Composite heat accumulation and composite heat accumulating burner

A burner and composite technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of explosion, regenerative combustion equivalent imbalance, etc., and achieve the effect of unique solution and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

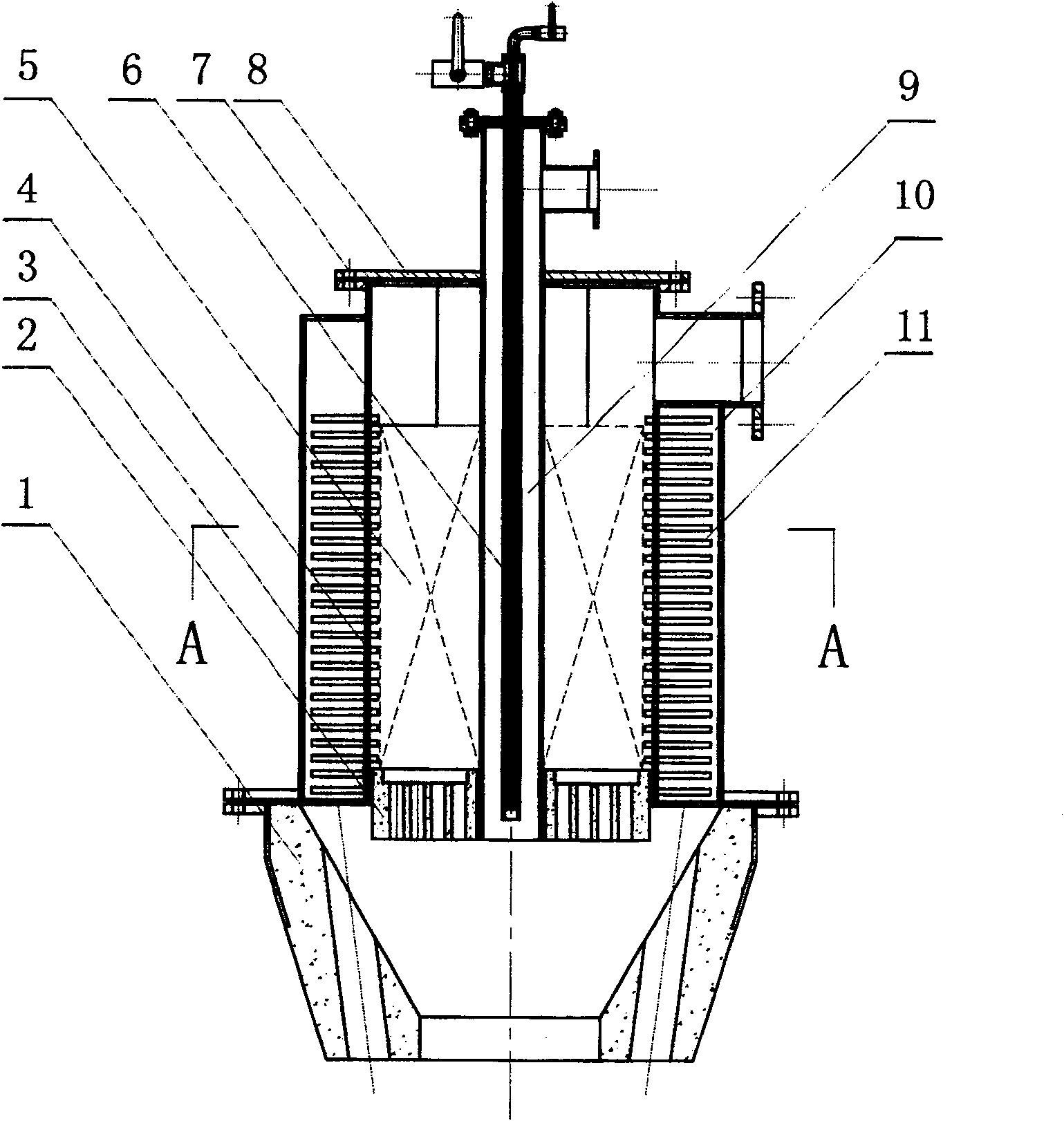

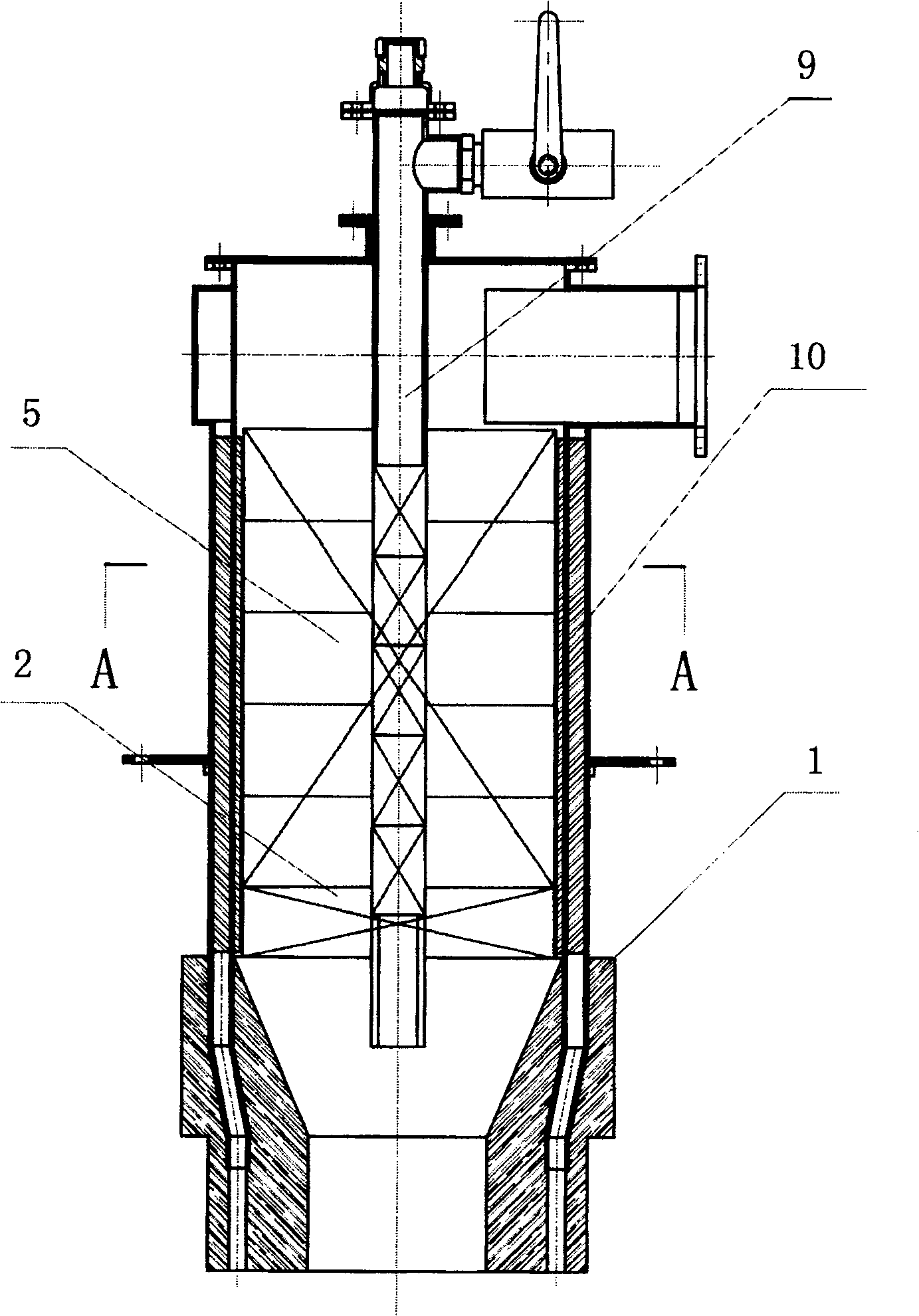

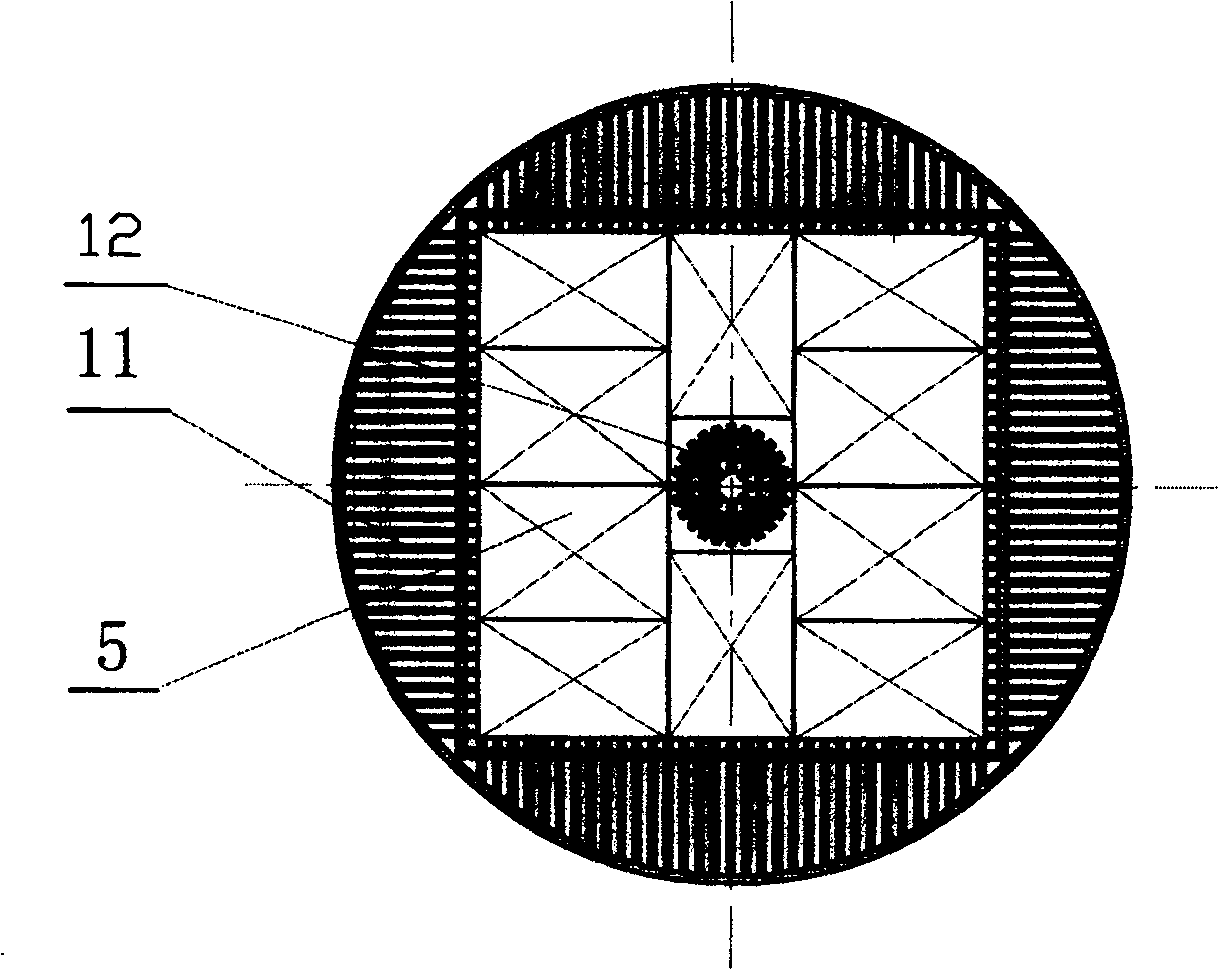

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Regenerative combustion is a relatively new combustion technology that has only been developed in recent years. The regenerative combustion in the prior art only uses regenerative bodies to store heat no matter whether it is single heat storage or double heat storage. The composite heat storage proposed by the present invention is a new type of heat storage method created by the inventor in the process of solving technical problems in actual work. It solves the problem of "explosion" in the gas channel in the double heat storage of large burners, and also solves the problem of equivalent imbalance caused by the single heat storage of radiant tube burners. The composite heat storage method of the present invention can also be applied to other In the combustion equipment, it has a wide range of promotion and application valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com