Preparation method of fragrant peanut oil and peanut oil

A technology of peanut oil and manufacturing method, which is applied in the direction of fat oil/fat refining, fat production, edible oil/fat, etc., can solve the problems of low flavor extraction efficiency, poor product stability, high solvent residue, etc., and achieve the reduction of uncontrollable or accidental factors No impact, easy to control, good fragrance retention in cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

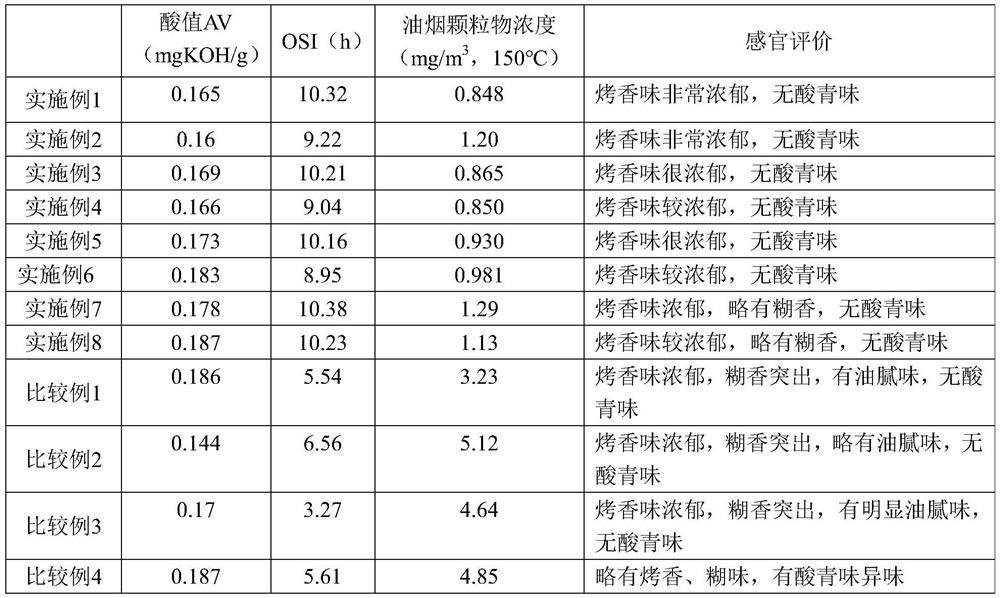

Examples

preparation example Construction

[0091] The preparation method of the fragrant peanut oil of the present invention comprises: the step of thermally reacting the above-mentioned peanut powder and the above-mentioned peanut oil under vacuum condition.

[0092] In some preferred embodiments of the present invention, preferably according to the solid-to-liquid ratio (ie, mass ratio) of 1:(3-10), the above-mentioned peanut powder and the above-mentioned peanut oil are mixed and subjected to thermal reaction. The above-mentioned mass ratio is more preferably 1:(3-4). In some specific embodiments, the mass ratio of the above-mentioned peanut powder to the above-mentioned peanut oil is preferably 1:3 or 1:4.

[0093] By setting the mass ratio of peanut powder and peanut oil within the above range, a flavored peanut oil with high oxidation stability can be obtained, and the flavored peanut oil has less soot and has a strong roasted flavor. If the mass ratio is less than 1:3, the oxidation stability is poor, and the r...

Embodiment 1

[0159] After different batches of peanuts were blended in a certain ratio according to the batch measurement results, peanut raw materials with a ratio of oleic acid to linoleic acid in fatty acid composition of 0.95:1 were obtained. Weigh 2kg of the above-mentioned peanut raw materials and fry the seeds in a flat-bottomed frying furnace. The temperature of the material out of the frying furnace is about 165°C, and the materials are fried in the frying furnace for about 10 to 15 minutes. Stir-fry until the color is yellow but not burnt, extract oil and degrease to obtain peanut cake, and further use a traditional Chinese medicine grinder to crush or pulverize to obtain peanut cake powder.

[0160] Weigh 100g of the above-mentioned crushed peanut powder and pass through a 40-mesh sieve, add 400g of refined peanut oil to a 1L reactor (manufactured by PARR, USA) and vacuumize to -1bar, then heat and stir at 140°C, react for 2h, and control the pressure within 2bar After the react...

Embodiment 2

[0162] After different batches of peanuts were blended in a certain ratio according to the batch measurement results, peanut raw materials with a ratio of oleic acid to linoleic acid in fatty acid composition of 1.24:1 were obtained. Weigh 2kg of the above-mentioned peanut raw materials and fry the seeds in a flat-bottomed frying furnace. The temperature of the material out of the frying furnace is about 165°C, and the materials are fried in the frying furnace for about 10 to 15 minutes. Stir-fry until the color is yellow but not burnt, extract oil and degrease to obtain peanut cake, and further use a traditional Chinese medicine grinder to crush or pulverize to obtain peanut cake powder.

[0163] Weigh 100g of the above-mentioned crushed peanut powder and pass through a 40-mesh sieve, add 400g of refined peanut oil to a 1L reactor (manufactured by PARR, USA) and vacuumize to -1bar, then heat and stir at 140°C, react for 2h, and control the pressure within 2bar After the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com