Method for rolling whole leaf rolled cigar

A technology of cigars and manufacturing methods, which is applied in the manufacture of cigars, tobacco, and applications. It can solve the problems of long rolling time and high rolling strength, and achieve the effect of uniform and sufficient combustion and beautiful cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0015] A method for rolling a whole-leaf rolled cigar comprises the following steps:

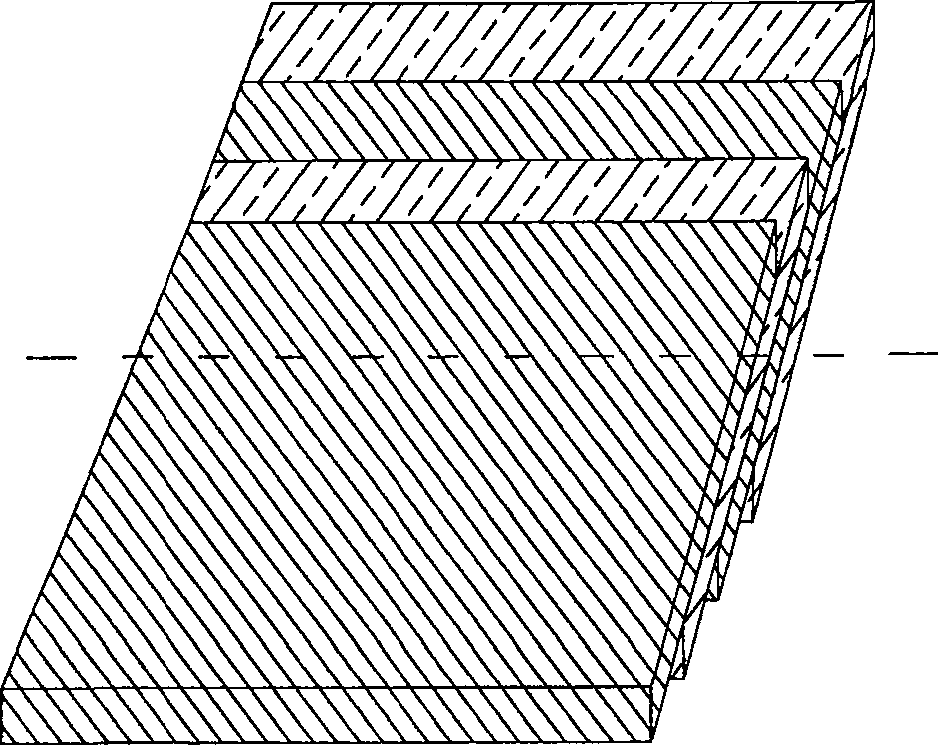

[0016] A. If figure 1 As shown, 3 to 5 cigar leaves are overlapped, the upper cigar leaf is overlapped with a part of the lower cigar leaf, and a part of the upper cigar leaf is also exposed, and all the cigar leaves are retreated in one direction from bottom to top;

[0017] B. Fold the cigar leaves in half from the center of the overlapping cigar leaves along the direction of parallel cigar retreat;

[0018] C. Roll the cigar leaves tightly in one direction from the folded part to form a cigar roll.

[0019] Compared with the prior art, the beneficial effect of the present invention is that the properties of the tobacco leaves are not required to be the same during rolling, and the rolled tobacco is precise, has a beautiful cross section, and is evenly and sufficiently burned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com