Electrolytic solution and battery

An electrolyte and battery technology, which is applied in the field of electrolyte and batteries, can solve the problems of cycle characteristics decline, charge and discharge efficiency drop, electrolyte easy to decompose, etc., and achieve the effect of improving cycle characteristics and inhibiting decomposition reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1 to 1-5

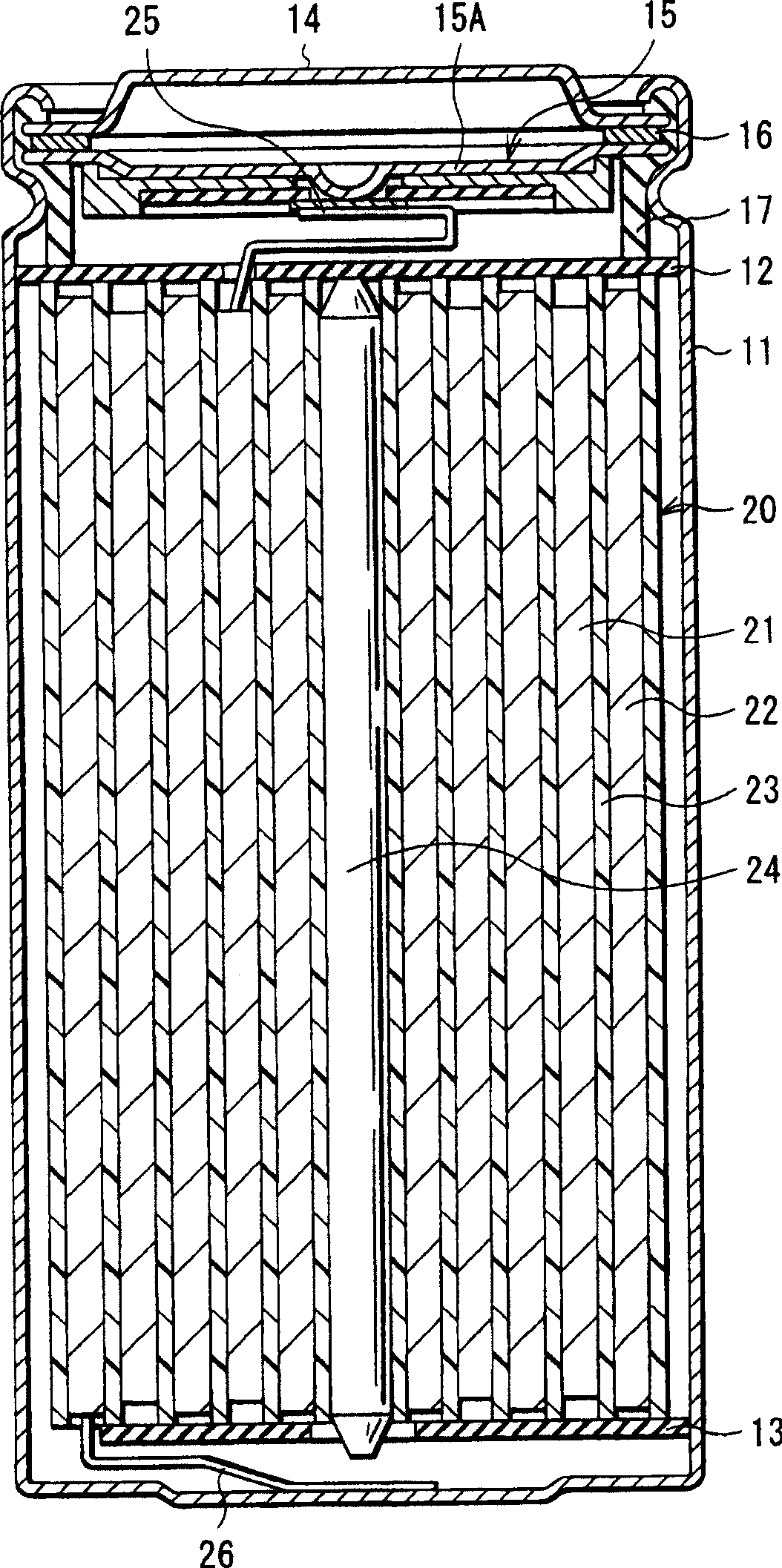

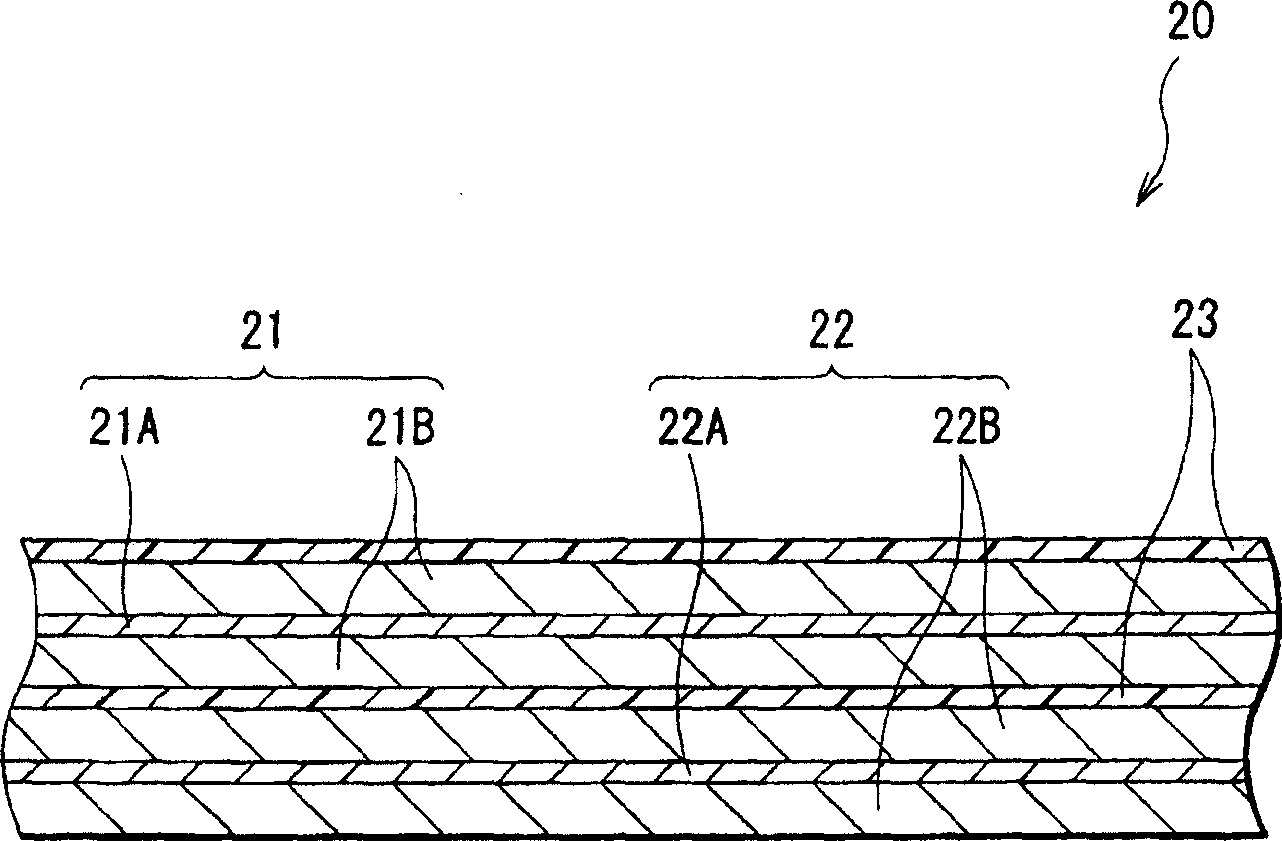

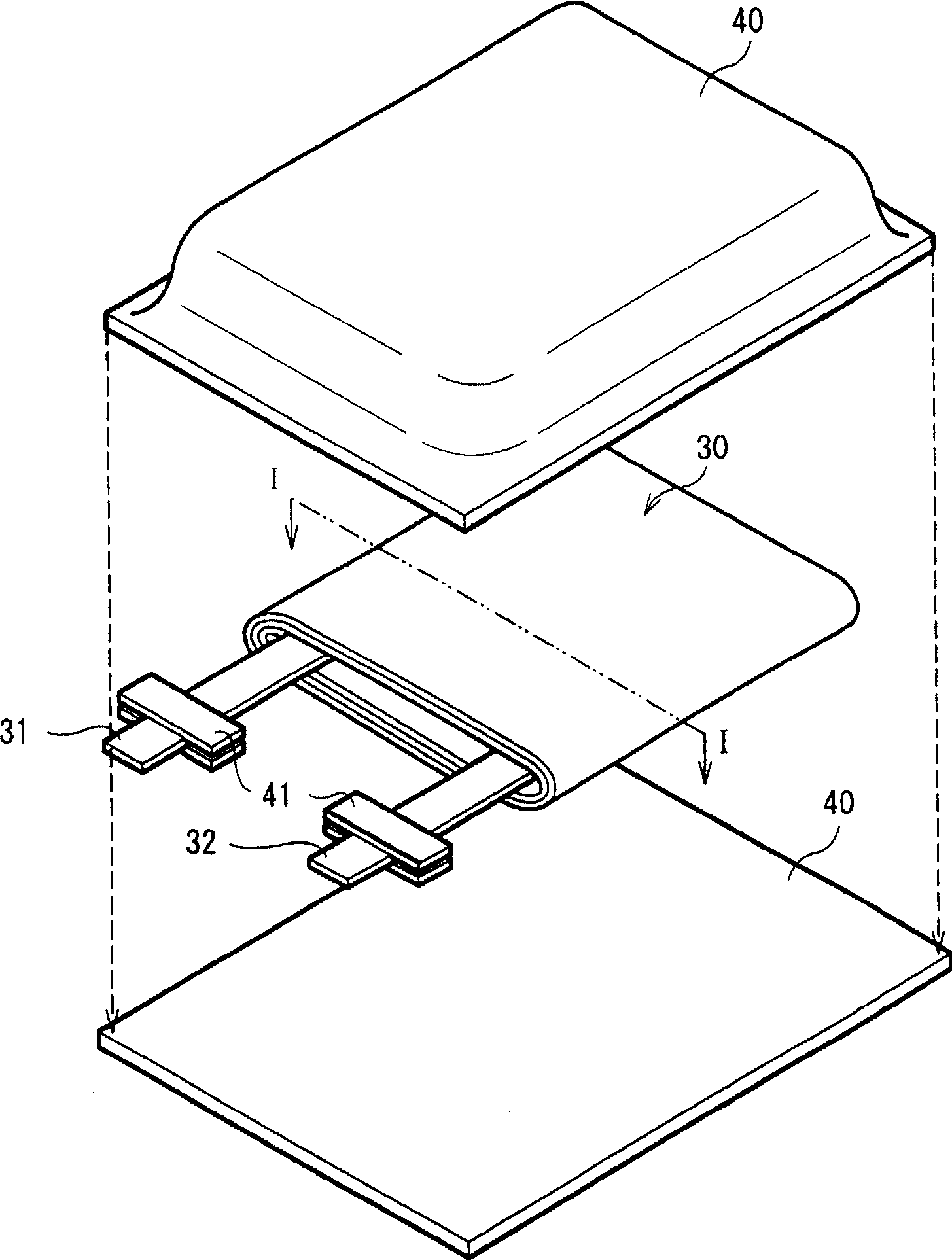

[0127] form Figure 5 The coin-type secondary battery shown in . This secondary battery was formed through the following steps. The positive electrode 51 and the negative electrode 52 are laminated with a separator 53 impregnated with an electrolytic solution in between, and they are sandwiched between a packing case 54 and a packing cap 55 . Then, the packing case 54 and the packing cap 55 are caulked with the gasket 56 to form a secondary battery. First, 94 parts by weight of lithium cobalt composite oxide (LiCoO 2 ), 3 parts by weight of graphite as an electrical conductor and 3 parts by weight of polyvinylidene fluoride as a binder are mixed to form a mixture, and N-methyl-2-pyrrolidone as a solvent is added to the mixture to form a positive electrode mixed slurry material. Next, the obtained positive electrode mixed slurry was uniformly applied on the positive electrode current collector 51A made of aluminum foil with a thickness of 20 μm, and dried to form the positi...

Embodiment 2-1 to 2-5

[0142] (Example 2-1 to 2-5, 3-1 to 3-5)

[0143] As Examples 2-1 to 2-5, in addition to using tin as the negative electrode active material, a 5 μm thick negative electrode active material layer 52B made of tin is formed by vapor deposition on a 15 μm thick negative electrode current collector made of copper foil. Except on the body 52A, a coin-type secondary battery was formed as in Examples 1-1 to 1-5. At the same time, adjust the filling amount of the positive active material and the negative active material so that the open circuit voltage becomes 4.20V when fully charged, and prevent lithium metal from being precipitated on the negative electrode 52 during the charging process, so that the capacity of the negative electrode 52 is determined by the intercalation and desorption of lithium. Embedded capacity section representation.

[0144] As Examples 3-1 to 3-5, in addition to using CoSnC-containing material powder including indium and titanium as the negative electrode a...

Embodiment 4-1 to 4-4

[0165] In addition to using graphite as the negative electrode active material, and mixing 97 parts by weight of graphite and 3 parts by weight of polyvinylidene fluoride as a binder to form a mixture, and adding N-methyl-2-pyrrolidone to the mixture, And this mixture was uniformly applied on a 15 μm thick negative electrode current collector 52A made of copper foil, and then dried to form a 70 μm thick negative electrode active material layer 52B, as in Example 1-1 to form a coin-shaped secondary Battery. At the same time, the positive active material is lithium-manganese-cobalt-nickel composite oxide (LiMn 0.3 co 02 Ni 0.5 o 2 ). And, adjust the filling amount of positive electrode active material and negative electrode active material so that when fully charged, the open circuit voltage becomes 4.60V in embodiment 4-1, becomes 4.50V in embodiment 4-2, becomes 4.50V in embodiment 4-3 becomes 4.35V in Example 4-4 and becomes 4.25V in Example 4-4. In addition, lithium me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com