Developing unit for developing static latent image

A developing unit and electrostatic latent image technology, applied to the electric recording process using charge pattern, equipment for electric recording process using charge pattern, and electric recording, which can solve the problem of thinning of toner image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

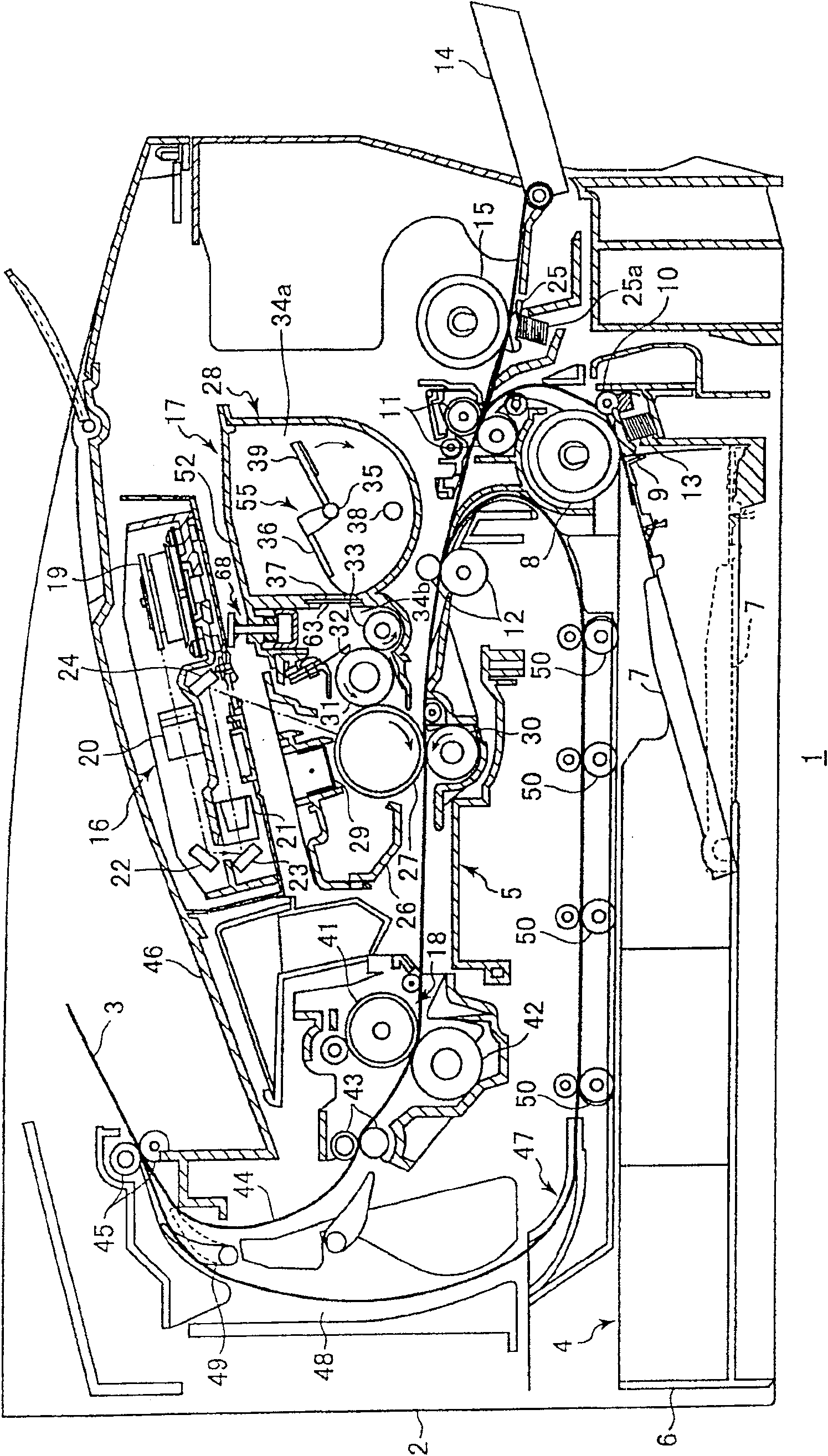

[0027] Next, refer to Figure 2 to Figure 6(b) A laser printer incorporating the developing cartridge according to the first embodiment of the present invention will be described.

[0028] Such as figure 2 As shown, the laser printer 1 includes a main casing 2 , a feeding unit 4 and an imaging unit 5 . The feeding unit 4 and the imaging unit 5 are accommodated in the main housing 2 . The feeding unit 4 feeds the paper 3 to the image forming unit 5 . The image forming unit 5 forms a desired image on the supplied paper 3 .

[0029] The feed unit 4 is located at the lower part of the main casing 2 and includes a paper feed tray 6 , a paper platen 7 , a paper feed roller 8 , a paper feed pad 9 , paper dust removing rollers 10 , 11 and registration rollers 12 . The paper feed tray 6 is detachably attached to the main casing 2 . A paper platen 7 is pivotally and movably provided in the paper feed tray 6 . A paper feed roller 8 and a feed low pad 9 are provided on one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com