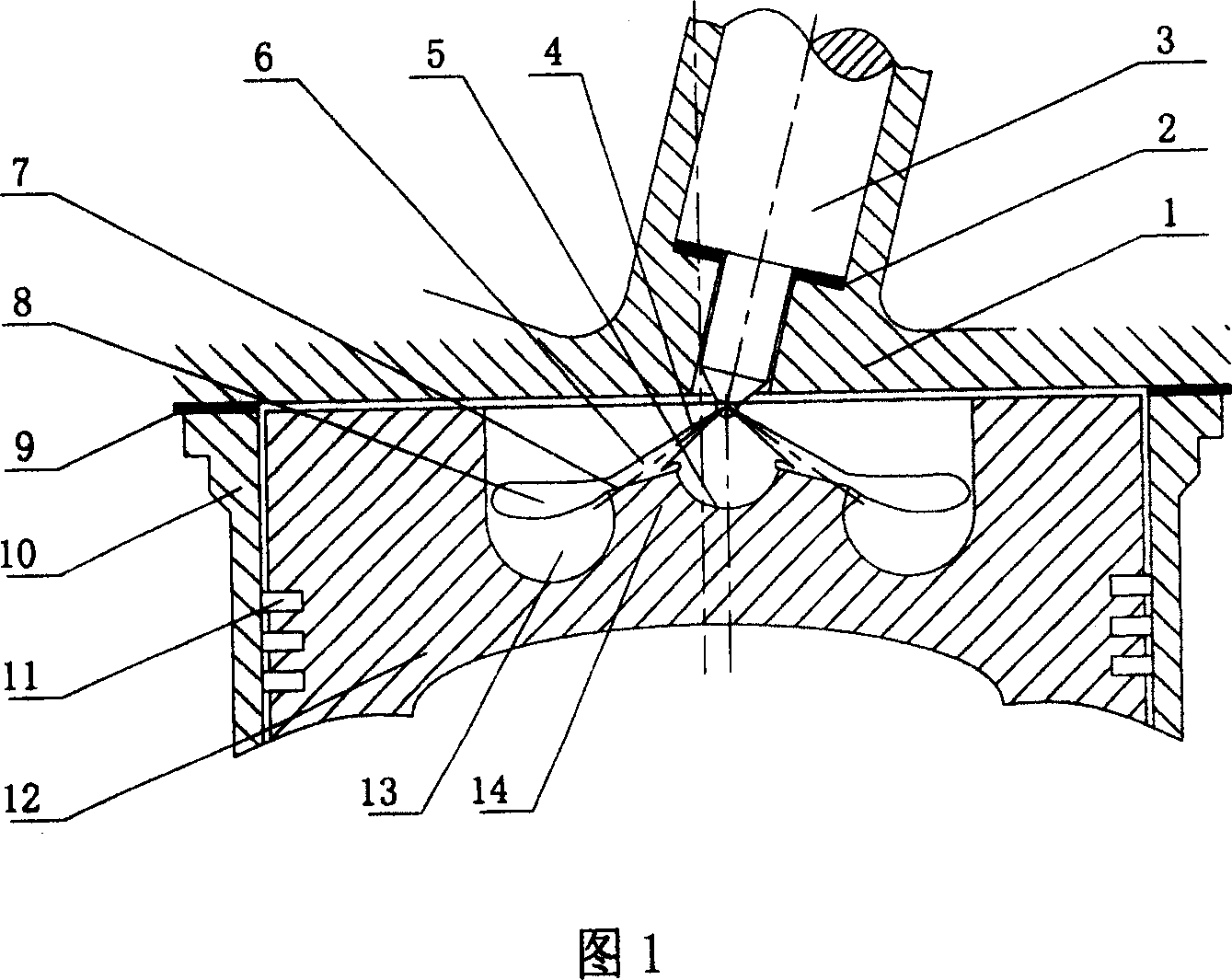

[0007] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0008] As shown in Figure 1, the present invention comprises a cylinder head 1, a sealing gasket 2, a porous injector 3, a sealing copper pad 9, a cylinder 10, a piston ring 11, a piston 12, a combustion chamber 13, and a central boss 14. The multi-hole injector 3 is a traditional internal combustion engine injector with 4 to 8 injection holes and a cone angle of 80° to 140°. The cylinder head 1 is a general internal combustion engine cylinder head. The multi-hole injector 3 is fixed in the cylinder head 1, and a sealing gasket 2 is installed between the two. Combustion chamber 13 is straight mouth type or narrowing mouth type, and the central part of its bottom wall protrudes to form a rotary boss——central boss 14 . It squeezes part of the air near the centerline of the combustion chamber 13 to the outside, so that it can be fully util...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com