Hydraulic cylinder low-pressure linear output realizing method

A linear output and realization method technology, applied in the hydraulic field, can solve the problems of high cost, waste of material resources, low control precision, etc., and achieve the effect of facilitating upgrading, less system changes and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

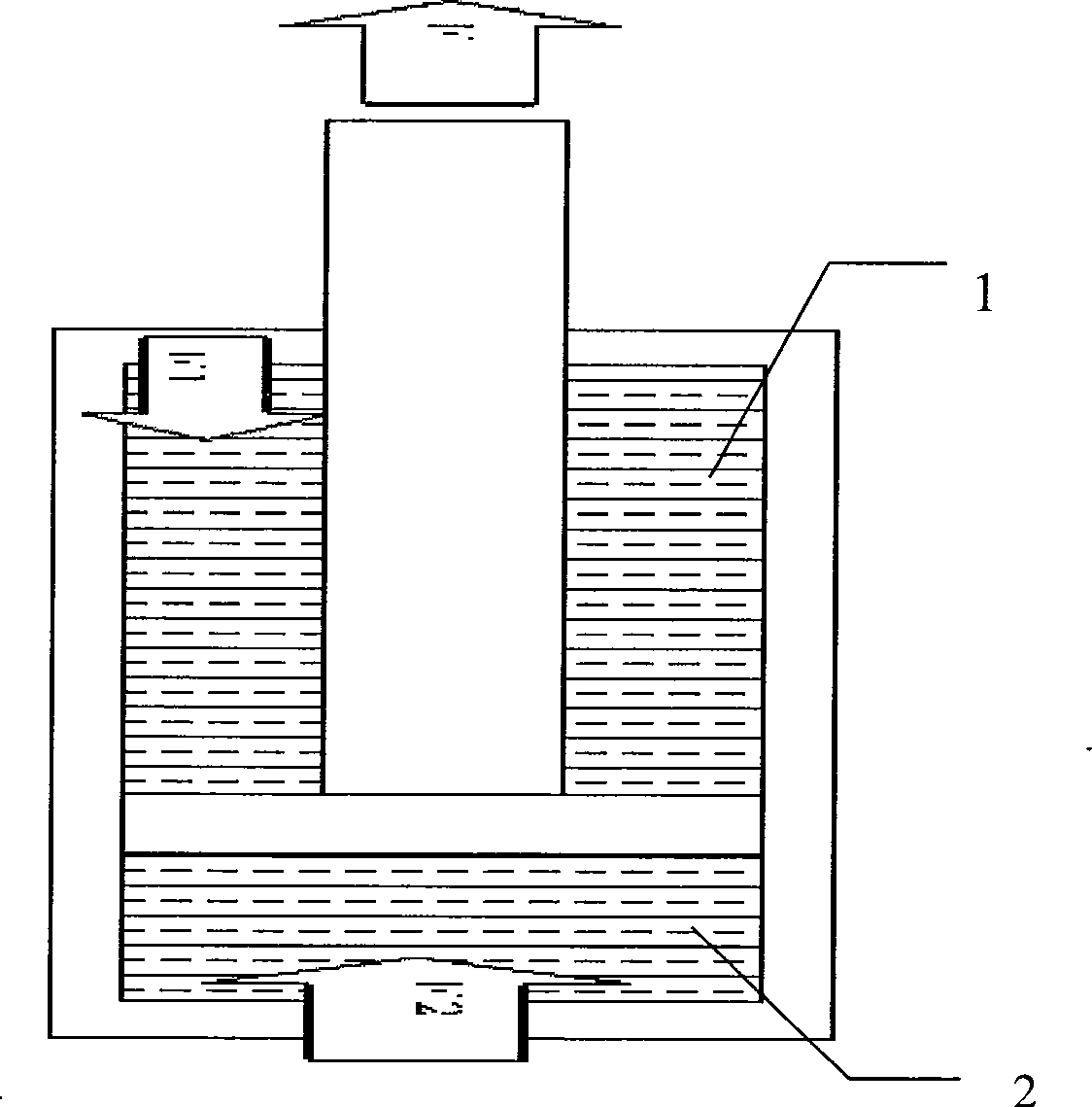

Image

Examples

Embodiment Construction

[0014] In this embodiment, a magnesium alloy plate deep drawing test machine is selected.

[0015] Due to the poor formability of magnesium alloy sheet at room temperature, it needs to be heated to a certain temperature range before it can be drawn. However, as the temperature increases, the strength of the material decreases. The required blank-holding force and deep-drawing force are relatively small, and most of the required blank-holding force in the deep-drawing process is less than 1 ton. Since the tonnage of the hydraulic cushion cylinder of the hydraulic press is 40 tons, and the minimum controllable pressure is 4 tons, it is necessary to improve the hydraulic cushion system of the hydraulic press.

[0016] After analysis, the main cause of the excessively high minimum pressure is the opening pressure of the valve in the hydraulic system. When the hydraulic valve is working normally, the hydraulic pressure in the system has already made the piston of the hydraulic cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com