Direct platemaking offset plate of ink-jetting computer

A computer and offset printing plate technology, which is applied in the photoengraving process of the pattern surface, opto-mechanical equipment, and photosensitive materials for opto-mechanical equipment, etc. and other problems, to achieve the effect of fast absorbing ink, easy to wash and good image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

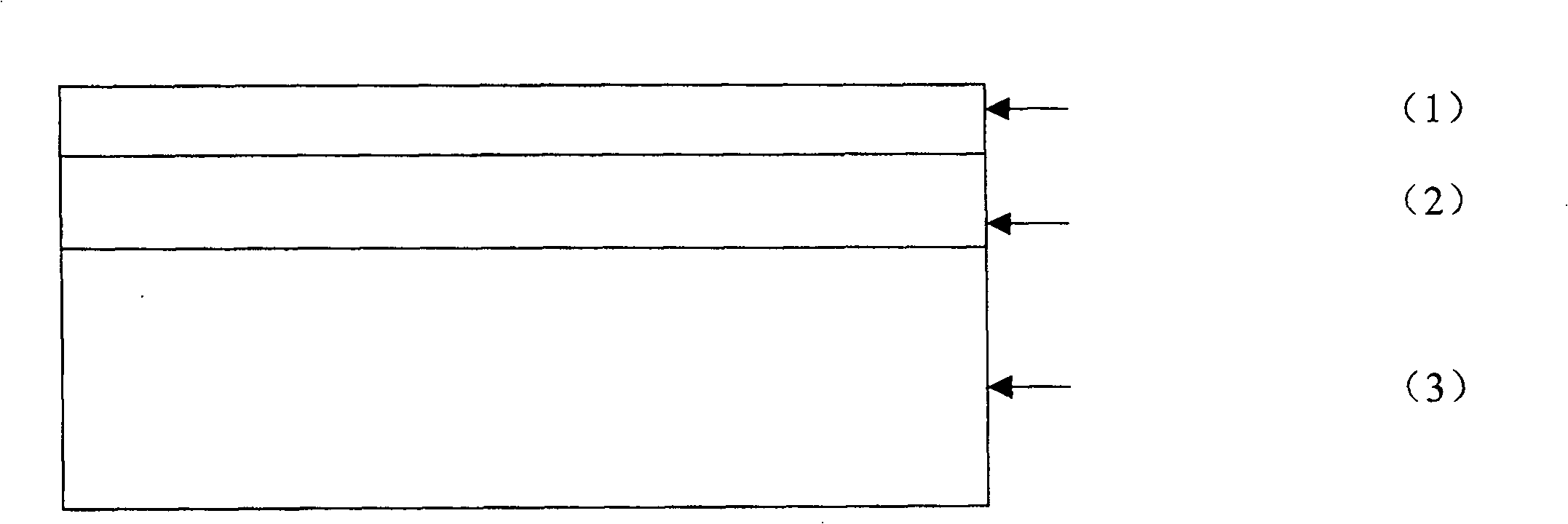

Image

Examples

example 1

[0034] 1.1 Preparation of coating solution

[0035] Hydroxypropyl Methyl Cellulose 2.5g.

[0036] Diisooctyl sodium succinate sulfonate 4% aqueous solution 2 ml.

[0037] Microporous colloidal silica 1.25g

[0038] Water 95.5ml.

[0039] 1.2 Preparation of offset printing plate of the present invention

[0040] Disperse the above materials by ball milling for 8 hours and then filter to obtain a uniform coating solution, the content of which is about 3-4%, and then apply this solution on the photosensitive layer of the positive PS plate by roller coating method, and then apply The amount is 2-3 grams per square meter, and the drying temperature is 80-85°C.

example 2

[0042] 2.1 Preparation of coating solution

[0043] Carrageenan 50% aqueous solution 8g

[0044] Sorbitan ester and polyoxyethylene compound 4% aqueous solution 4ml

[0045] Microporous colloidal alumina 2 grams

[0046] water 88ml

[0047] 2.2 Preparation of offset printing plate of the present invention

[0048] Disperse the above materials by ball milling for 8 hours and then filter to obtain a uniform coating solution with a solid content of about 6-7%. Then this solution is coated on the photosensitive layer of the positive PS plate by roller coating. The cloth weight is 2-4 g / m2, and the drying temperature is 80-85°C.

example 3

[0050] 3.1 Preparation of coating solution

[0051] Water-soluble alkyd resin 50% aqueous solution 10g

[0052] 4% aqueous solution of diisooctyl sulfonate sodium succinate 2 ml

[0053] Microporous colloidal silicon dioxide 2 grams

[0054] water 86ml

[0055] 3.2 Prepare the offset printing plate of the present invention

[0056] Disperse the above materials by ball milling for 8 hours and then filter to obtain a uniform coating solution with a solid content of about 7-8%. Then this solution is coated on the photosensitive layer of the positive PS plate by roller coating. The cloth weight is 2-5 g / m2, and the drying temperature is 80-85°C.

[0057] In the present invention, some commonly used chemical additives, such as defoamers, antioxidants, and pH regulators can be added to the coating solution to make the offset printing plate more functional.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com