Lock catch device of vehicle sliding groove and method of manufacturing the same

The invention relates to a locking device and a manufacturing method, which are applied in the field of automobile chute locking devices, and can solve the problems of failure of the automobile sliding slot locking device, troublesome stopping, matching errors, etc., so as to improve the product qualification rate and production efficiency, and improve the Safety, Overcoming Failure Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

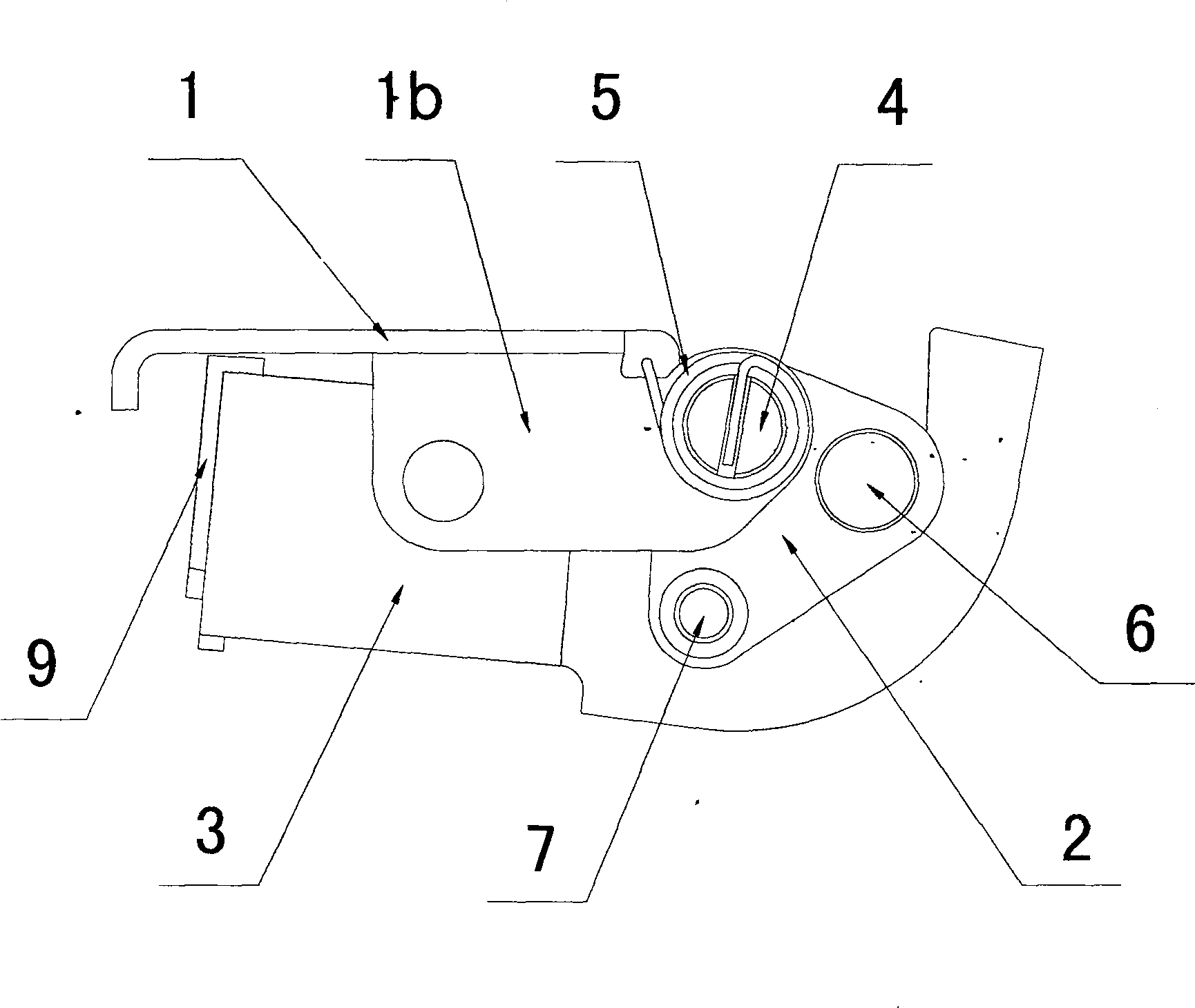

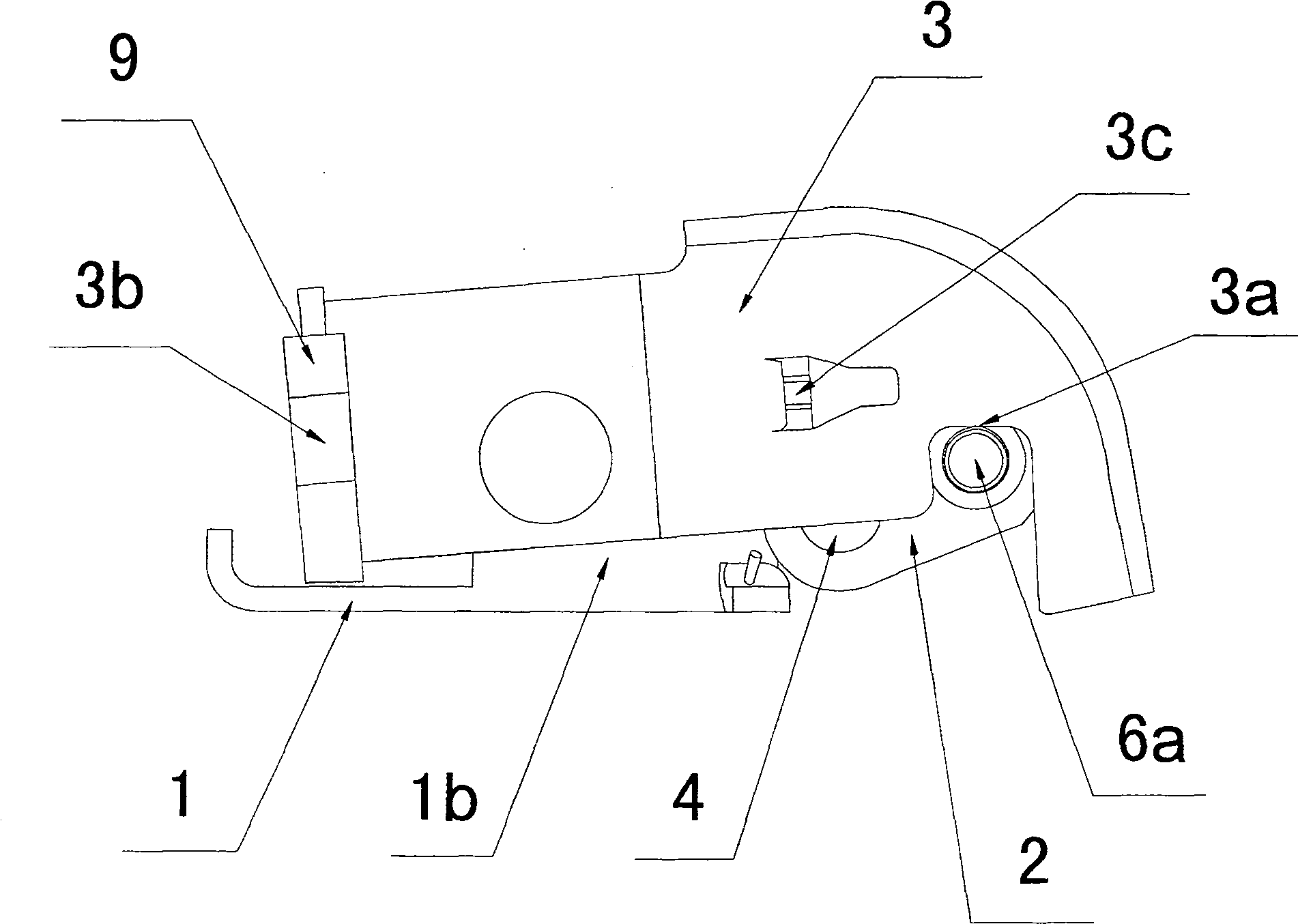

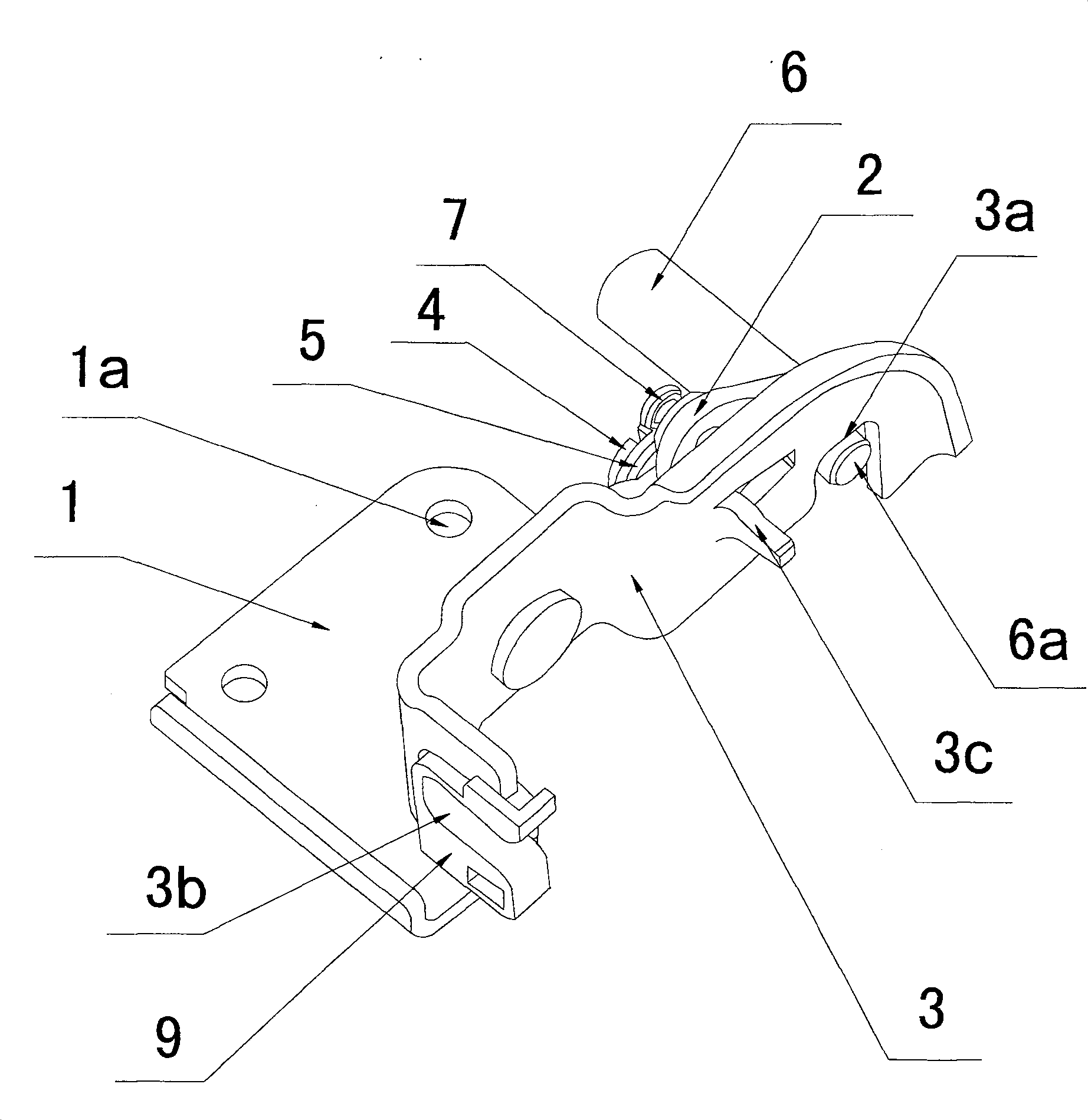

[0026] Example: such as figure 1 , figure 2 , image 3 Shown is the specific embodiment of the automobile chute locking device of the present invention, which includes a base frame 1, a rotating piece 2 and a trigger frame 3; a number of fixing holes 1a are opened on the body of the base frame 1, and a joint connected to the body is formed. The folded part 1b and the rotating piece 2 are riveted below the folded part 1b by a split rivet 4. The split rivet 4 is covered with a torsion spring 5; 1b is movable and riveted, that is, it cannot rotate with the rotating piece 2; and one end of the torsion spring 5 is fixed on the base frame 1, and the other end is inserted into the bayonet of the split rivet 4.

[0027] The rotating piece 2 is also fixedly riveted with a long shaft 6 and a rivet 7, and the riveted part 6a of the long shaft 6 protrudes from the rotating piece 2; The buckle groove 3a, the riveting portion 6a of the long axis 6 abuts into the buckle groove 3a.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com