Patents

Literature

106results about How to "Suppresses image defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

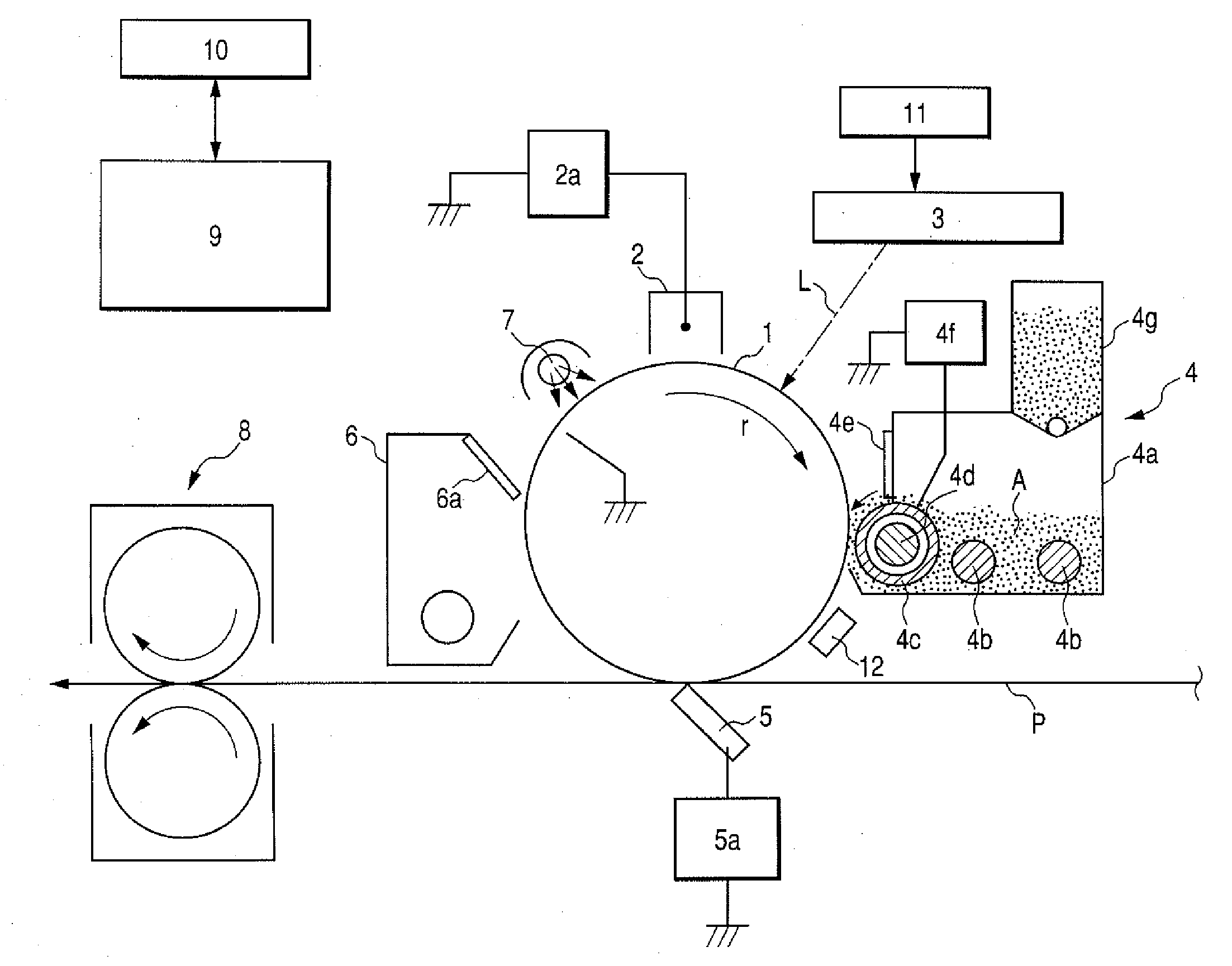

Image forming apparatus

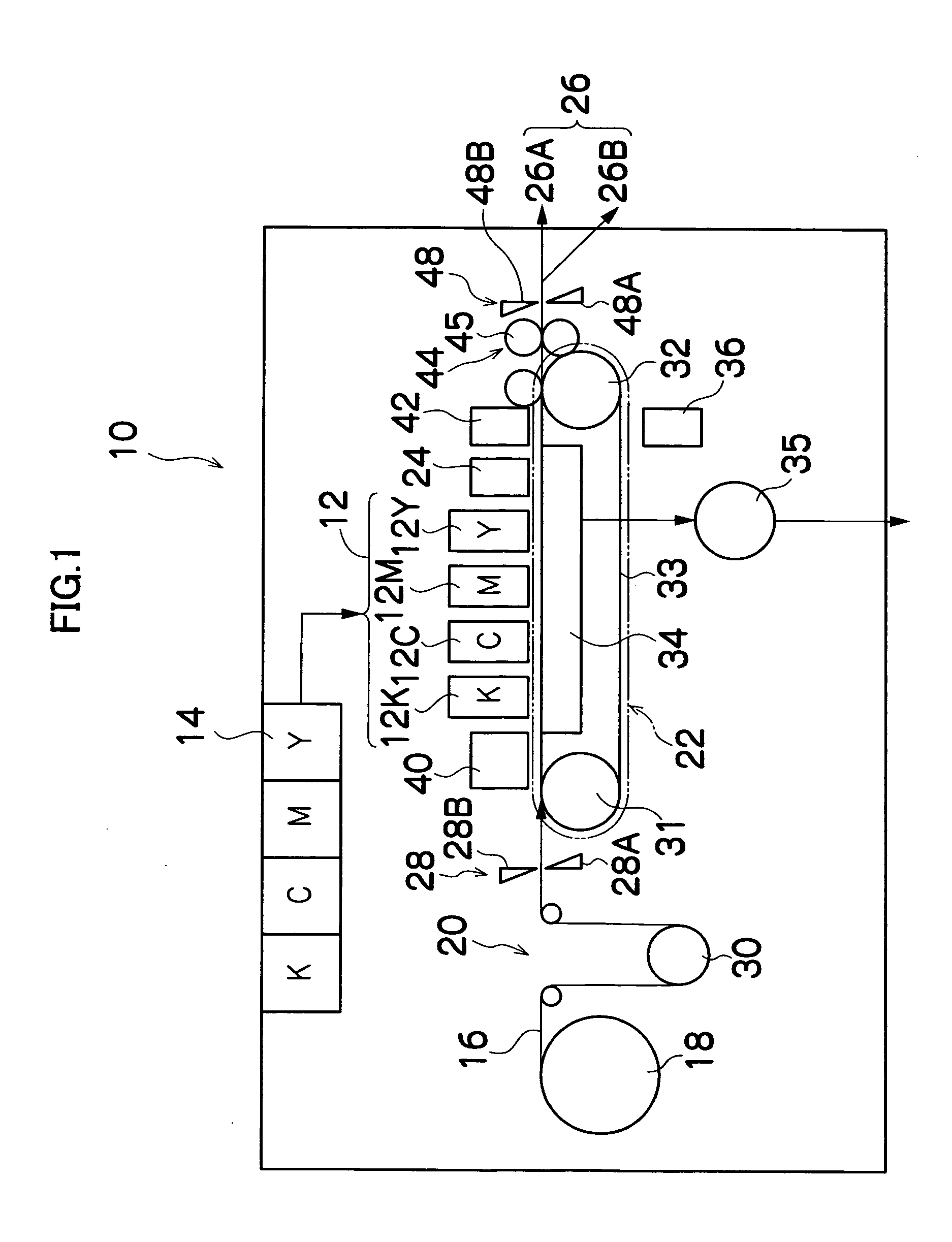

ActiveUS20080232862A1Improve balanceGood toner adherenceElectrographic process apparatusElectrical resistance and conductanceLatent image

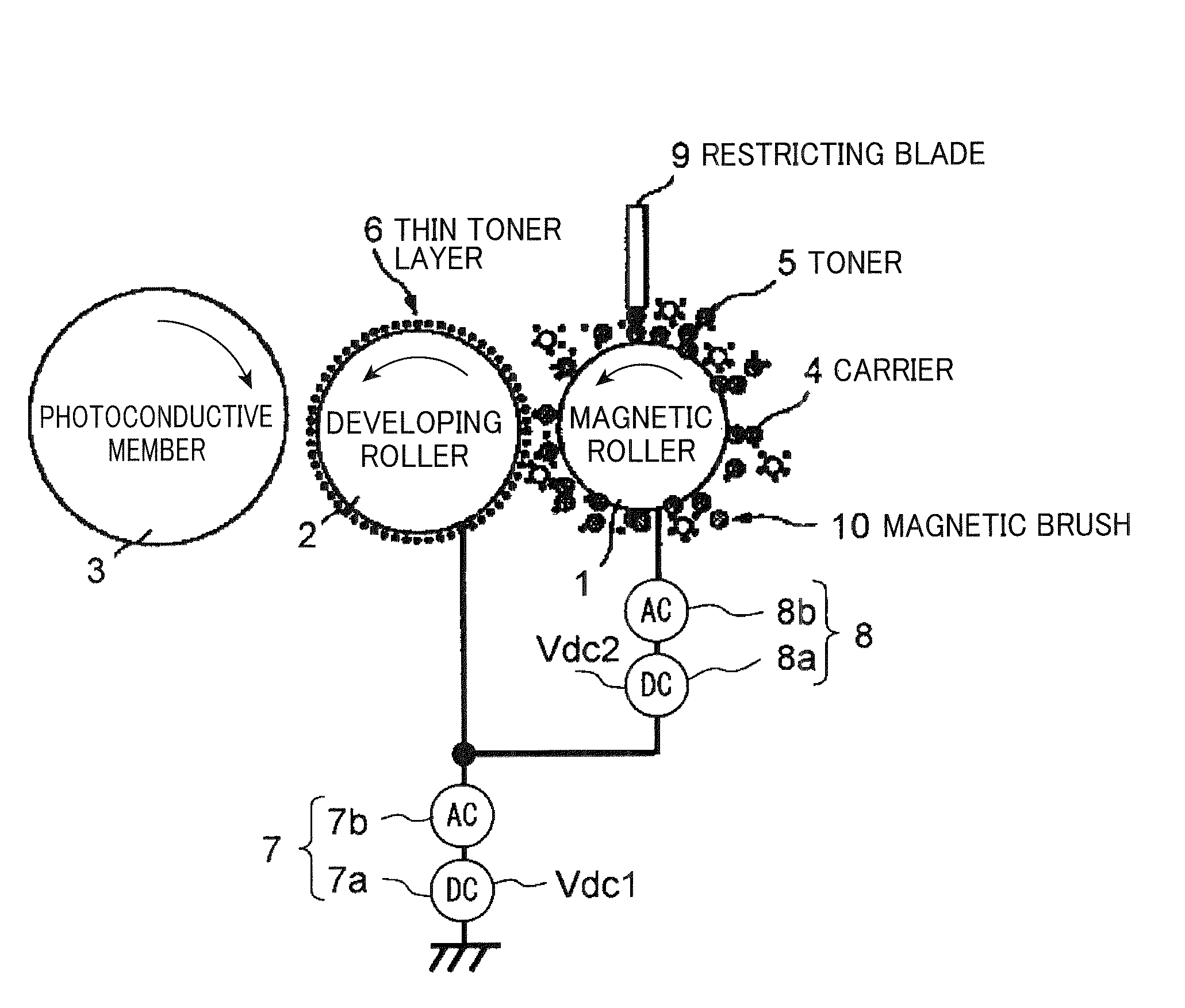

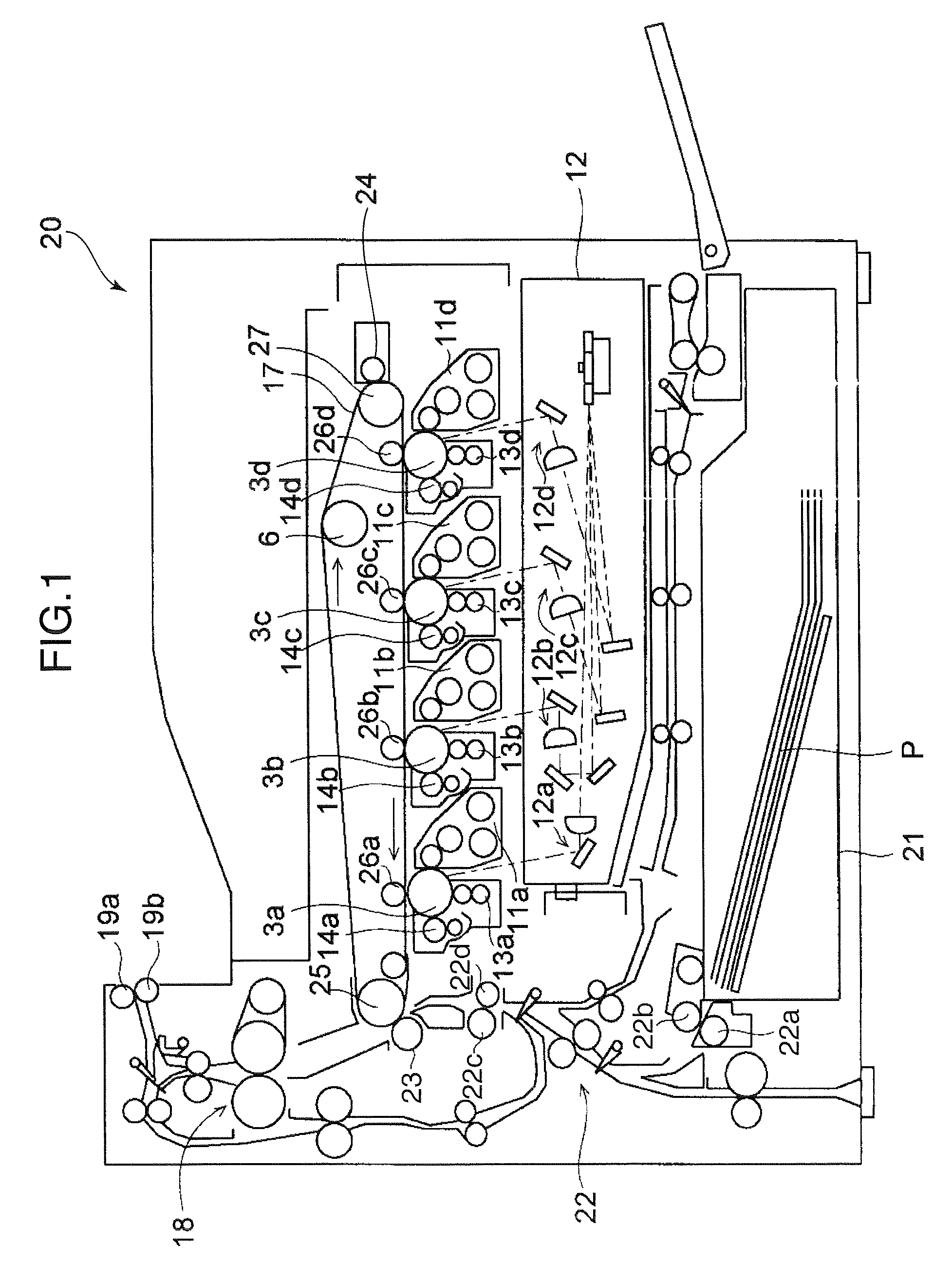

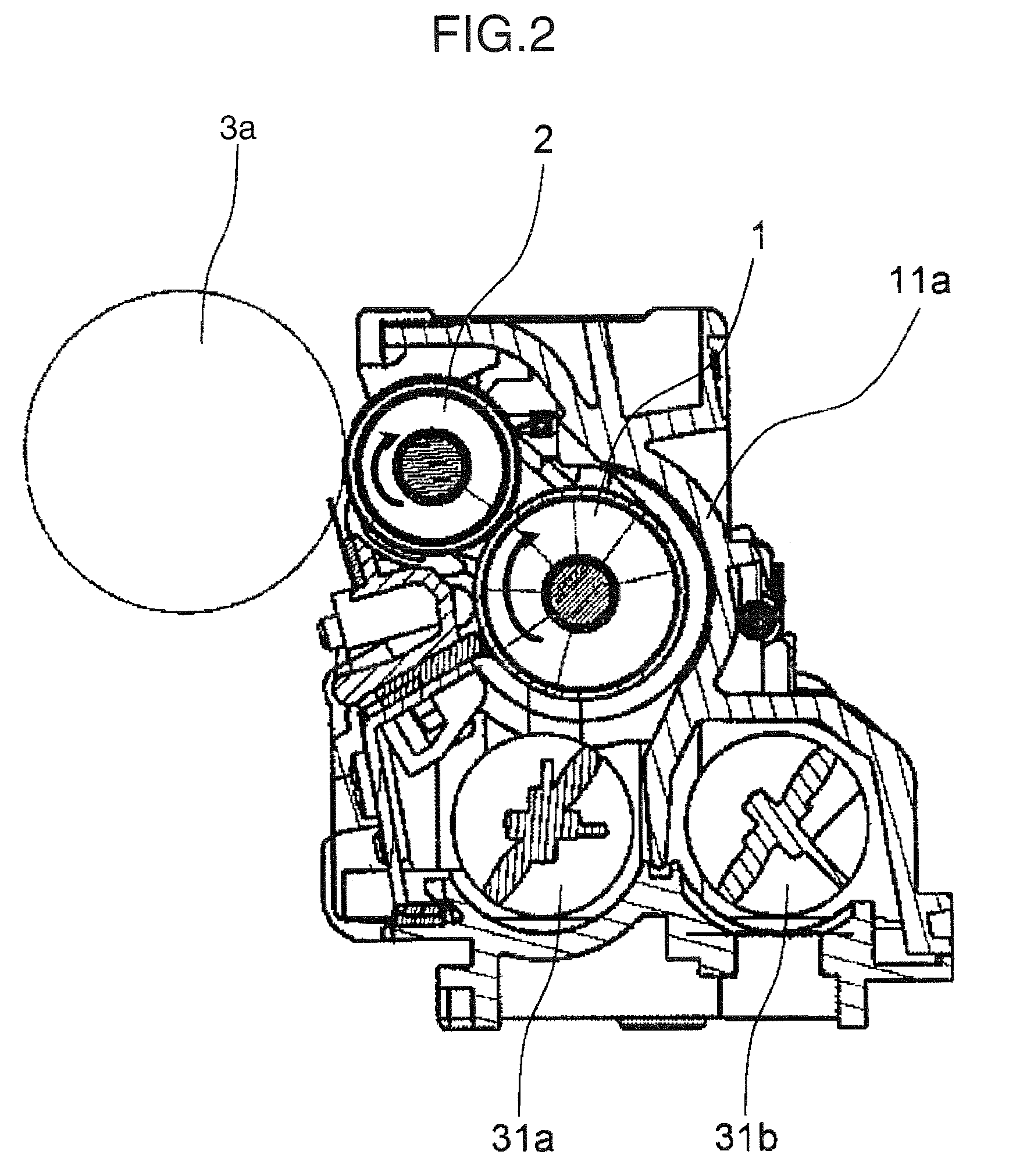

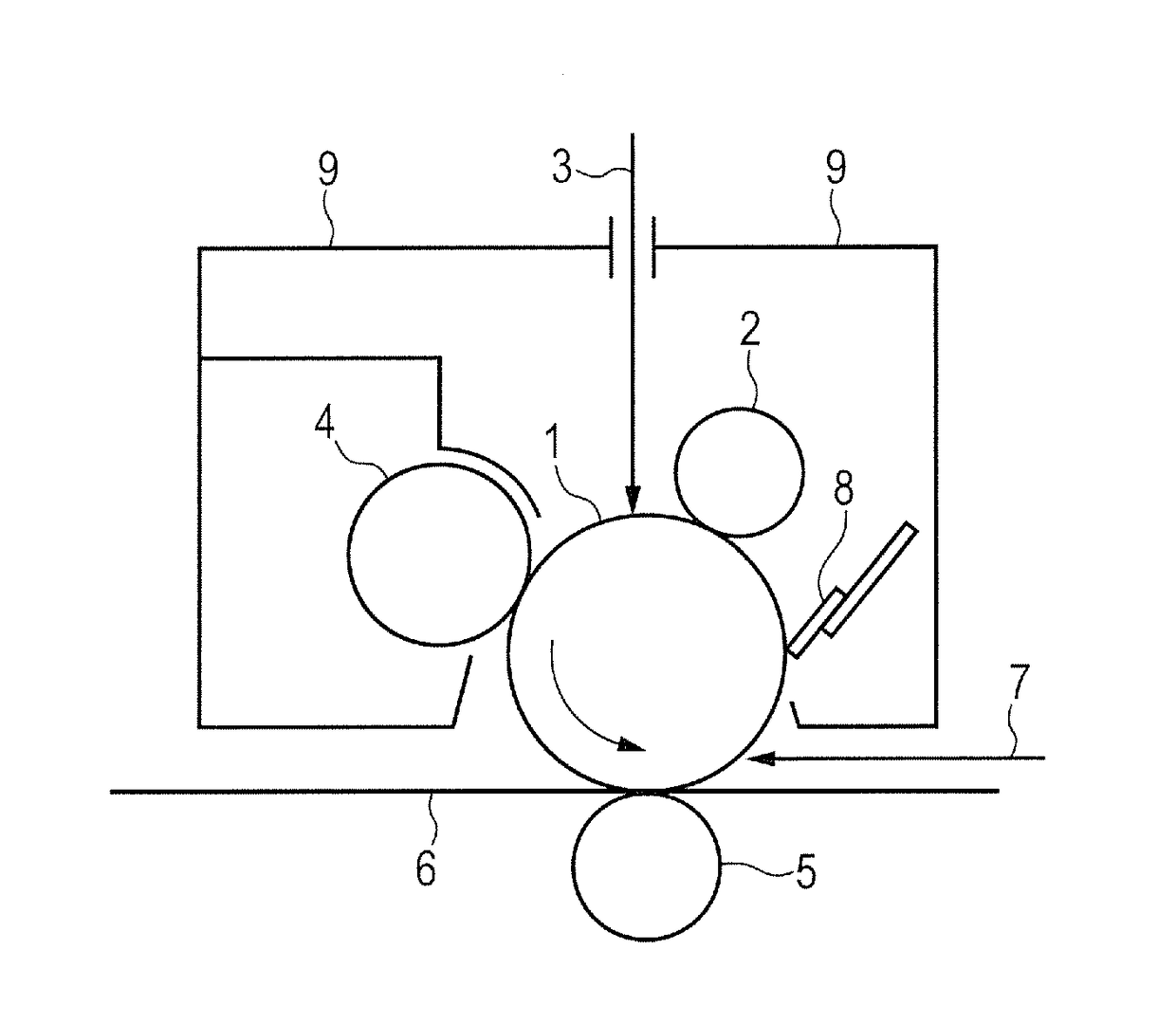

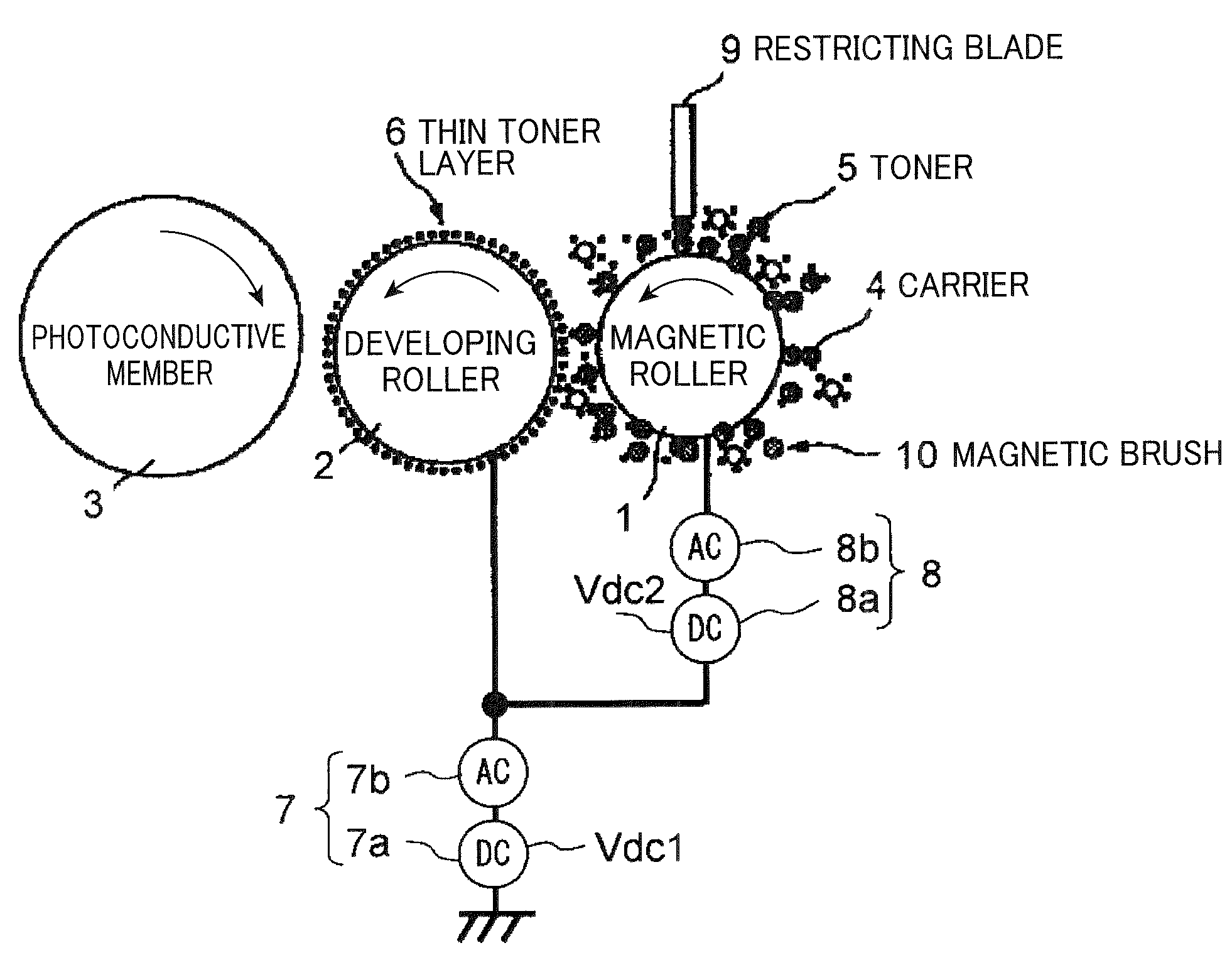

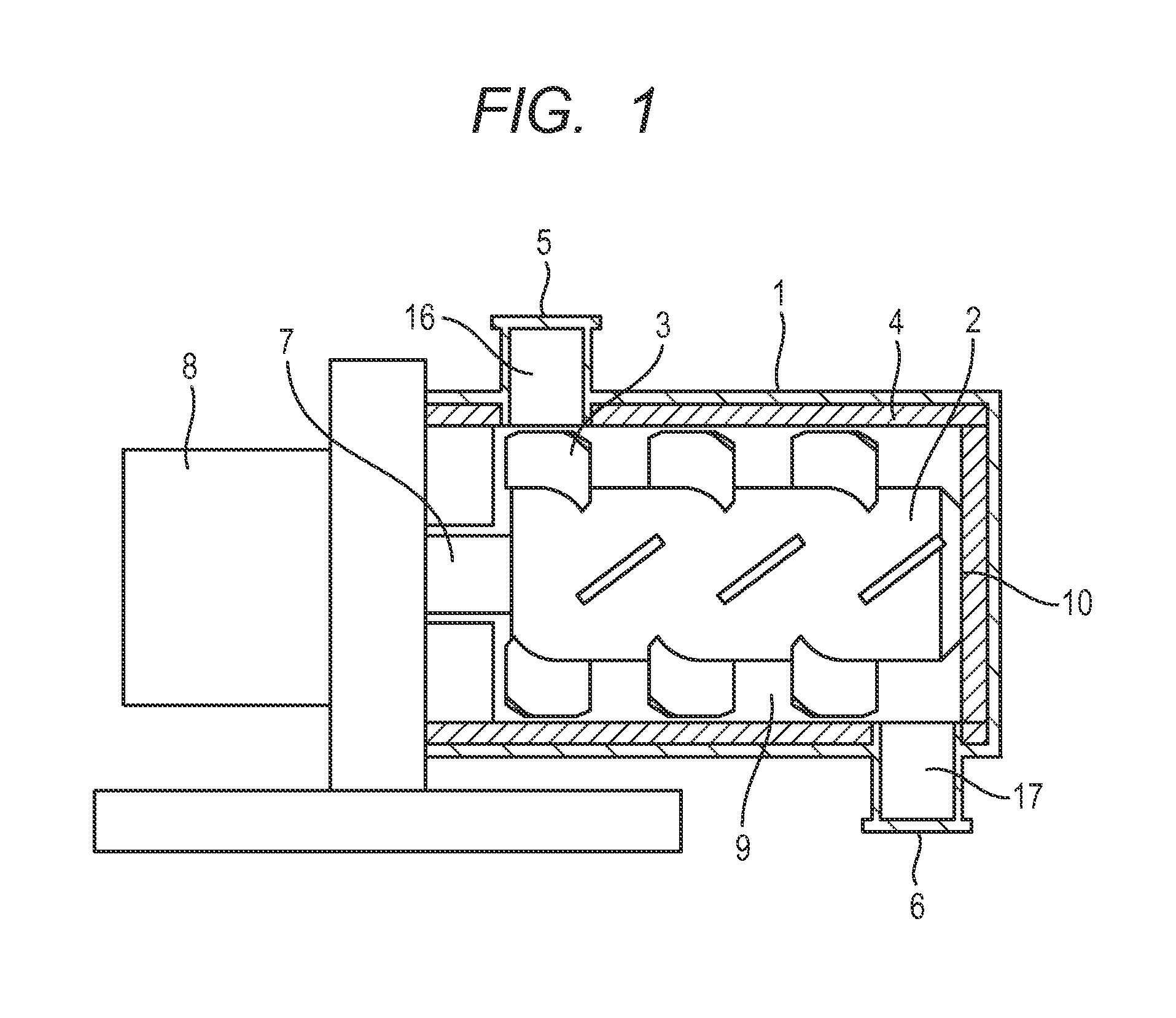

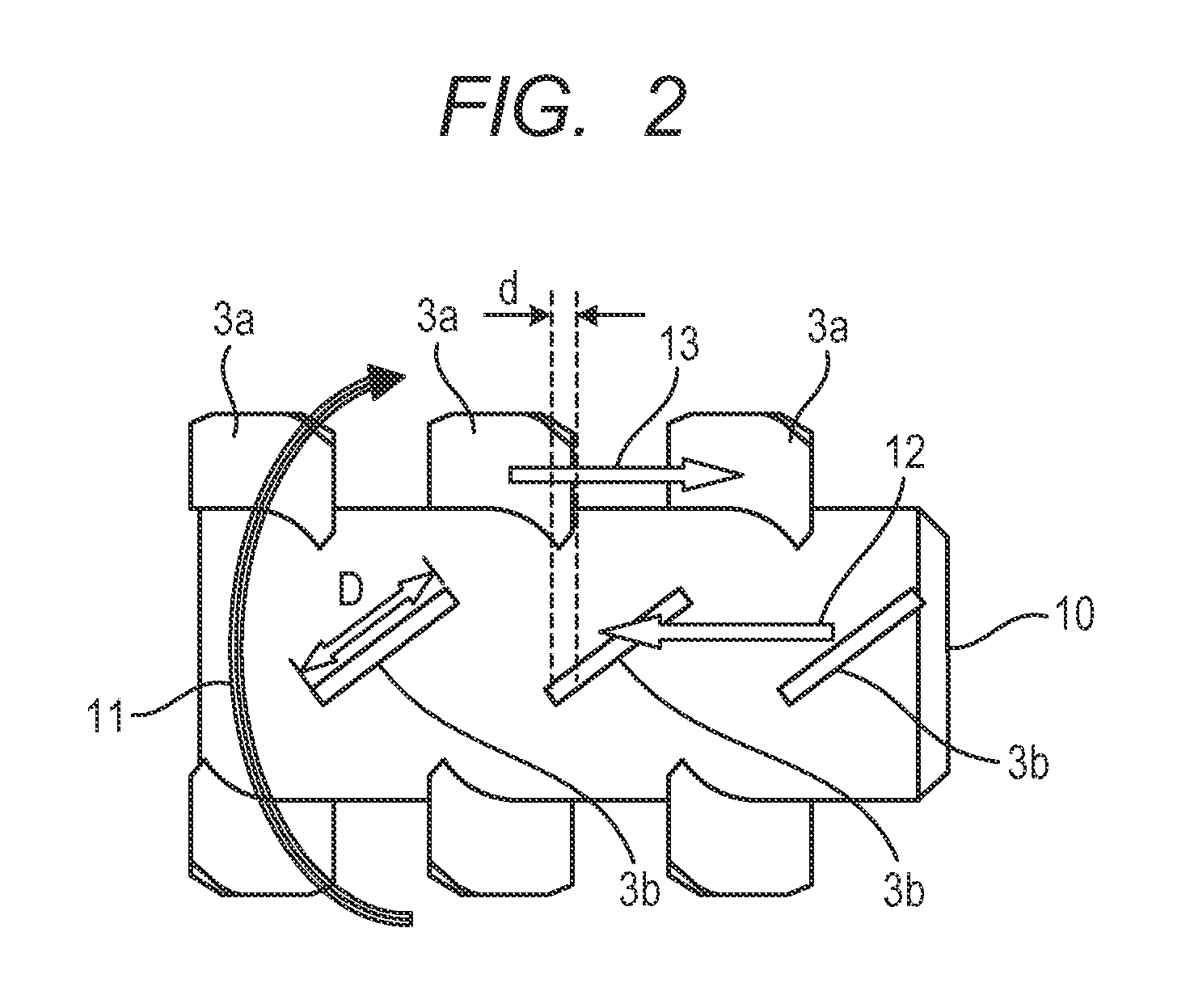

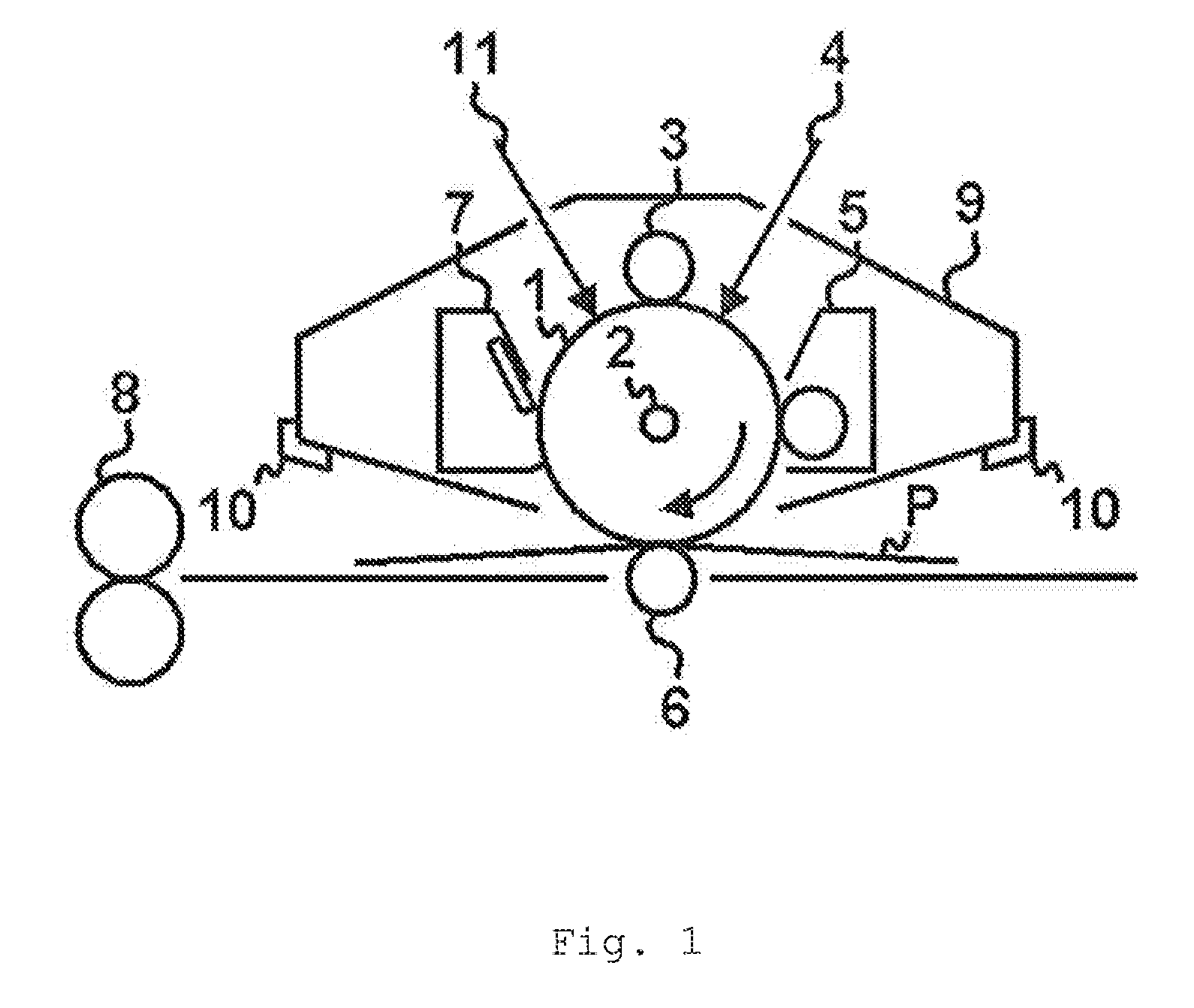

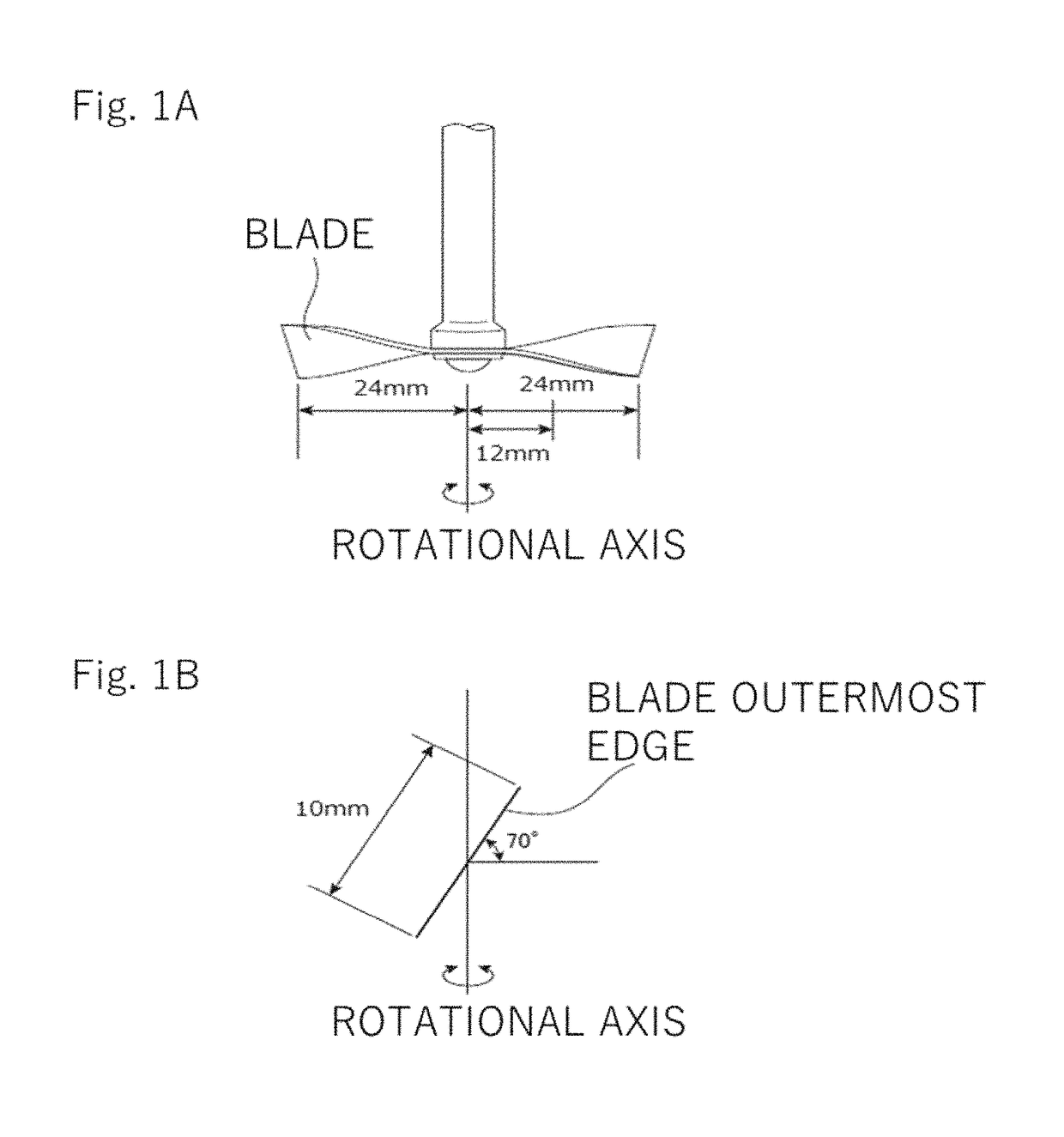

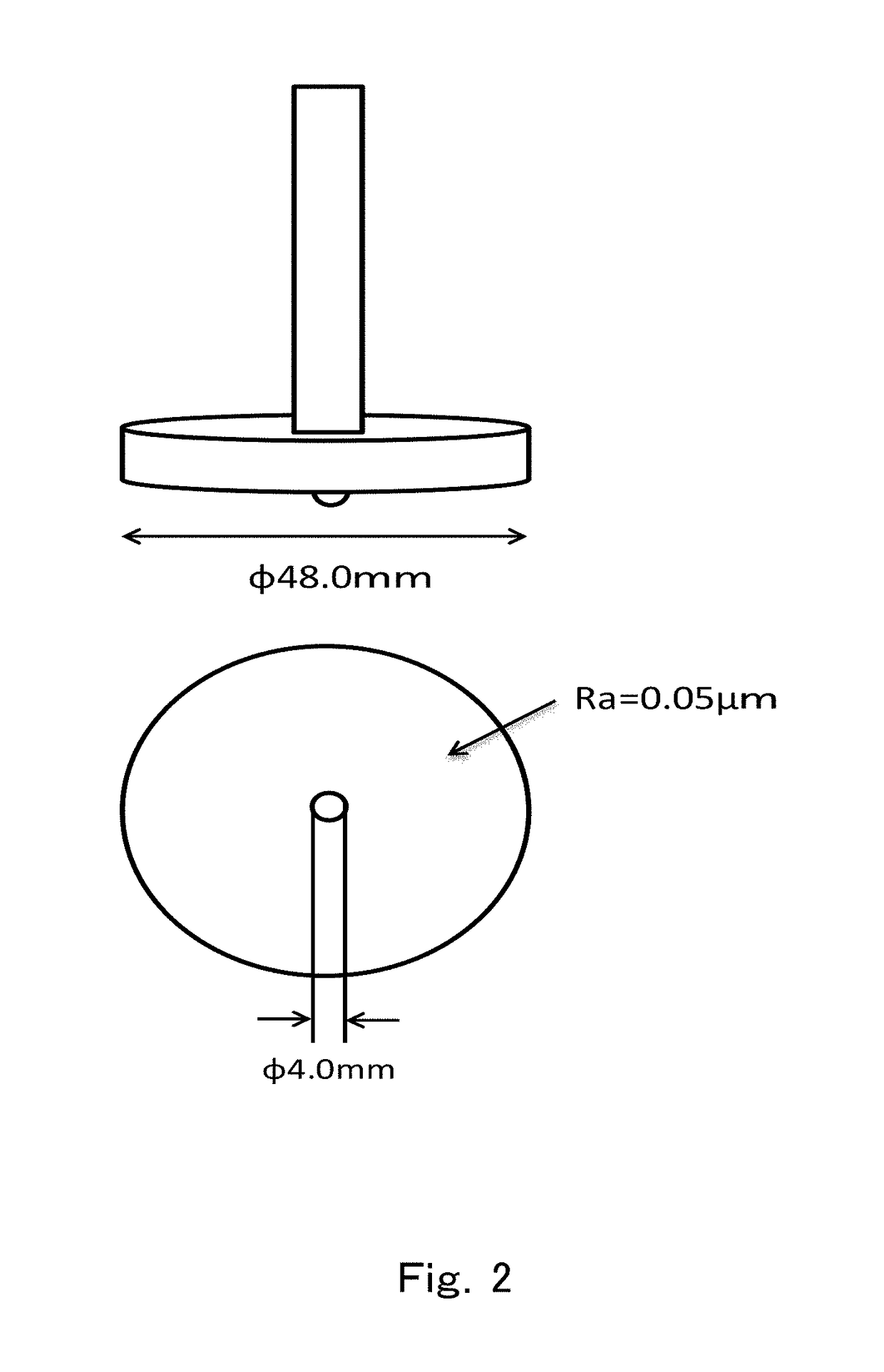

An image forming apparatus has a photoconductive member, and a developing roller develops a latent image on the photoconductive member by a first alternating-current bias in the form of a rectangular wave. The following relationships are satisfied in calculating the duty ratio (D1) of the first alternating-current bias using an application period of voltage in a direction to transfer the toner from the developing roller towards the photoconductive member as a positive period:a CV value in the number particle size distribution of the toner is ≦25%,4 μm≦Dt≦7 μm,105 Ω·cm≦pv≦109 QΩcm,0.4 μm≦Ra≦1.5 μm, and35%≦D1≦75%.where Dt denotes the volume average particle diameter of the toner, pv denotes the intrinsic resistance value of a developing roller surface, Ra denotes the arithmetic average roughness of the developing roller surface.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

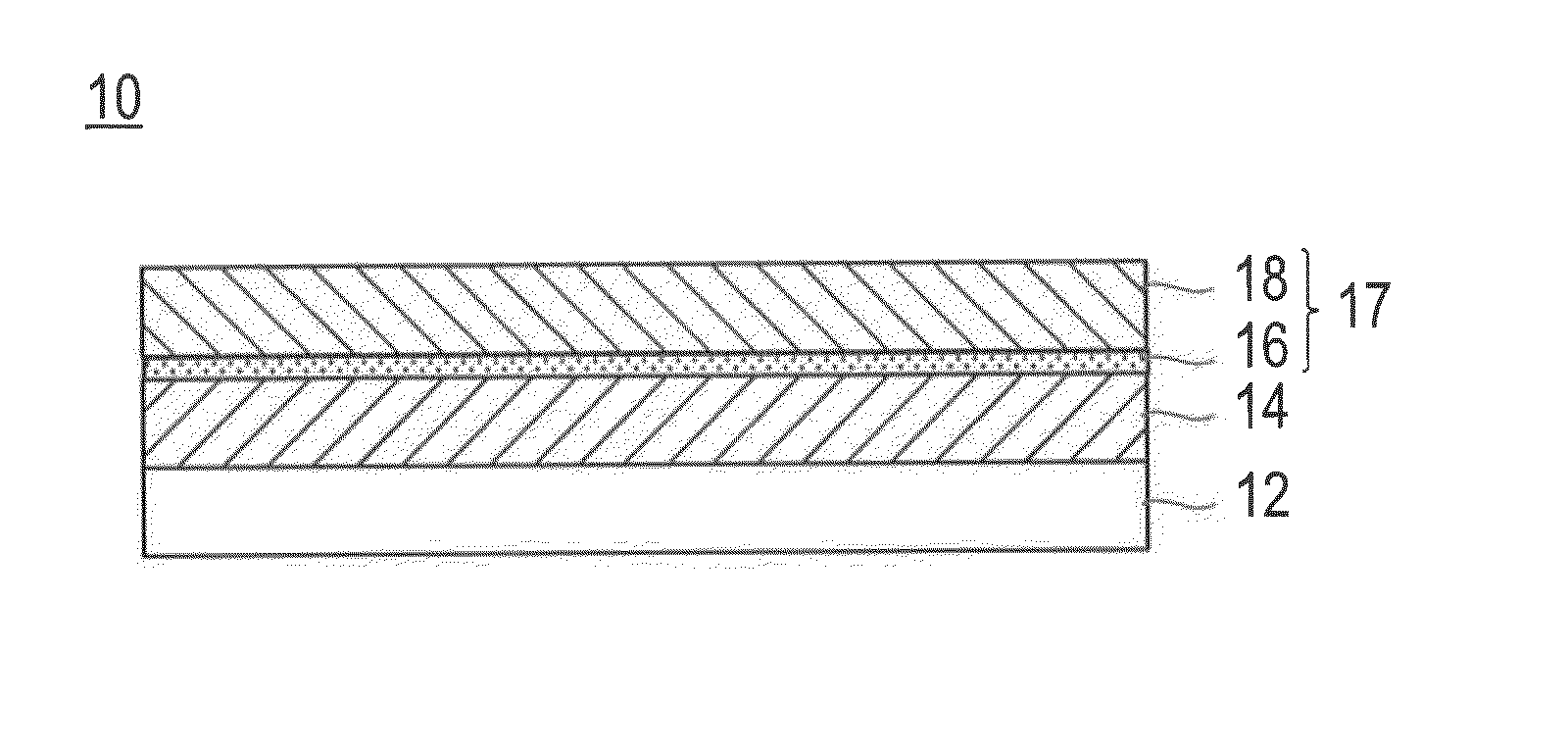

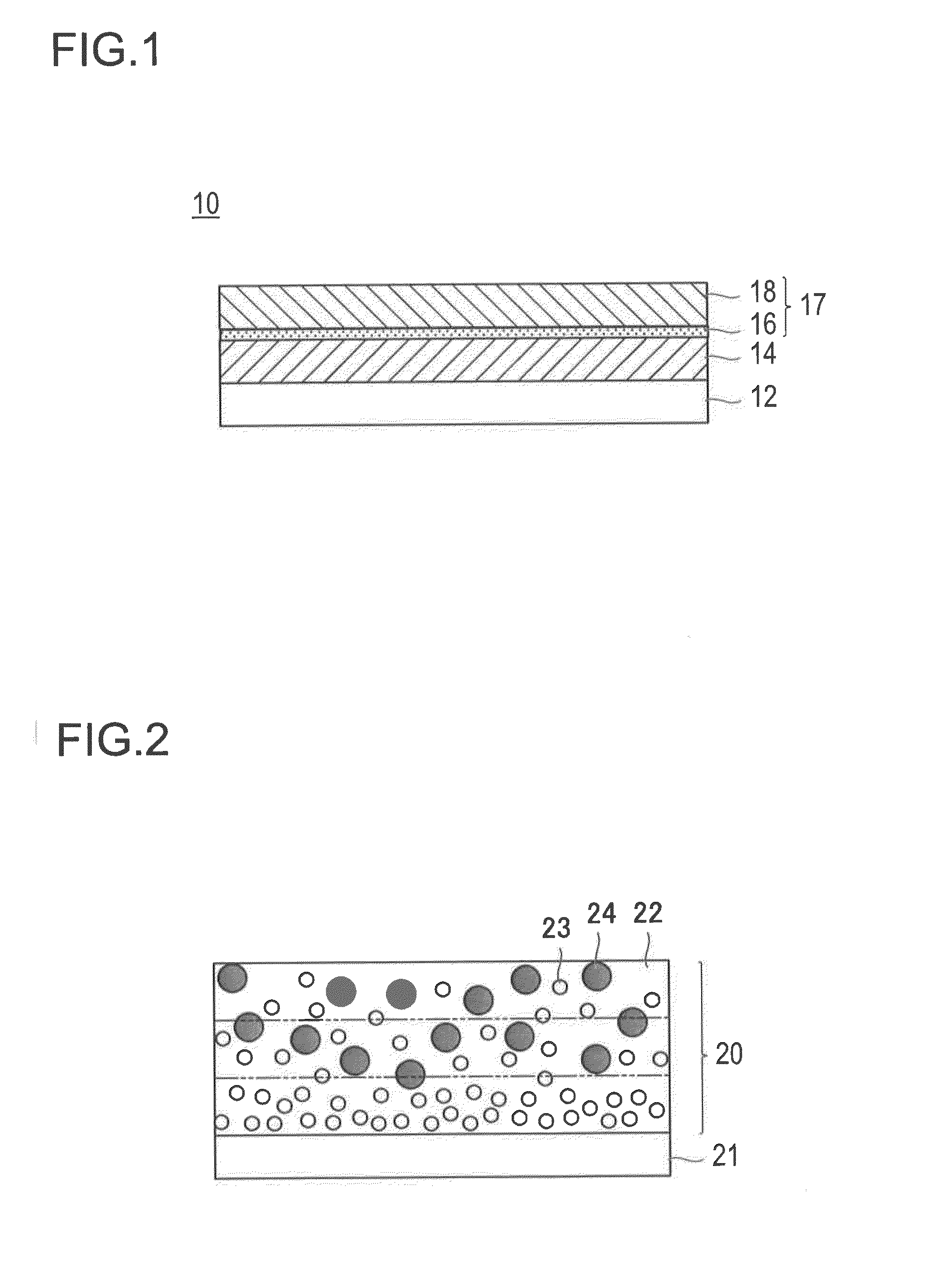

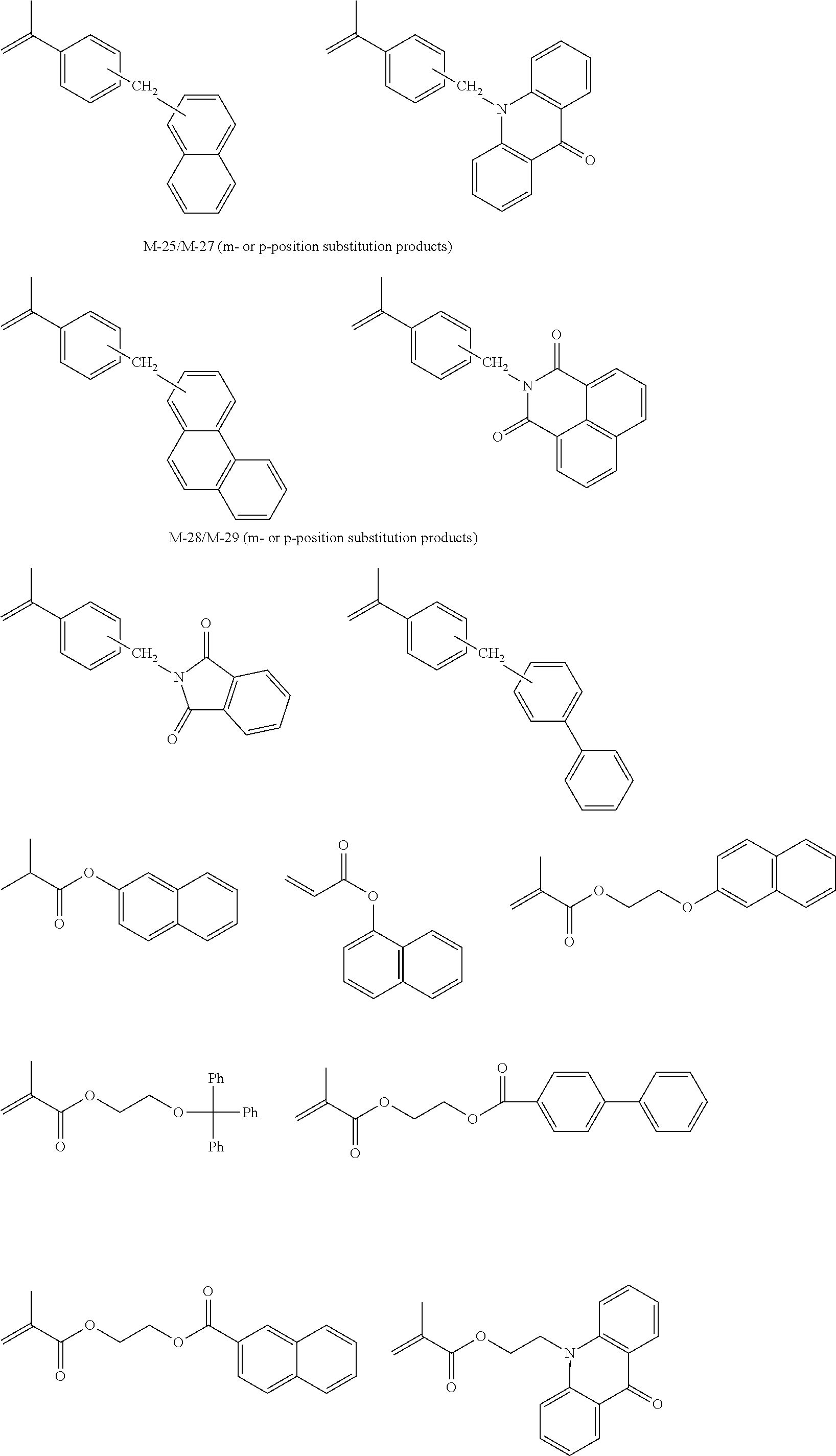

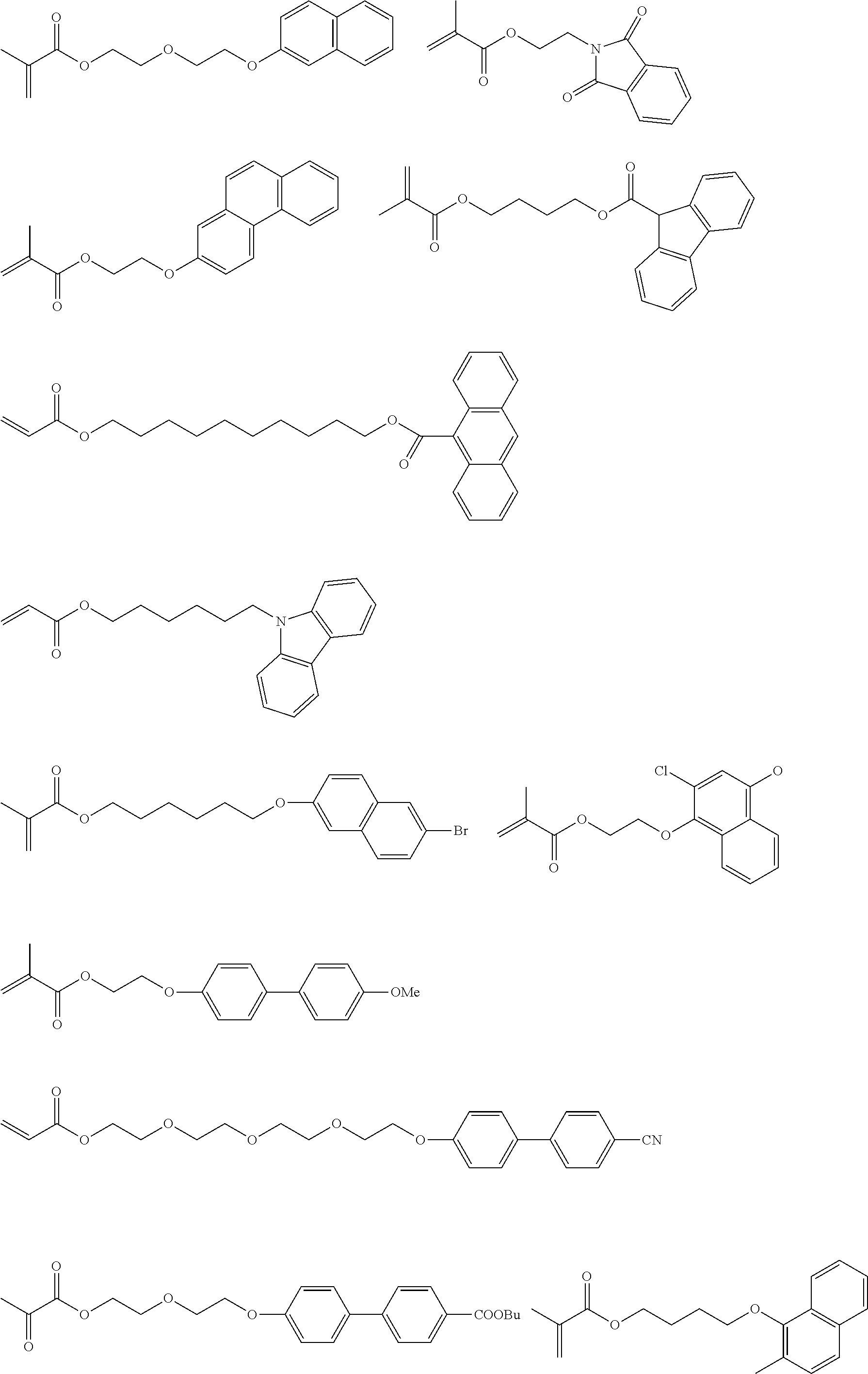

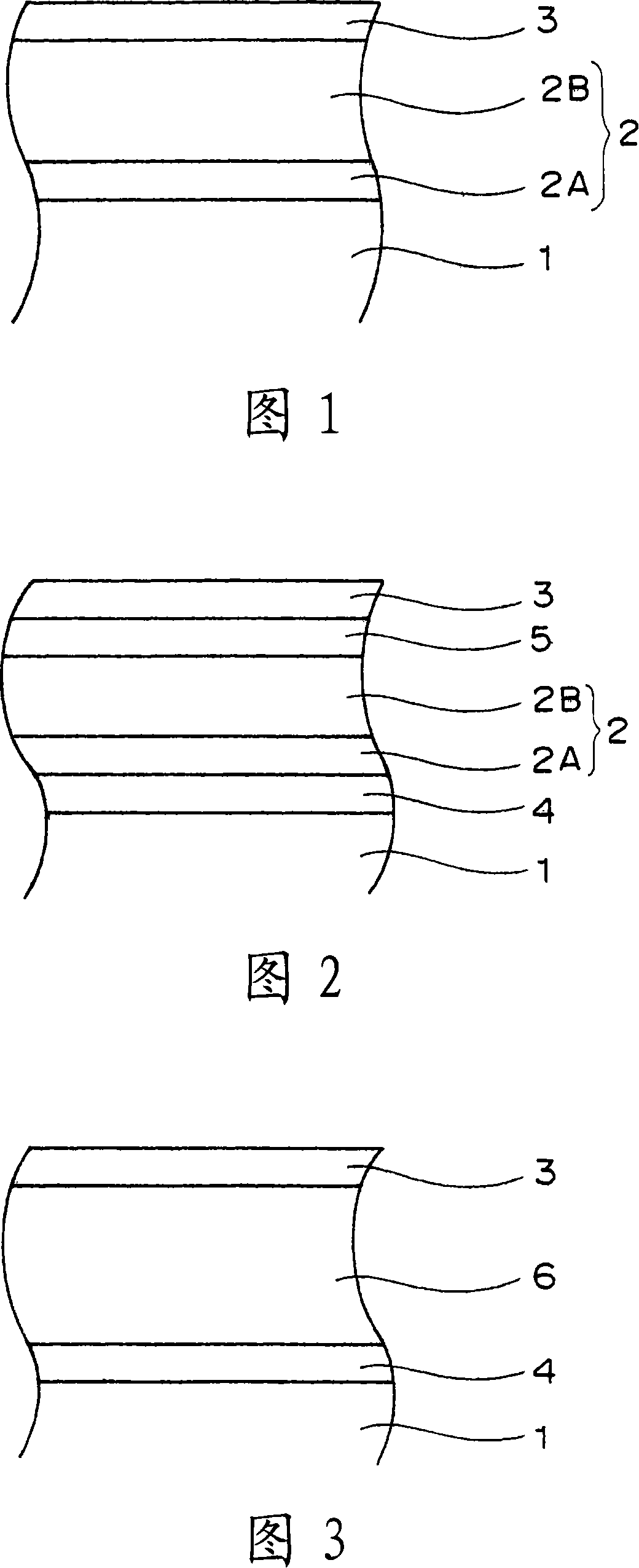

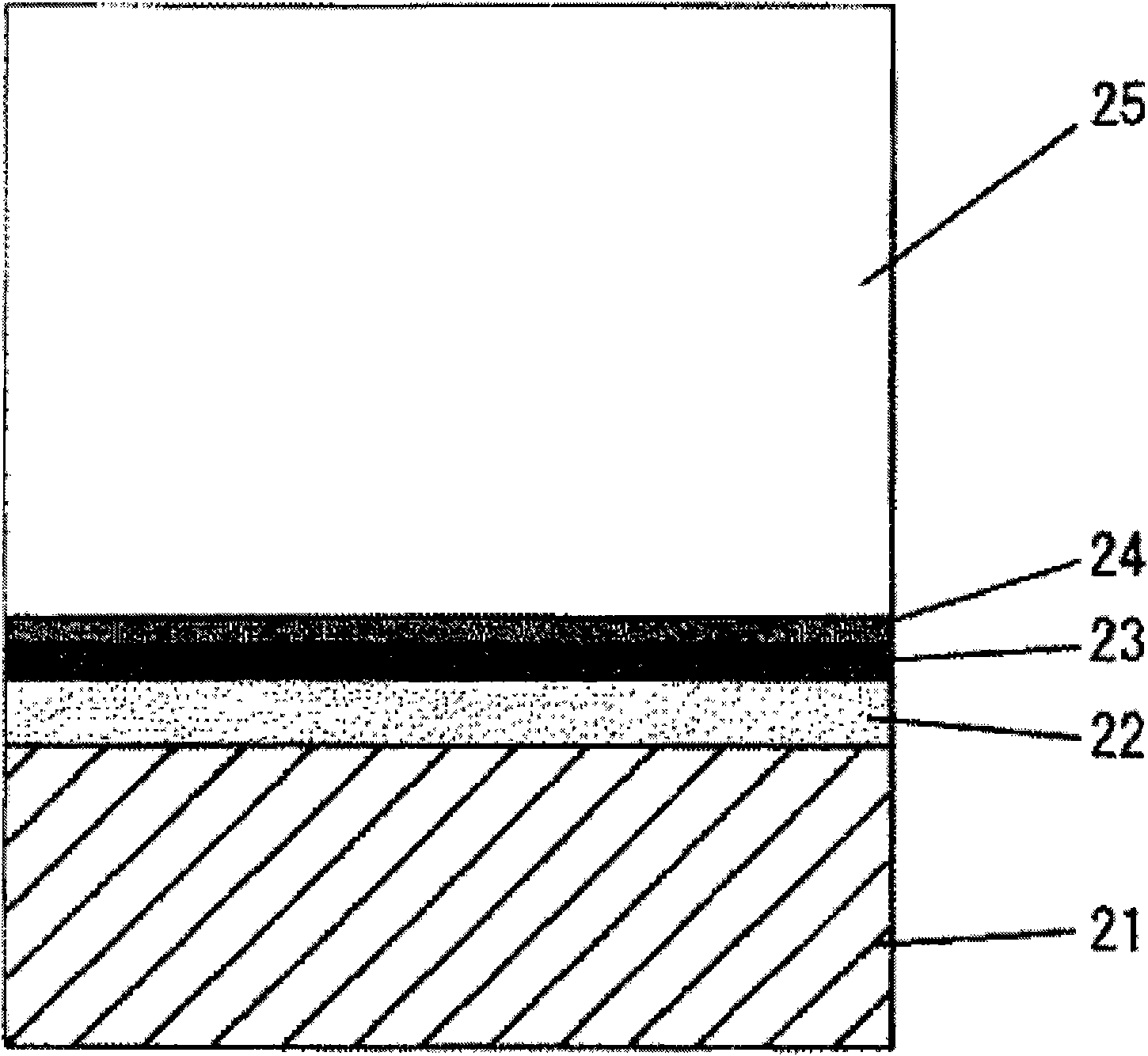

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

ActiveUS8524430B2Excellent film stateSuppresses image defectsElectrographic process apparatusCorona dischargePolymer sciencePolyolefin

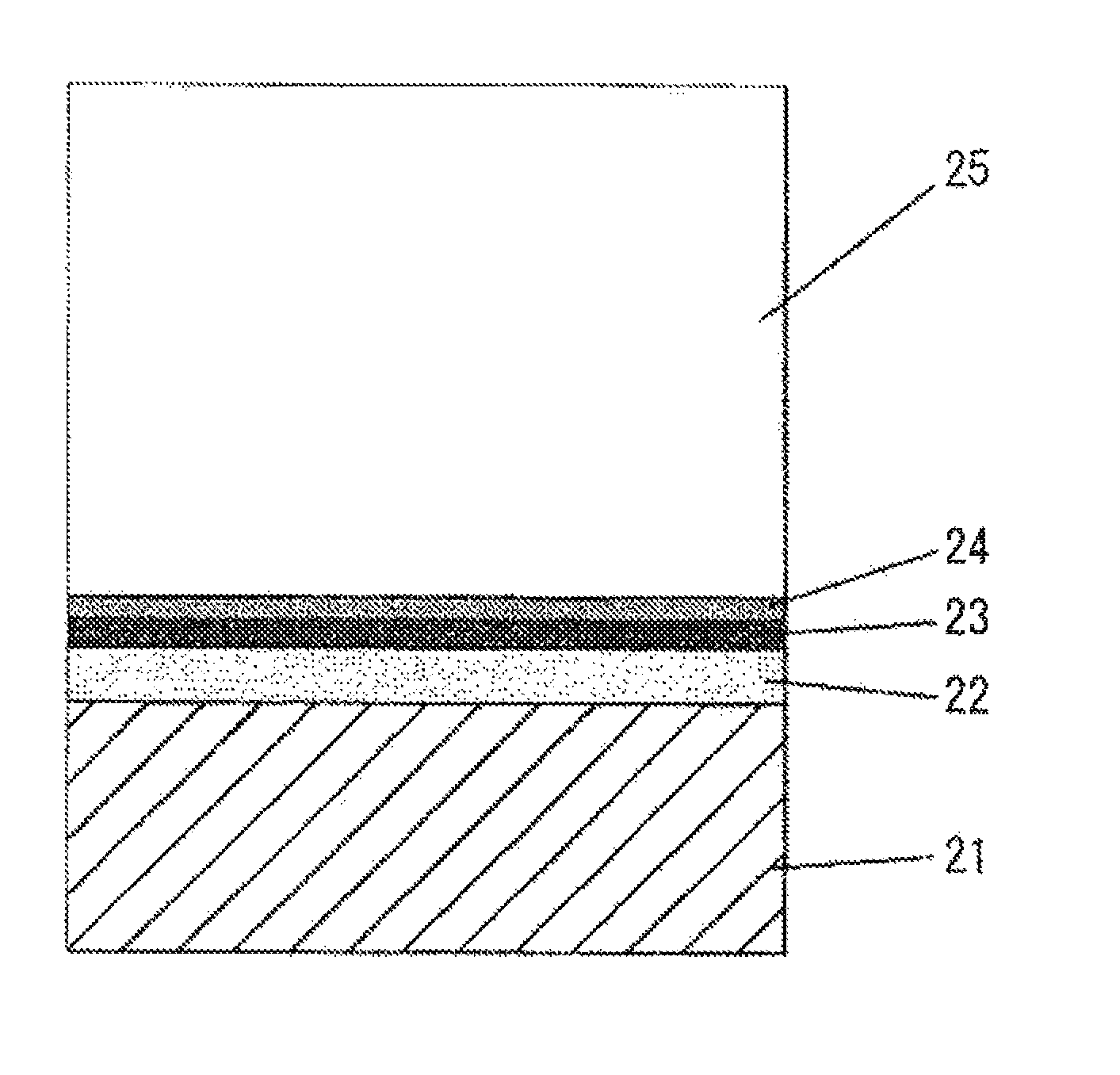

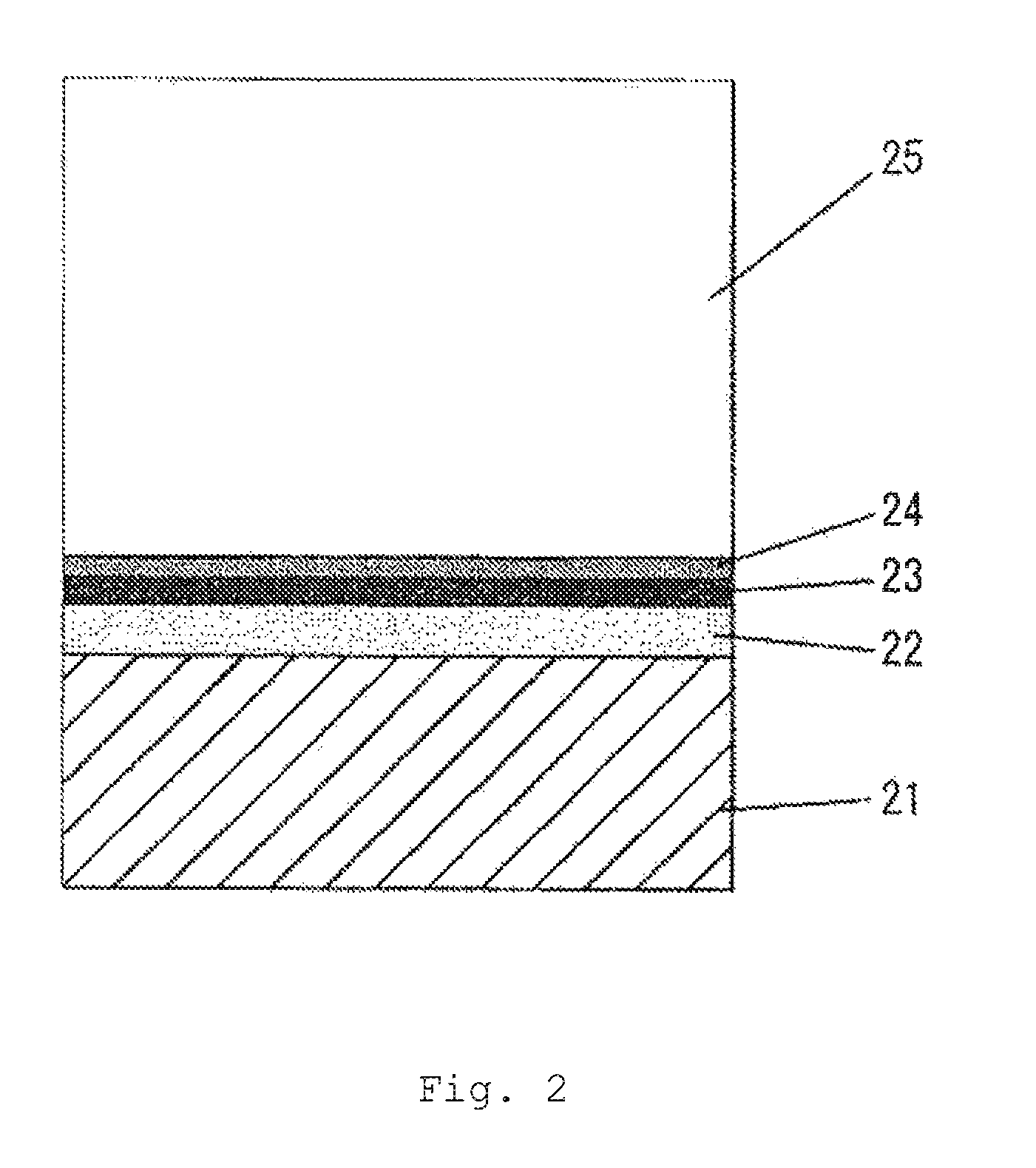

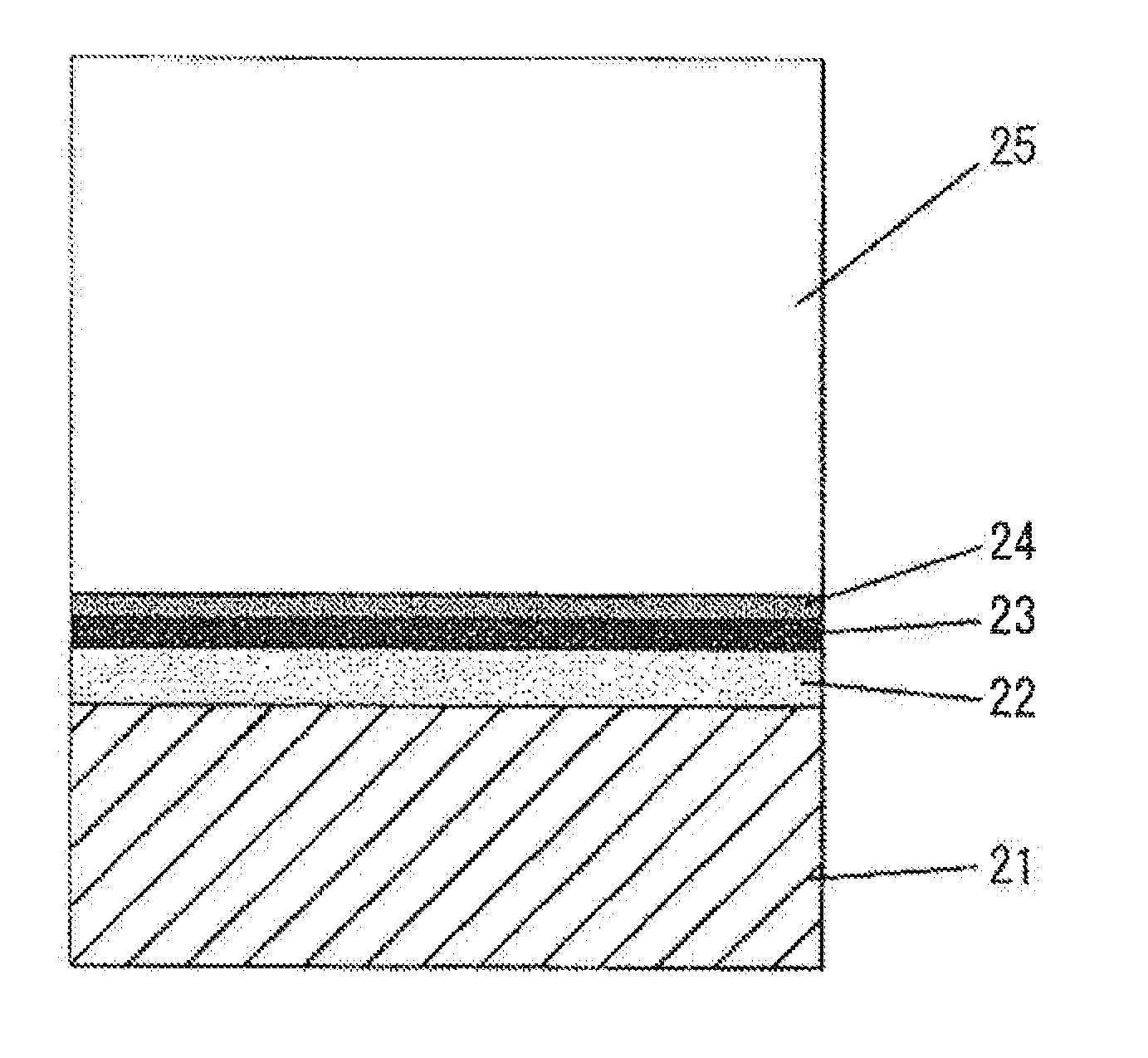

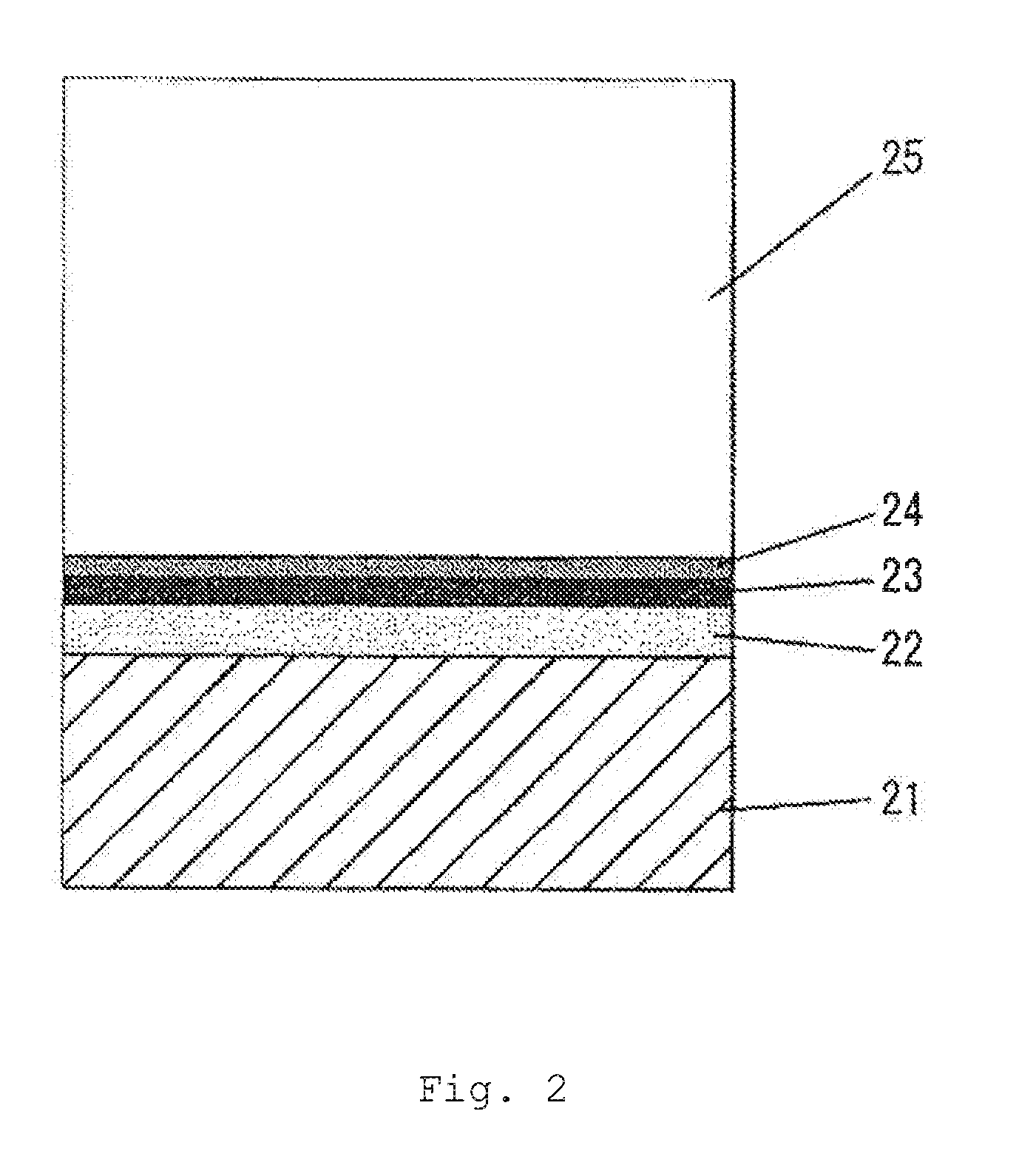

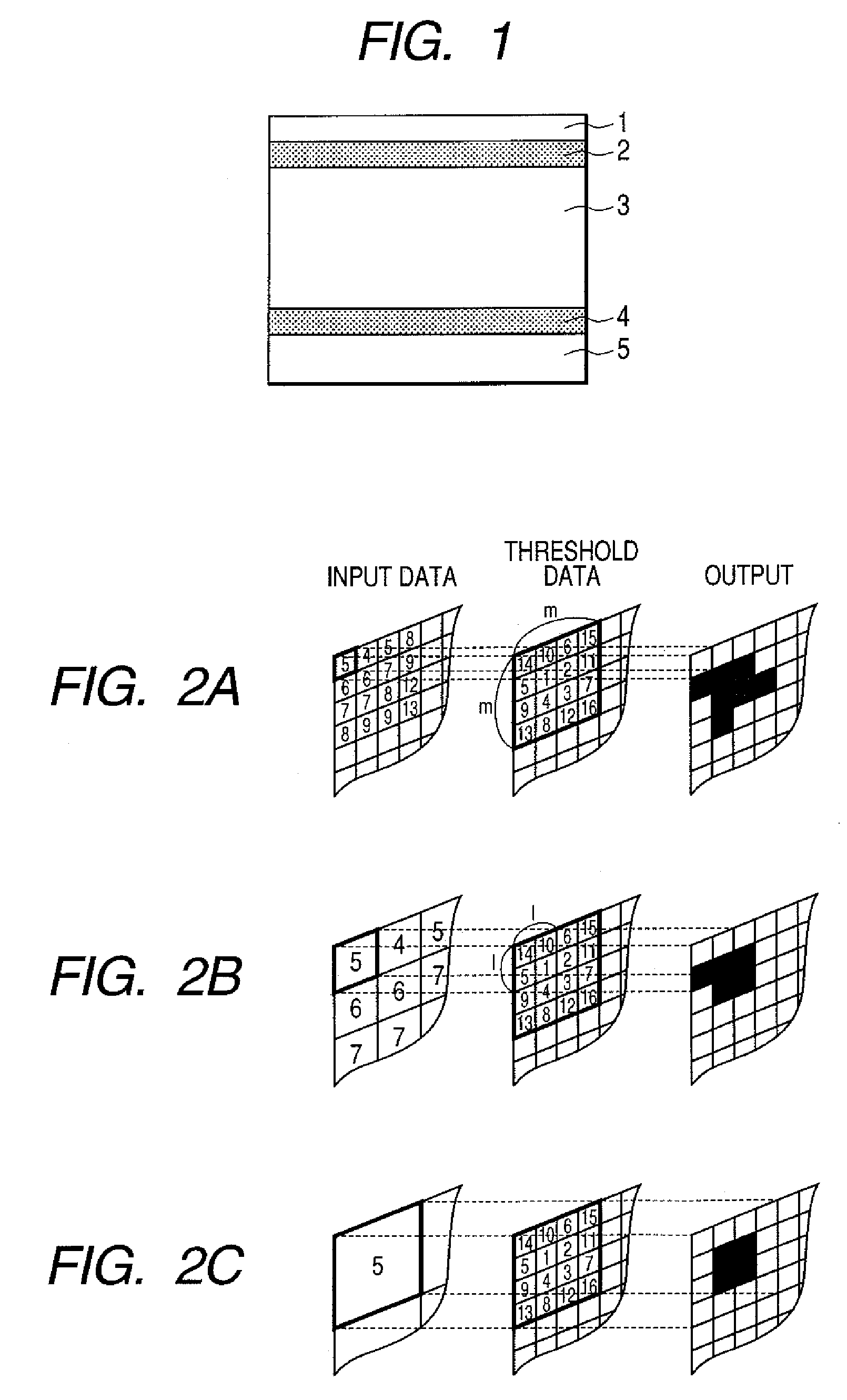

The present invention relates to an electrophotographic photosensitive member obtained by providing, on a conductive support, a conductive layer containing conductive particles having a volume-average particle diameter of 0.1 μm or more, an intermediate layer, and a photosensitive layer in the stated order in which the conductive layer contains a polyolefin resin containing a specific repeating structural unit at a specific ratio, and a process cartridge and an electrophotographic apparatus each having the electrophotographic photosensitive member.

Owner:CANON KK

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

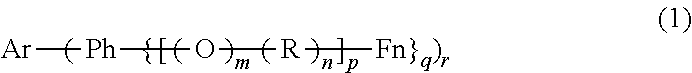

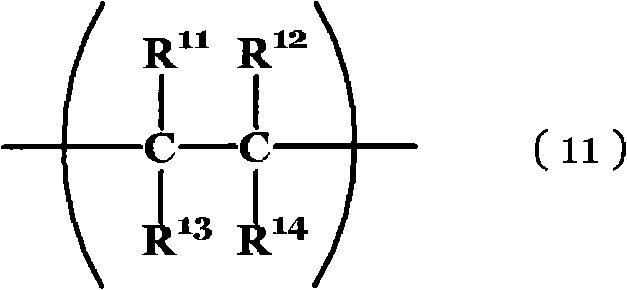

ActiveUS9594318B2Improve wear resistanceSuppresses image defectsElectrography/magnetographySurface layerStructural formula

Provided is an electrophotographic photosensitive member, including: a support; and a photosensitive layer formed on the support, in which a surface layer of the electrophotographic photosensitive member contains a polymerized product of a compound represented by the following structural formula (1).

Owner:CANON KK

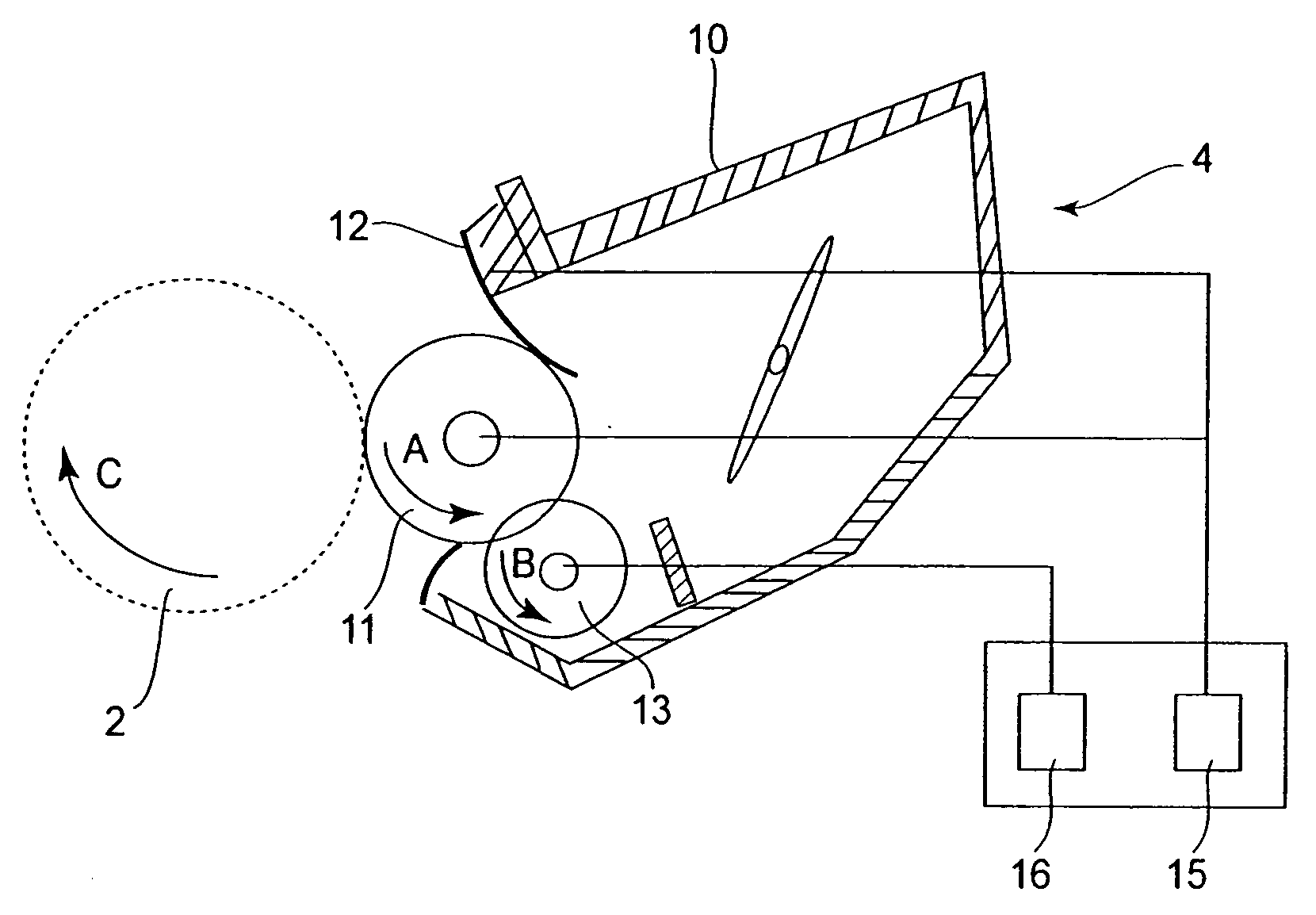

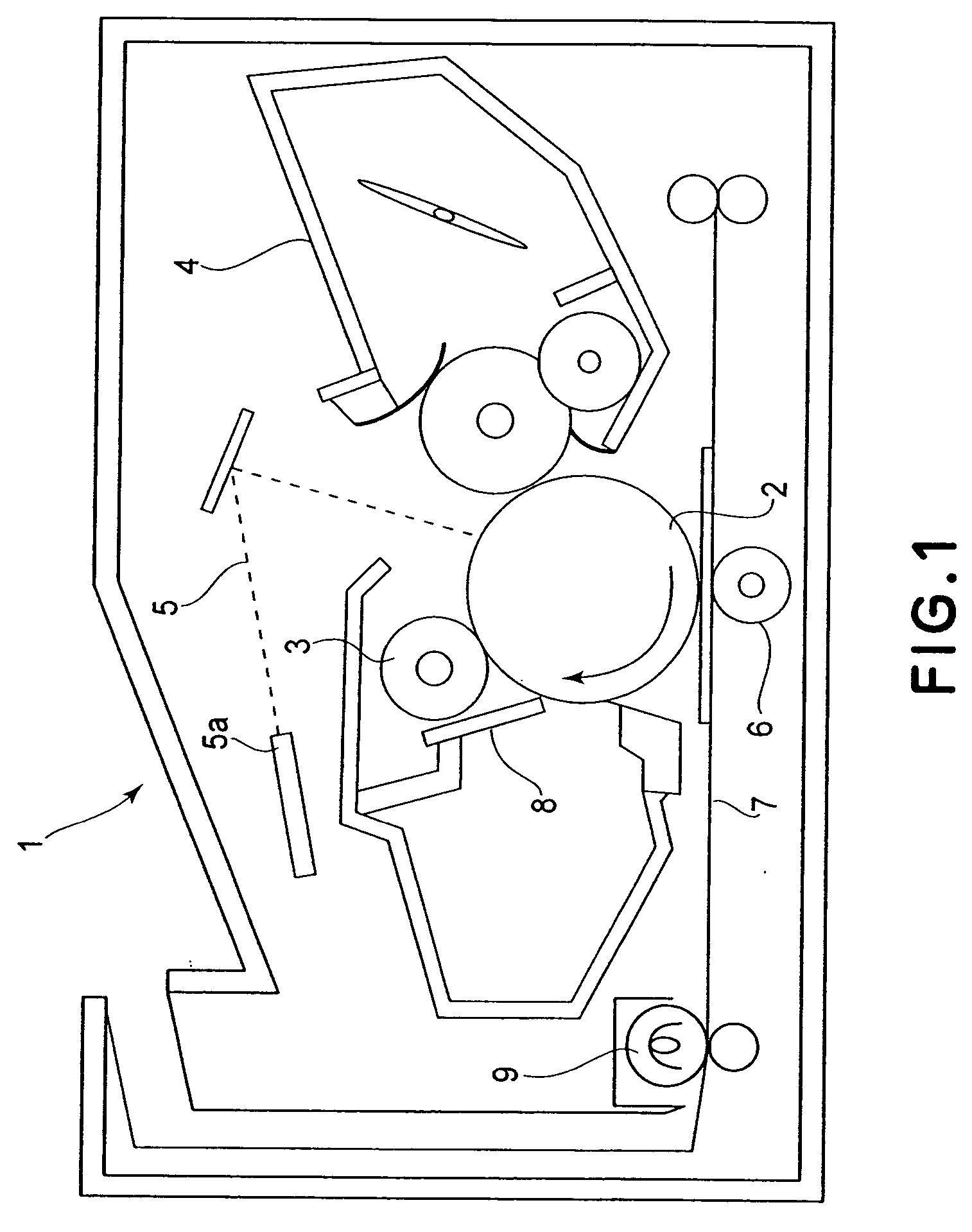

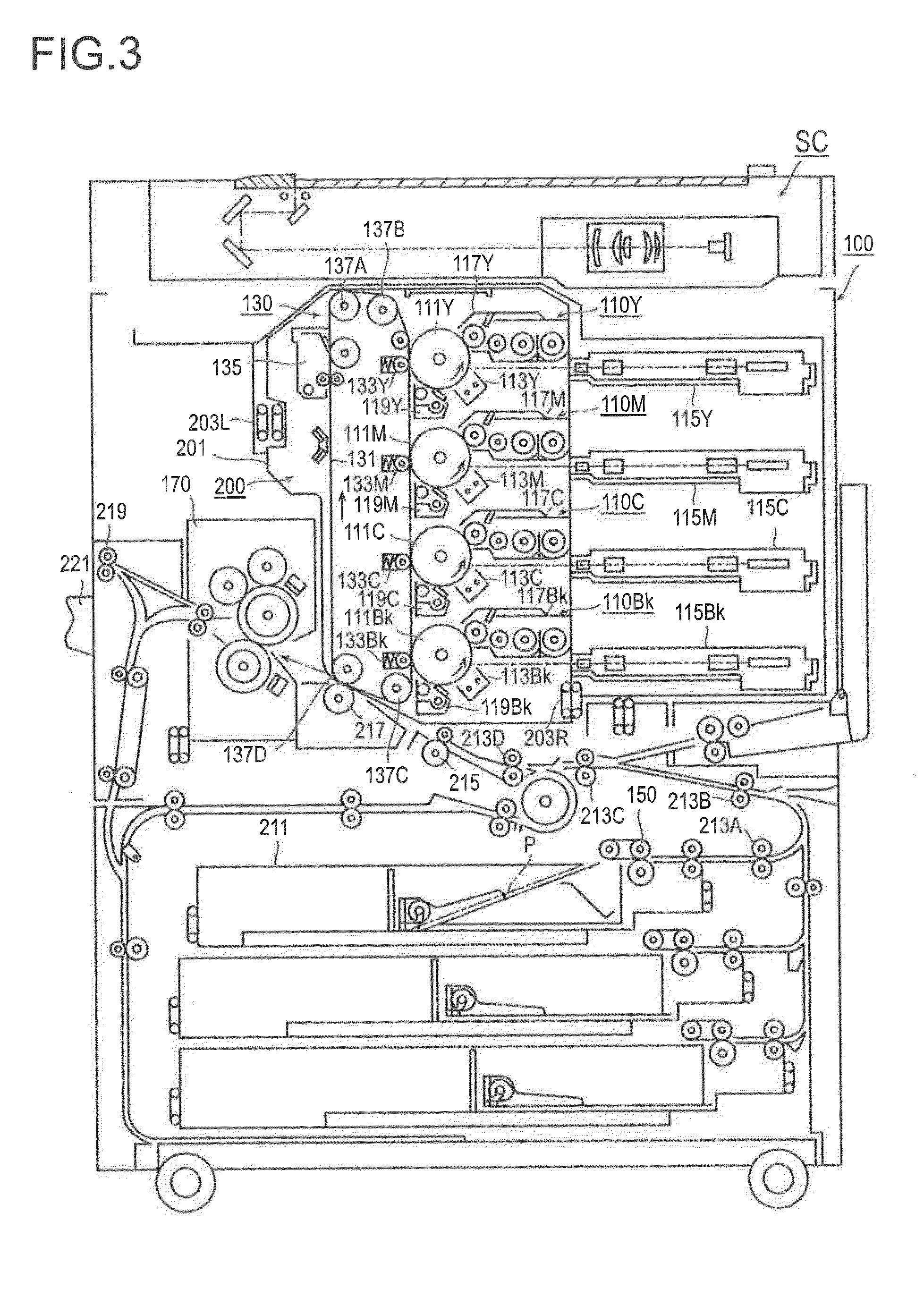

Image forming apparatus

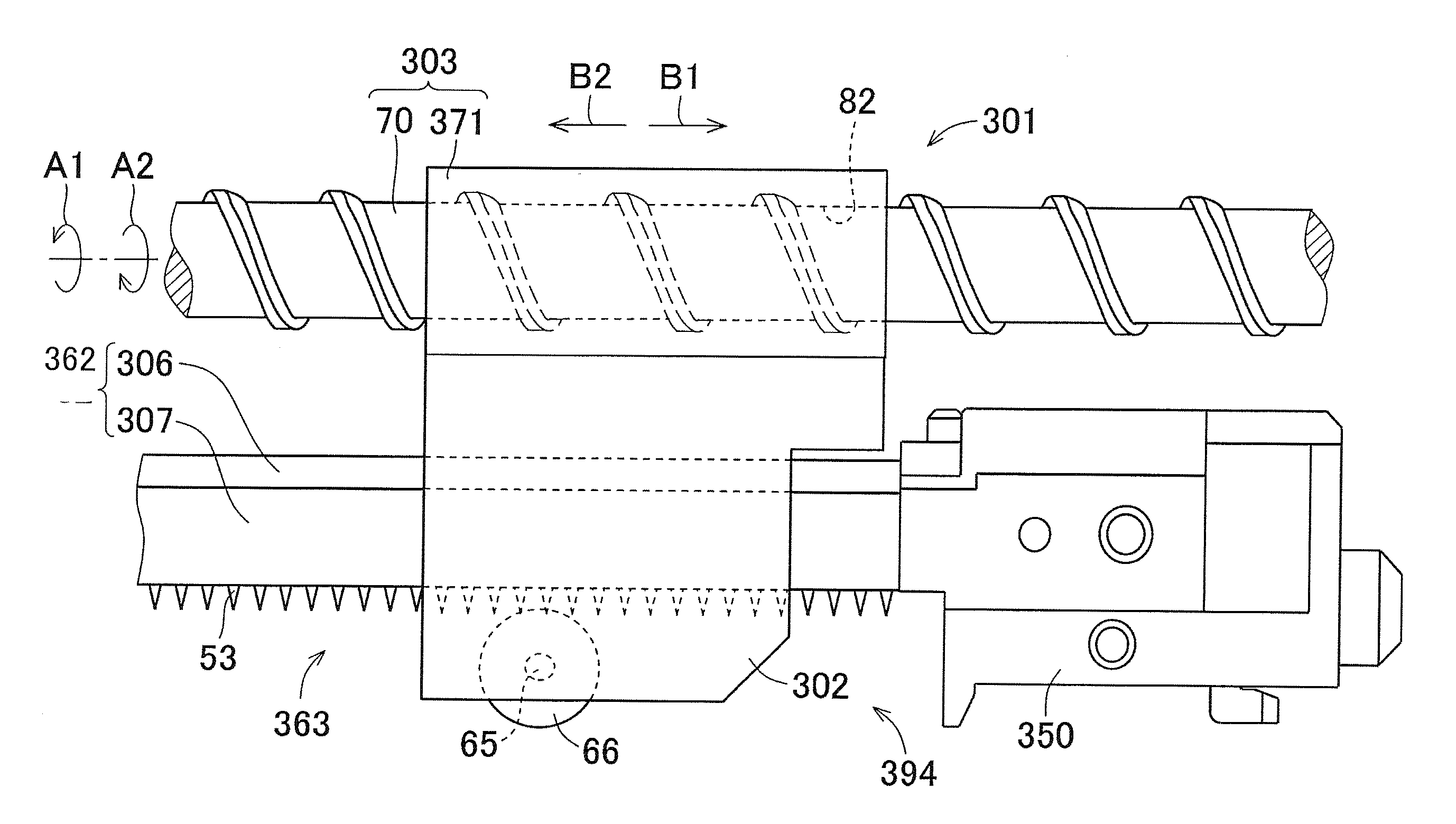

InactiveUS20070098459A1Long term usabilitySuppress image defectElectrographic process apparatusEngineeringMechanical engineering

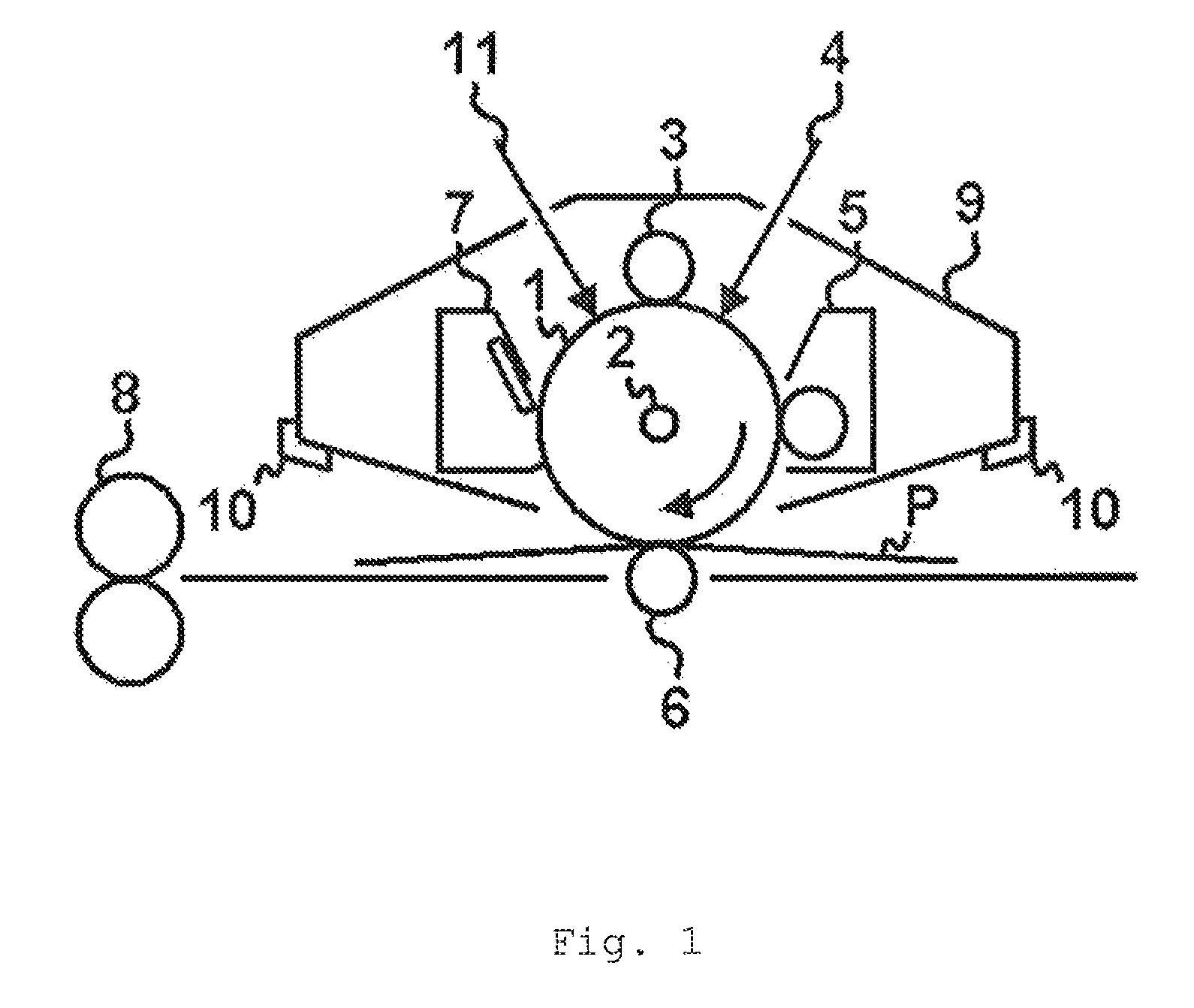

An image forming apparatus includes an image bearing member; a developer carrying member, contactable to the image bearing member, for carrying a developer to a developing position to develop an electrostatic image formed on the image bearing member with the developer; a supplying member for supplying the developer to the developer carrying member, wherein a peripheral speed of the developer carrying member is not less than 1.05 times and not more than 1.20 times a peripheral speed of the image bearing member, and an arithmetic average roughness Ra is not less than 0.20 times and not more than 0.33 times a volume average particle size of the developer, wherein a potential applied to the supplying member is different from a potential applied to the developer carrying member toward a larger potential of a regular charge polarity of the developer.

Owner:CANON KK

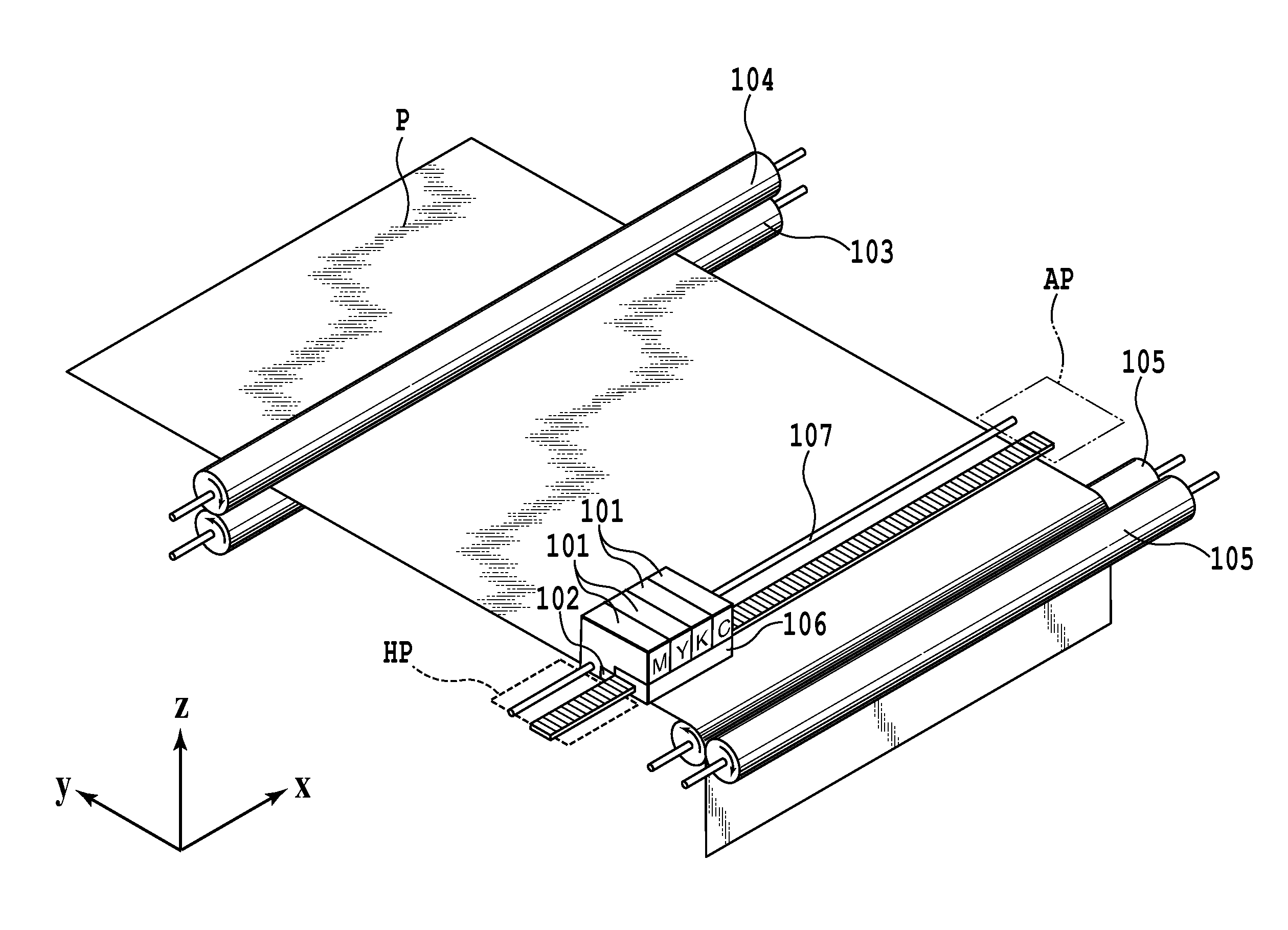

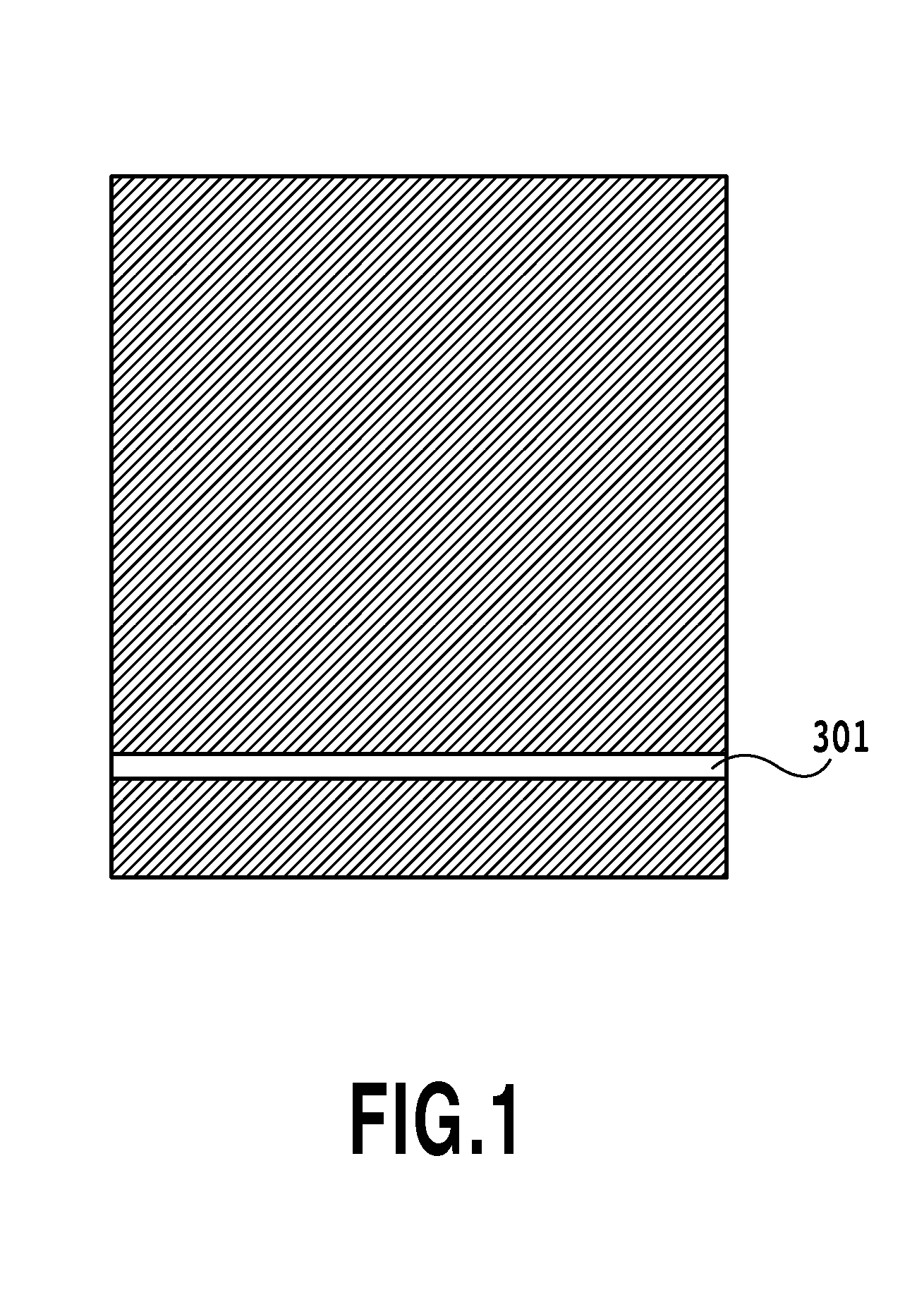

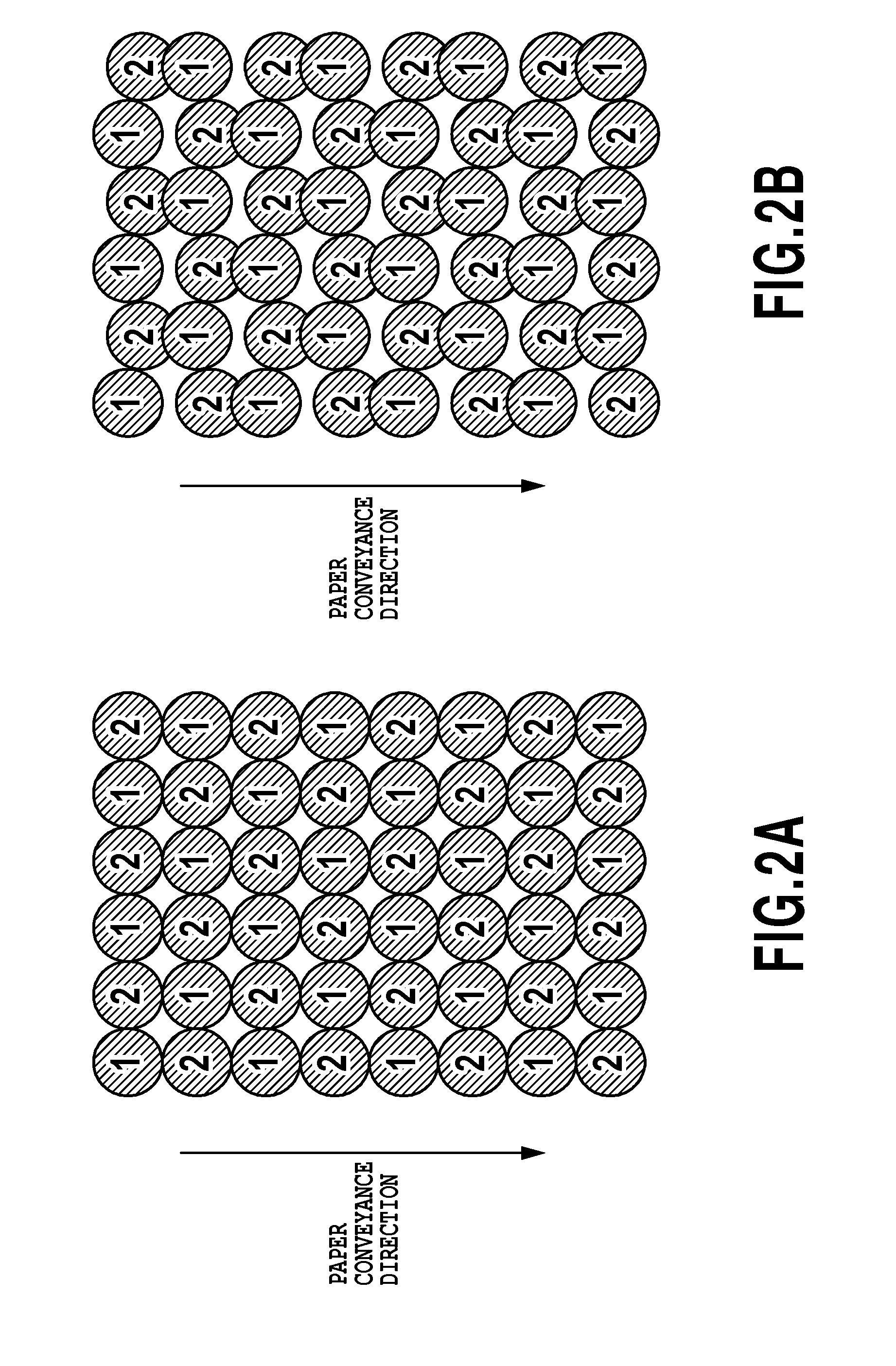

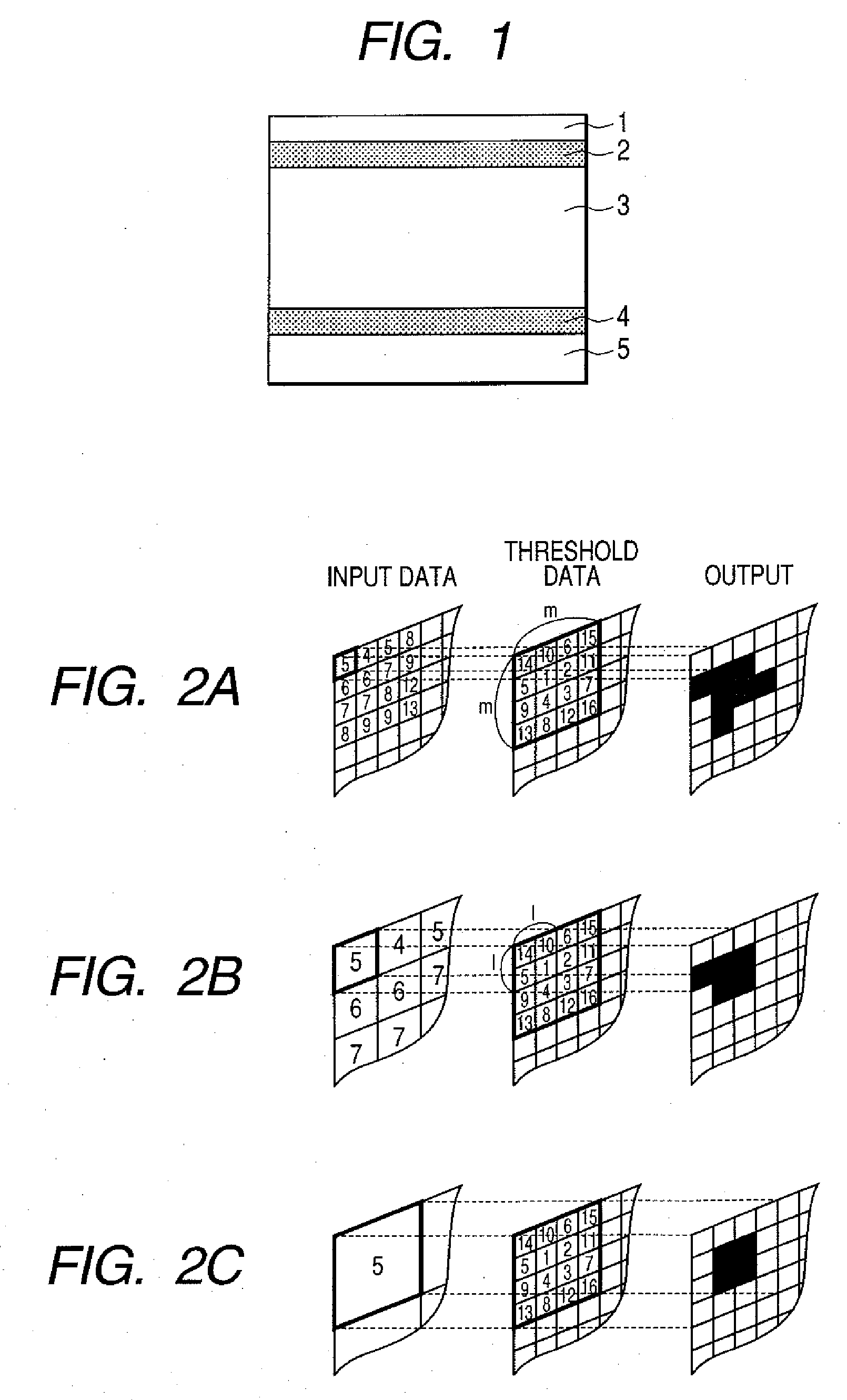

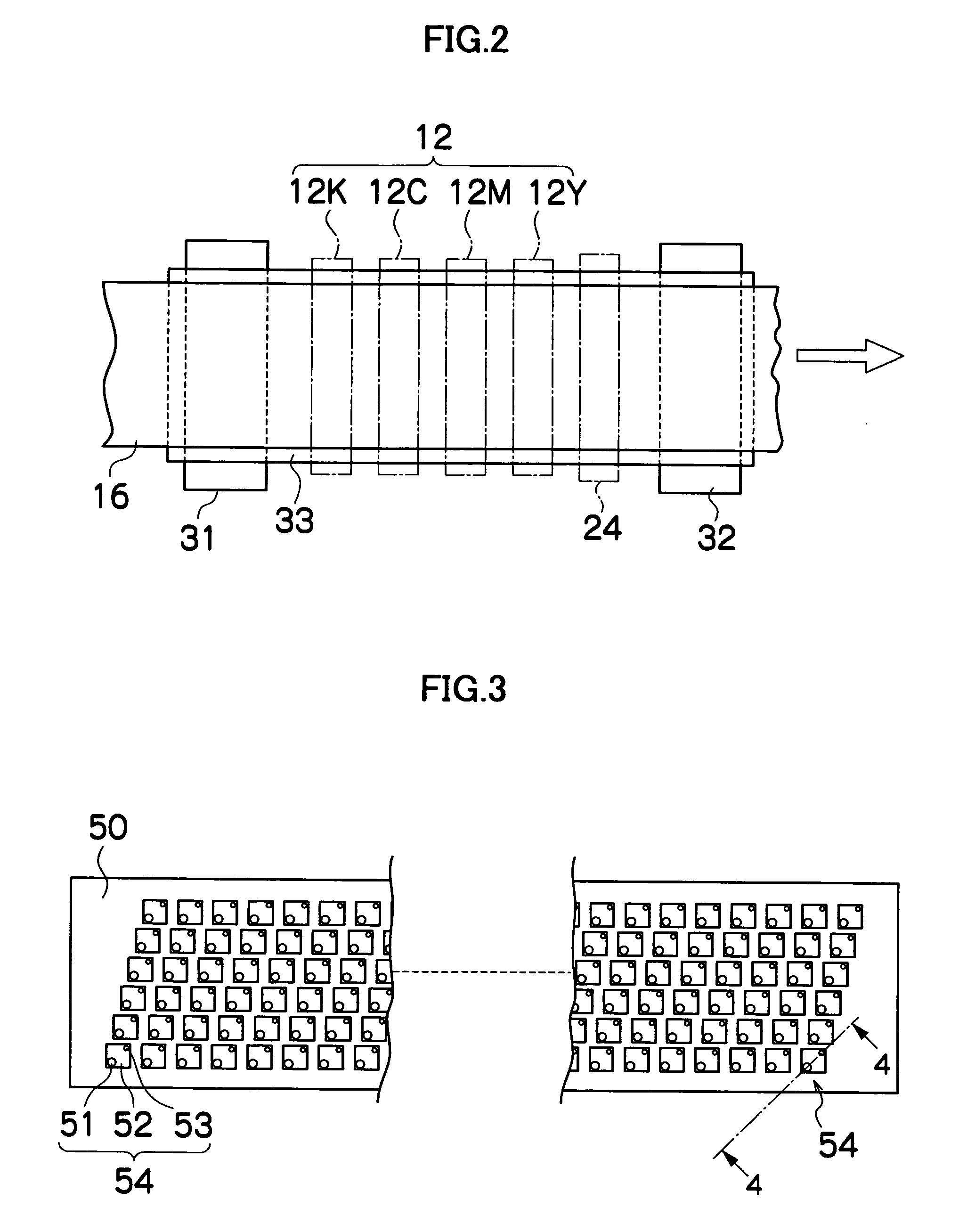

Ink jet printing apparatus and method

InactiveUS20110134177A1Suppresses image defectsVisual presentationOther printing apparatusComputer scienceDistance error

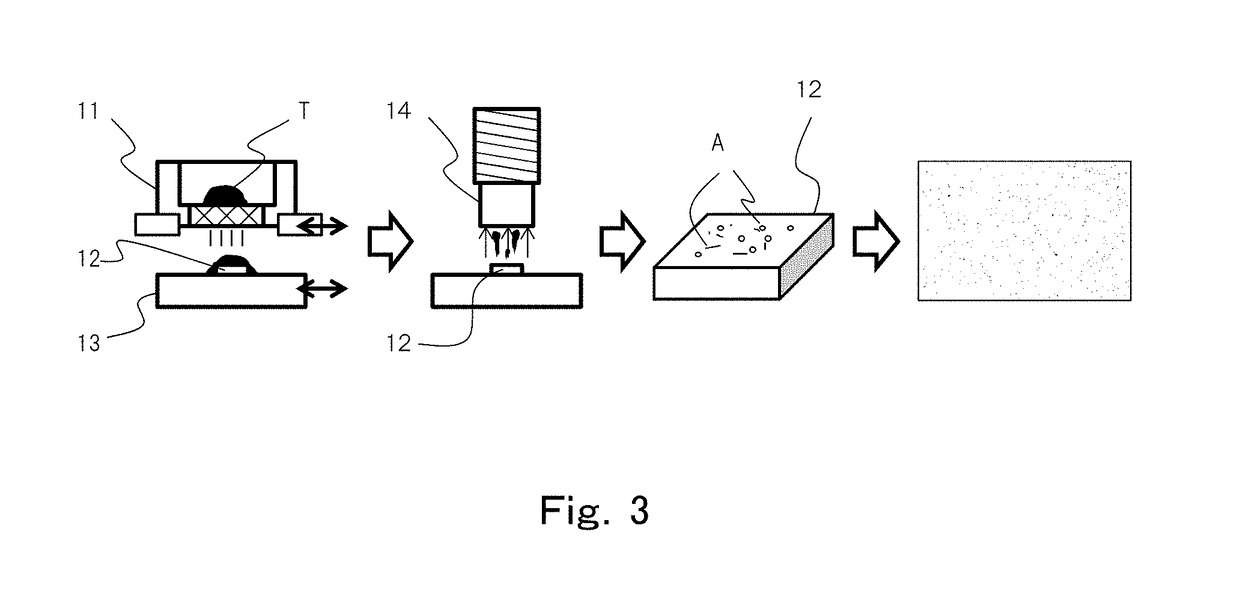

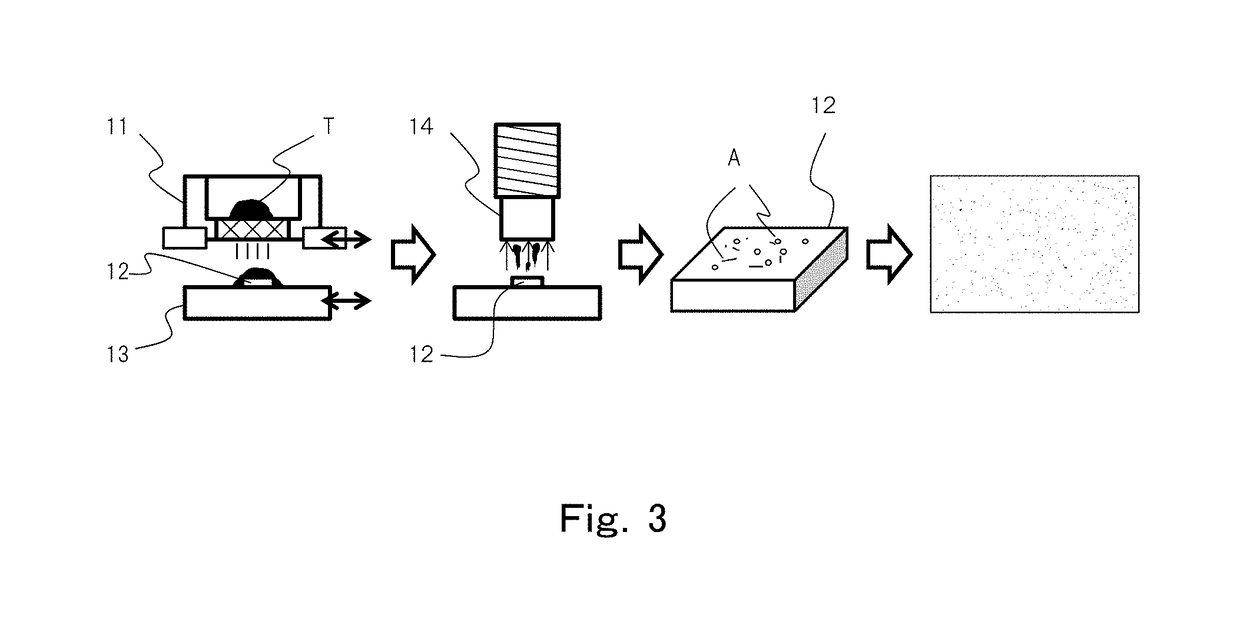

Through the use of a mask with an appropriate pattern, depending on dot size or density, in an in jet printing apparatus, image defects caused by conveyance distance errors are suppressed. More concretely, at the masking unit A an interlaced mask pattern is used and a masking process is performed with respect to 2 pl dot data obtained from the dot pattern development unit 604. On the other hand, at the masking unit B a random mask pattern is used and masking is performed with respect to 5 pl dot data. Herewith it has become possible, at all gradations, to suppress the 2 image defects, density unevenness and graininess, caused by conveyance distance errors.

Owner:CANON KK

Electrophotographic photoreceptor

InactiveUS20140178809A1Enhanced electron transport capabilitiesSuppresses image defectsElectrographic process apparatusInter layerHigh electron

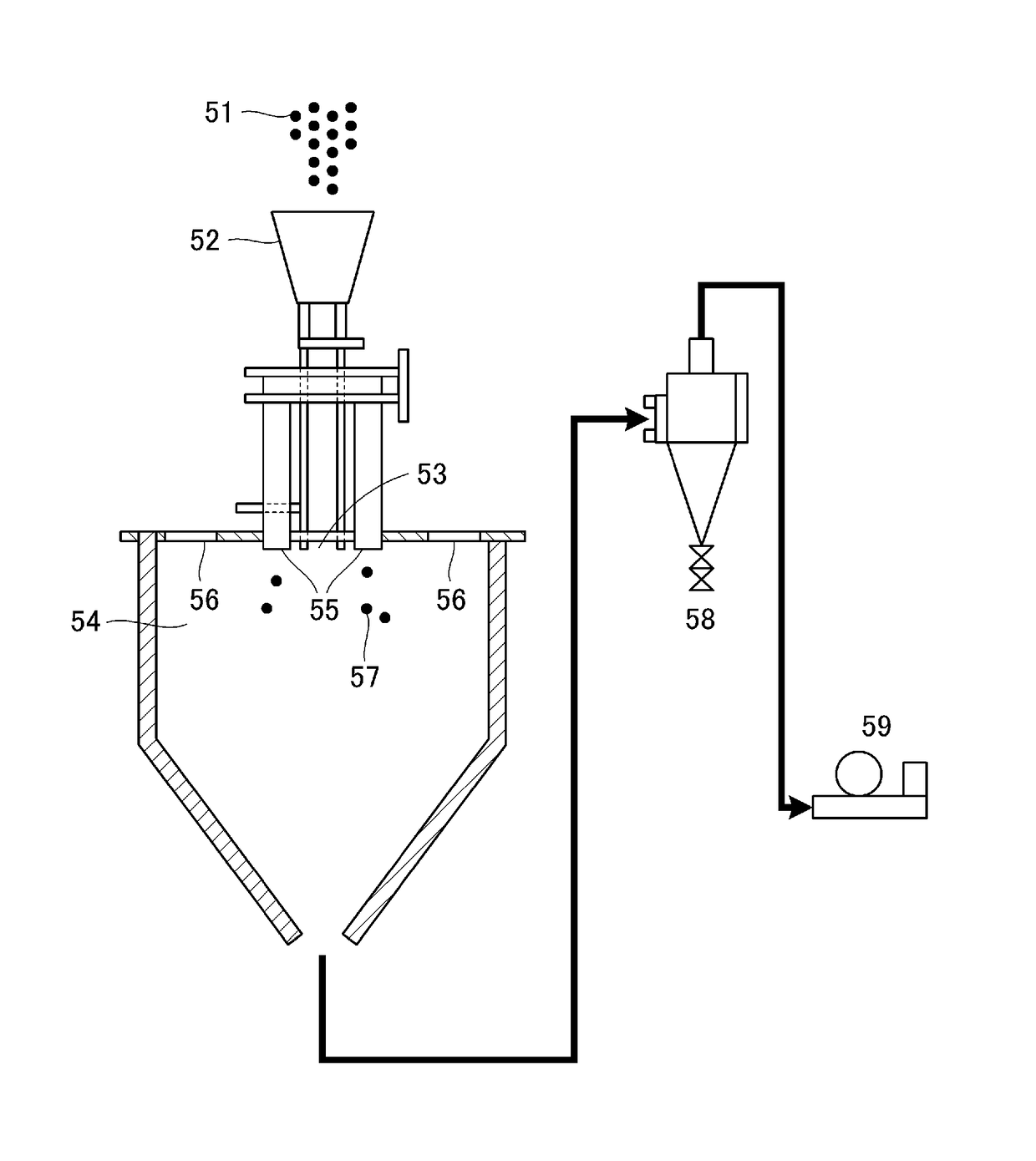

According to the present invention, an electrophotographic photoreceptor comprising an intermediate layer is provided. The intermediate layer is a single layer and contains first metal oxide particles, second metal oxide particles having higher electron-transporting properties than those of the first metal oxide particle and a binder resin. The first metal oxide particles are unevenly distributed in the thickness direction of the intermediate layer.

Owner:KONICA MINOLTA INC

Image forming apparatus

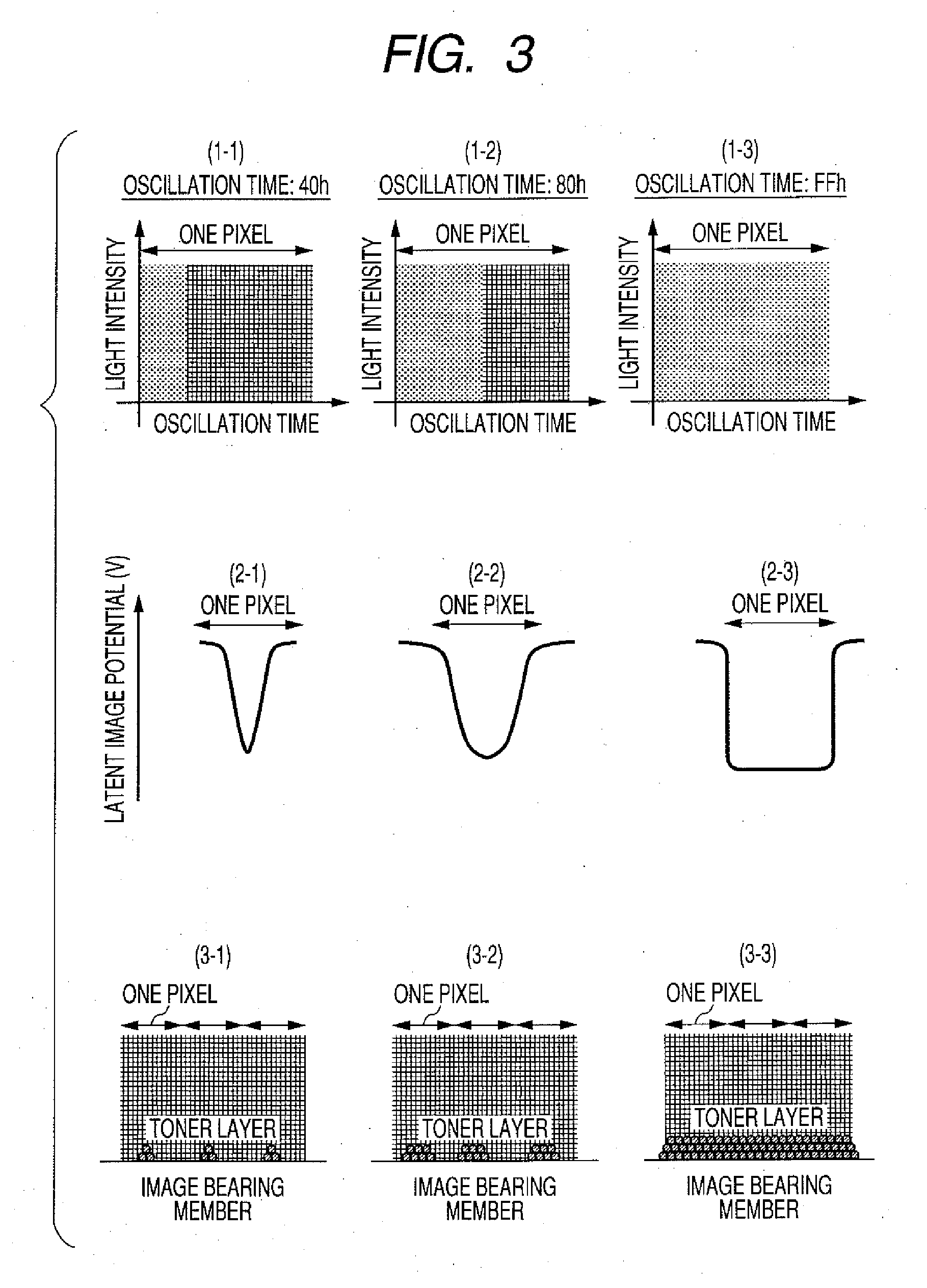

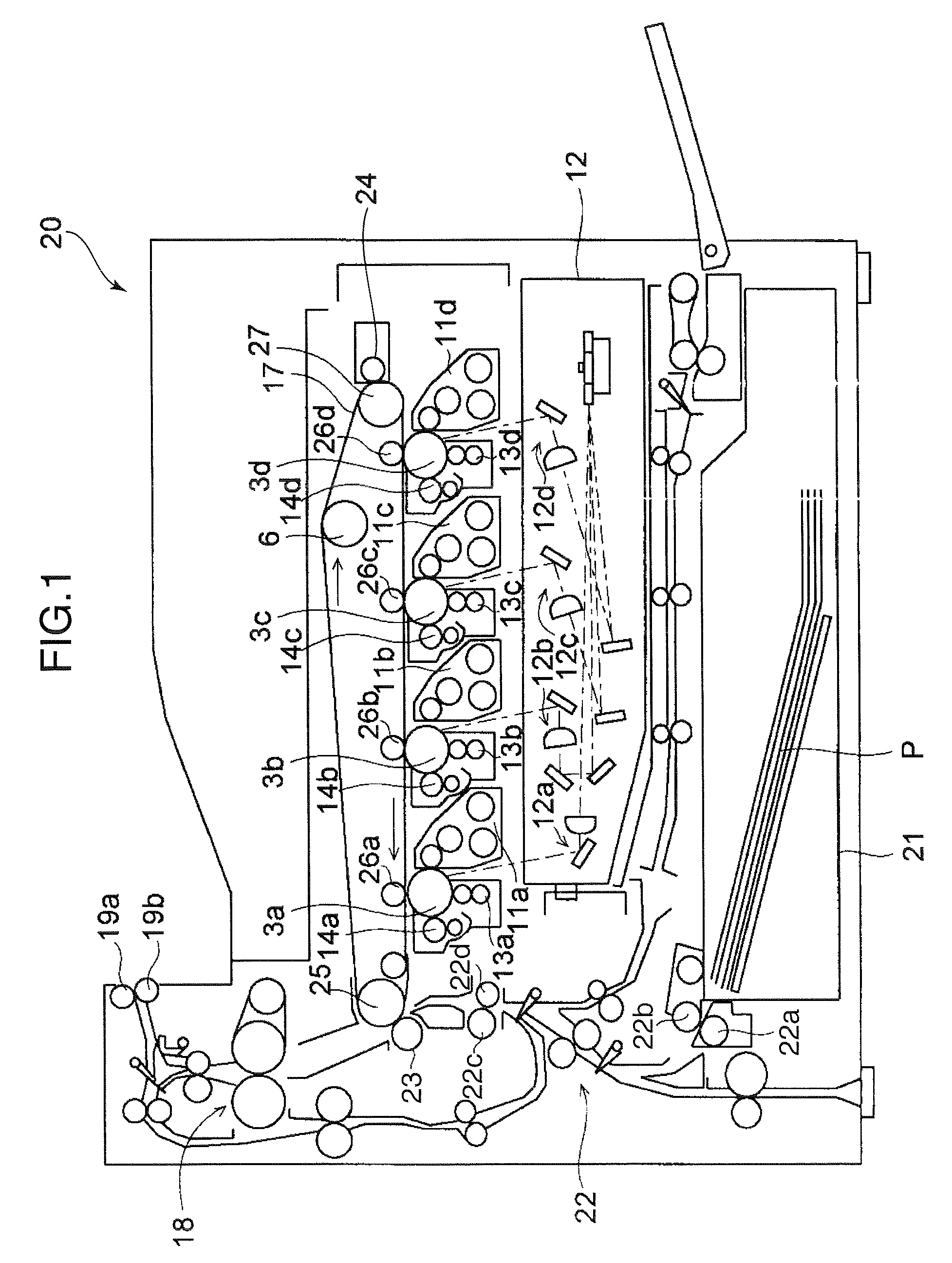

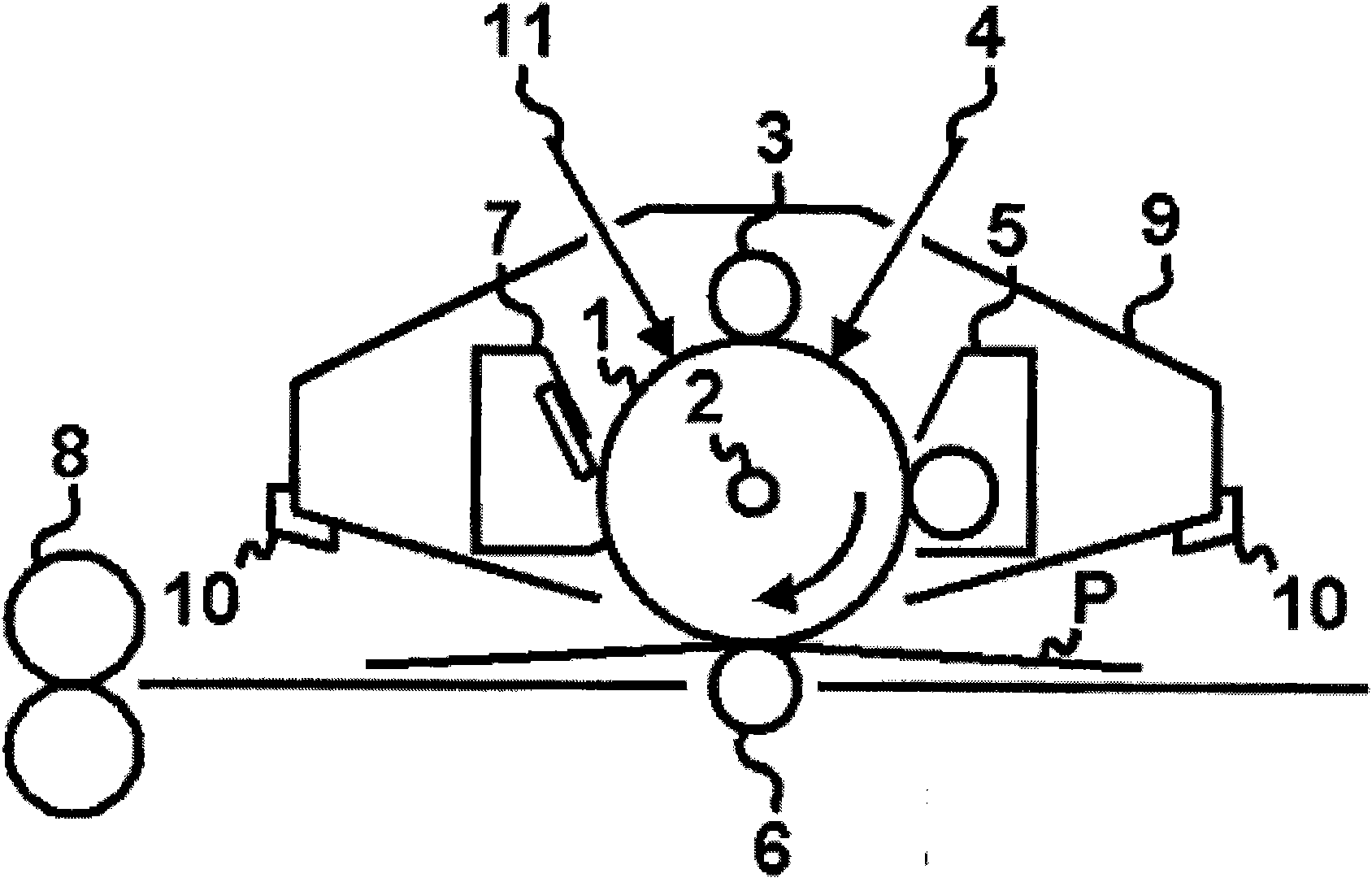

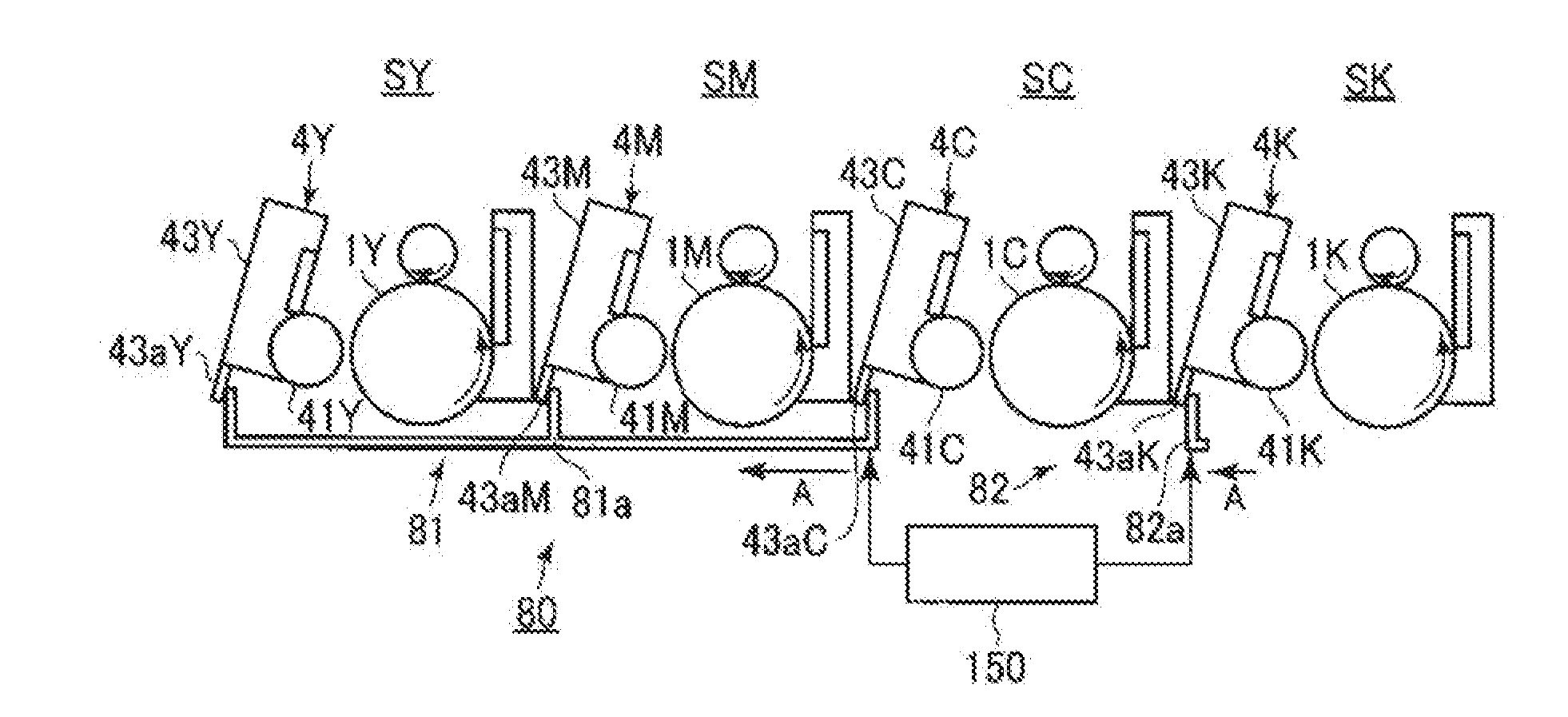

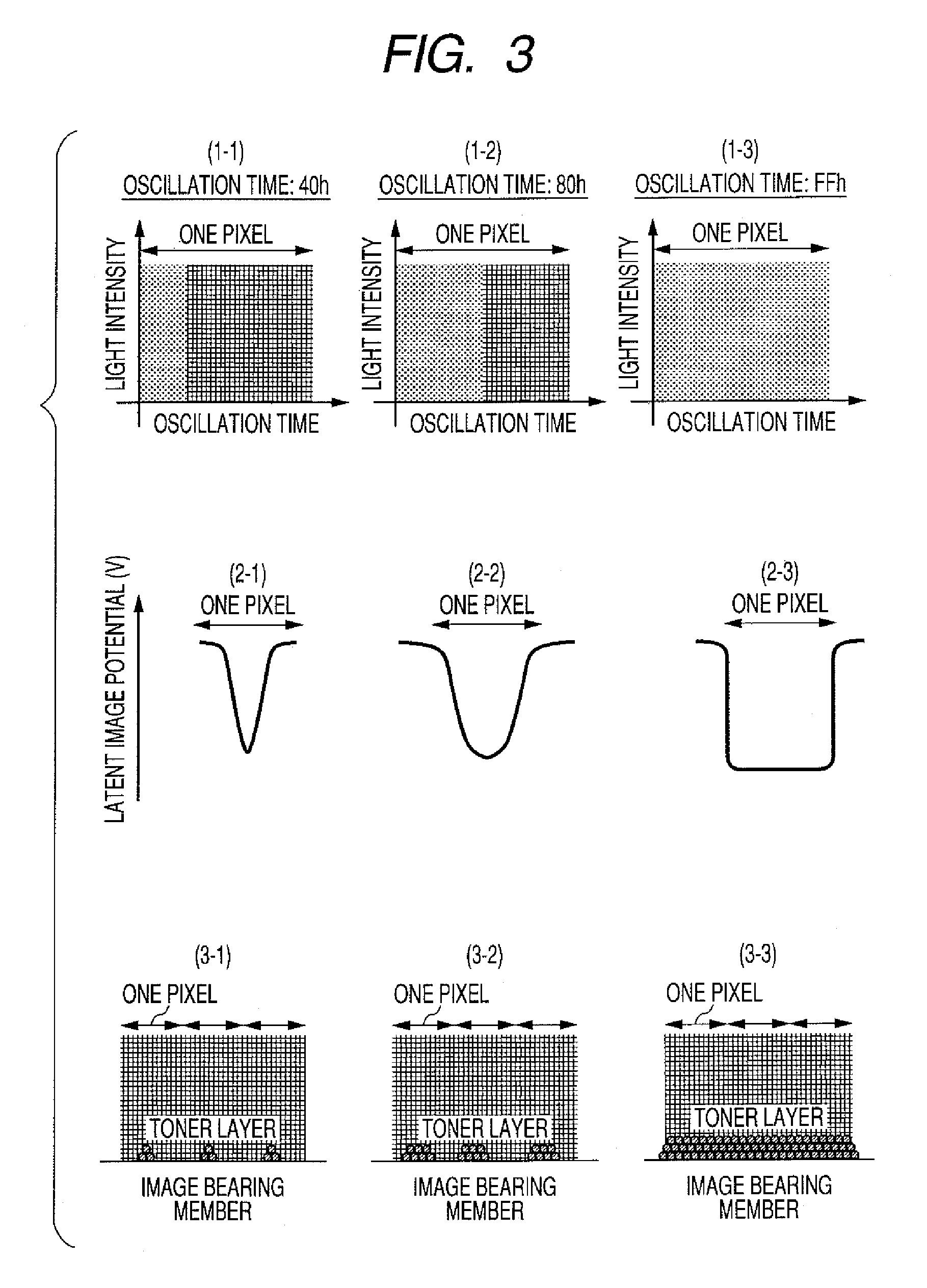

ActiveUS20070071472A1Suppresses image defectsIncrease capacitanceElectrographic process apparatusCapacitanceImage formation

An image forming apparatus includes a photosensitive member, having a capacitance per unit area of 1.7×10−6 (F / M2) or larger; an exposure device, which exposes the photosensitive member in order to form thereon an electrostatic image according to image information; a developing device, which develops the electrostatic image with a toner to form a toner image on the photosensitive member; and a transfer device, which transfers the toner image onto a recording material; wherein, in forming a solid toner image on the recording material, the exposure device is capable of forming electrostatic images of different potential levels on the photosensitive member, thereby forming toner images of different toner heights on the photosensitive member.

Owner:CANON KK

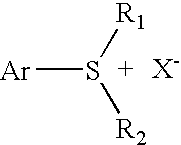

Lithographic printing starting plate

ActiveUS20050064340A1Excellent developing latitudeHigh sensitivityRadiation applicationsSemiconductor/solid-state device manufacturingOrganic acidAqueous solution

A positive-working lithographic printing starting plate for an infrared laser is provided that includes a support having a hydrophilic surface and a heat-sensitive layer provided above the support. The heat-sensitive layer includes a water-insoluble and alkali-soluble resin, an infrared-absorbing dye, and a sulfonium salt represented by Formula below. The heat-sensitive layer increases its solubility in aqueous alkaline solution upon exposure to an infrared laser. (In the formula, R1 and R2 independently denote an optionally substituted alkyl group having 1 to 12 carbons, an optionally substituted cycloalkyl group having 3 to 8 carbons, an optionally substituted aralkyl group having 7 to 12 carbons, or an optionally substituted aryl group having 6 to 15 carbons, R1 and R2 may bond to each other to form a cyclic structure; Ar denotes an optionally substituted aromatic hydrocarbon group having 6 to 15 carbons and having at least one OH group at the ortho- and / or para-position; and X− denotes an anion of an organic acid.)

Owner:FUJIFILM HLDG CORP +1

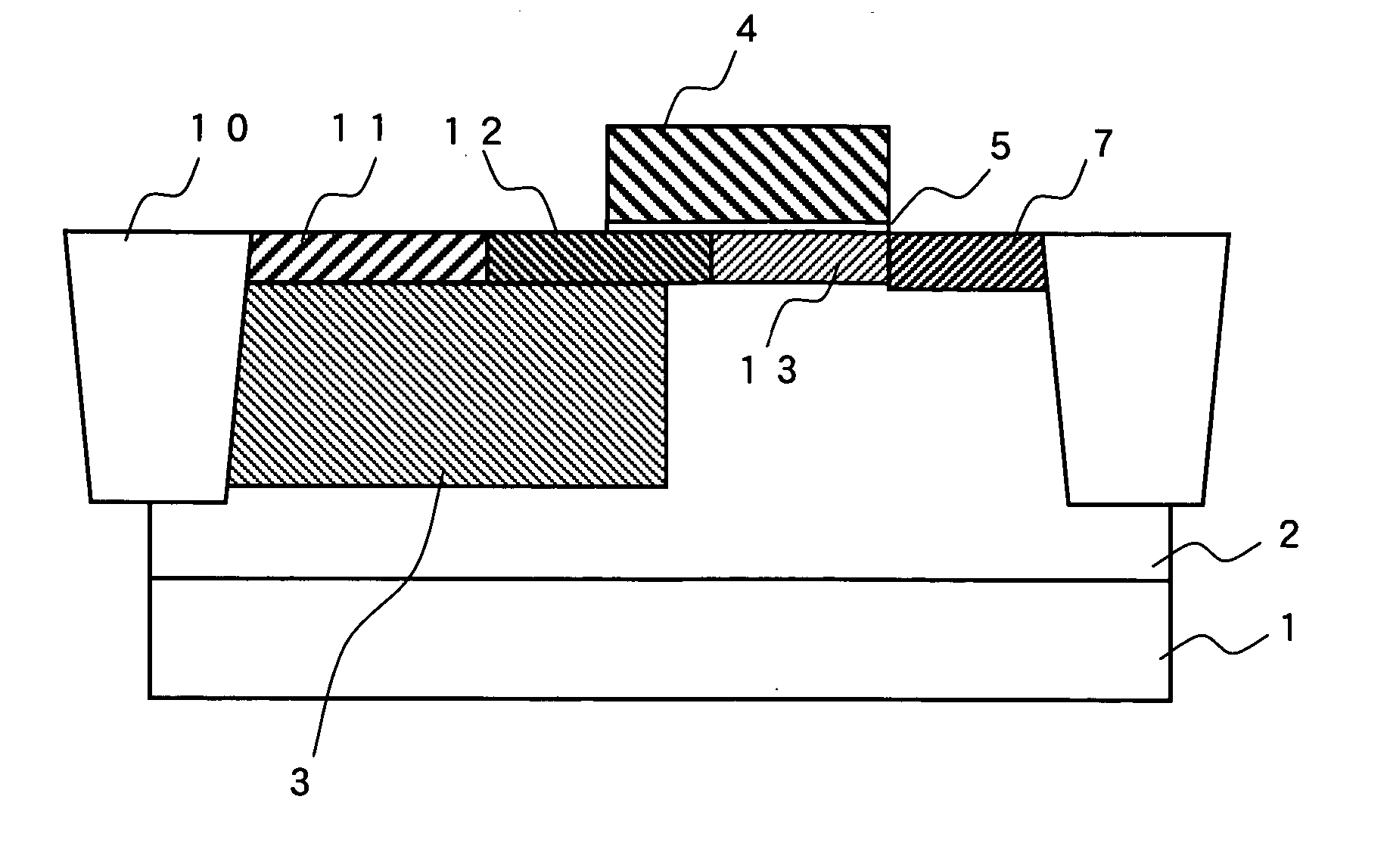

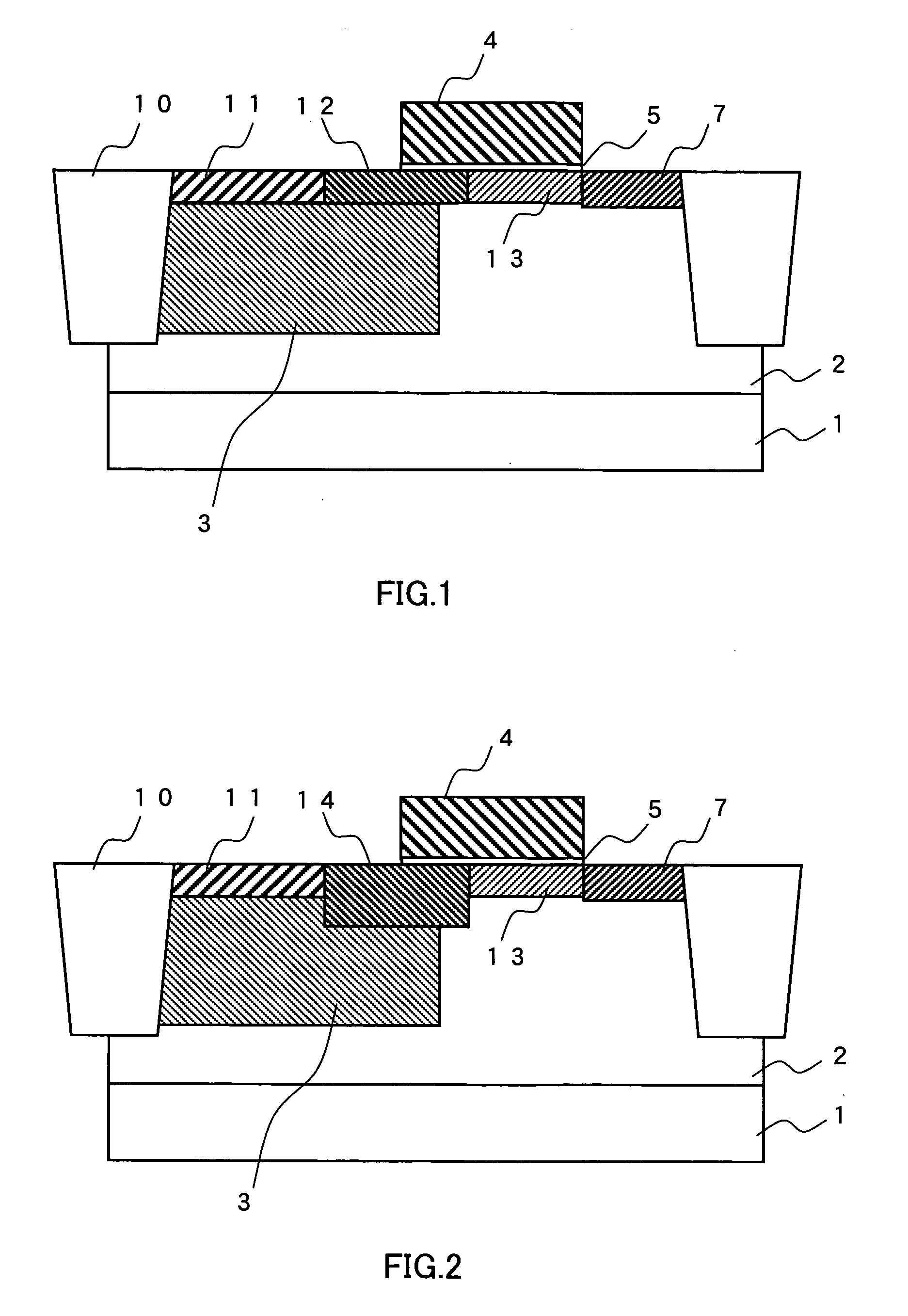

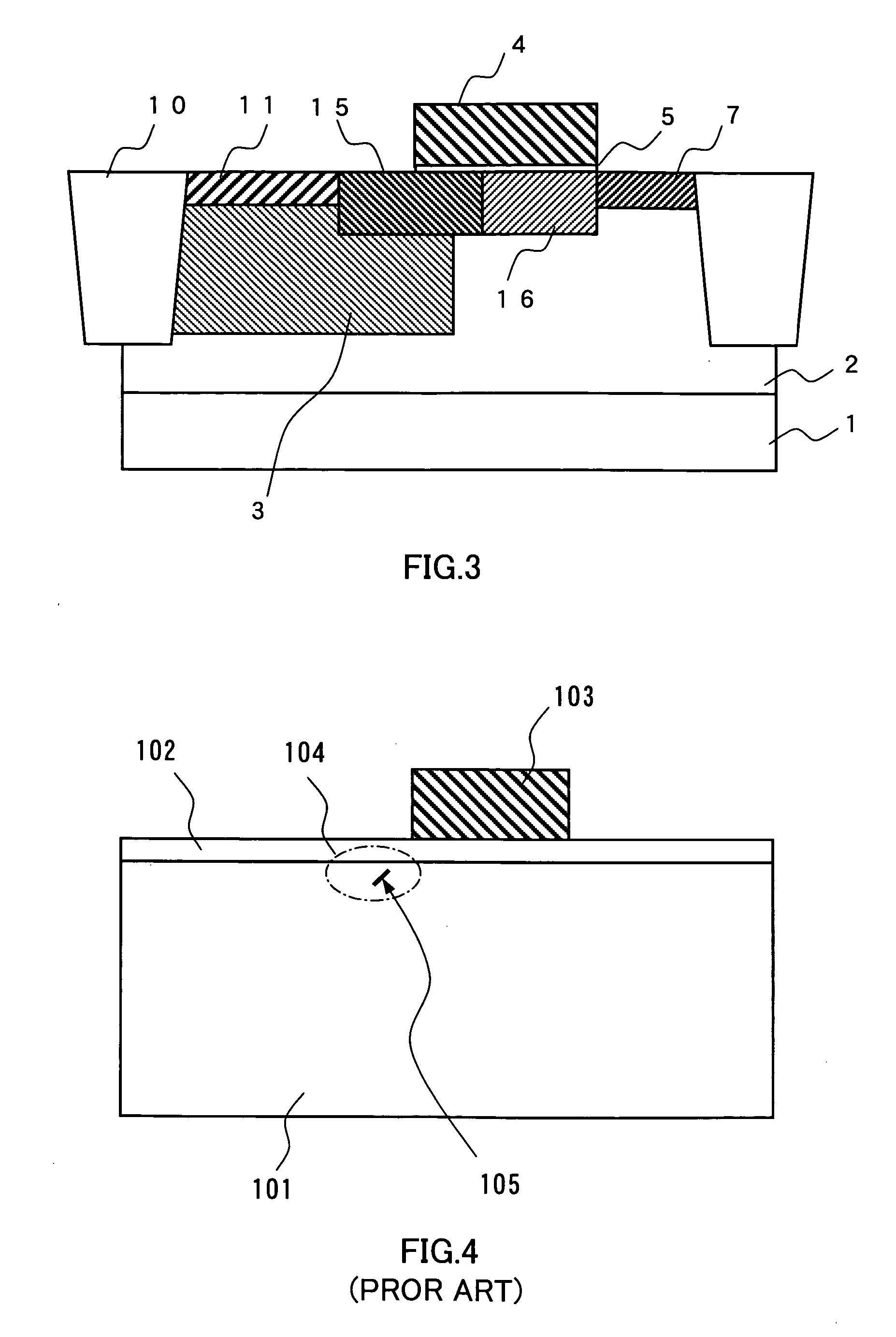

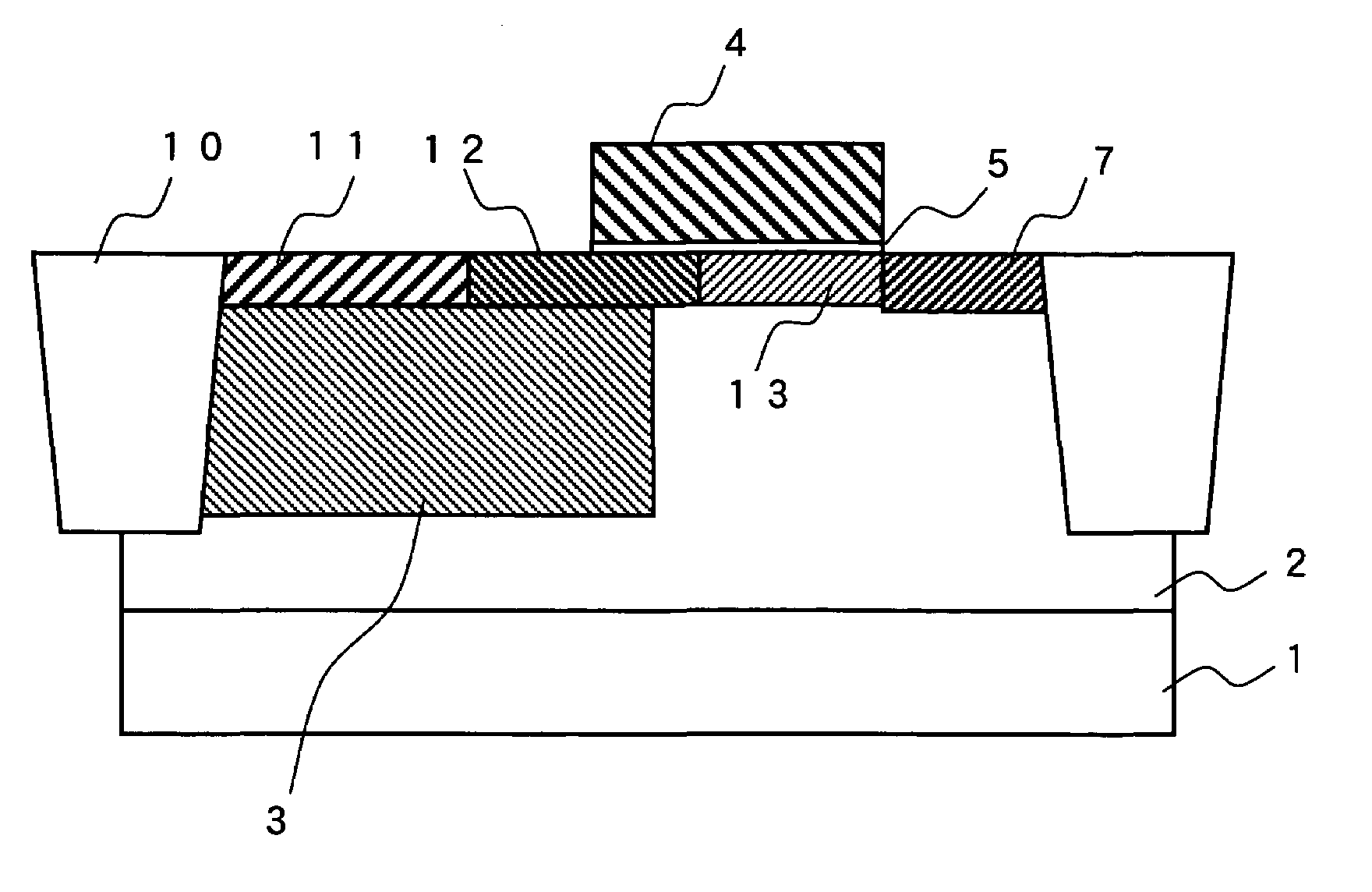

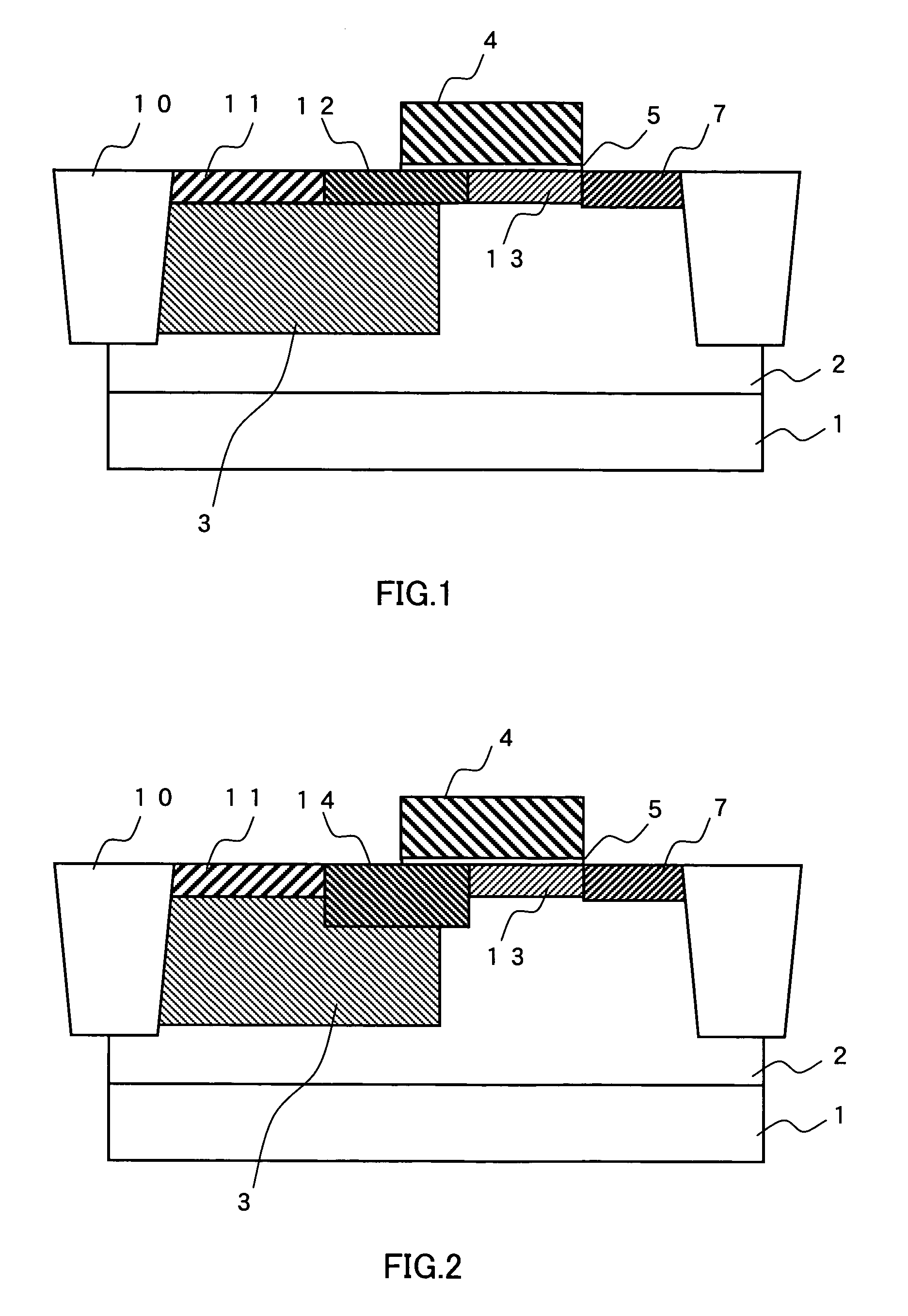

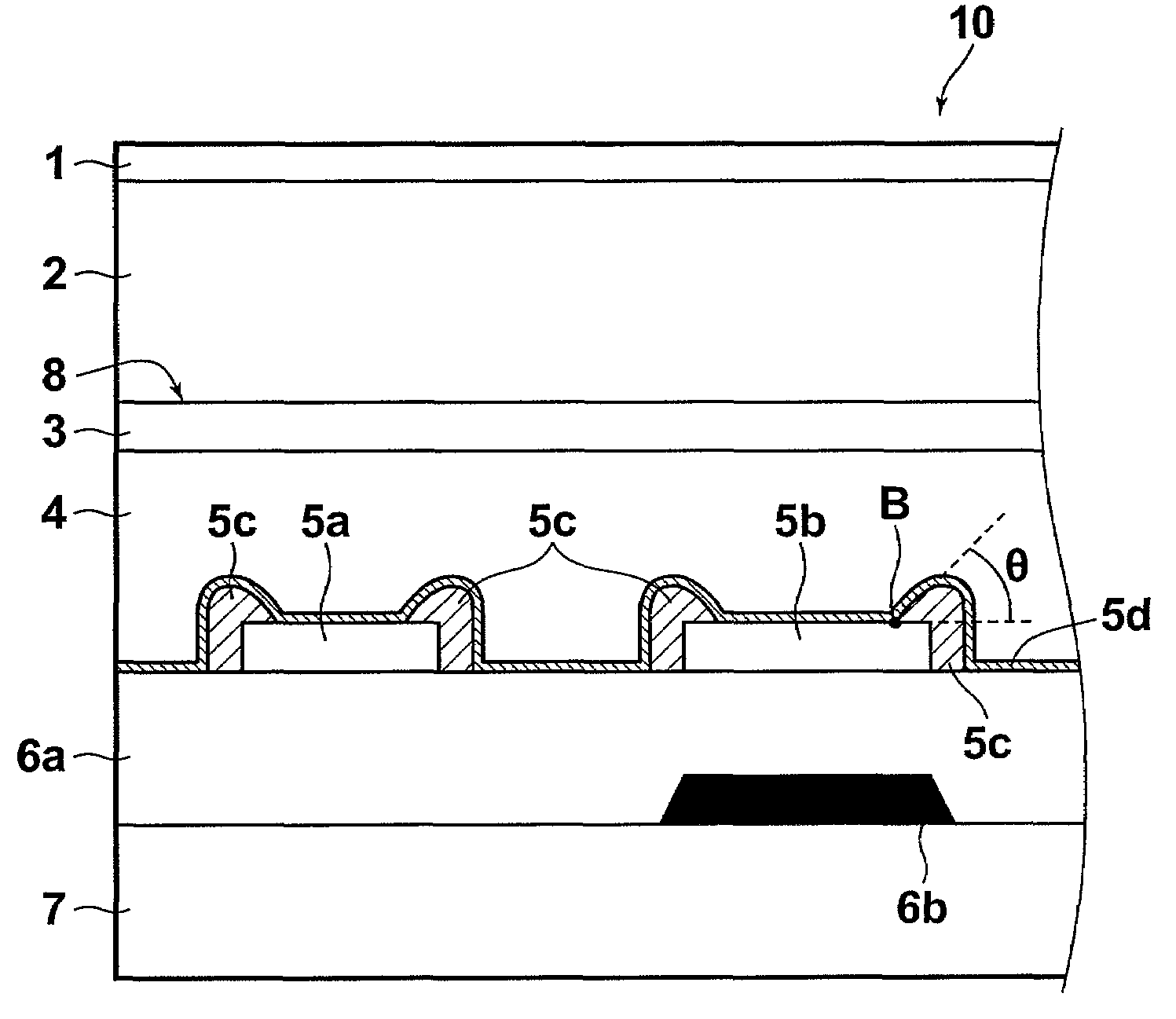

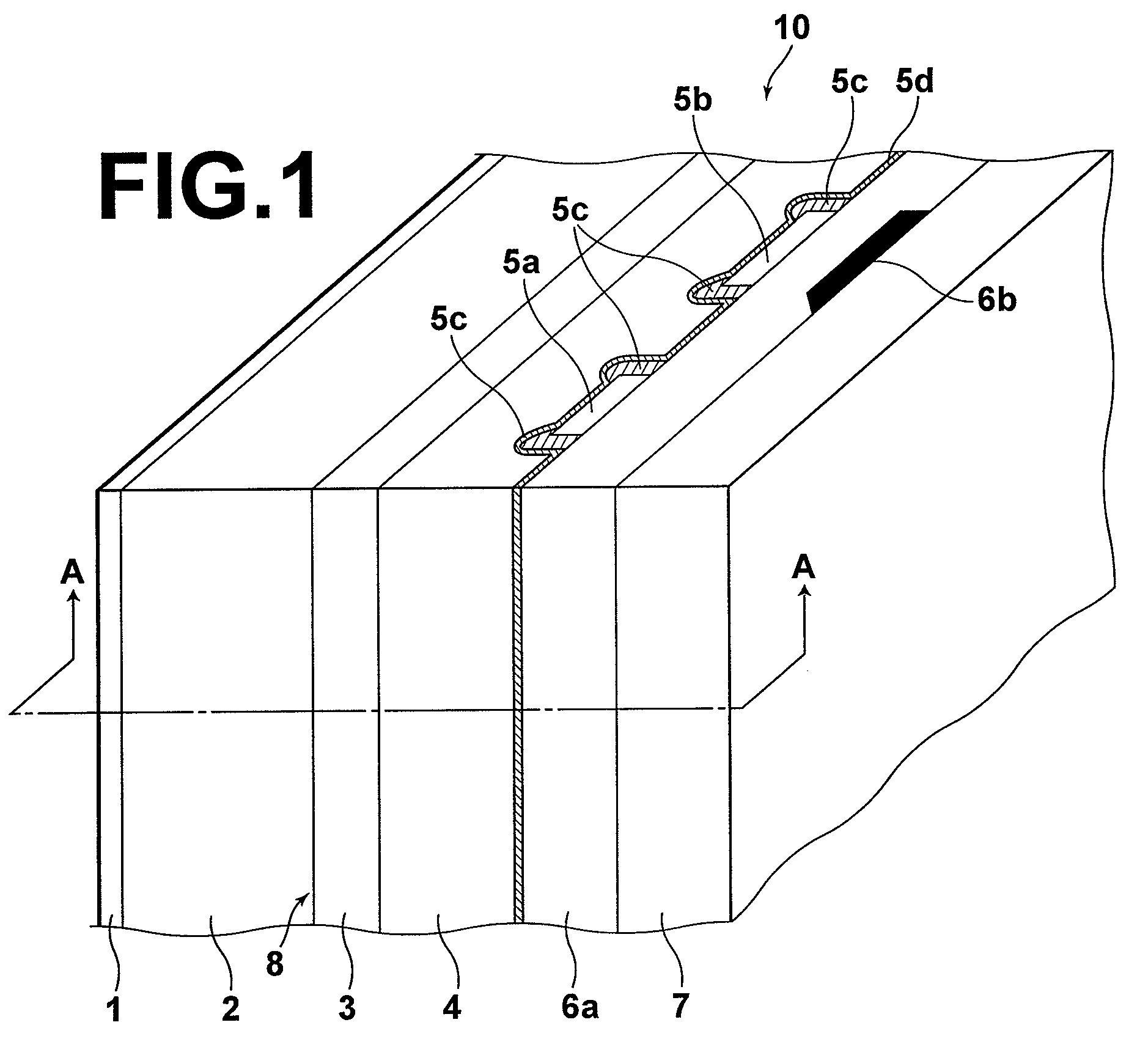

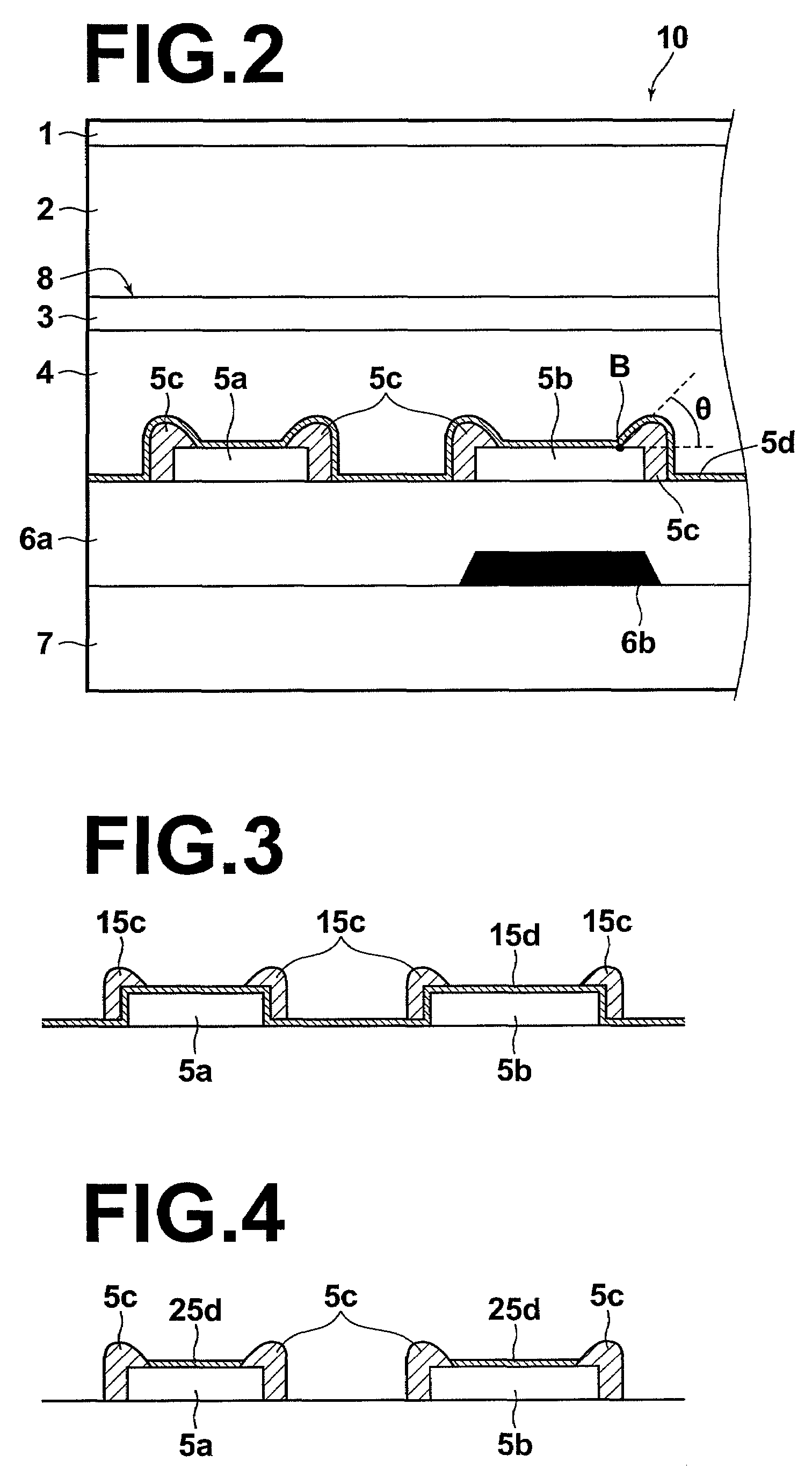

Solid-state imaging device and method of manufacturing the same

InactiveUS20050082631A1Improved readout characteristicSuppresses image defectsTelevision system detailsSolid-state devicesLow voltageEngineering

A solid-state imaging device includes: a plurality of N-type photodiode regions formed inside a P-type well; a gate electrode having one edge being positioned adjacent to each of the photodiode regions; a N-type drain region positioned adjacent to the other edge of the gate electrode; an element-isolating portion having a STI structure, and a gate oxide film having a thickness of not more than 10 nm. One edge of the gate electrode overlaps the photodiode region. First, second and third regions are formed on a surface portion extending from the photodiode region to the drain region, in conditions such that the first region is disposed with a predetermined distance from one edge of the gate electrode and has a P-type first concentration C1, the second region is disposed with one edge positioned adjacent to the first region and the other edge overlapping the gate electrode and has a P-type second concentration C2, and the third region is disposed with one edge positioned adjacent to the second region and the other edge positioned adjacent to the drain region and has a P-type third concentration C3, wherein C1>C2>C3 or C1≈C2>C3. The readout characteristic at a low voltage is satisfactory, and image defects such as white flaws and dark current are suppressed sufficiently.

Owner:COLLABO INNOVATIONS INC

Ink composition, ink set and image forming method

ActiveUS20120212536A1High resolutionStable formationDucting arrangementsNon-fibrous pulp additionWaxWater insoluble

An ink composition is disclosed which includes carbon black; at least one selected from the group consisting of a cyan pigment and a magenta pigment; at least one selected from the group consisting of polyvinyl pyrrolidone, polyvinyl alcohol, and polyethylene glycol, at a ratio of 0.01% by mass or higher but lower than 1.00% by mass, relative to the total amount of the composition; water-insoluble or substantially water-insoluble resin particles, water-insoluble or substantially water-insoluble wax particles or any mixture thereof; and water. An ink set and an image forming method are also disclosed.

Owner:FUJIFILM CORP

Electrophotographic photoreceptor, process cartridge and image forming device using the same

ActiveCN101149573AIncreased durabilityImprove oxidation resistanceElectrographic process apparatusSurface layerOxygen

An electrophotographic photoreceptor comprising a photosensitive layer and a surface layer laminated on a conductive substrate in this order, wherein the surface layer contains a group 13 element and oxygen, and absorption peak intensities showing bonds other than a bond between the group 13 element and oxygen are 0.1 times or less of an absorption peak intensity showing a bond between the group 13 element and oxygen in an infrared absorption spectrum in a range of 4000 cm<-1 >to 400 cm<-1>, is provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

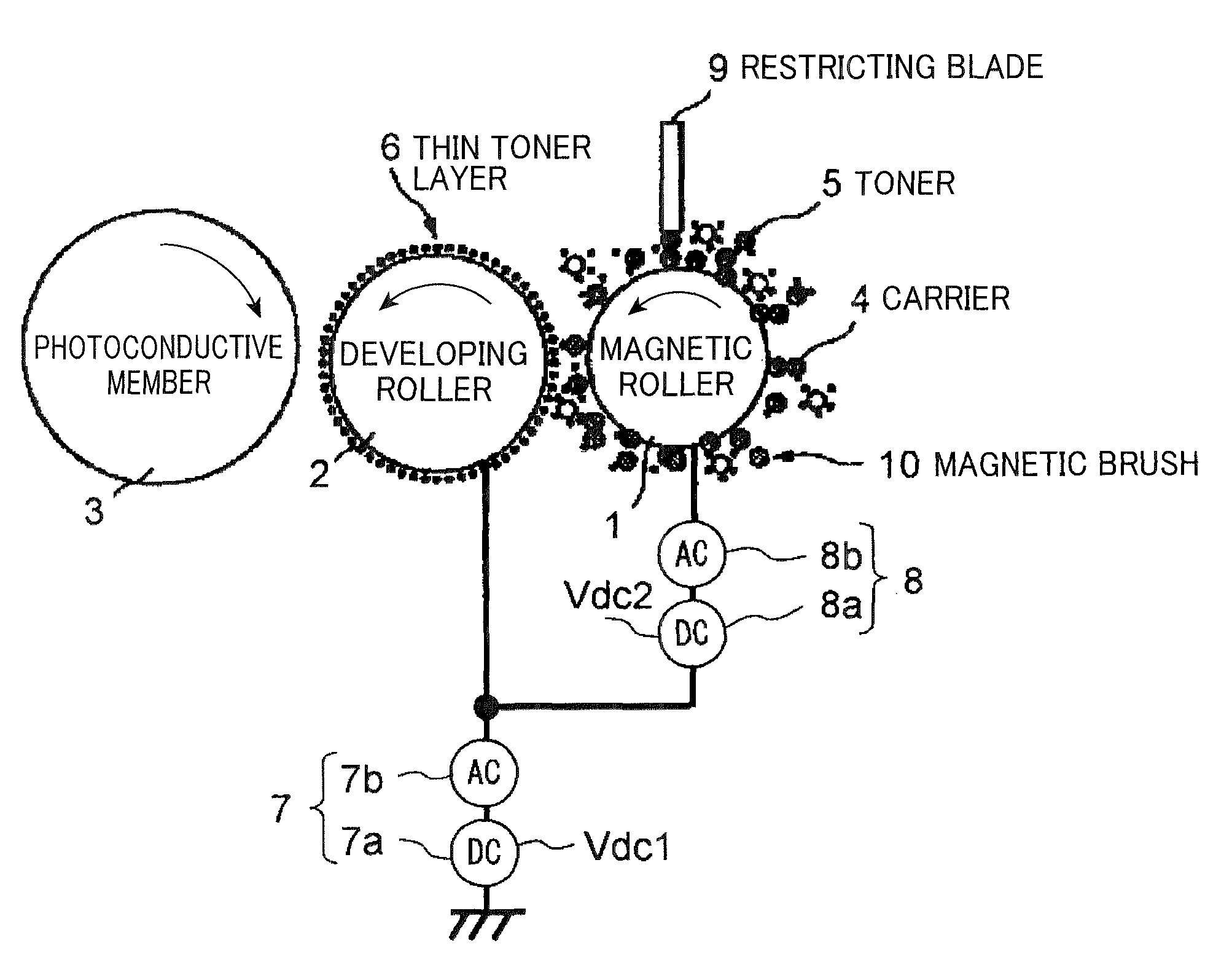

Image forming apparatus

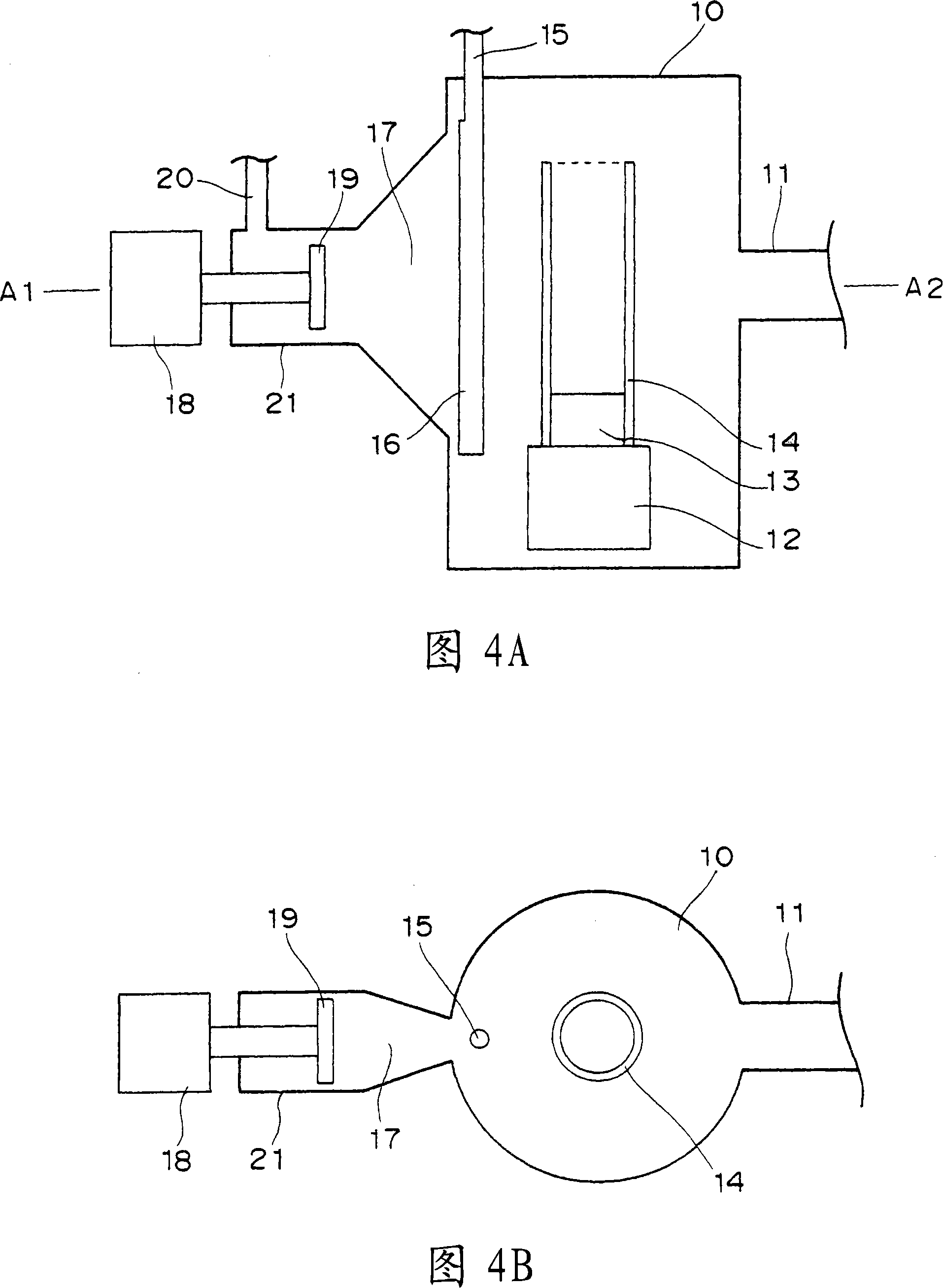

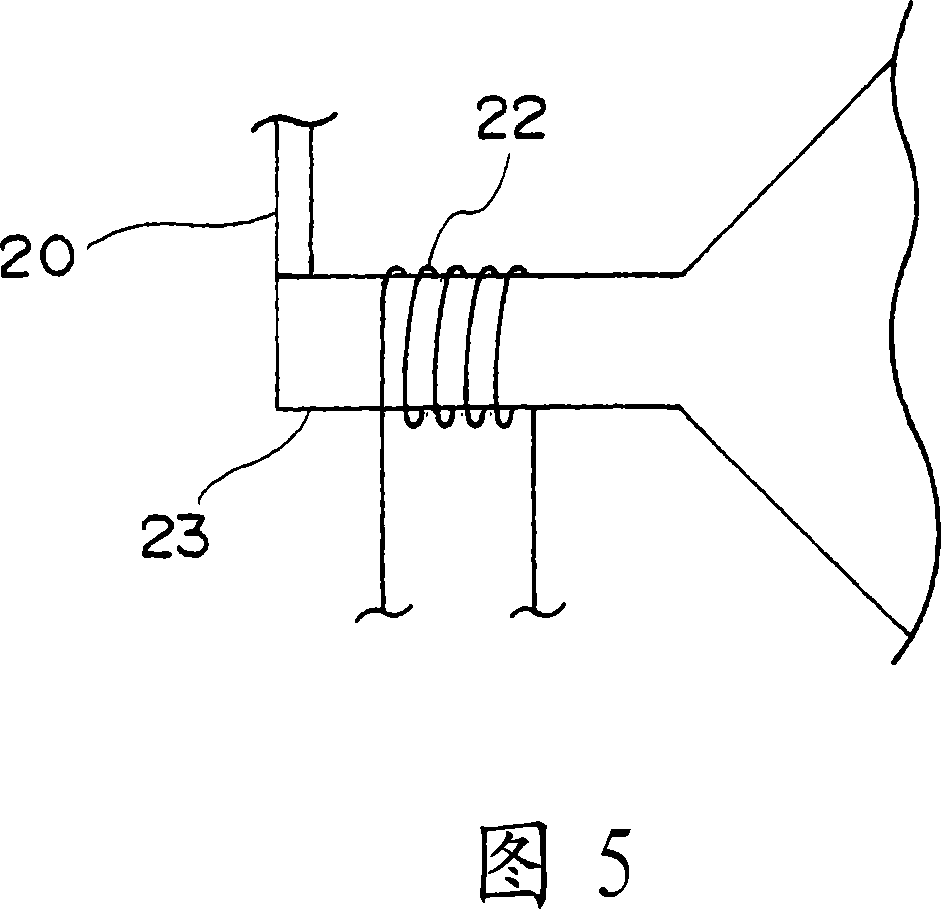

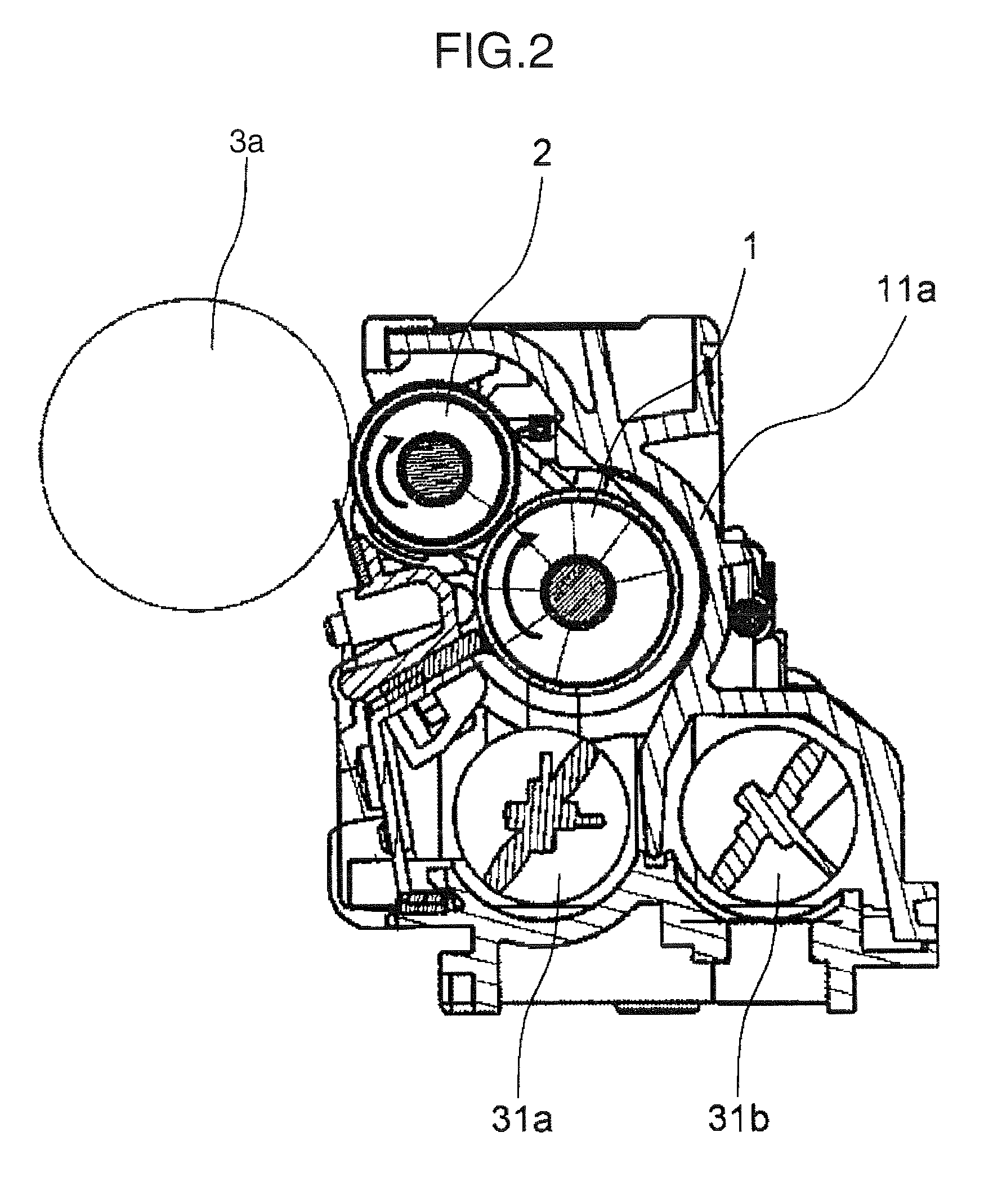

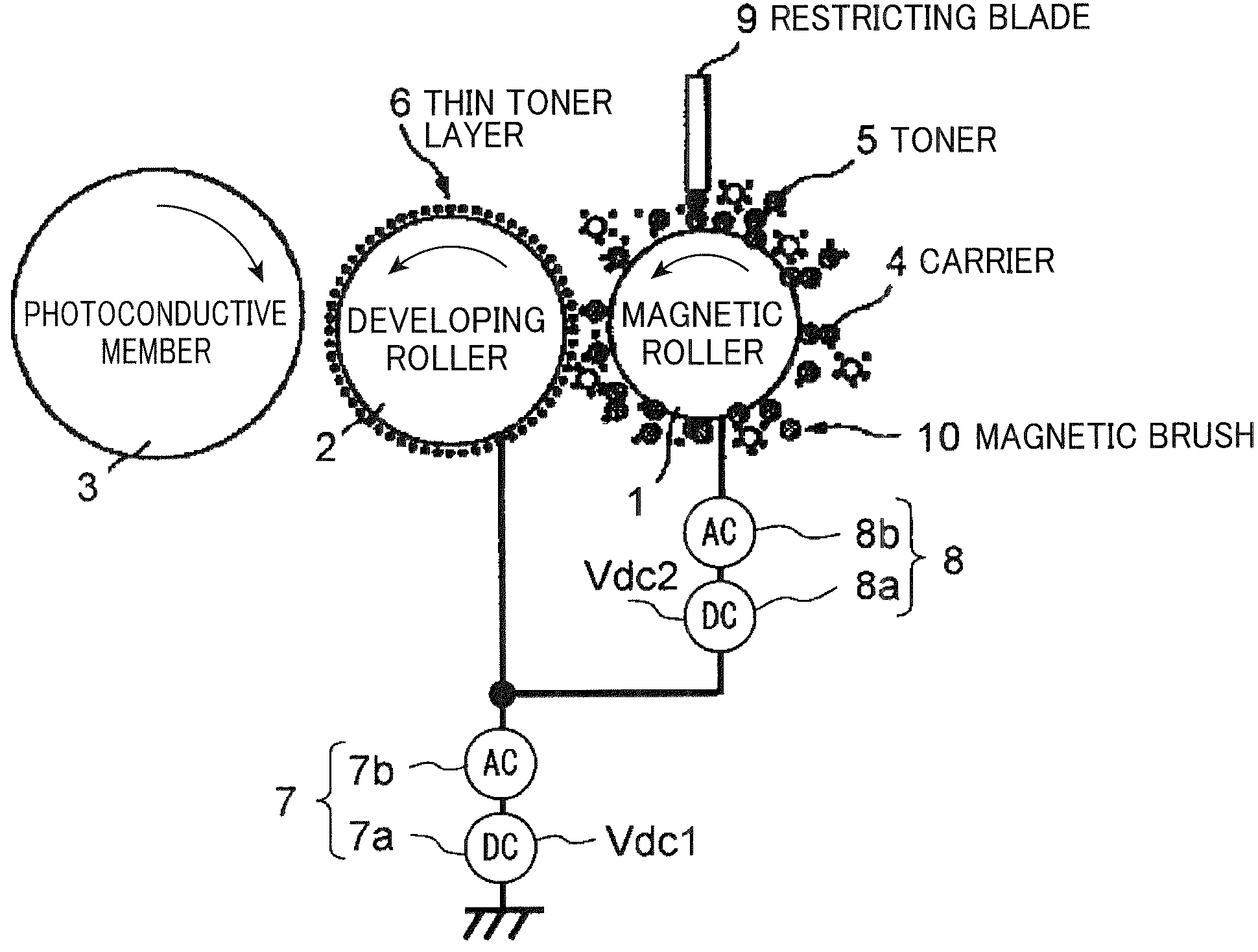

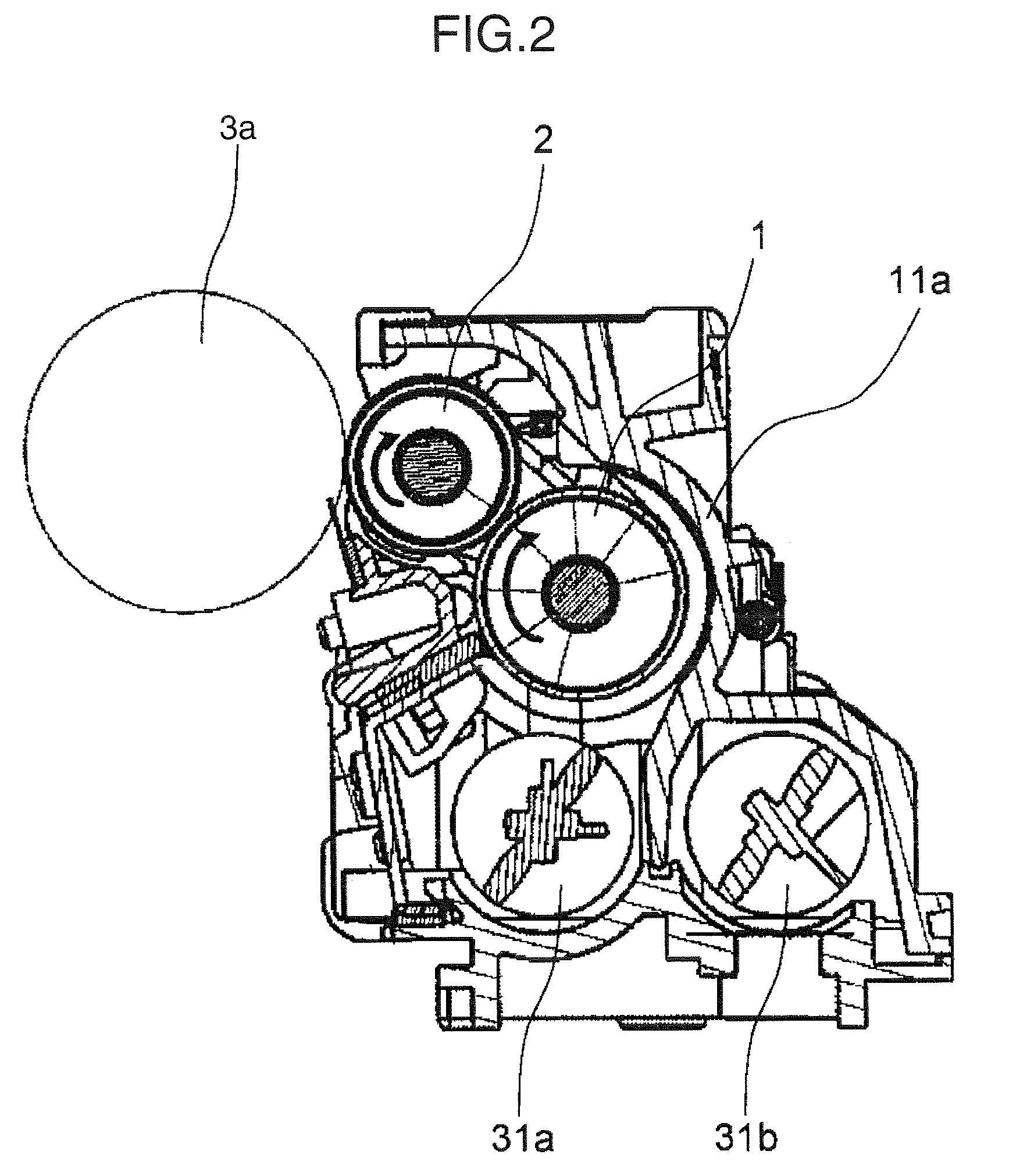

InactiveUS7742727B2Improve balanceGood toner adherenceElectrographic process apparatusHigh resistanceLatent image

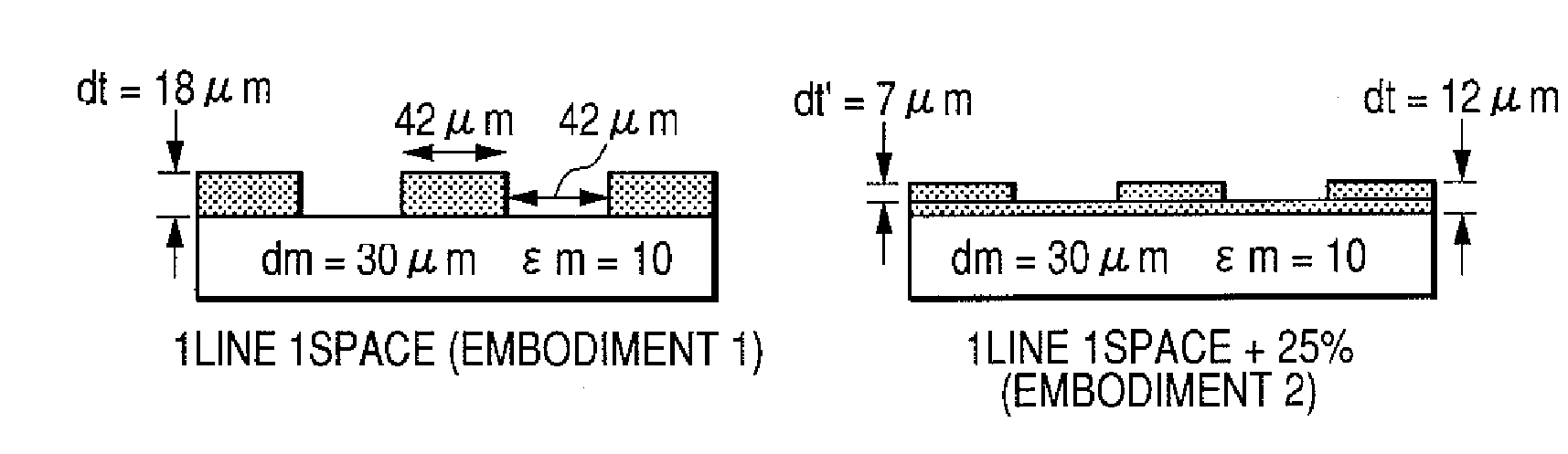

An image forming apparatus has a photoconductive member on which a latent image is to be formed, a developing roller for developing the latent image on the photoconductive member by a first bias. A magnetic roller forms a magnetic brush thereon with a two-component developer and forms a thin toner layer on the developing roller by a second bias. The developing roller is aluminum with a surface treated for high resistance. The thickness (T) of the toner layer and the duty ratio (D1) of the first alternating-current bias satisfy relationships of the following equations for calculating the duty ratio (D1) using an application period of a voltage in a direction to transfer the toner from the developing roller towards the photoconductive member as a positive period:7 μm≦T≦13 μm, and35%≦D1≦70%.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Solid-state imaging device and method of manufacturing the same

InactiveUS7030433B2Improved readout characteristicSuppresses image defectsTelevision system detailsSolid-state devicesLow voltageEngineering

A solid-state imaging device includes: a plurality of N-type photodiode regions formed inside a P-type well; a gate electrode having one edge being positioned adjacent to each of the photodiode regions; a N-type drain region positioned adjacent to the other edge of the gate electrode; an element-isolating portion having a STI structure, and a gate oxide film having a thickness of not more than 10 nm. One edge of the gate electrode overlaps the photodiode region. First, second and third regions are formed on a surface portion extending from the photodiode region to the drain region, in conditions such that the first region is disposed with a predetermined distance from one edge of the gate electrode and has a P-type first concentration C1, the second region is disposed with one edge positioned adjacent to the first region and the other edge overlapping the gate electrode and has a P-type second concentration C2, and the third region is disposed with one edge positioned adjacent to the second region and the other edge positioned adjacent to the drain region and has a P-type third concentration C3, wherein C1>C2>C3 or C1≈C2>C3. The readout characteristic at a low voltage is satisfactory, and image defects such as white flaws and dark current are suppressed sufficiently.

Owner:COLLABO INNOVATIONS INC

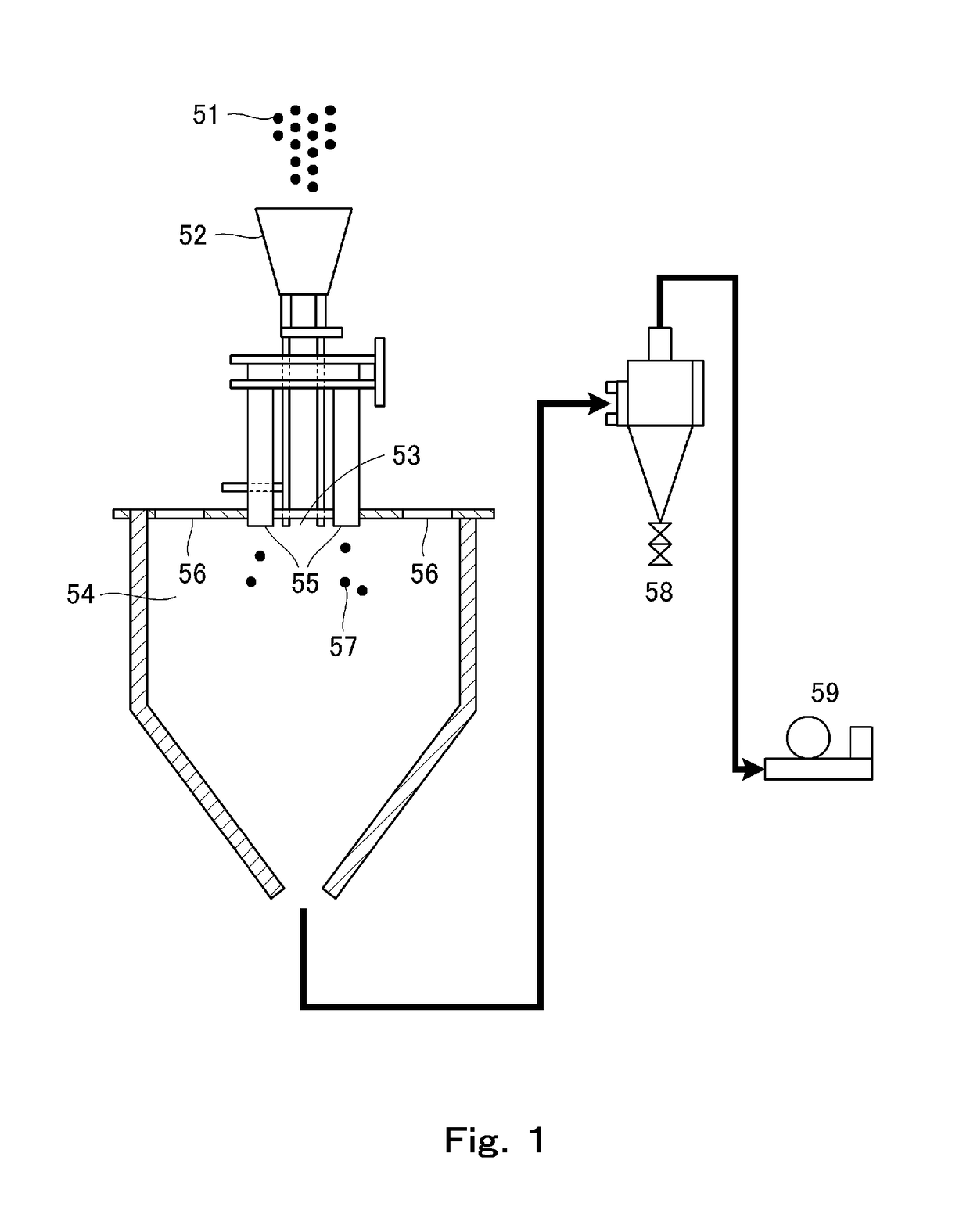

Toner

ActiveUS20160070192A1Satisfactory initial densityProcess stabilityDevelopersCoverage ratioMaterials science

The toner comprising a toner particle containing a binder resin and a colorant, an iron oxide particle and an organic-inorganic composite fine particle, wherein the organic-inorganic composite fine particle comprises a vinyl resin particle, and inorganic fine particles which are embedded in the vinyl resin particle, and at least a part of which is exposed at surface of the organic-inorganic composite fine particle; the organic-inorganic composite fine particle has convexes derived from the inorganic fine particles, and wherein: a coverage ratio of the surface of the organic-inorganic composite fine particle with the inorganic fine particle is 20-70%; and the content of the iron oxide particle present on a surface of the toner particle is 0.1-5.0 mass % based on the mass of the toner particle.

Owner:CANON KK

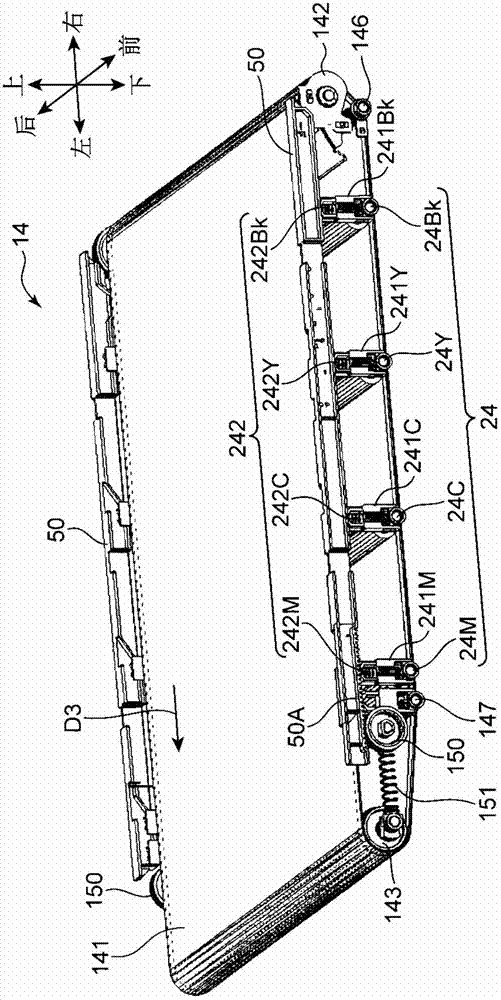

Transfer device and image forming apparatus including same

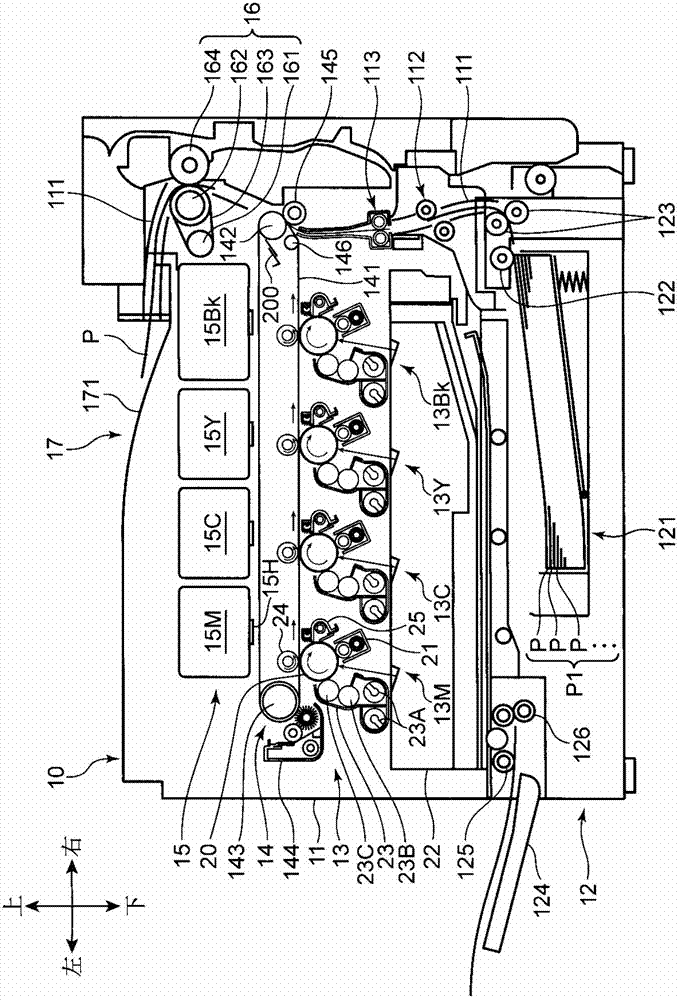

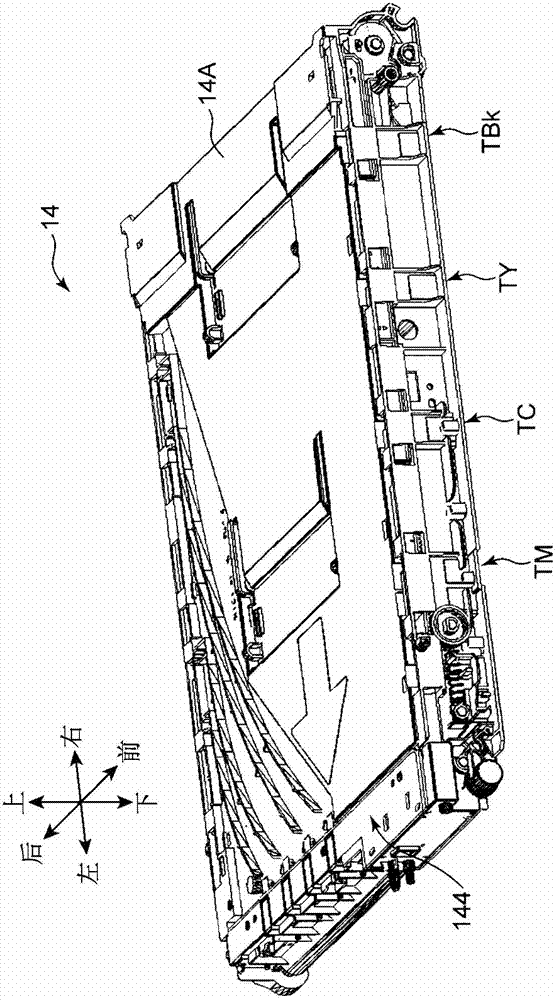

ActiveCN103838116ASuppresses image defectsElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Image forming apparatus

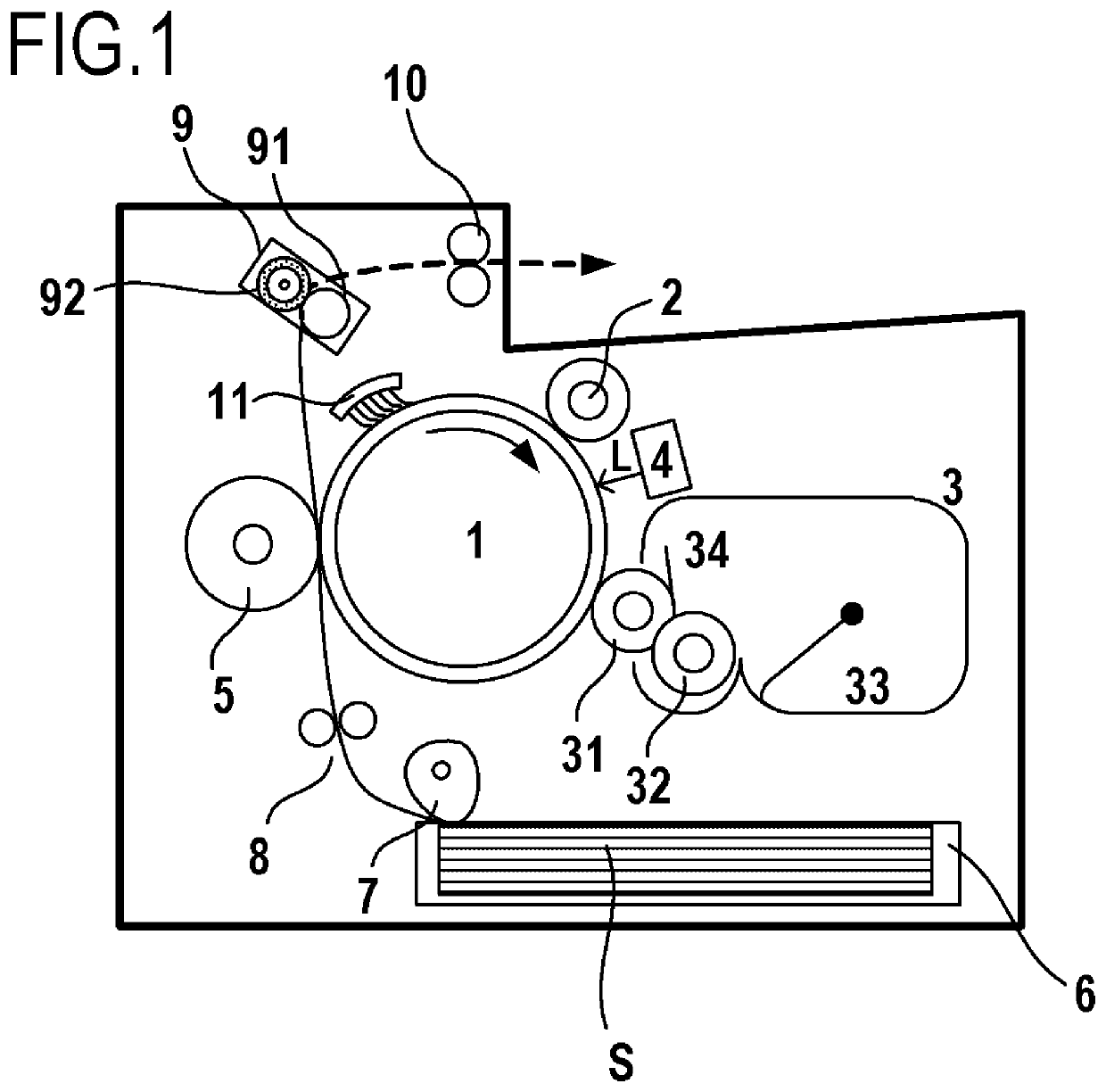

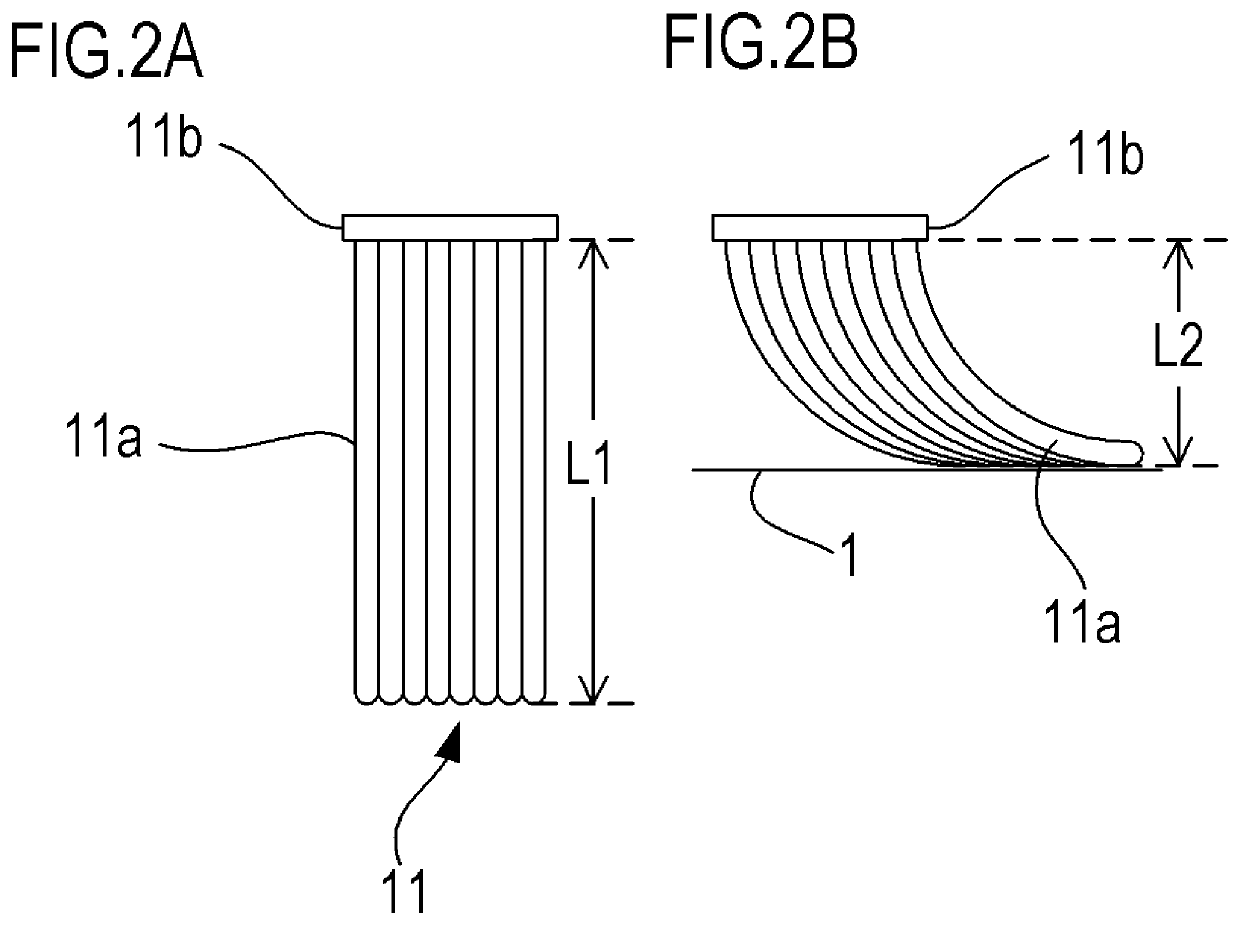

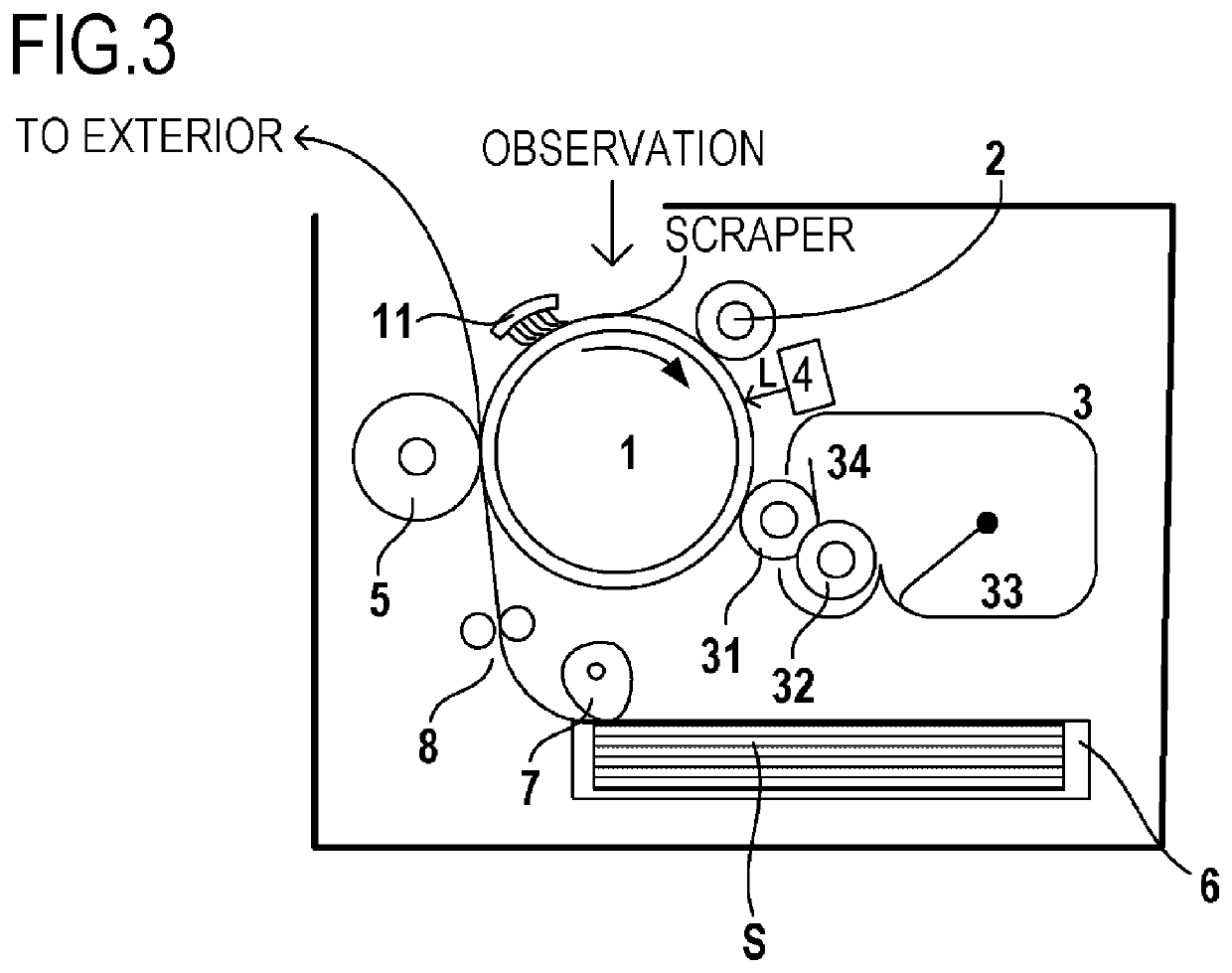

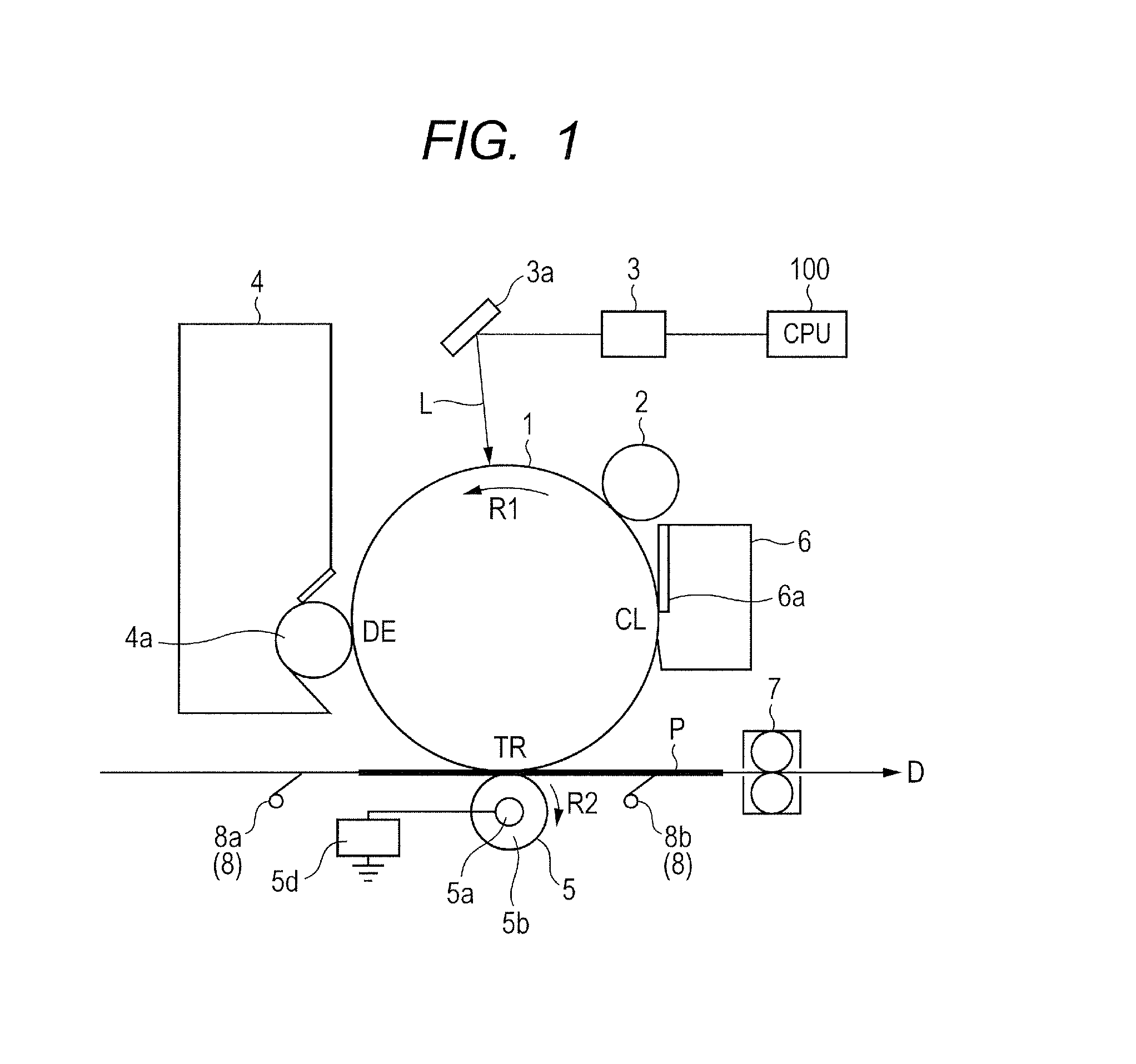

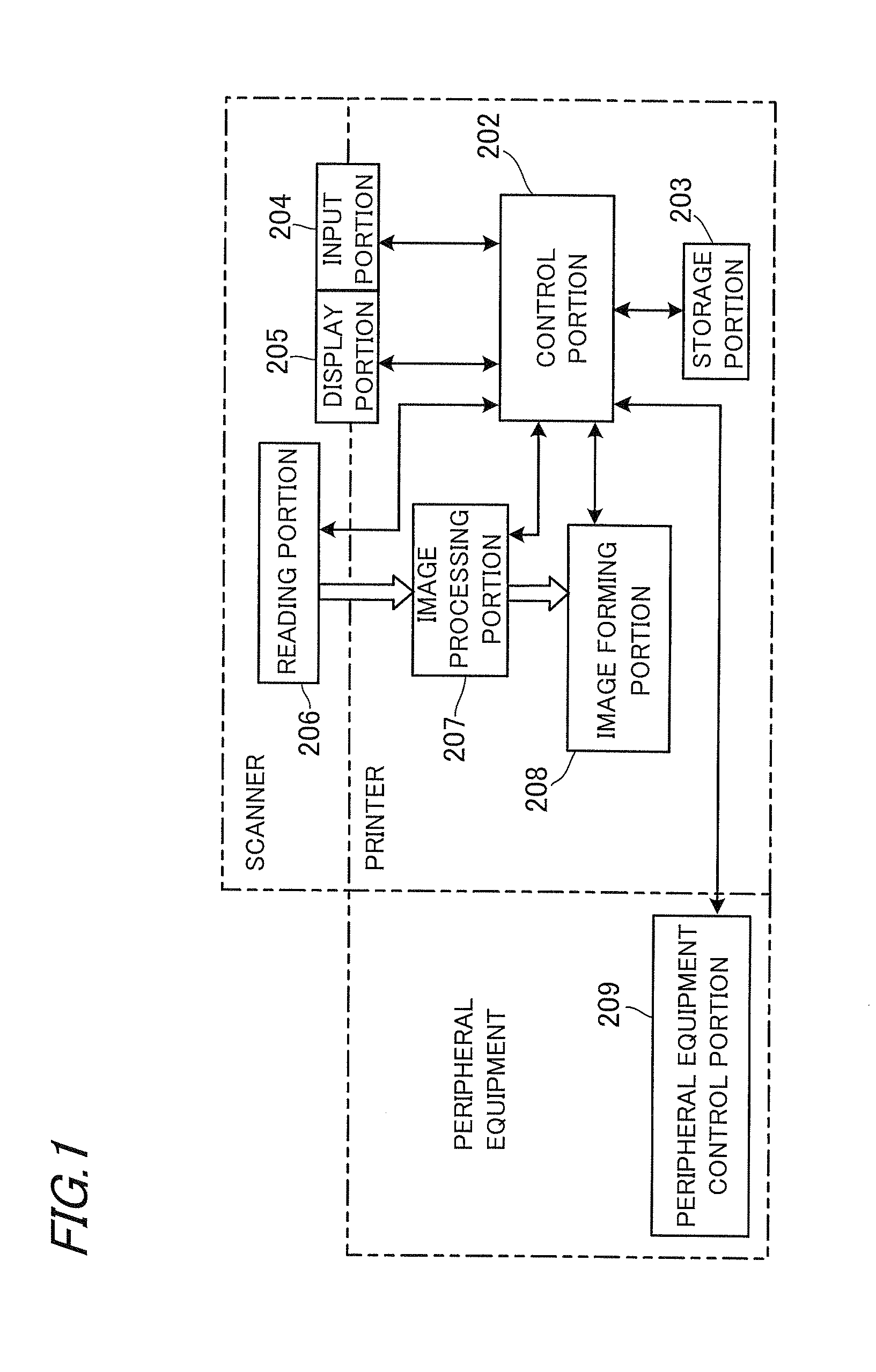

ActiveUS20210382430A1Suppresses image defectsAdd equipmentElectrographic process apparatusCorona dischargeLatent imageImage formation

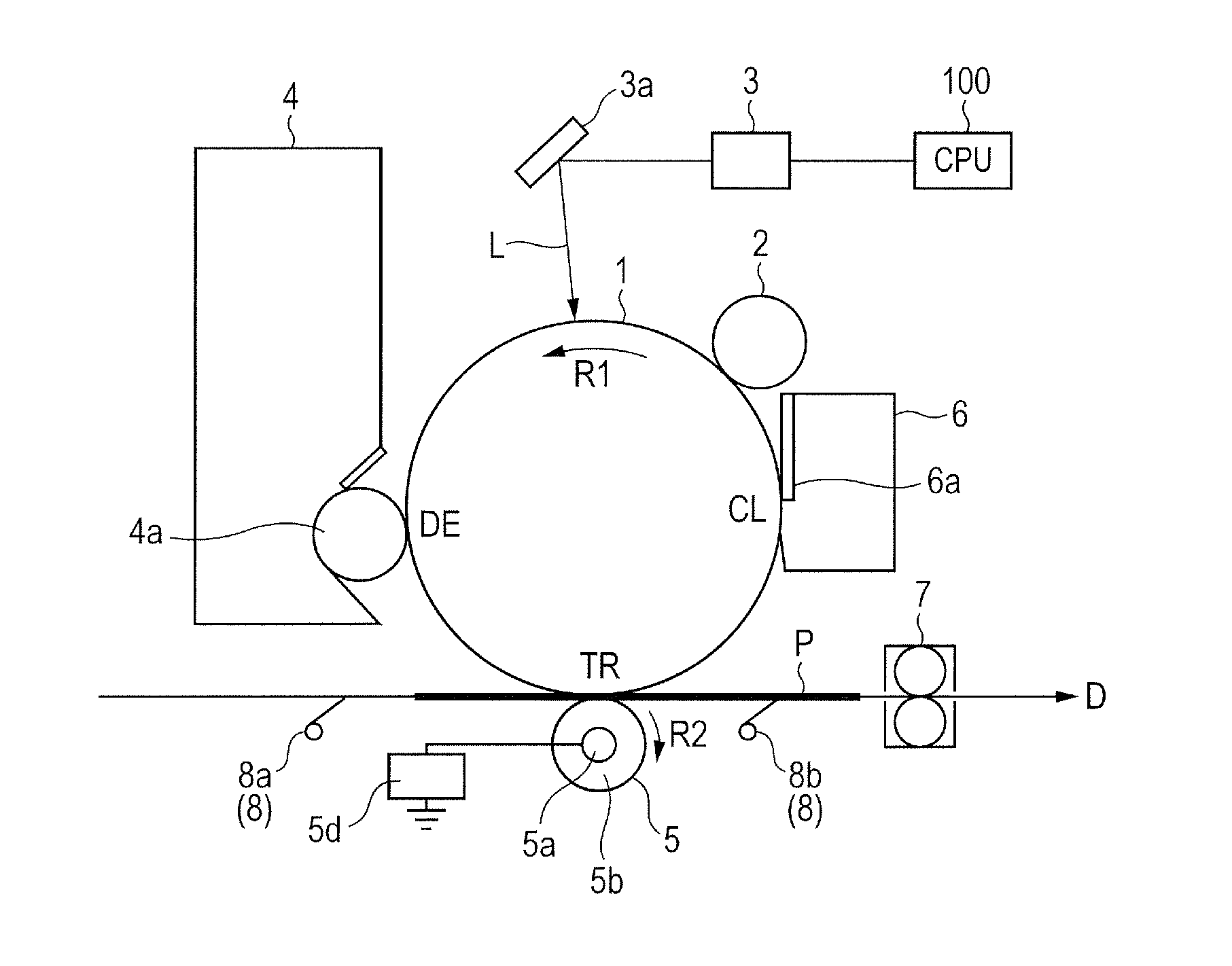

Provided are an image bearing member; a charging member that charges the image bearing member; an exposure unit that exposes the image bearing member; a developing unit that develops an electrostatic latent image as a developer image by supplying a developer, charged to regular polarity, to the image bearing member; a transfer member that transfers the developer image to a transfer-receiving body; and a collecting member that collects a deposit on the image bearing member downstream of a transfer portion of the image bearing member at which the developer image is transferred to the transfer-receiving body by the transfer member, and upstream of a charging portion of the image bearing member charged by the charging member, in a rotation direction of the image bearing member. After transfer of the developer image to the transfer-receiving body, the developer remaining on the image bearing member is collected by the developing unit.

Owner:CANON KK

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

ActiveUS20110104601A1Suppresses image defectsExcellent film stateElectrographic process apparatusCorona dischargePolyolefinInter layer

The present invention relates to an electrophotographic photosensitive member obtained by providing, on a conductive support, a conductive layer containing conductive particles having a volume-average particle diameter of 0.1 μm or more, an intermediate layer, and a photosensitive layer in the stated order in which the conductive layer contains a polyolefin resin containing a specific repeating structural unit at a specific ratio, and a process cartridge and an electrophotographic apparatus each having the electrophotographic photosensitive member.

Owner:CANON KK

Magnetic toner

ActiveUS9971262B2Excellent charging performance uniformitySatisfactory charging performance uniformityDevelopersCoverage ratioUltimate tensile strength

A magnetic toner containing a magnetic toner particle having a binder resin and a magnetic body, and inorganic fine particles, wherein when the inorganic fine particles are classified as first inorganic fine particles, second inorganic fine particles, and third inorganic fine particles in accordance with fixing strength thereof to the magnetic toner particle and in the sequence of the weakness of the fixing strength, the content of the first inorganic fine particles, the ratio of the second inorganic fine particles to the first inorganic fine particles, and the coverage ratio X of coverage of the magnetic toner surface by the third inorganic fine particles are in prescribed ranges.

Owner:CANON KK

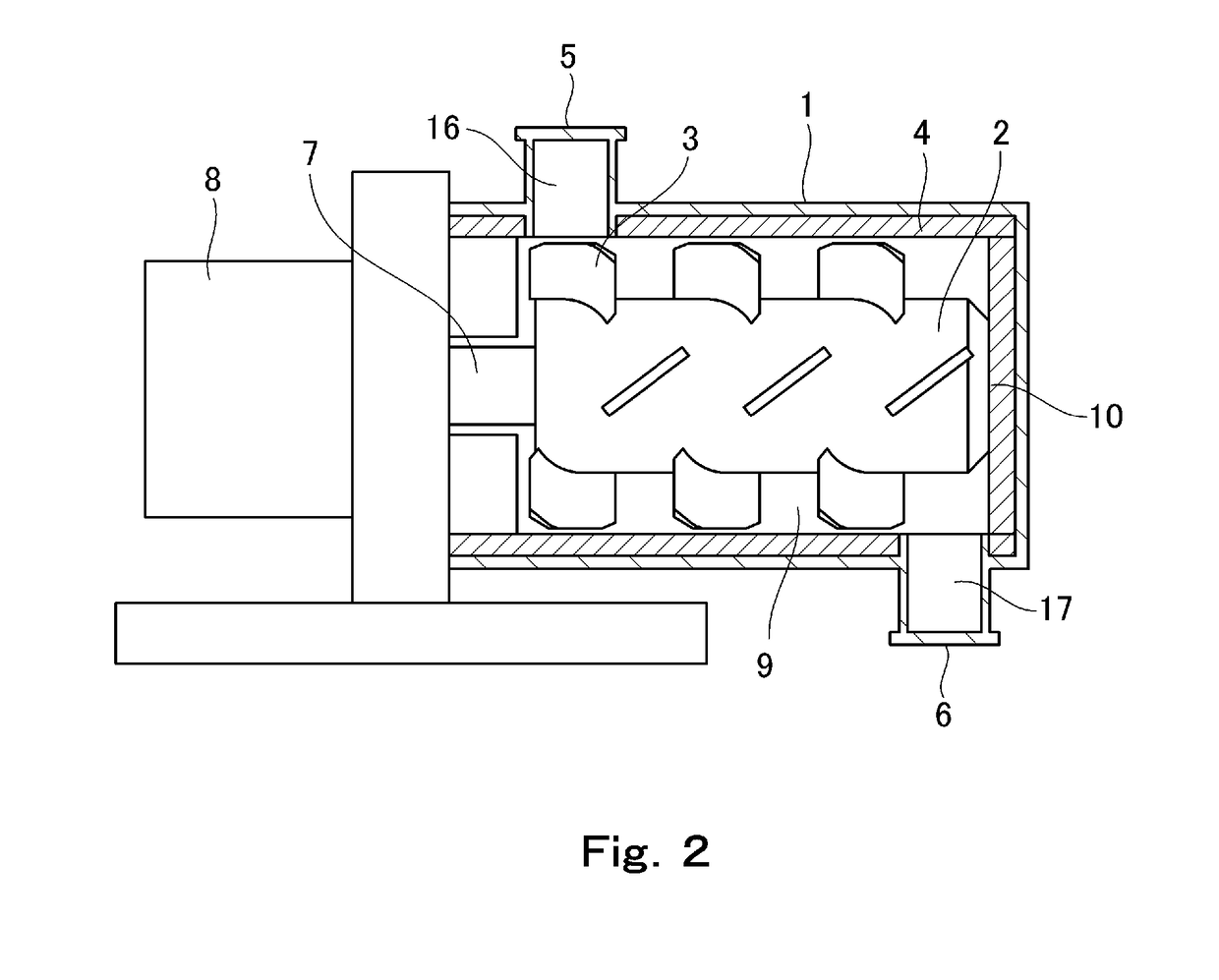

Image forming apparatus

ActiveUS7941080B2Improve balanceExcellent developabilityElectrographic process apparatusElectrographic processes using charge patternLatent imageImage formation

An image forming apparatus is provided with a photoconductive member on which a latent image is to be formed, a developing roller for developing the latent image formed on the photoconductive member by a first bias, and a magnetic roller for forming a magnetic brush thereon with a two-component developer and forming a thin toner layer on the developing roller by a second bias. If (D1) denotes the duty ratio of a first alternating-current bias included in the first bias and (D2) denotes the duty ratio of a second alternating-current bias included in the second bias, the duty ratios (D1, D2) satisfy the following relationship:D1>100−D2.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Image forming apparatus with controlled application of alternating-current bias

ActiveUS7826781B2Improve balanceGood toner adherenceElectrographic process apparatusElectrical resistance and conductanceLatent image

An image forming apparatus has a photoconductive member, and a developing roller develops a latent image on the photoconductive member by a first alternating-current bias in the form of a rectangular wave. The following relationships are satisfied in calculating the duty ratio (D1) of the first alternating-current bias using an application period of voltage in a direction to transfer the toner from the developing roller towards the photoconductive member as a positive period:a CV value in the number particle size distribution of the toner is ≦25%,4 μm≦Dt≦7 μm,105 Ω·cm≦pv≦109 Ω·cm,0.4 μm≦Ra≦1.5 μm, and35%≦D1≦75%.where Dt denotes the volume average particle diameter of the toner, pv denotes the intrinsic resistance value of a developing roller surface, Ra denotes the arithmetic average roughness of the developing roller surface.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Toner and method of producing toner

ActiveUS10228630B2Lower performance requirementsElectrostatic attachment force between the photosensitive drum and toner is increasedDevelopersCharge controlFriction angle

Owner:CANON KK

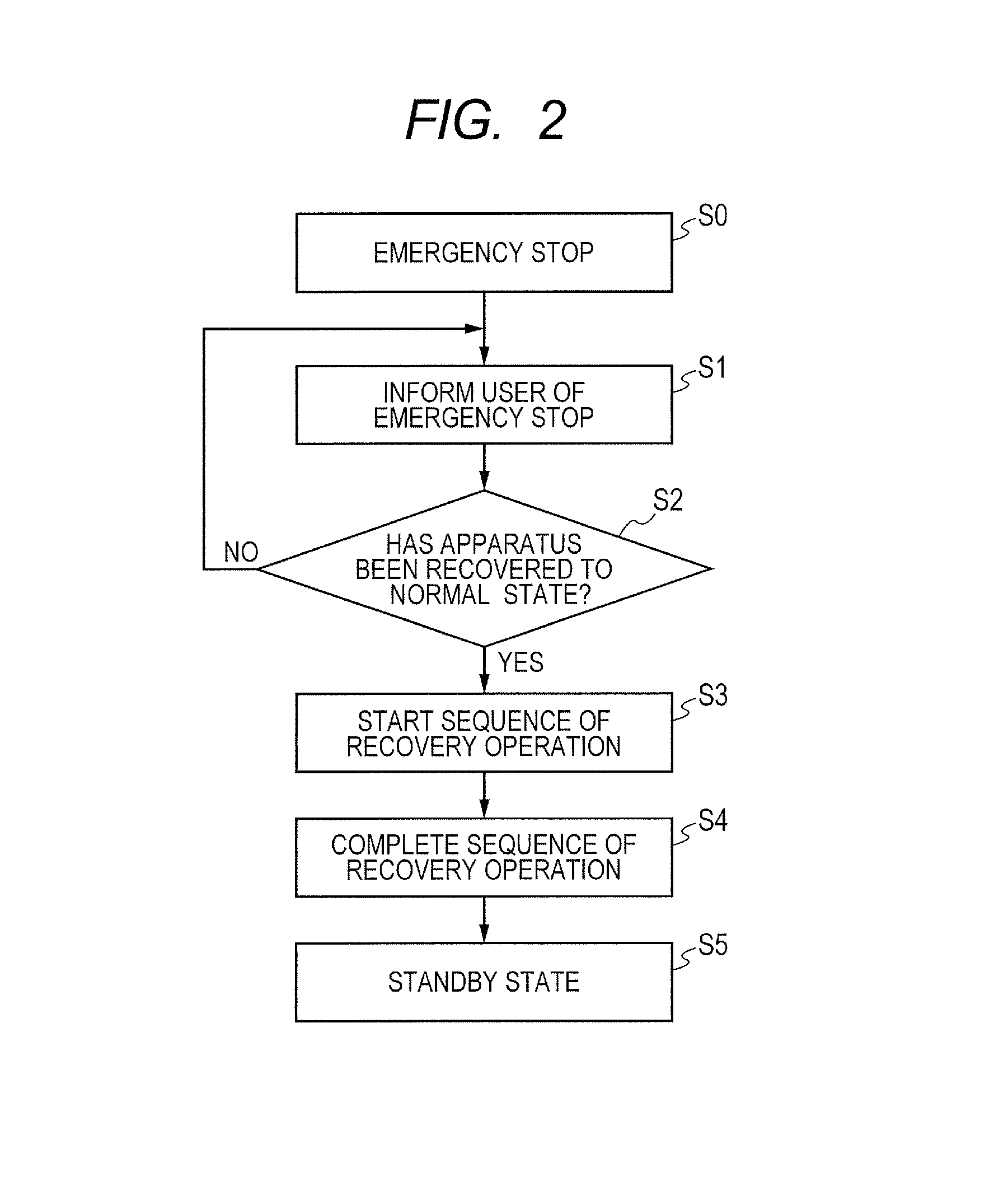

Image forming apparatus

ActiveUS20130336670A1Suppresses image defectsElectrographic process apparatusImage formationEngineering

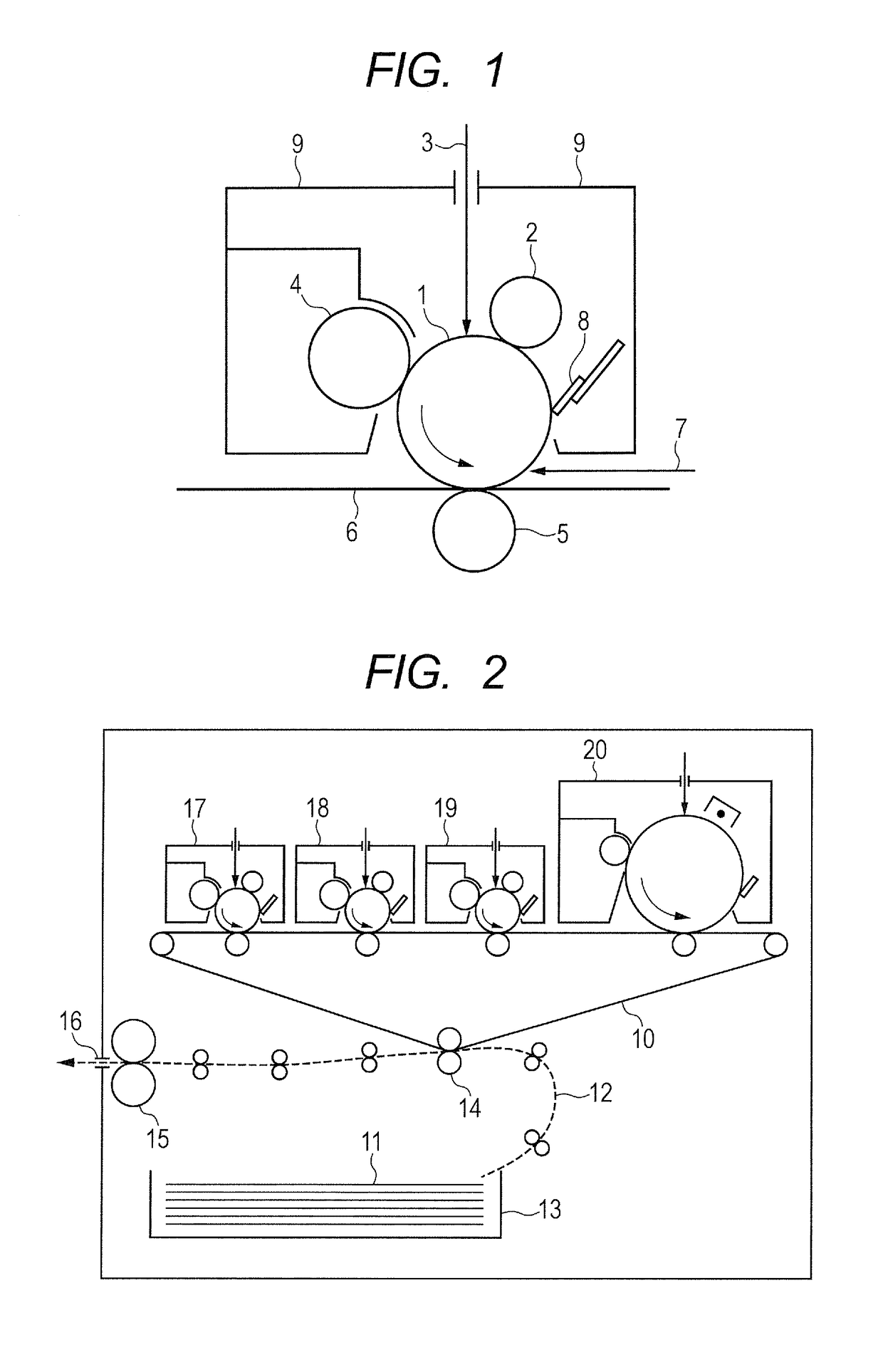

An image forming apparatus, including: a rotatable image bearing member; a developing unit configured to supply a developer onto the image bearing member; a transfer unit configured to transfer the developer on the image bearing member to a recording medium by a transfer voltage being applied to the transfer unit by a voltage applying unit; and a cleaning unit configured to remove the developer on the image bearing member, wherein when the apparatus stops an image forming operation halfway, the apparatus executes a recovery operation in which the image bearing member is rotated while the voltage applying unit applies a voltage to the transfer unit so that a part of the developer remaining on the image bearing member is once transferred from the image bearing member to the transfer unit, transferred again from the transfer unit to the image bearing member, and then removed by the cleaning unit.

Owner:CANON KK

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

ActiveCN102053510ASuppresses image defectsExcellent film stateElectrographic process apparatusPolyolefinInter layer

The present invention relates to an electrophotographic photosensitive member obtained by providing, on a conductive support, a conductive layer containing conductive particles having a volume-average particle diameter of 0.1 [mu]m or more, an intermediate layer, and a photosensitive layer in the stated order in which the conductive layer contains a polyolefin resin containing a specific repeating structural unit at a specific ratio, and a process cartridge and an electrophotographic apparatus each having the electrophotographic photosensitive member.

Owner:CANON KK

Radiation image detector

InactiveUS7564050B2Suppressing imageHigh sensitivityPhotometrySolid-state devicesDielectricElectricity

Owner:FUJIFILM CORP

Image forming apparatus and cleaning control method

ActiveUS20130136486A1Suppresses image defectsSolution to short lifeElectrographic process apparatusCorona dischargeImage formationEngineering

In an image forming apparatus for forming an image by electrophotography, a charging device is comprised of a needle electrode in which a plurality of saw teeth are arrayed in one direction; a cleaning rubber roller that cleans the needle electrode; a cleaning member supporter; a moving portion that moves the cleaning member supporter; and a control portion that controls the charging device, and the control portion includes a function to increase a saw-tooth current value by increasing print cumulative count; and a function to decrease the saw-tooth current value at the time of performing cleaning.

Owner:SHARP KK

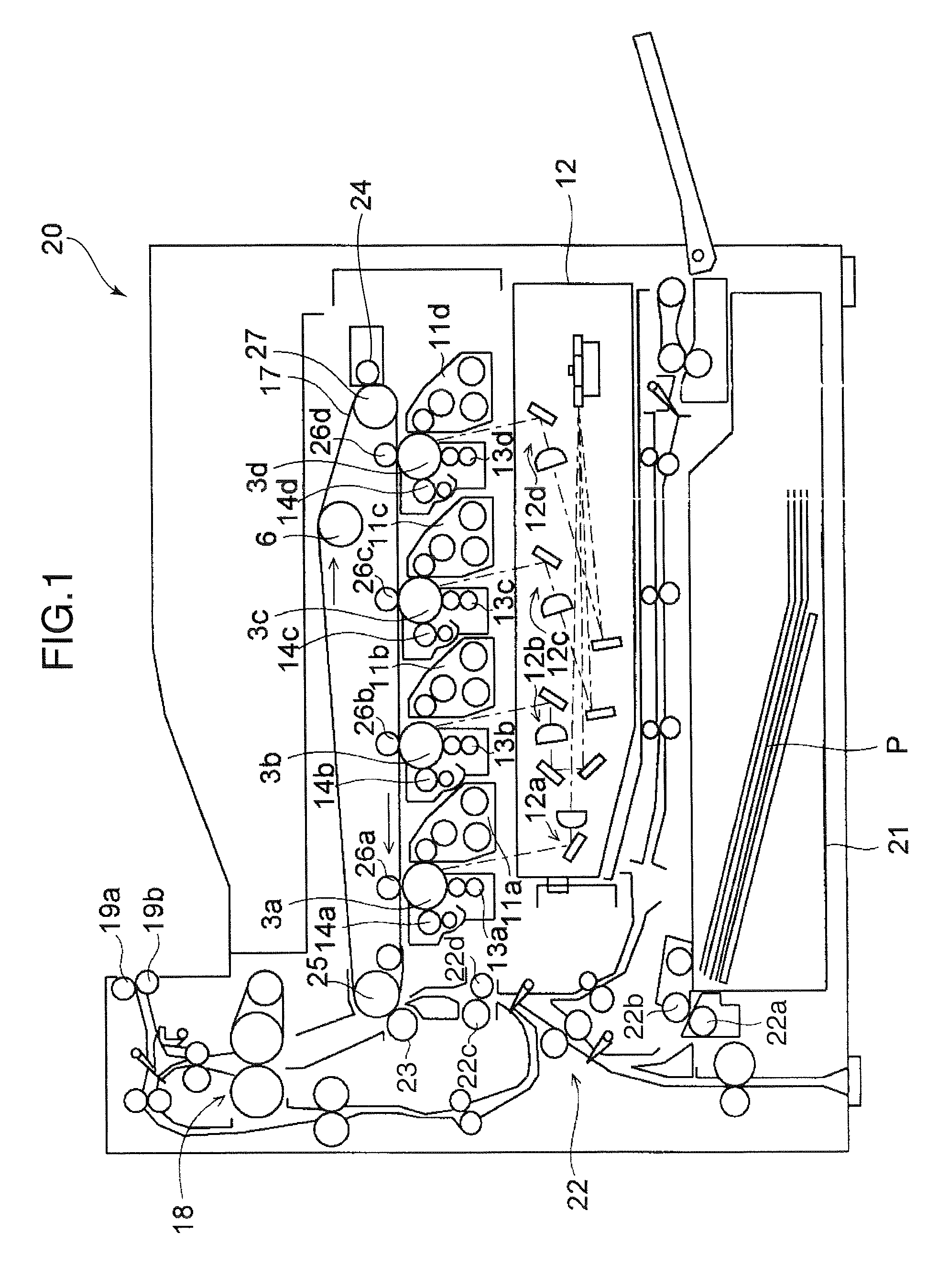

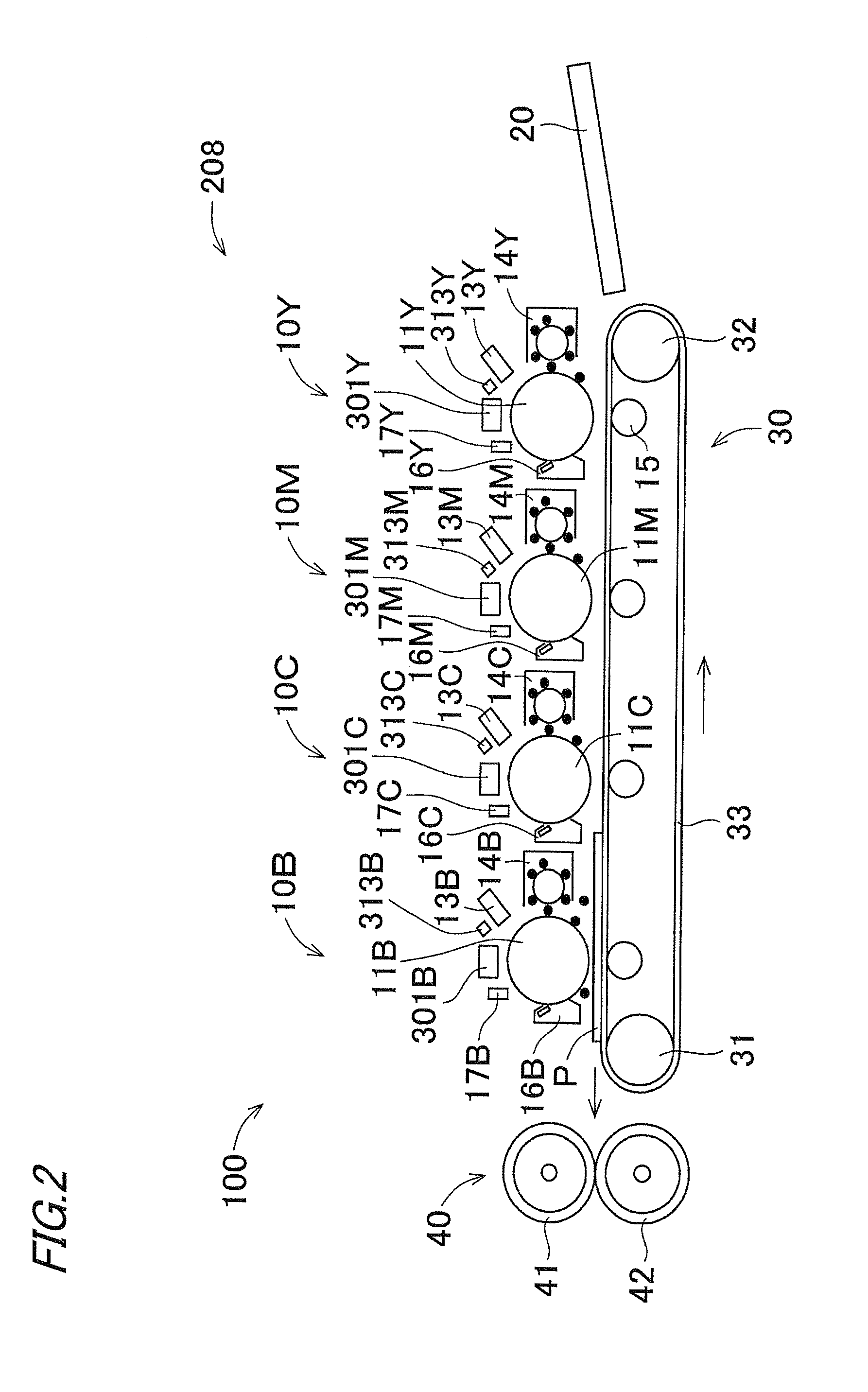

Image forming apparatus

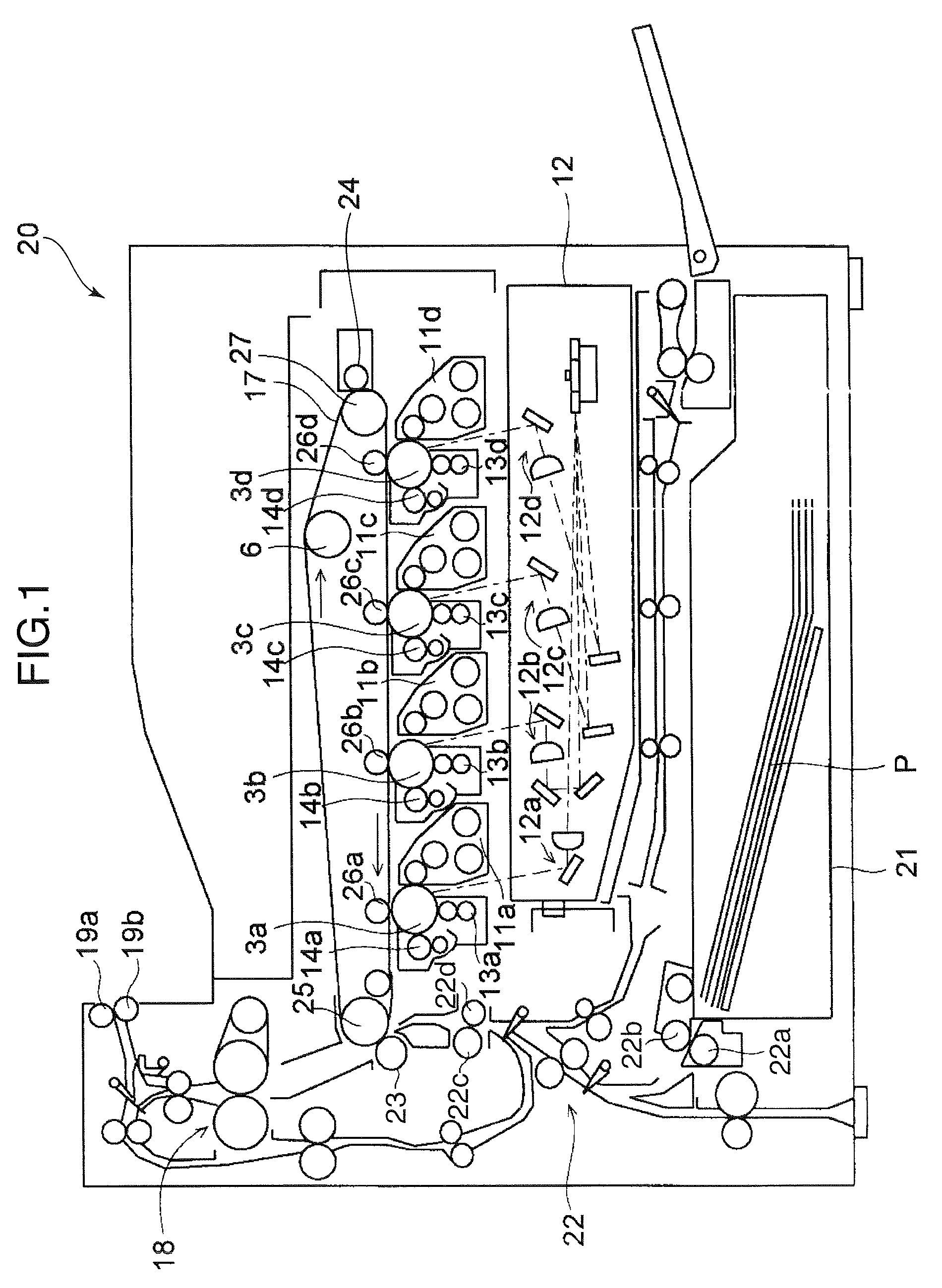

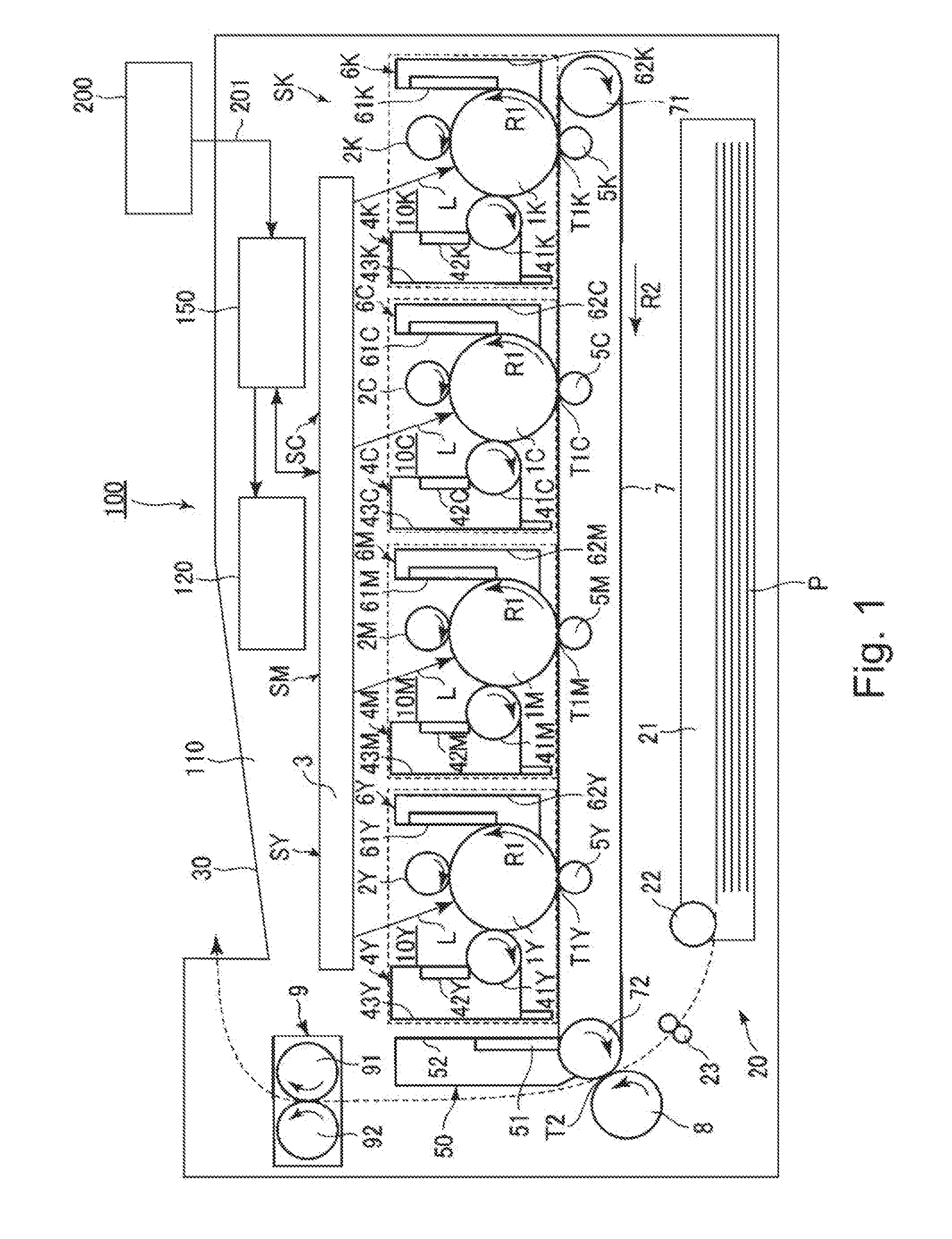

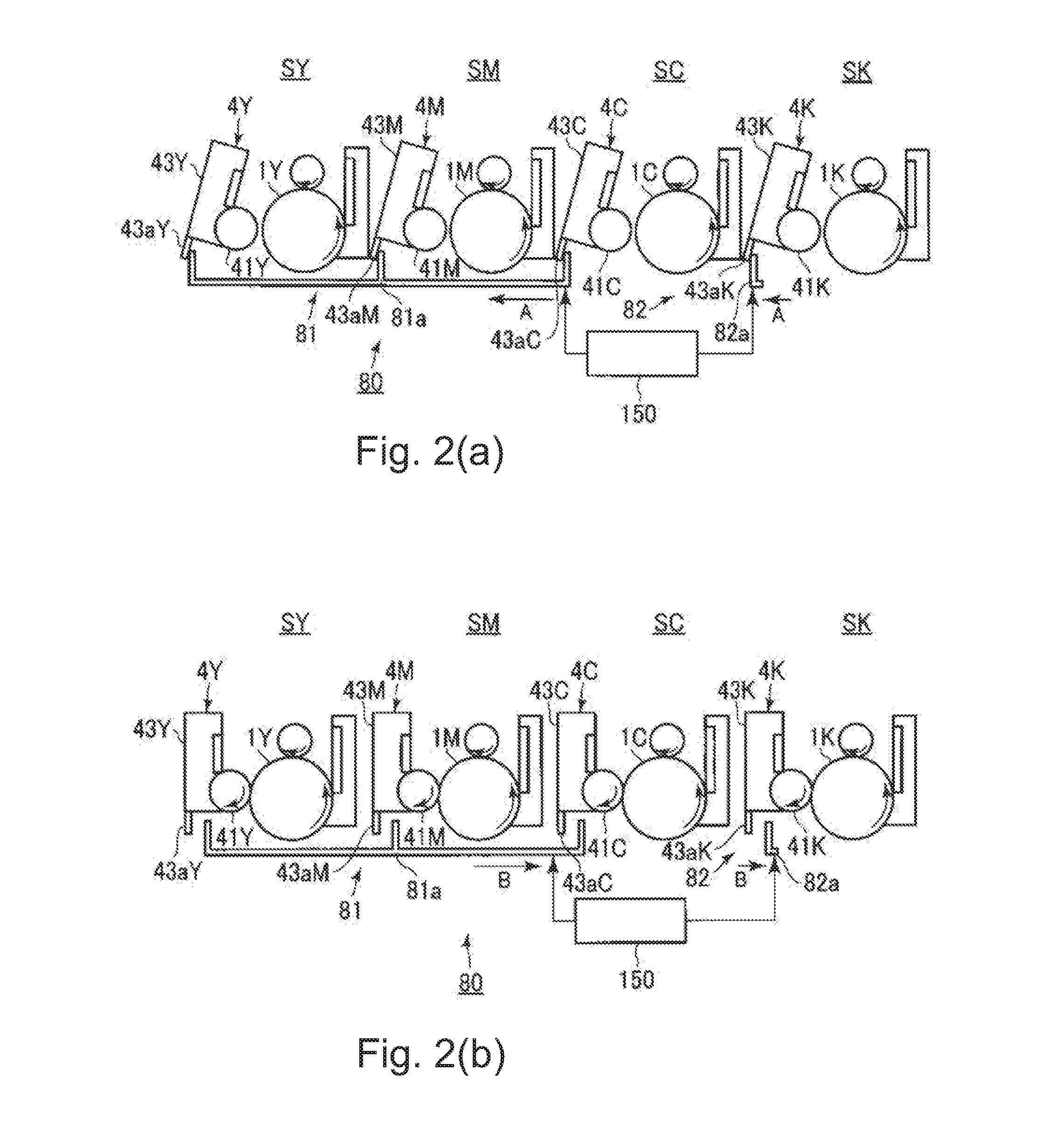

ActiveUS20160231693A1Simple constitutionLow costElectrographic process apparatusLatent imageImage formation

An image forming apparatus includes image bearing members, a latent image forming portion, developing units each including a developing member, a movable member, a common driving source, a contact-and-separation unit, and a control unit. The image forming apparatus is capable of forming the images in an operation in an image forming mode. After end of the latent image formation on one of the image bearing members on which latent image formation is finally started and before end of transfer of an associated image from the one image bearing member, the control unit outputs a spacing signal for spacing associated developing members from the other image bearing members, during the image formation in the operation in the mode.

Owner:CANON KK

Toner and method of producing toner

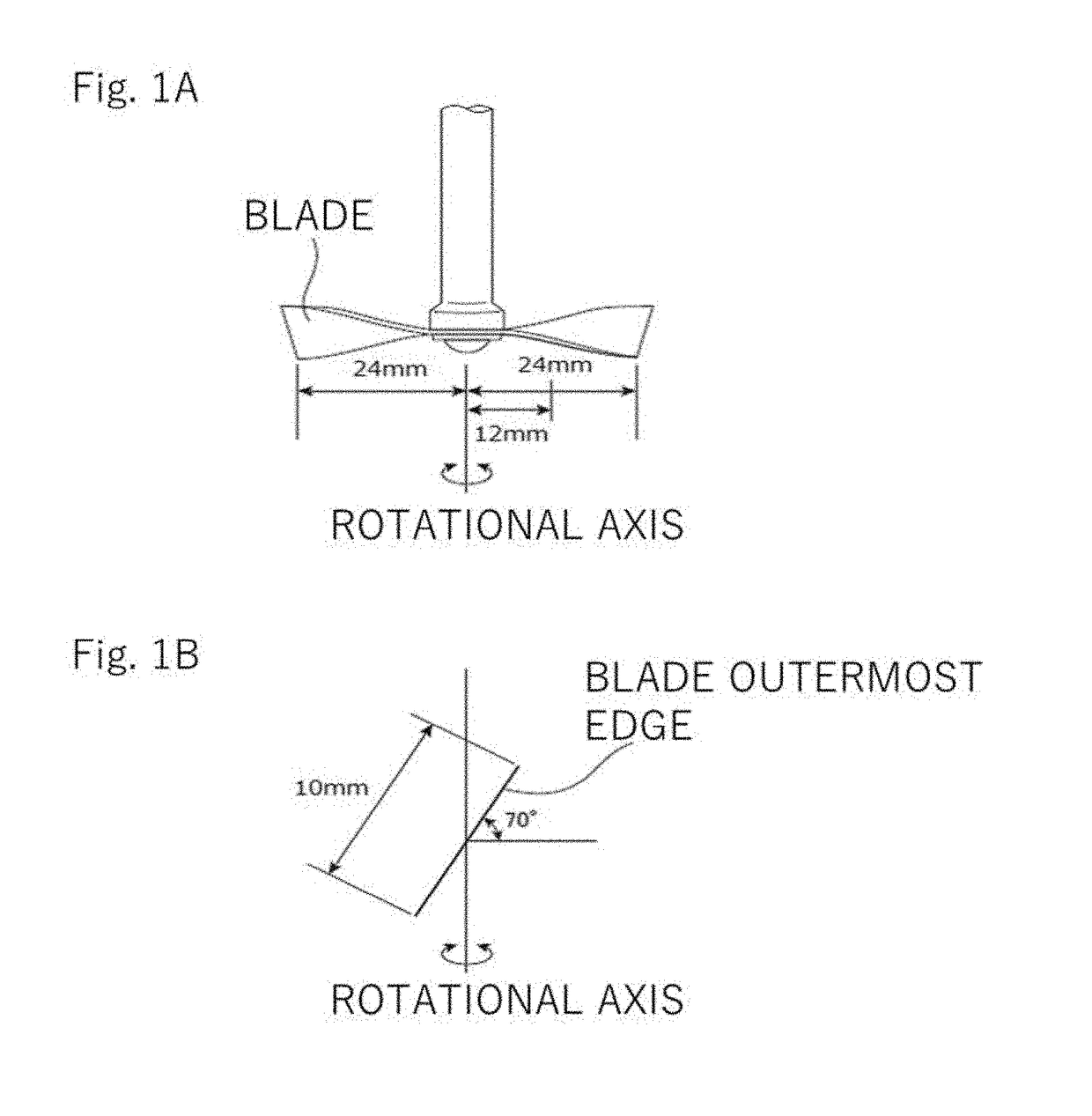

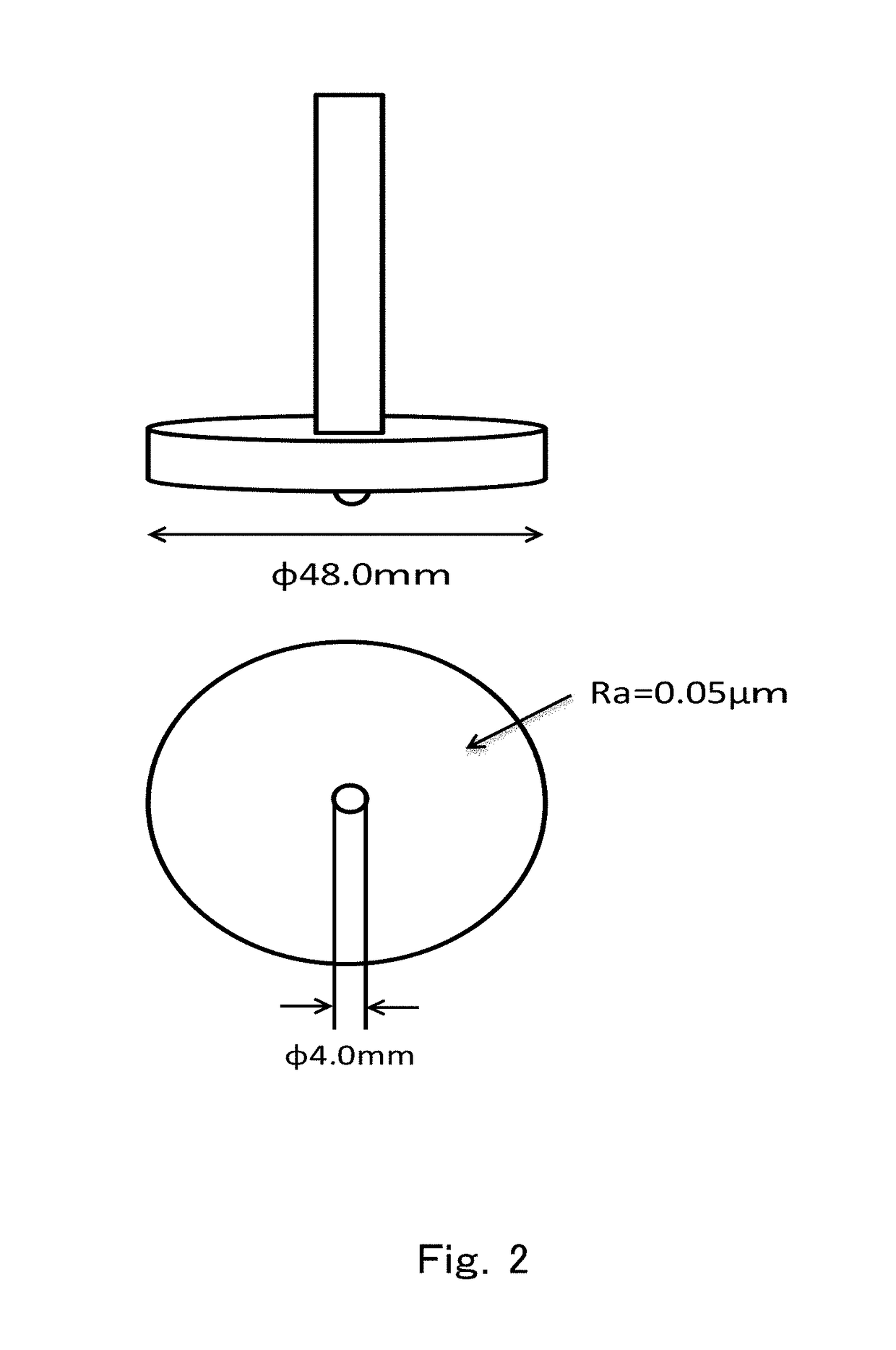

ActiveUS20180074425A1Lower performance requirementsElectrostatic attachment force between the photosensitive drum and toner is increasedDevelopersCharge controlFriction angle

A toner comprising an external additive A, and a toner particle containing a binder resin and a colorant, wherein the external additive A: i) is an external additive that has a charge control agent on the surface thereof; ii) has a wall friction angle θ calculated from the following formula (1) of not more than 25.0°θ=τ / 5.0 formula (1);iii) has a number-average particle diameter (D1) of primary particles of at least 70 nm and not more than 500 nm; and iv) has a solidity as given by the following formula (2) of at least 0.40 and not more than 0.90solidity=area of external additive A / area of region encompassed by envelope for external additive A formula (2).

Owner:CANON KK

Image forming apparatus having a photosenstive member of high capacitance

ActiveUS8326165B2Suppresses image defectsIncrease capacitanceElectrographic process apparatusCapacitanceImage formation

Owner:CANON KK

Image forming apparatus

InactiveCN1959555ASuppresses image defectsAchieving long-term availabilityElectrographic process apparatusEngineeringVolume average

An image forming apparatus includes an image bearing member; a developer carrying member, contactable to the image bearing member, for carrying a developer to a developing position to develop an electrostatic image formed on the image bearing member with the developer; a supplying member for supplying the developer to the developer carrying member, wherein a peripheral speed of the developer carrying member is not less than 1.05 times and not more than 1.20 times a peripheral speed of the image bearing member, and an arithmetic average roughness Ra is not less than 0.20 times and not more than 0.33 times a volume average particle size of the developer, wherein a potential applied to the supplying member is different from a potential applied to the developer carrying member toward a larger potential of a regular charge polarity of the developer.

Owner:CANON KK

Image processing method and image processing apparatus, and image forming apparatus comprising image processing apparatus

InactiveUS20060256151A1Suppresses image defectsVisual presentationPrintingImaging processingComputer graphics (images)

An image processing method comprises the steps of: determining dot arrangement in forming an image with dots on a recording medium; and forming the image on the recording medium by means of a dot formation device according to the dot arrangement, wherein dot arrangement data concerning each of dot formation positions on the recording medium is created from input image data, according to a dot model which is established with respect to each of the dot formation positions, the dot model being determined according to at least one of dot formation characteristics of the dot formation device and fixing characteristics of the recording medium, and including information relating to at least one of a dot shape, dot density, a dot position, and presence or absence of a satellite, of each dot formed on the recording medium.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com