Method for producing essence in flesh odor thorugh extrusion technique

A meat-flavored essence and technical technology, which is applied in the field of meat-flavored essence production, can solve problems such as non-continuous production, high production cost, and long production cycle, and achieve the effects of low production cost, high production efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] The raw material formula of applying extrusion technology to produce meat flavor essence is:

[0054] Glucose 10%, Glycine 5%, L-Cysteine Hydrochloride 5%, VB1 1%, Refined Butter 2%, Yeast Powder 20%, Water 10%, Rice Flour 47%.

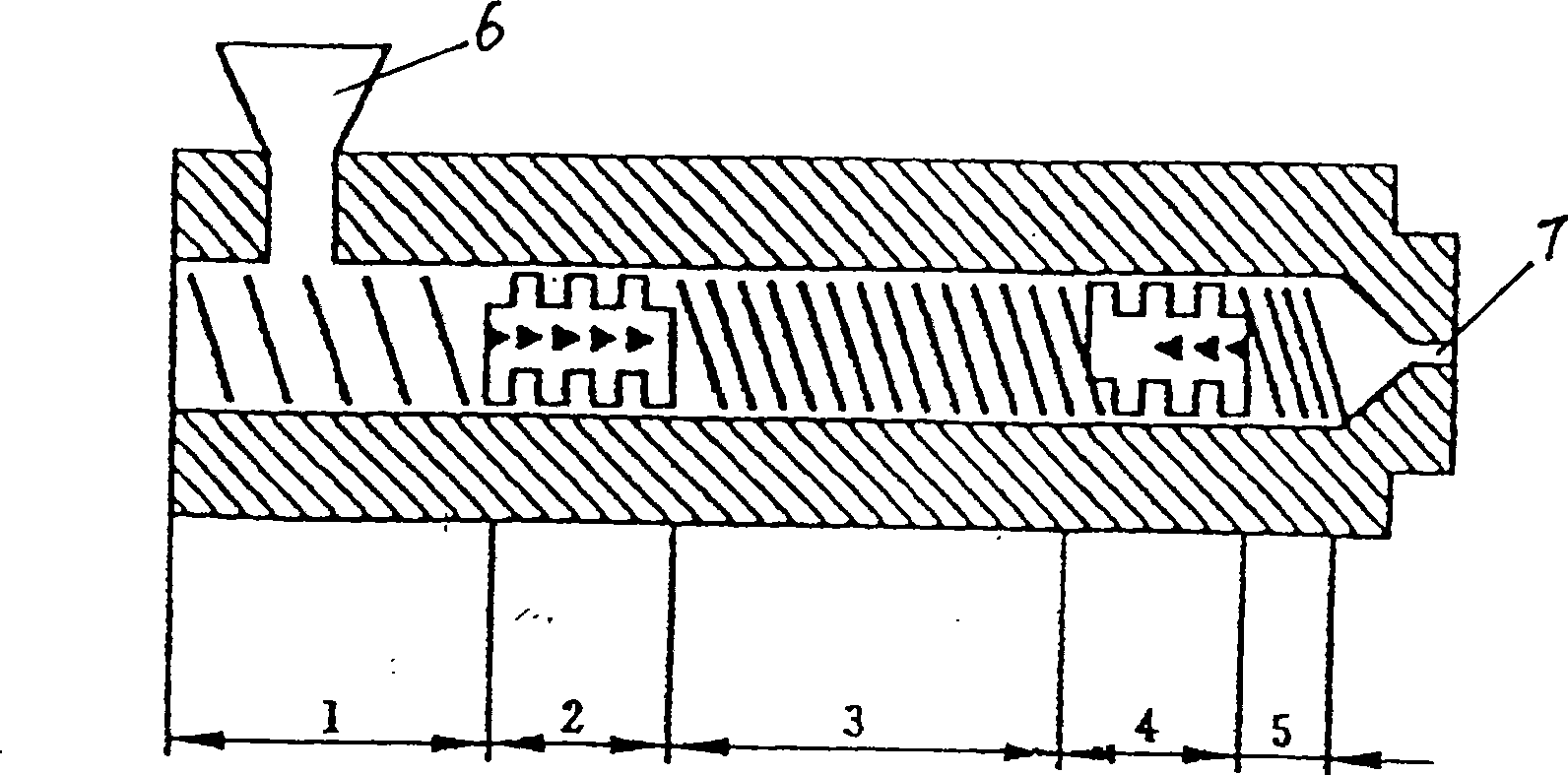

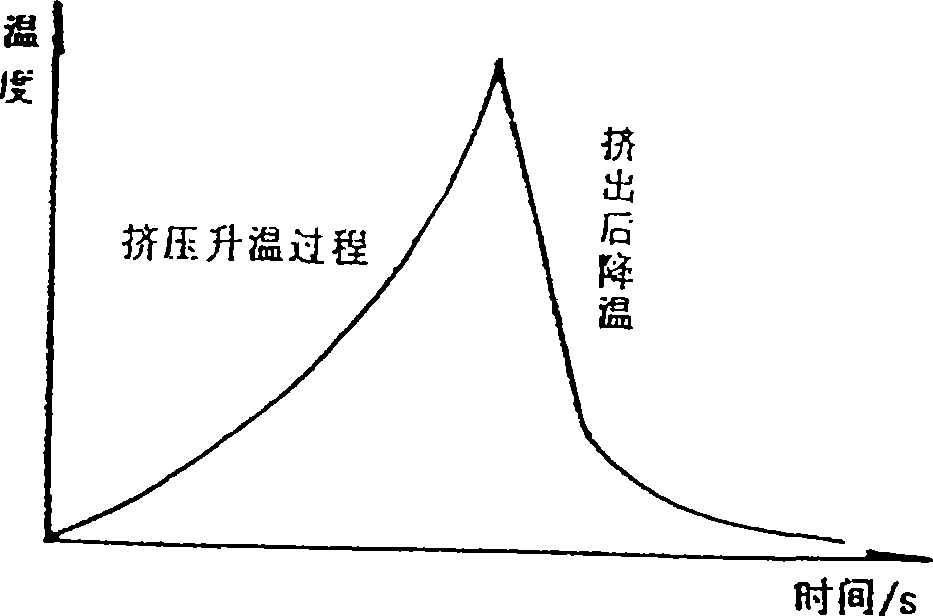

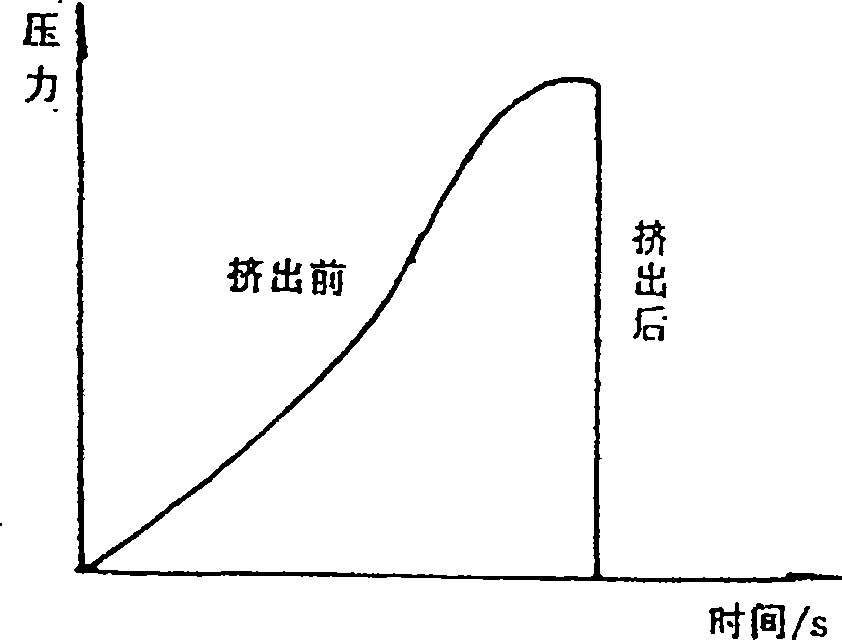

[0055] According to the formula, each raw material is added into a mixer and mixed uniformly to obtain an extruded raw material with a water content of 17%. The twin-screw extruder was preheated to the specified temperature, the mixing zone temperature was 70°C, the shear zone was 120°C, and the melting zone was 170°C. Add the extruded raw materials into the hopper of the twin-screw extruder, start the extruder, and adjust the screw speed to 200 rpm. The extruded raw material is added into the extruder from the feeding hopper at a speed of 70Kg / hour and extruded. The extruded reaction flavor is cooled to room temperature, and pulverized to obtain the powdery reaction flavor of the meat flavor. Various natural fragrances and natural equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com