Protective element for a tread

A technology for protecting components and treads, applied in tire parts, tire treads/tread patterns, vehicle components, etc., to solve problems such as rupture of rubber compounds, and the effect of strip tread pattern technology cannot be sustained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

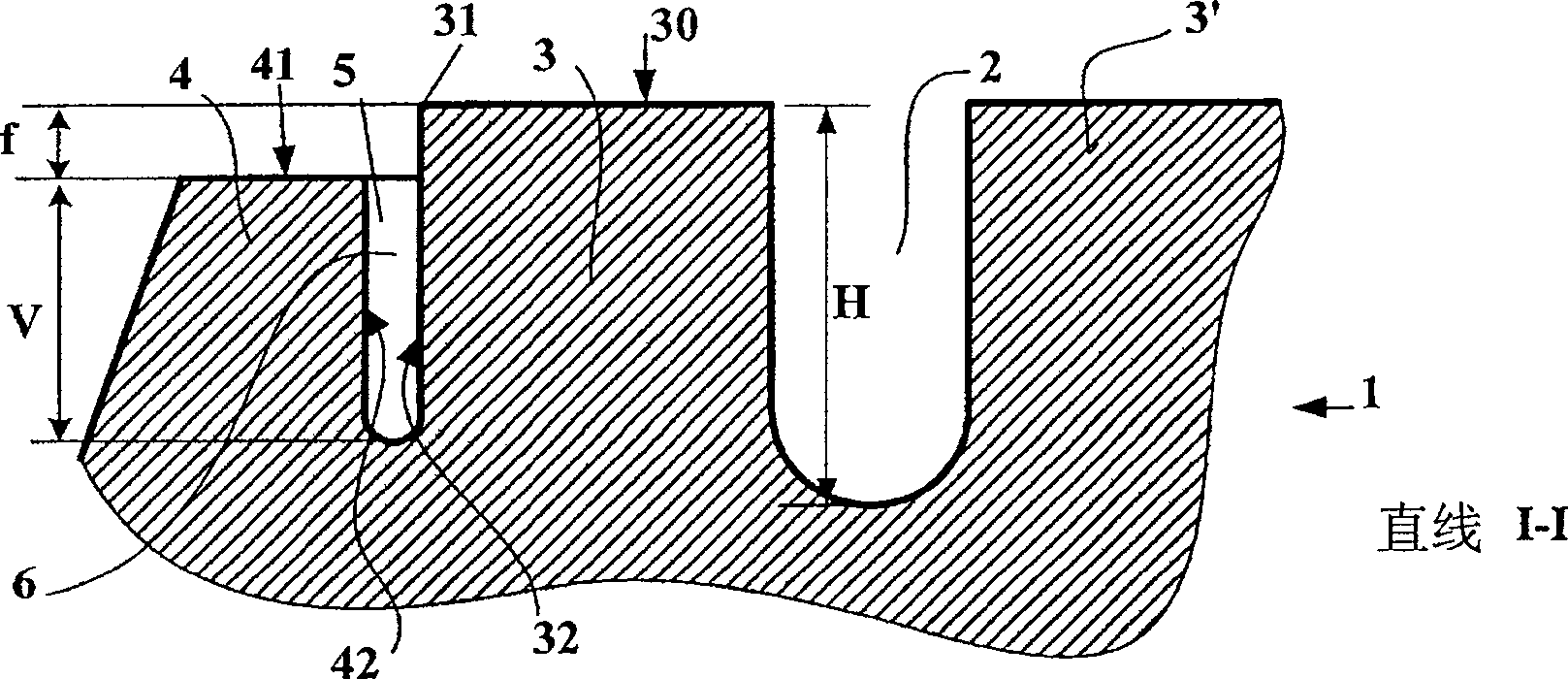

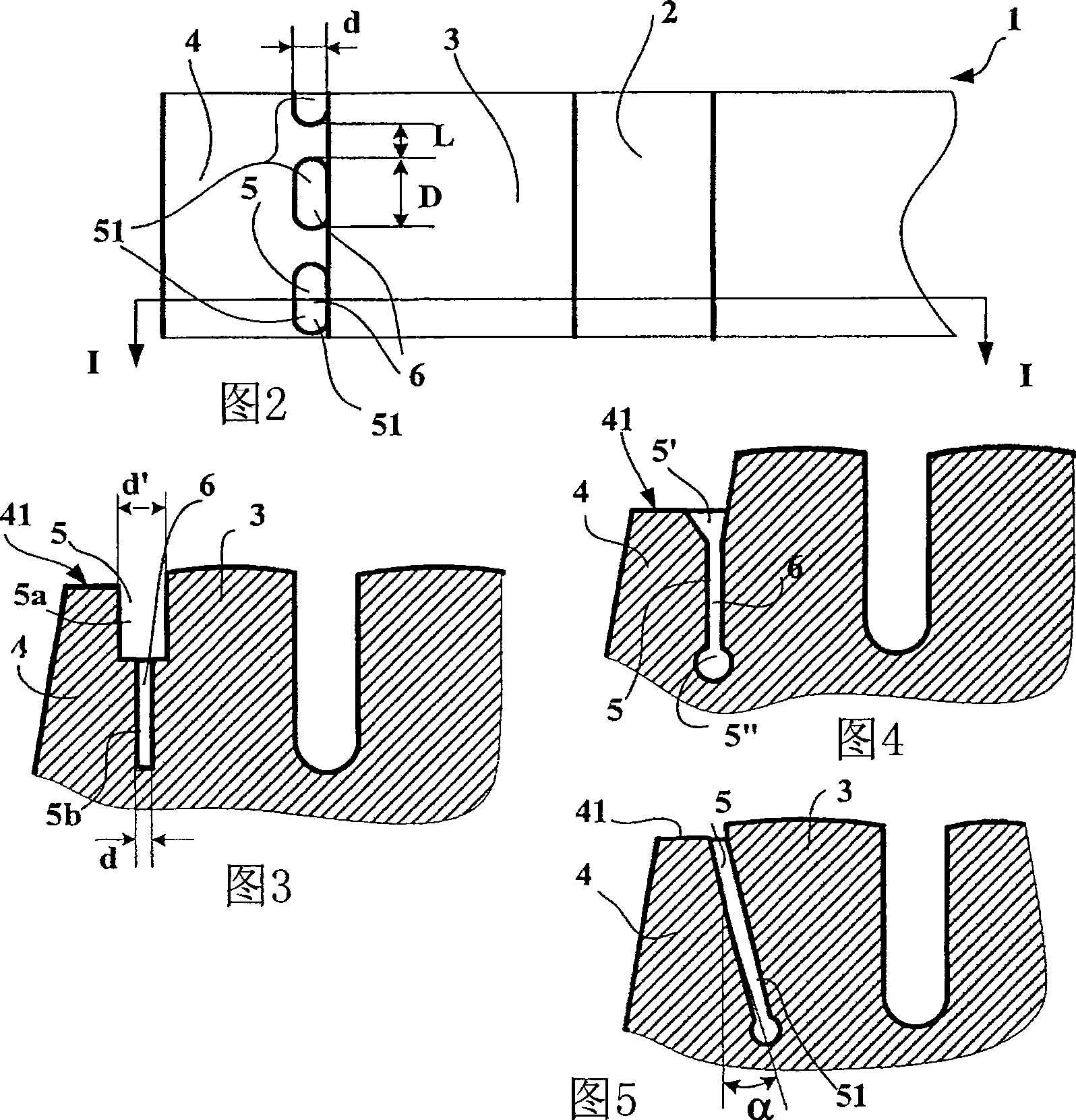

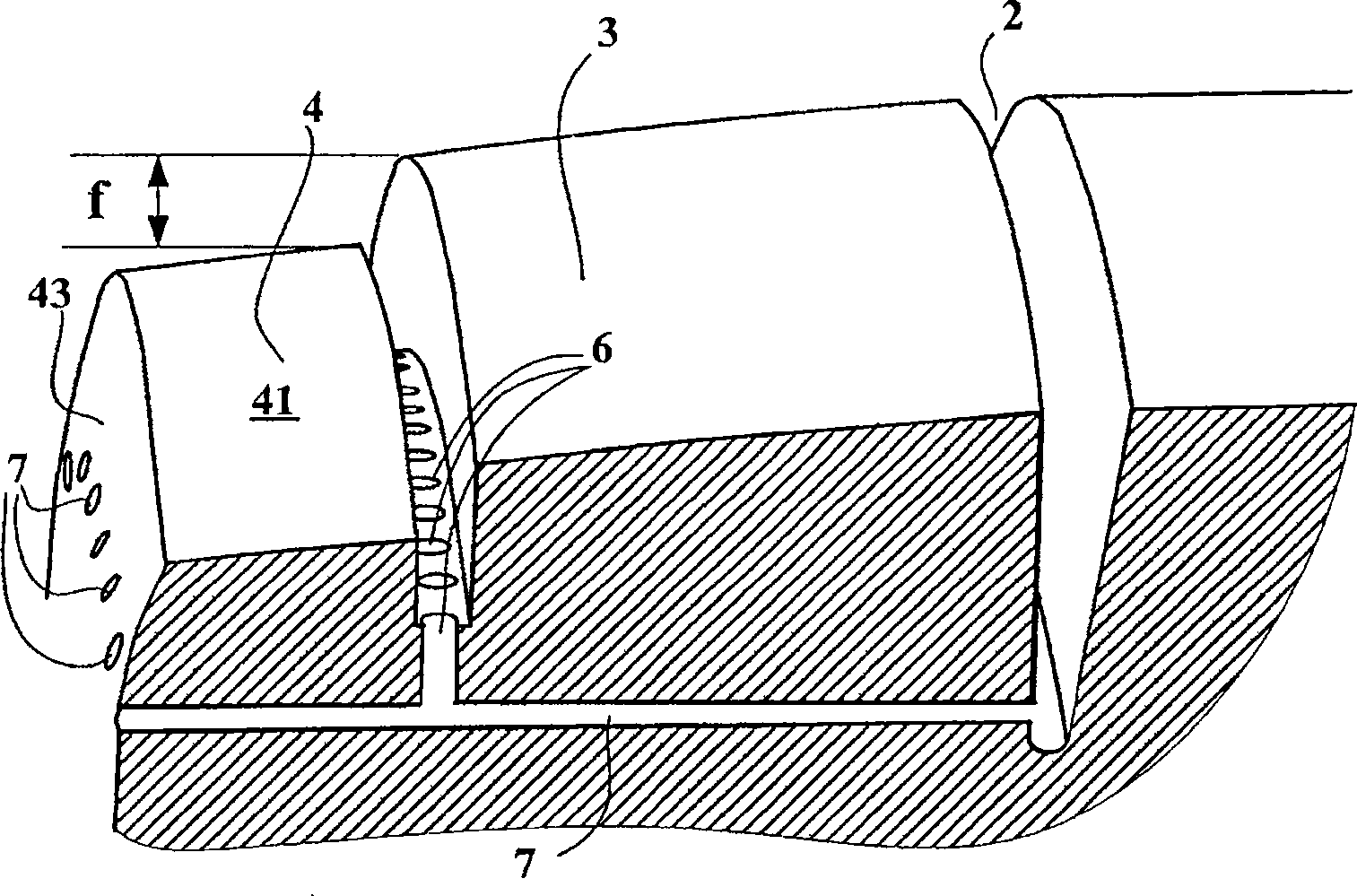

[0030] exist figure 1 In , a partial view of a tread 1 according to the invention can be seen. This partial cross-sectional view shows a longitudinal groove 2 of depth H separating the edge rib 3 of the tread 1 from another rib 3' of the tread pattern.

[0031] In order to prevent irregular wear of the outer surface 30 of this edge rib 3 , more specifically to prevent its axially outer sharp edges 31 from being rounded, a so-called "guard" rib 4 is arranged axially on the outside. The bezel 4 has an outer contact surface 41 intended to come into contact with the road surface during driving, the difference in rolling radius measured relative to the axis of rotation of the bezel 4 and the edge rib 3 leads to an increase Sliding on the rib 4 is protected, causing significant wear on this rib, with a corresponding reduction in irregular wear on the edge rib 3 .

[0032]The protection strip 4 has an offset of f in the tread thickness direction, and the depth formed by the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com