Dense type conveying trough plate strip

A conveying trough and fine type technology, applied in the field of fine conveying trough plates and belts, can solve the problems of large gaps, easy scattering of materials, affecting material transportation, etc., and achieve the effect of good rigidity, uniform feeding and good resistance to thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

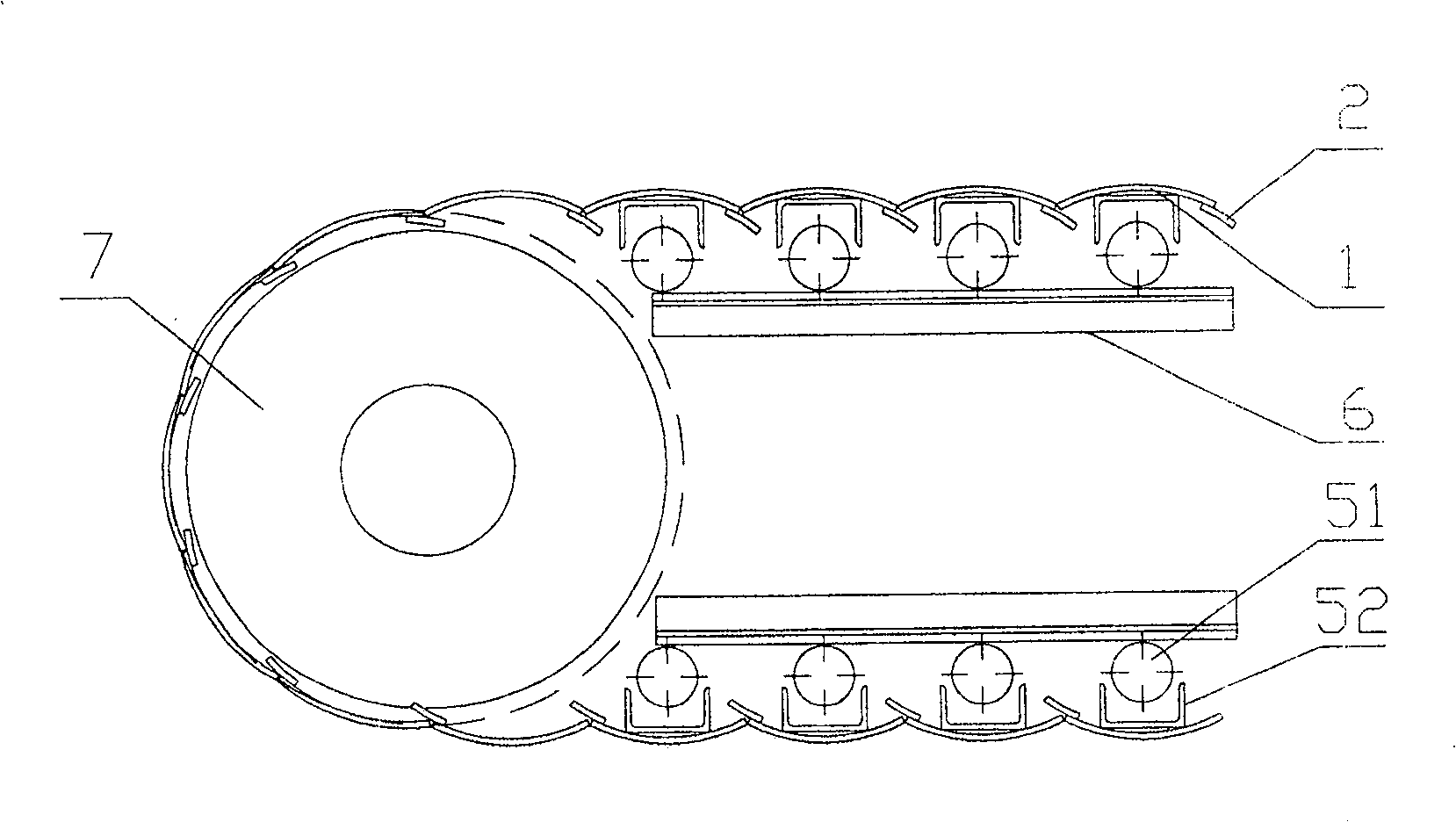

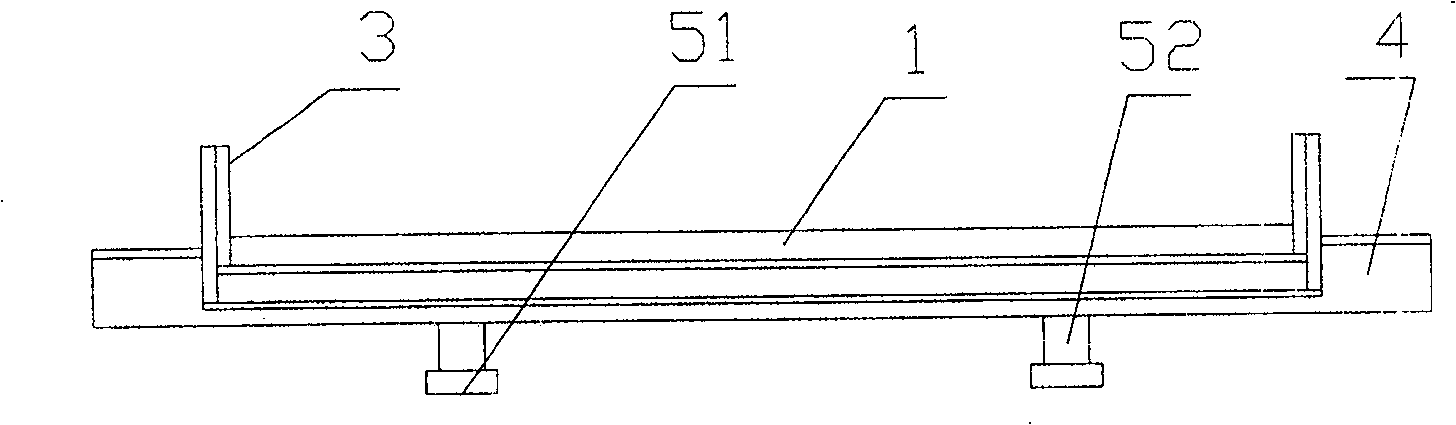

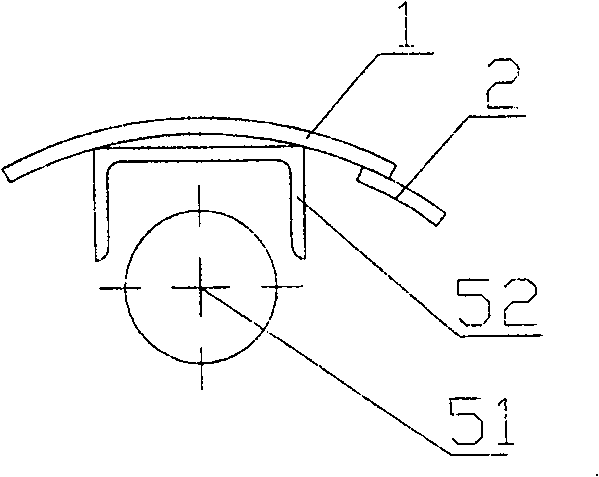

[0014] Such as figure 1 As shown, the fine-density conveying trough plate belt of the present invention is made of several conveying trough plates 1, and described conveying trough plate 1 is arc-shaped plate, and its material generally adopts steel, to strengthen the rigidity of trough plate, among the figure 7 is designed The rotary wheels at both ends of the conveying chute, the curvature of the rotary wheel is also the arc curvature of the turning route of the conveying chute. The conveying troughs 1 closely overlap one another at the ends in the conveying direction, so that powdery conveyed material cannot fall therefrom. The curvature of the conveyor chute 1 can be consistent with the arc curvature of the turning route. Such as image 3 As shown, the arc-shaped plate 2 fixed on the conveying trough plate is installed under the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com