Antiskid shoe with hydraulically extending spikes

A technology of hydraulic telescopic and telescopic nails, which is applied in the field of anti-skid shoes, can solve the problems of inconvenient operation, stiff fit, easy to damage the comfort of anti-skid shoes, etc., and achieve the effect of convenient and quick control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

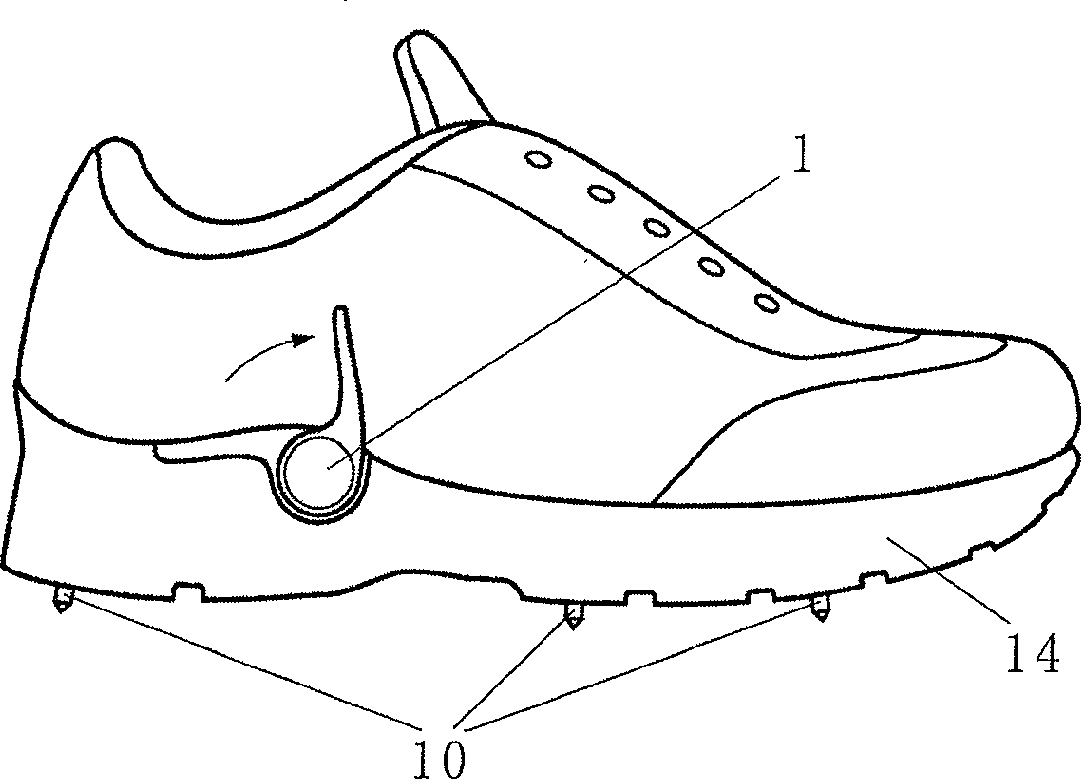

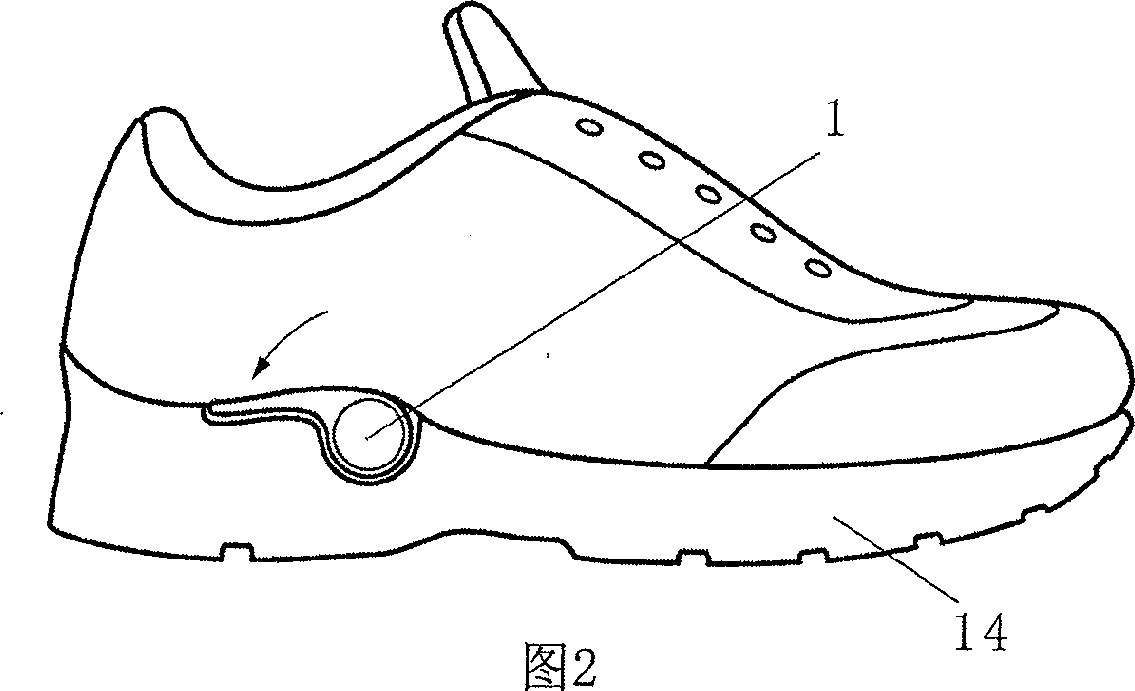

[0021] figure 1 , shown in 2, telescopic nail 10 stretches out from sole 14 when trigger 1 is pulled, and telescopic nail 10 indents sole 14 li when dialing back trigger 1.

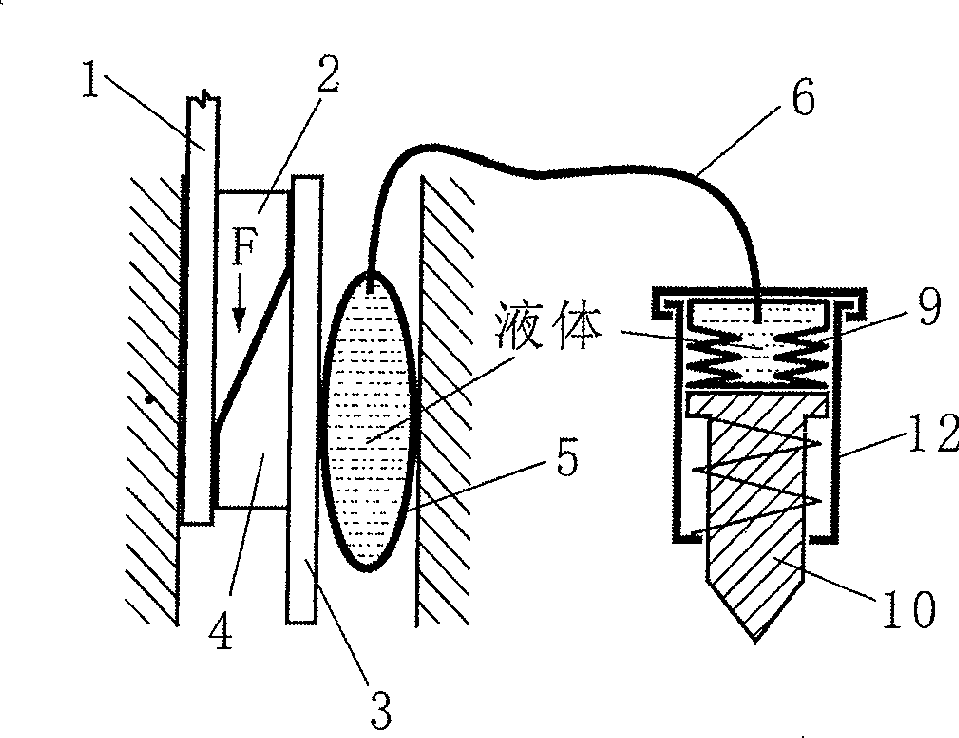

[0022] image 3 , 4 Shown is the working process of the hydraulic system. When the trigger 1 is pulled, the beveled protrusion 2 on the trigger 1 and the beveled protrusion 4 on the pressing piece 3 slide obliquely, so that the pressing piece 3 is displaced and the liquid bag 5 is squeezed. , the liquid is under pressure and flows to the laryngeal sac 9 through the pipeline 6, and the laryngeal sac 9 is stretched by the pressure of the liquid, pushing the telescopic nail 10 to protrude from the cylinder body 12. Obviously, this is a process that can be reversed. When the trigger 1 is turned back, the pressure piece 3 relaxes the squeeze on the liquid sac 5, the liquid sac 5 rebounds and the laryngeal sac 9 retracts to drive the liquid back into the liquid sac 5, and at the same time The spring 11 pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com