Orbiting vane compressor and piston thereof

一种压缩机、活塞阀的技术,应用在双活塞阀领域,能够解决产生噪声、降低装配效率、不易于簧片阀安装等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

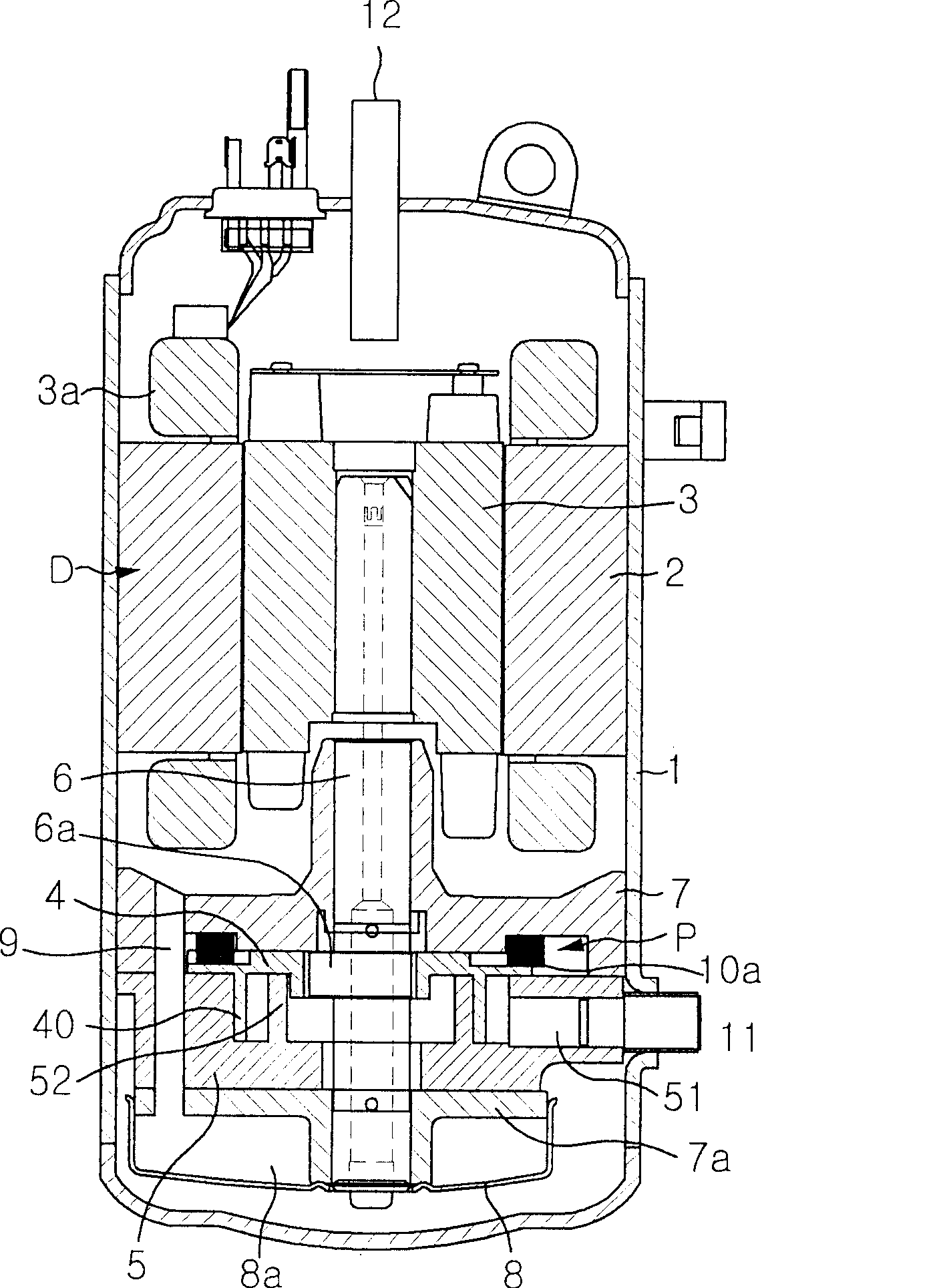

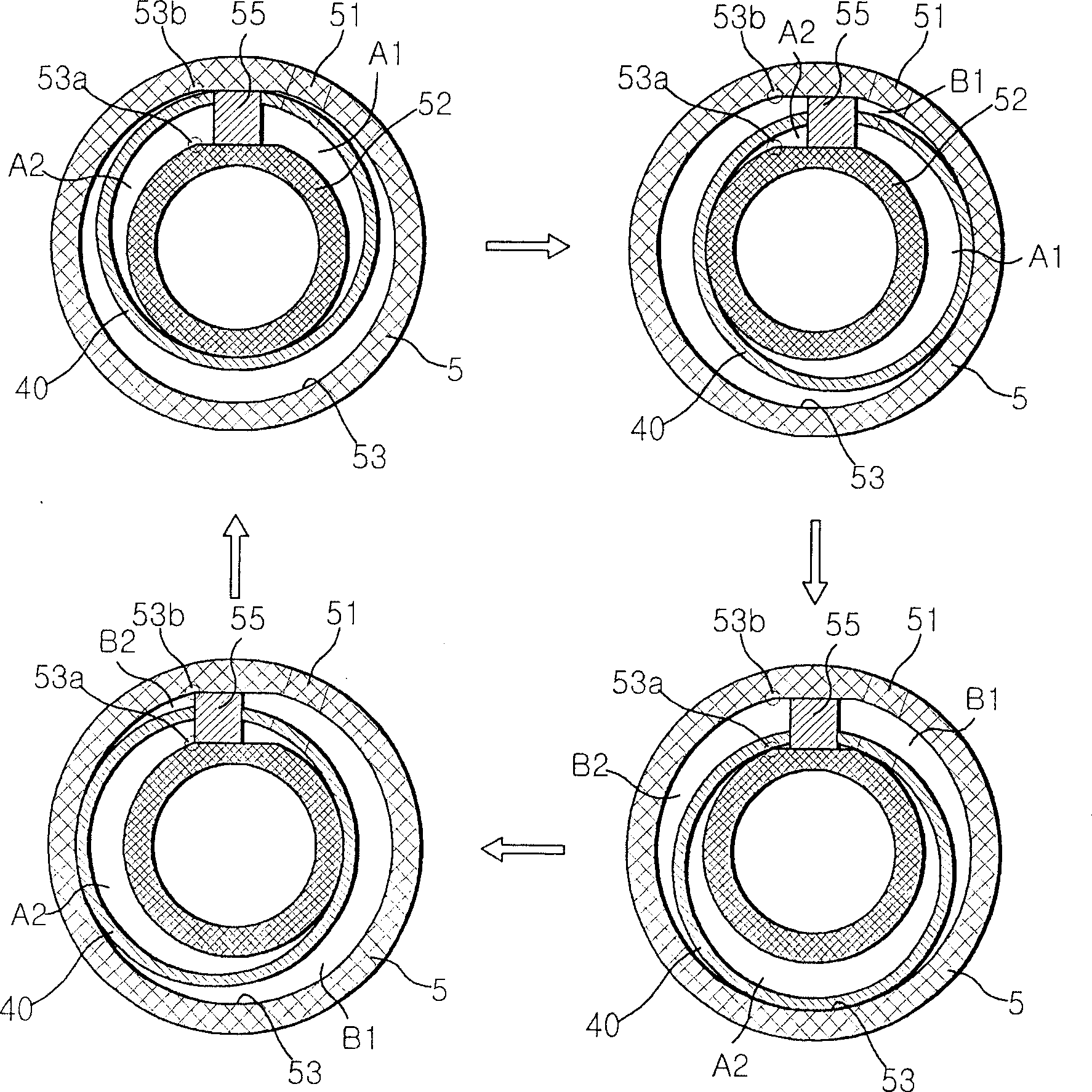

[0045] Generally, a rotary orbiting vane compressor includes a driving unit D and a compression unit P disposed below the driving unit D. As shown in FIG. The compression unit P is connected to the drive unit D via a shaft 6 . The rotary shaft 6 has opposite ends supported by a main bearing 7 and an auxiliary bearing 7 a located at upper and lower portions of the compression unit P. As shown in FIG. Such as image 3 As shown, the auxiliary bearing 7a has an inner outlet 53a and an outer outlet 53b extending through the cylinder 5 (see figure 1 ).

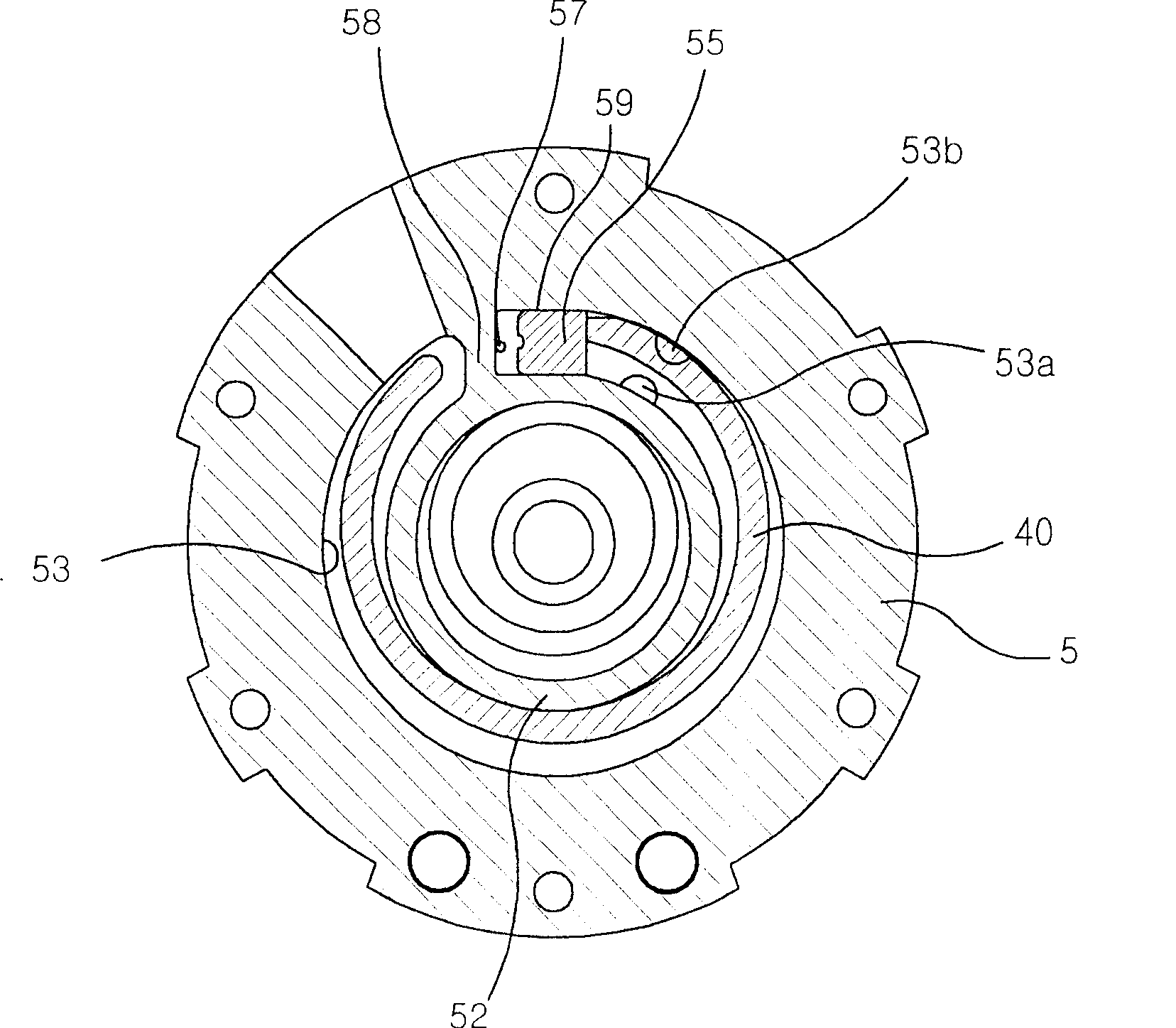

[0046] Figure 5 A perspective view showing the bottom of the auxiliary bearing 7a of the orbiting vane compressor to which the double piston valve according to the present invention is applied.

[0047] Such as Figure 5 As shown, the dual piston valve includes a valve housing 110 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com