Printing machine with laser perforating unit, laser perforation system and manufacture method of perforation pattern

A technology of laser perforation and manufacturing method, applied in the directions of printing, printed matter, manufacturing tools, etc., can solve the problem of inability to accurately form perforation patterns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

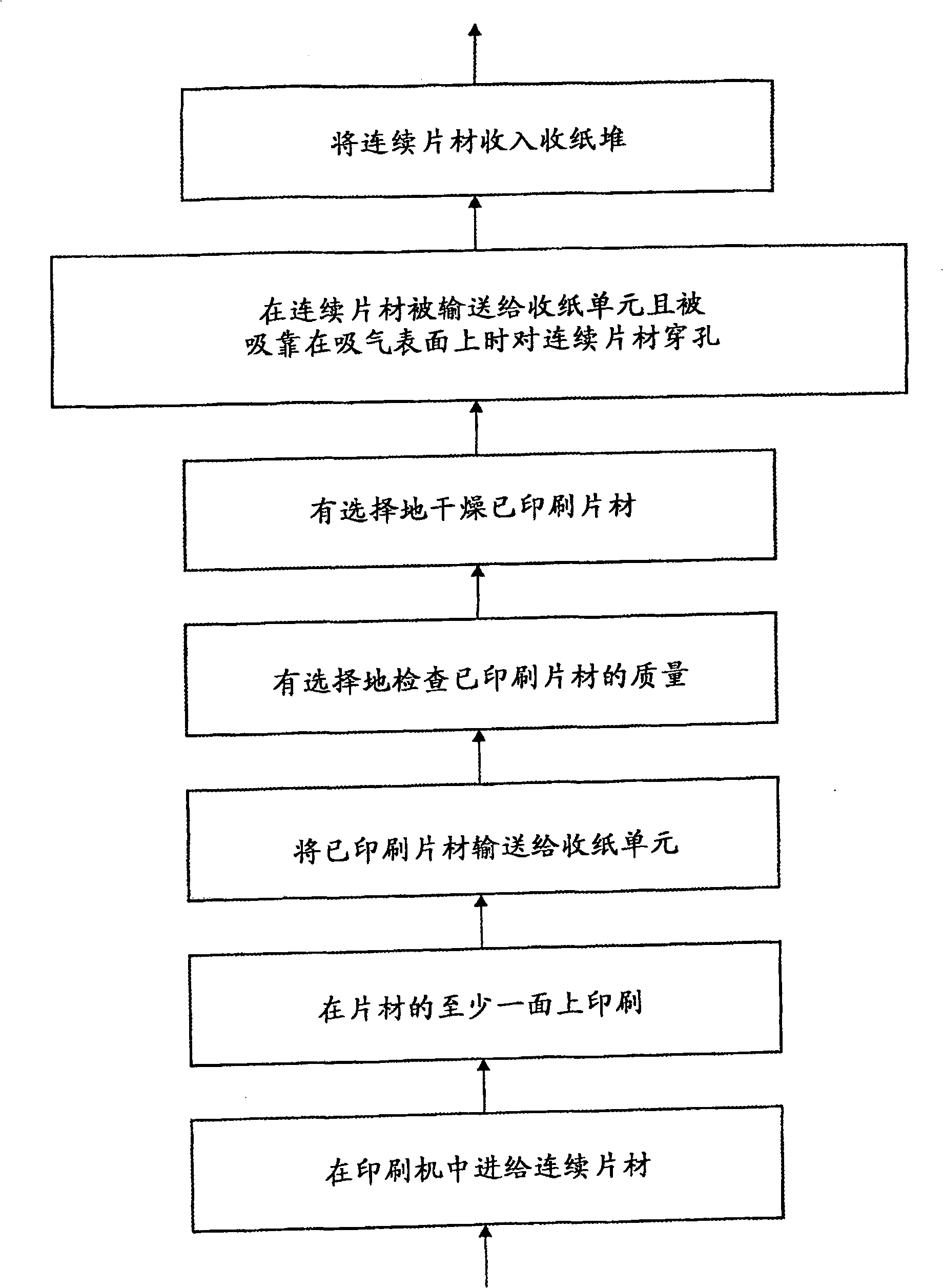

Method used

Image

Examples

Embodiment Construction

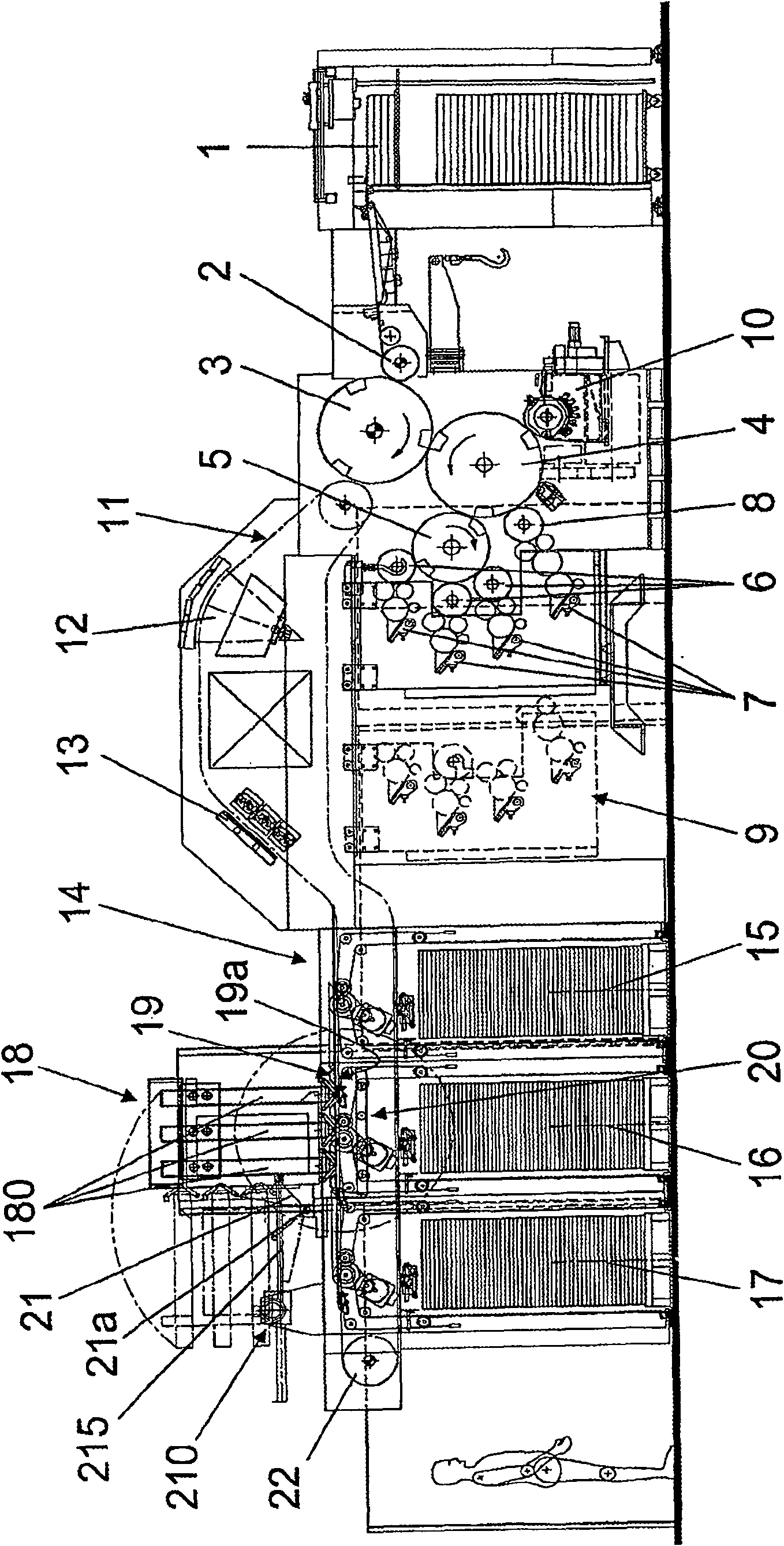

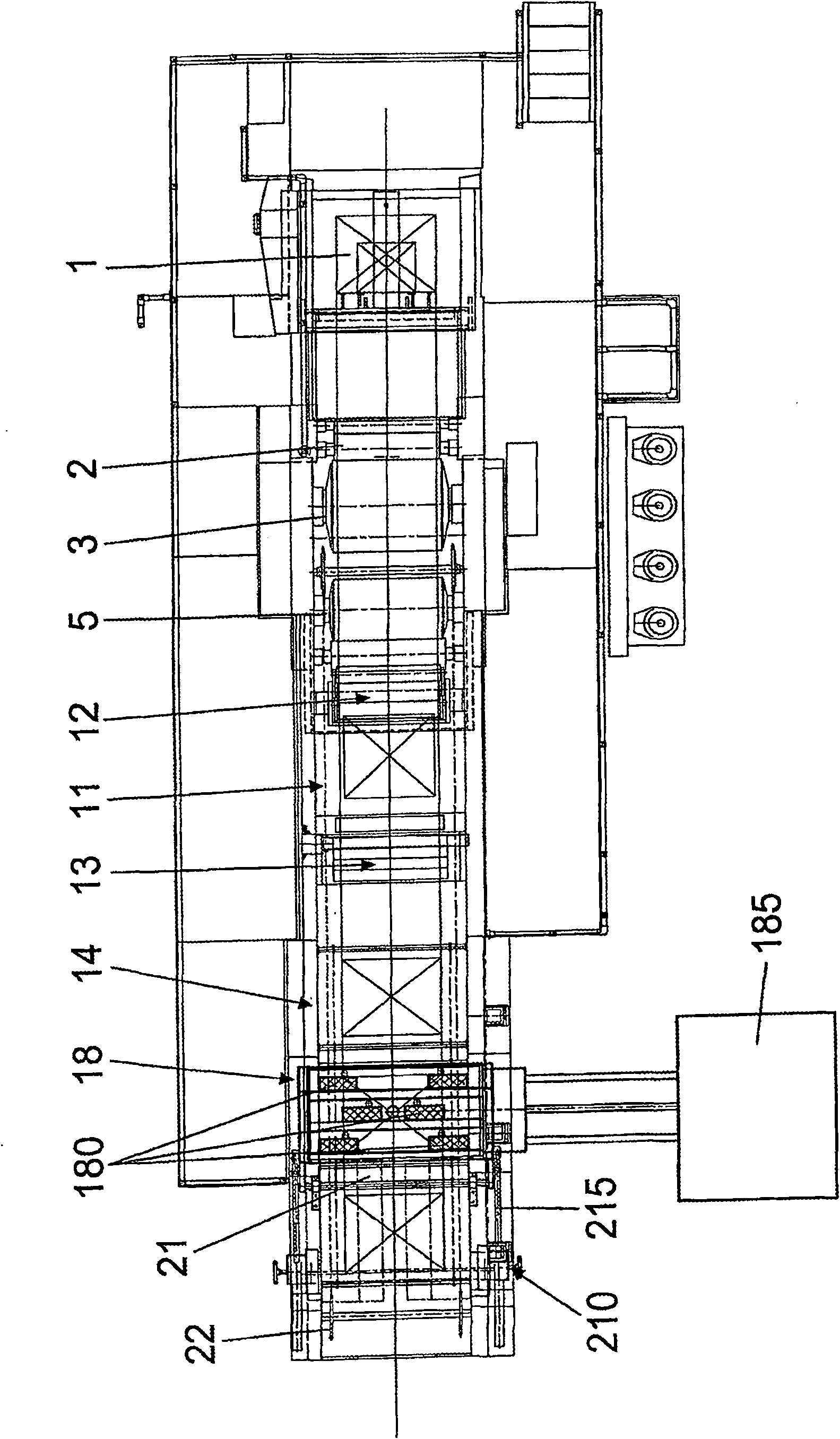

[0026] The invention will be described within the context of a specific embodiment, namely an intaglio printing machine equipped with a laser perforation system. It should be understood, however, that this embodiment should not be considered limiting and that the disclosed laser perforation system may be applied to other types of printing or processing machines.

[0027] Furthermore, within the scope of the present invention, "laser perforation" is to be understood as meaning that the sheet is irradiated with a laser beam, wherein at least part of the sheet material is ablated by the laser beam, thereby producing depressions or perforations in the thickness of the sheet. In other words, the "perforation pattern" obtained by "laser perforation" can be as in US Patent 5,975,583 figure 2 The pattern shown, where the perforations pass through the entire thickness of the sheet; image 3 The pattern shown, where only part of the material of the sheet is ablated; or a combination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com