U-shaped clamp

A clamping piece, U-shaped technology, applied in the field of clamping fixed to the plate, can solve the problems of difficult alignment bolt insertion and screwing, limiting the stability of the connection, etc., and achieve the effect of improving maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

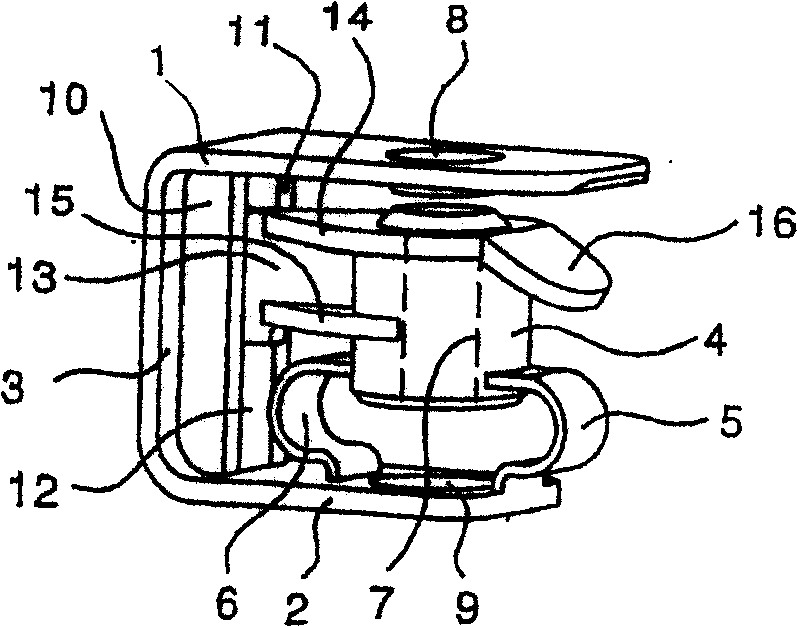

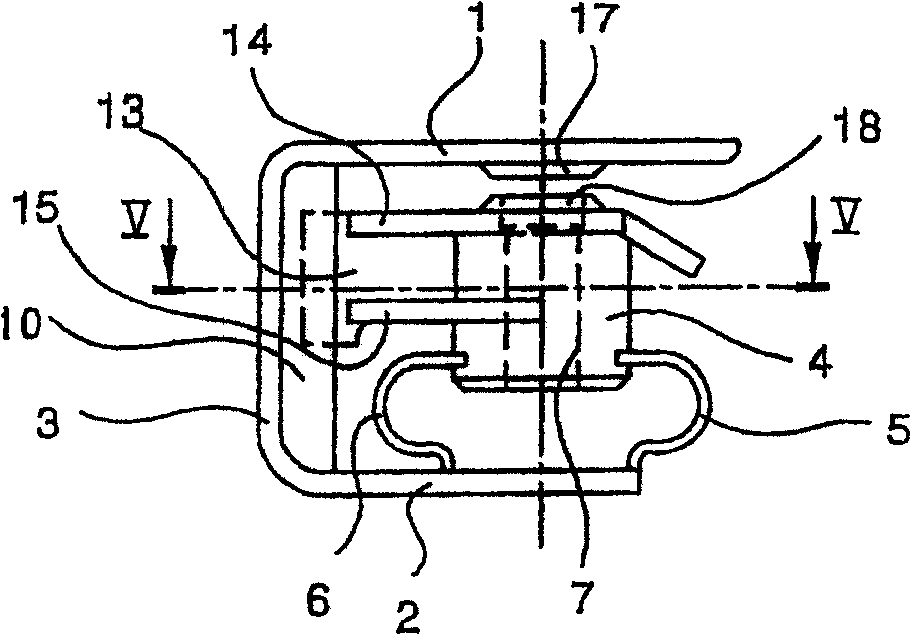

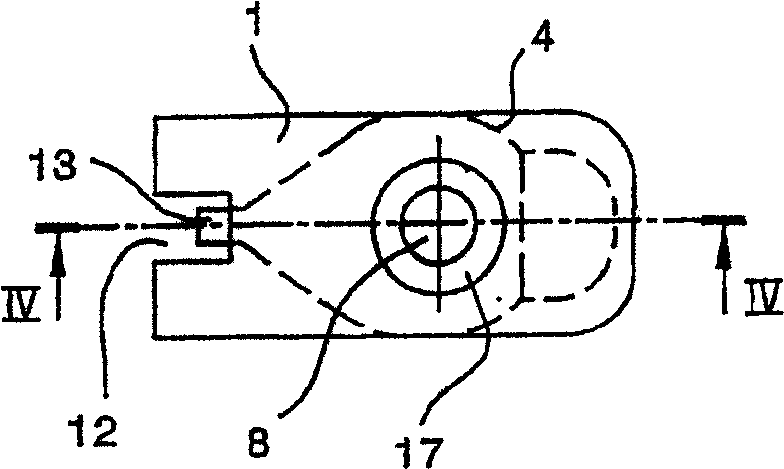

[0044] figure 1 The clamp shown in the perspective view of , comprises an upper leg 1 , a lower leg 2 and a yoke 3 connecting the two legs 1 and 2 . The clamp consists of allowing the two legs 1 and 2 to bend relative to the yoke 3 and then return elastically when the plate is inserted into the clamp (this will combine Figure 7 with Figure 8 are made of materials that will be described).

[0045] Arranged between the two legs 1 and 2 is a nut part 4 integrally connected to the leg 2 via arcuate bands 5 and 6 . The straps 5 and 6 are likewise made of elastic material and provide the nut part 4 with respect to the movability in the axial direction relative to the nut part 4 . Nut part 4 contains hole 7, as combined Figure 8 Bolts can be screwed into holes 7 as shown. In order to be able to introduce a screw into the nut part 4 , the leg 1 is provided with a hole 8 . The legs 2 also have similar holes 9 so that the entire clamp can be passed through by bolts (see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com