Color toner for electrophotography

A color toner, electrophotographic technology, applied in the direction of developer, electrography, instrument, etc., can solve the problems of poor fluidity of toner, poor text clarity, not long enough service life, etc. No deterioration in performance, stable image density, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

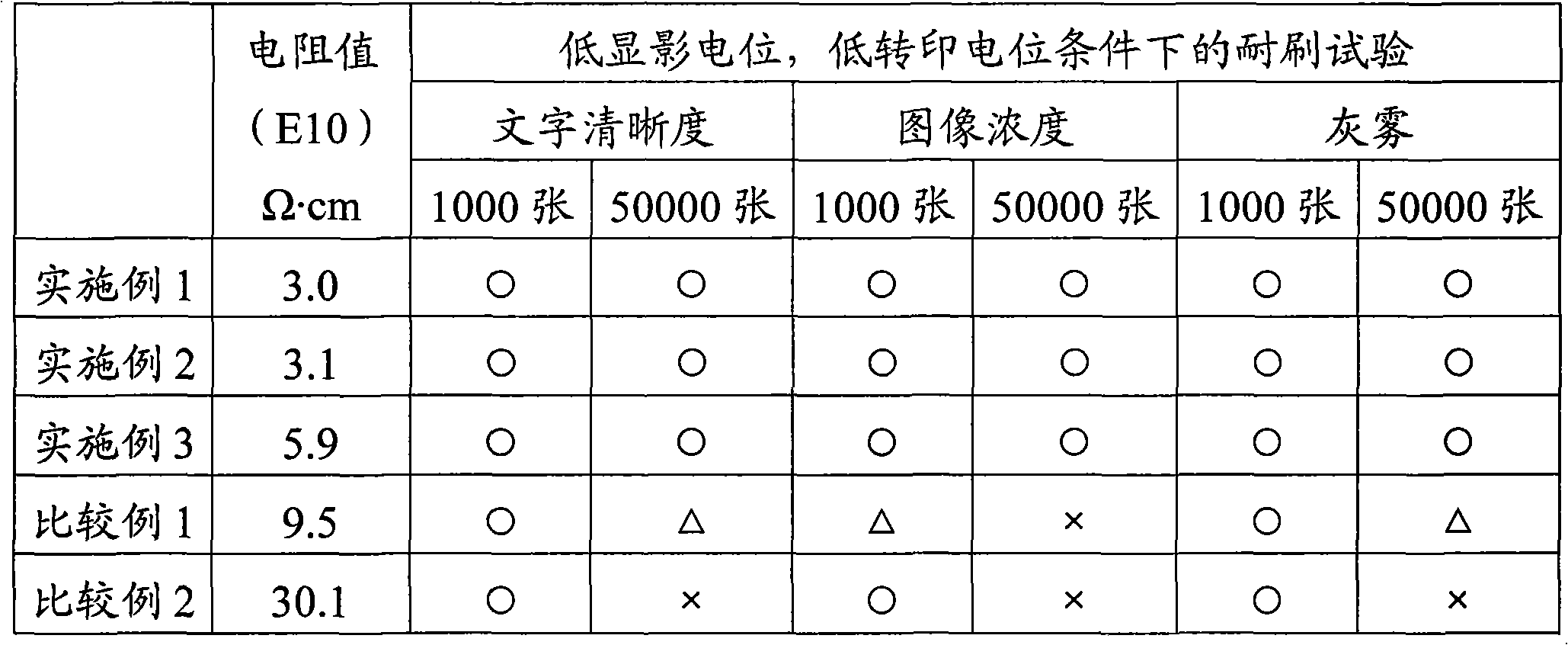

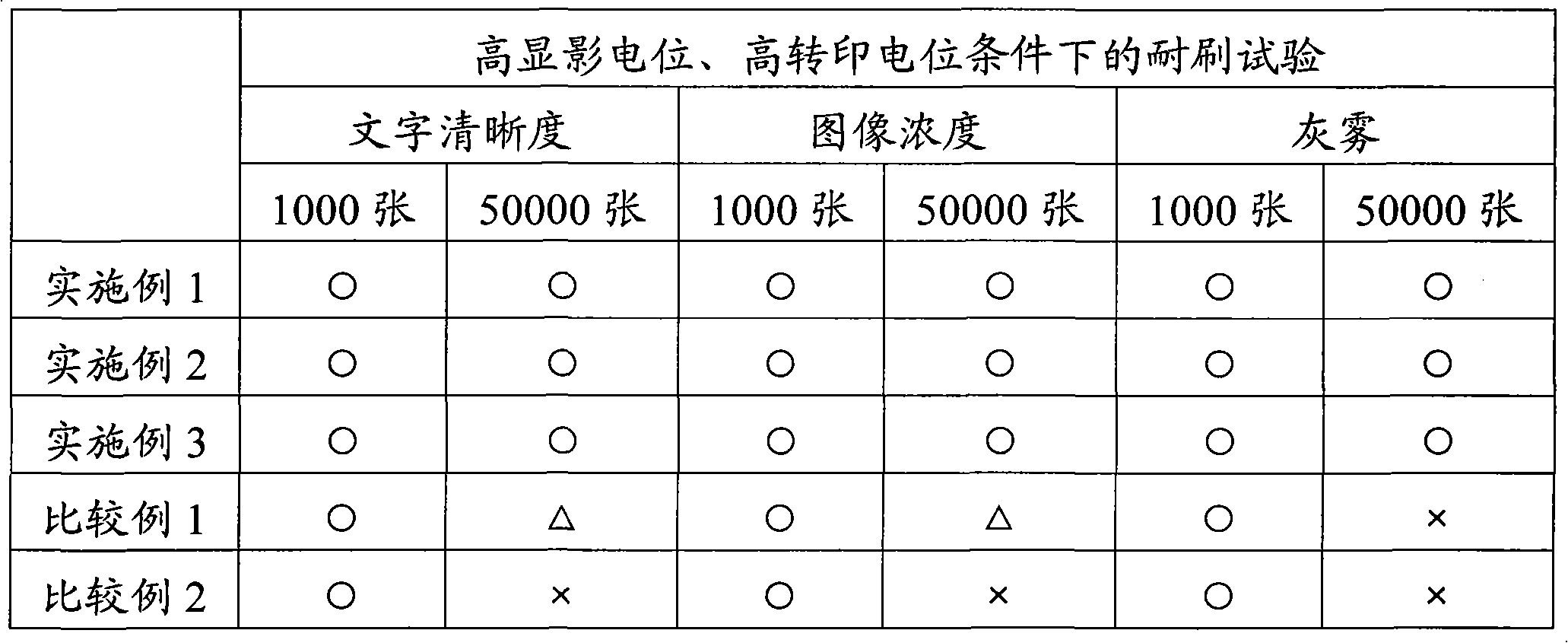

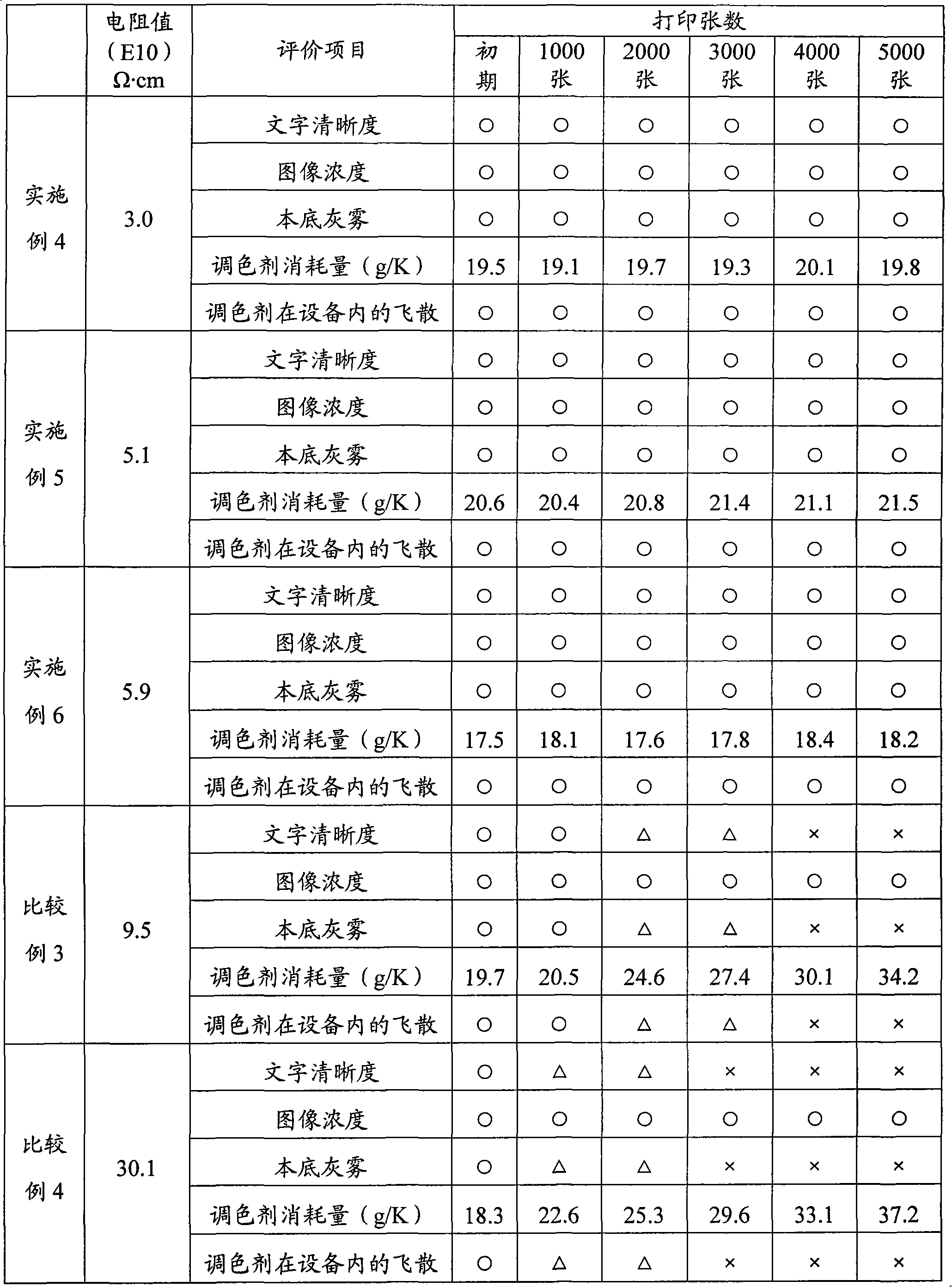

Embodiment 1

[0171] (Manufacture of antistatic composition)

[0172]In 100 parts (70° C.) of bis(2-(2-butoxyethoxy) ethyl) adipate (manufactured by Sanko Chemical Industry Co., Ltd.) as an organic compound of the component (A), 10 wt. Add lithium trifluoromethanesulfonate LiCF as (B) component in % 3 SO 3 (manufactured by Morita Chemical Industry Co., Ltd.), and dissolved.

[0173] Next, after setting this solution to 60° C., synthetic hydrotalcite (manufactured by Kyowa Chemical Industry Co., Ltd., trade name: “Kyoward KW-2000”) as a component having anion adsorption capacity was added so as to become 2% by weight, Stir at 60°C for 60 minutes.

[0174] This solution was filtered to obtain an antistatic composition (X) composed of a transparent liquid.

[0175] The volume intrinsic impedance value of the obtained antistatic composition (X) was 4.1×10 6 Ω·cm.

[0176] Here, the volume intrinsic impedance value of the liquid was measured with a digital multimeter TR6865 (manufactured b...

Embodiment 2

[0201] In Example 2, except having made the compounding quantity of the antistatic composition (X) into 0.1 weight part, it carried out similarly to Example 1, and obtained the nonmagnetic two-component developer of Example 2.

Embodiment 3

[0203] In Example 3, except that the compounding amount of the antistatic composition (X) was 1.0 parts by weight, and the binder resin was ethylene-norbornene copolymer resin (manufactured by Ticona (Ticona), Mw78000, Mn6500 , Tg58° C.), the same procedure as in Example 1 was carried out to obtain the non-magnetic two-component developer of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com