Hard disk and press block positioning structure thereof

A positioning structure, hard disk technology, applied in the direction of recording information storage, instruments, etc., can solve the problems of not providing positioning, vibration, etc., to achieve the effect of reducing vibration and enhancing the positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

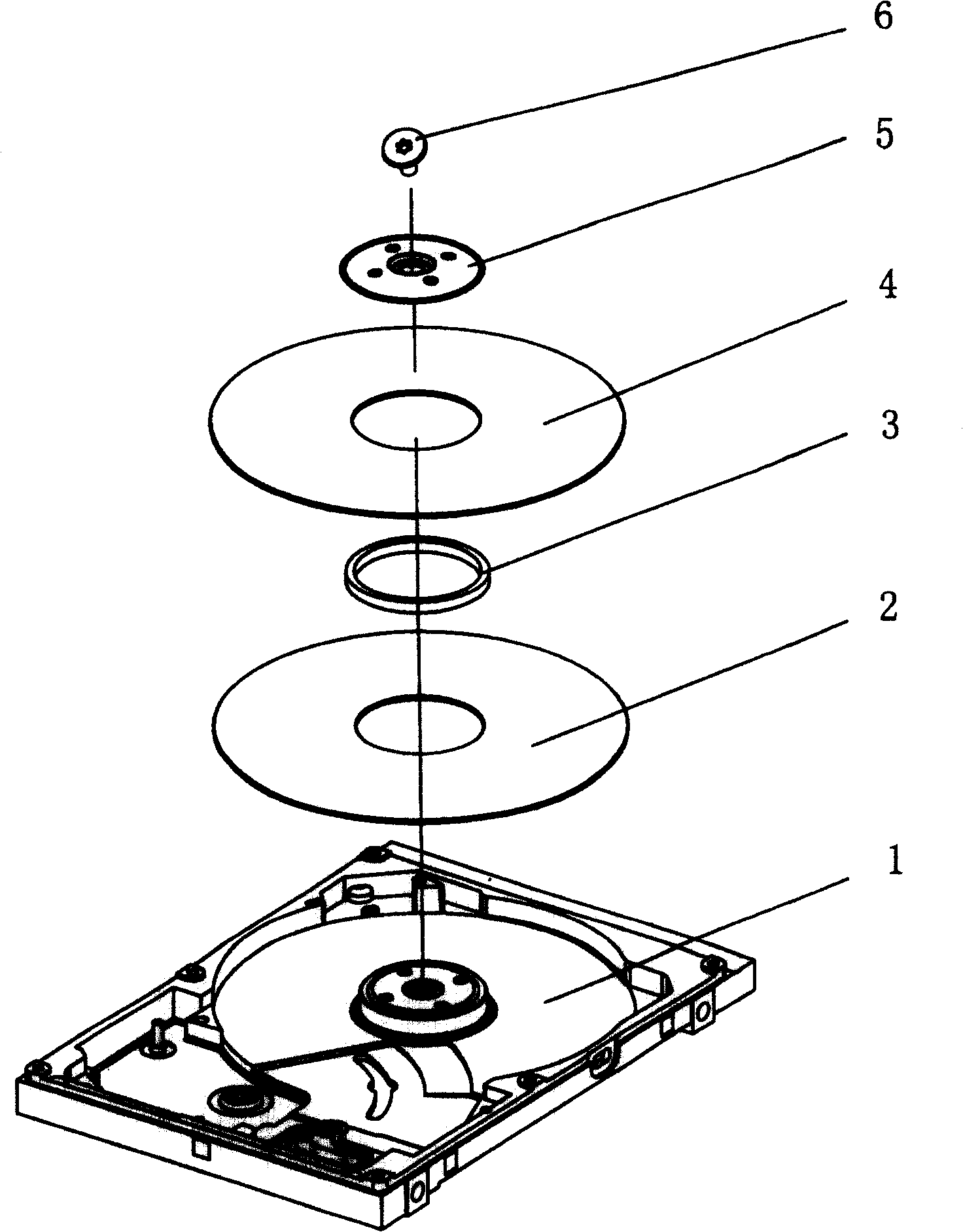

[0019] see Figure 2 to Figure 9 , The hard disk of the present invention includes a base 1 , a first disc 2 , a spacer 3 , a second disc 4 , a pressing block 5 and a fastener 6 .

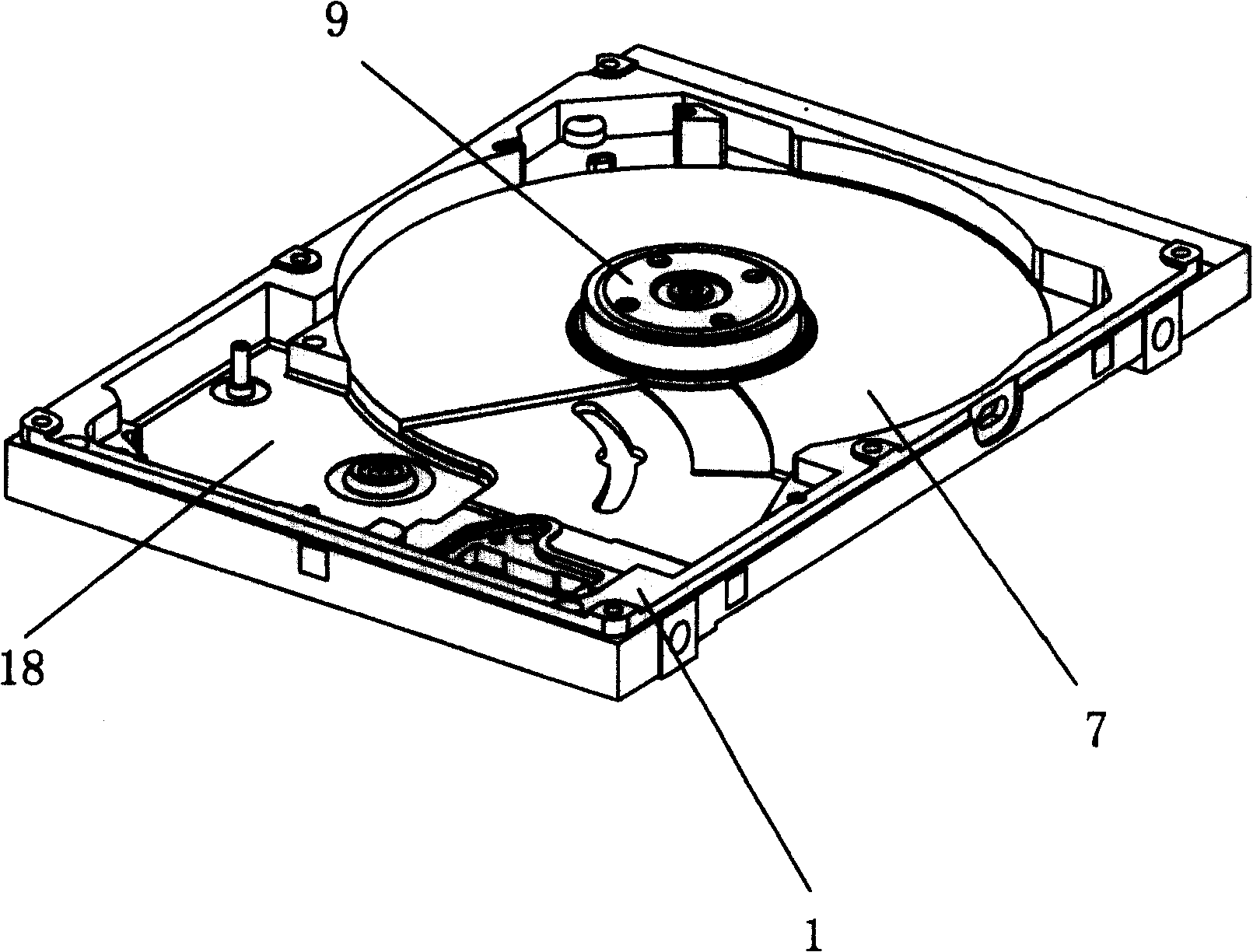

[0020] see image 3 and Figure 9 The base 1 is provided with a disk placement area 7 and a magnetic head assembly installation area 18, a cylindrical bearing motor 9 is installed at the center of the disk placement area 7, and a magnetic head assembly 19 and a magnetic head assembly are installed in the magnetic head assembly installation area 18. block assembly 30 .

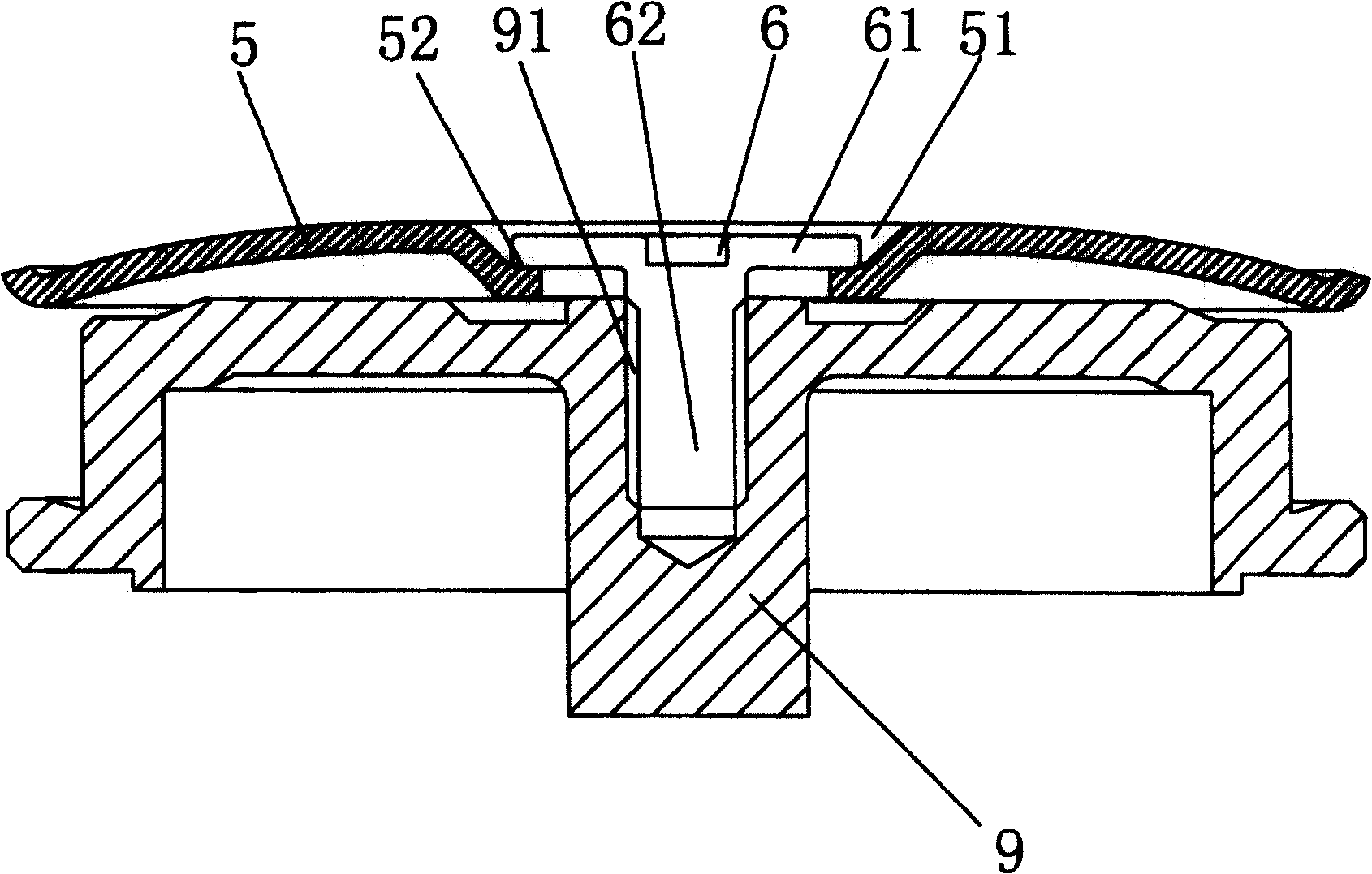

[0021] see Figure 4 , the bearing motor 9 has a smooth top surface 16, a groove 10 is recessed from the central position of the top surface 16 along the axial direction of the motor 9, and a groove 10 is formed vertically from the central position of the groove 10 along the axial direction The positioning boss 11 extends upwards, and the top surface 111 of the positioning boss 11 is higher than the top surface 16 of the motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com