Method for producing static anti-scaling solar vacuum heat collecting tube

A technology for vacuum heat collecting tubes and manufacturing methods, which is applied in the field of solar energy applications, and can solve problems affecting the thermal efficiency of all-glass vacuum heat collecting tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

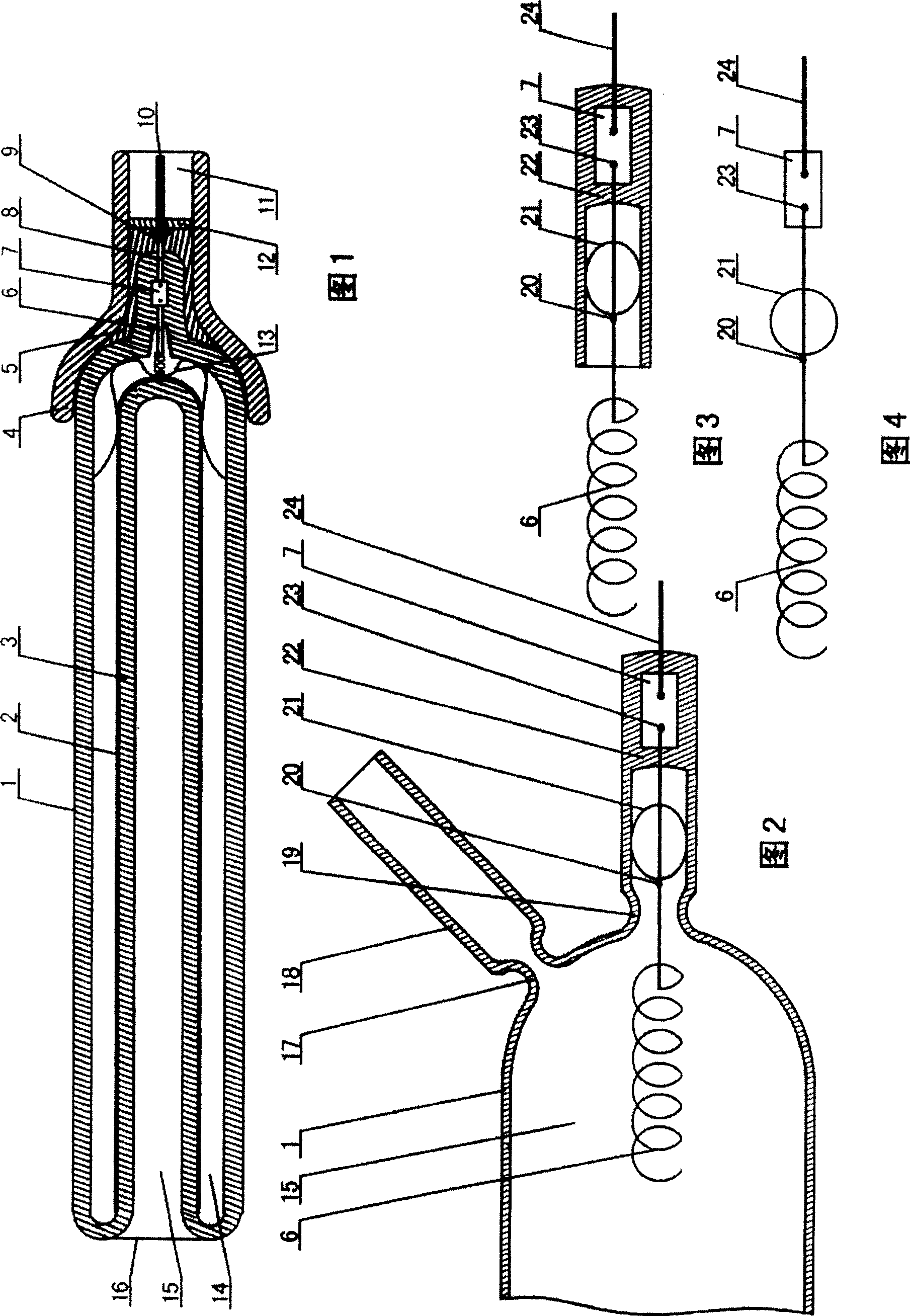

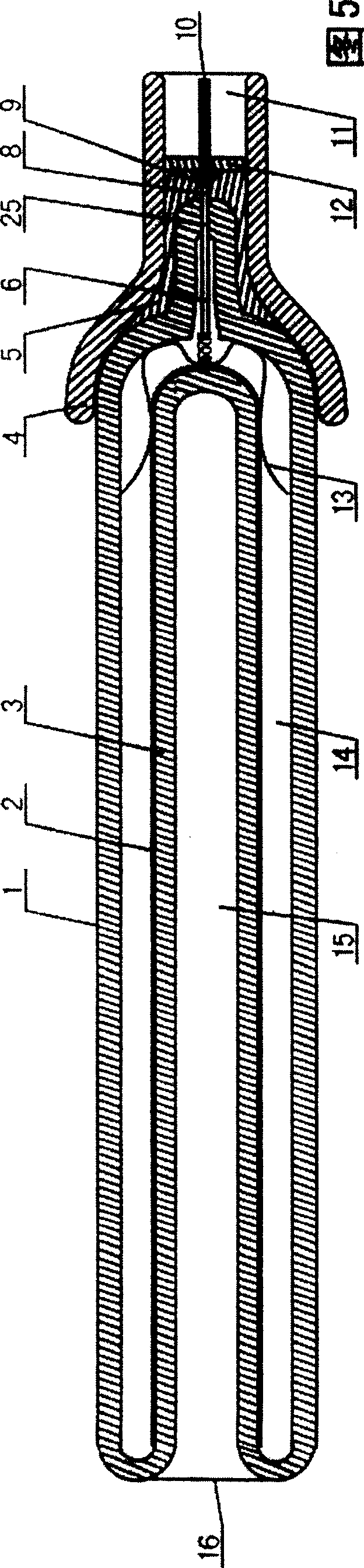

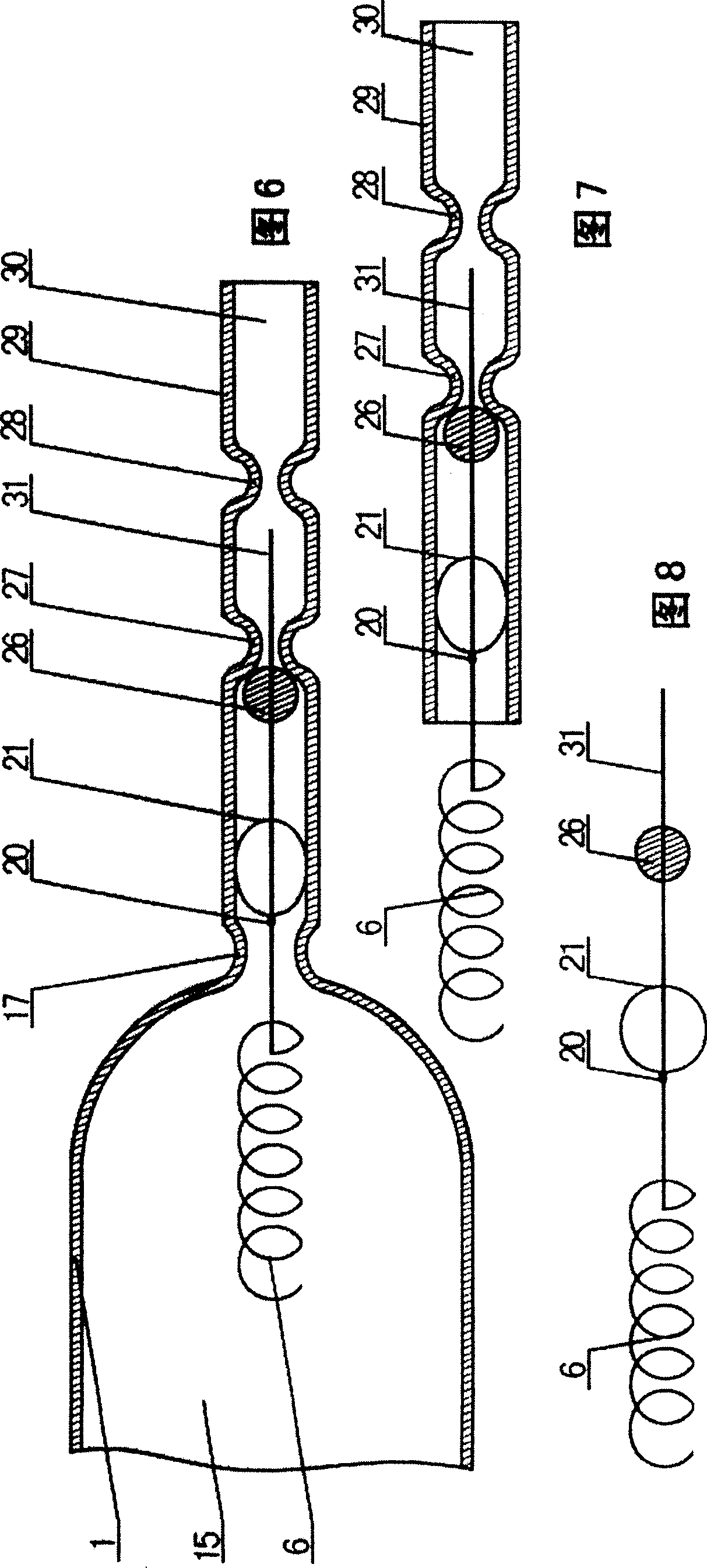

[0045] As shown in Figure 1, Figure 2, Figure 3, and Figure 4: the outer glass tube 1 of the vacuum heat collecting tube and the inner glass tube 3 of the vacuum heat collecting tube are aligned, and the vacuum heat collecting tube is coated on the inner glass tube 3 of the vacuum heat collecting tube to absorb heat After the film 2 is processed with the outer glass tube 1 of the vacuum heat collecting tube to form a glass tube with one end open and one end closed, a metal spring bracket 13 is installed in the interlayer of the closed end, and the outer glass tube 1 of the vacuum heat collecting tube and the inner glass tube of the vacuum heat collecting tube are installed. The interlayer of 3 is evacuated to form the vacuum chamber 14 of the heat collecting tube.

[0046] The conductive film electrically connects the spring 6, the metal molybdenum sheet 7, the lead wire 8 of the glass package, the electrode connector contact point 9 and the electrode connector 10 to form a con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap