Beverage pouring and boiling device

A beverage and brewing technology, which is applied in the field of beverage making devices, can solve the problems of flushing raw materials that cannot be beverages, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

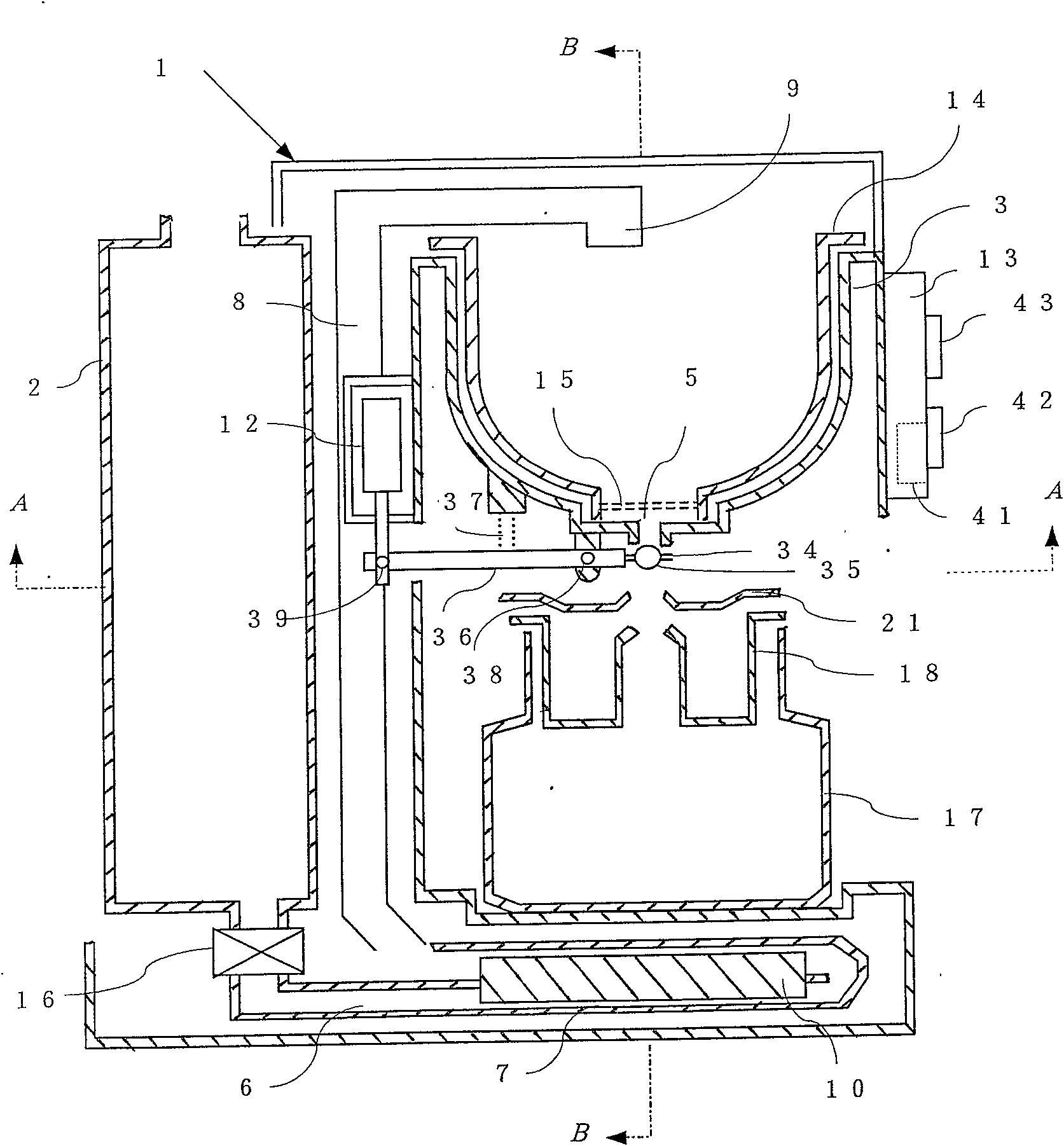

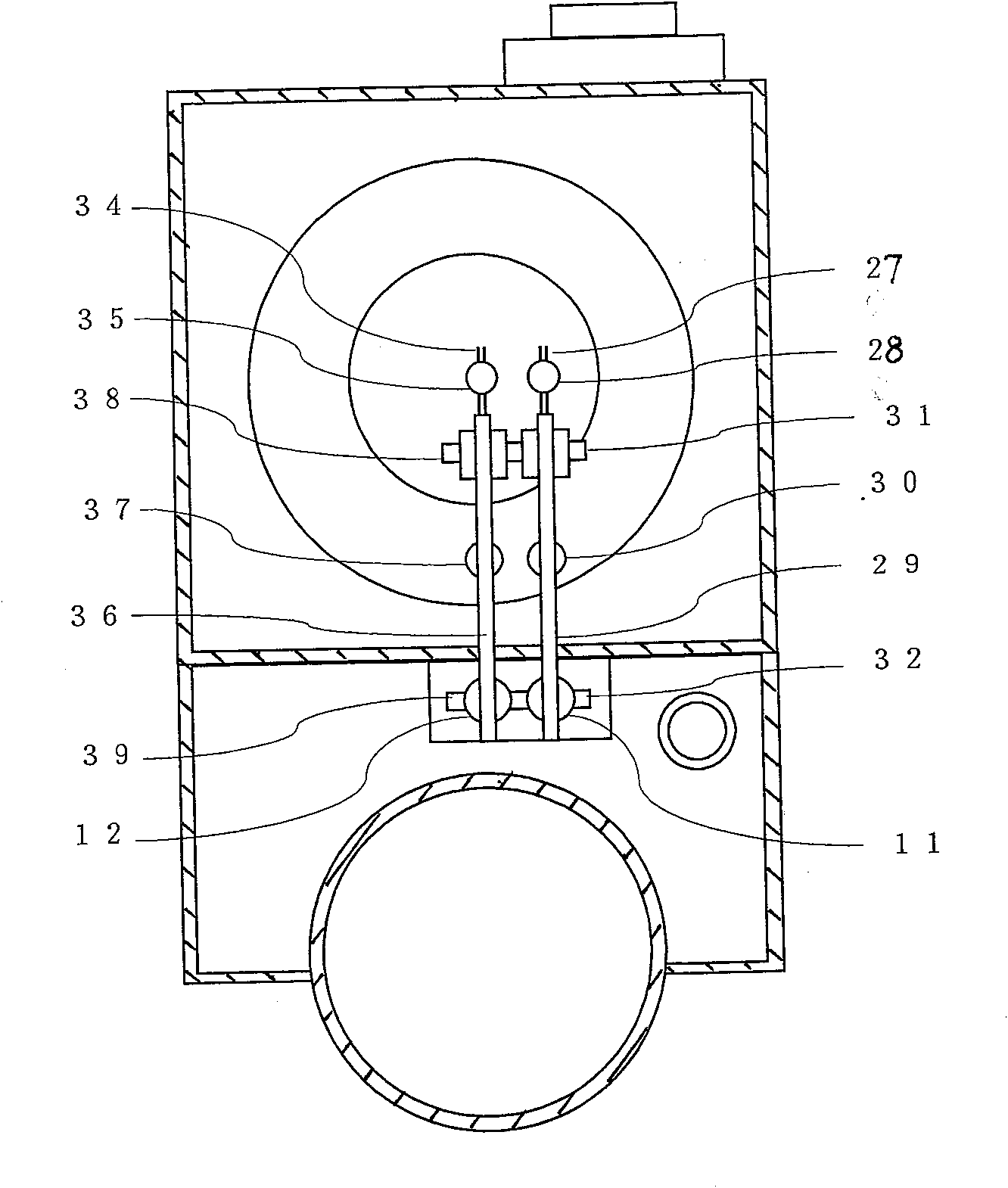

[0031] like figure 1 and figure 2 Shown is the schematic diagram of the design structure of Embodiment 1. The host 1 of the beverage brewing device of the present invention is mainly composed of a water storage tank 2 for storing normal-temperature drinking water, a heater 10, a beverage brewing container 3, and a water supply pipe 6 connected to the water storage tank 2 (the water supply pipe 6 includes a heating part where the heater 10 is arranged. 7 and guide the boiling water in the heating part 7 to the flow guide part 8 (tubular channel) and the boiling water part 9 in the beverage brewing container 3), the first electromagnetic coil 11 and the second electromagnetic coil 12, the above two coil control The valve control system, the opening and closing control system 13 that controls the two coils, etc. are composed. Beverage brewing system 3 internal design is equipped with the special filter bag 14 that can be freely disassembled for holding tea leaves, and the mesh...

Embodiment 2

[0042] like Figure 7 As shown, the present embodiment is basically the same as the first embodiment, the difference being that the beverage brewing container 3 is equipped with a free detachable coffee special filter bag 44 specially used for brewing coffee to replace the special filter bag 14, the special filter bag The cross-sectional shape of 44 is designed to be conical, and a hole 45 corresponding to the second water outlet 5 is provided at the bottom thereof.

[0043] Next, the working principle of this embodiment will be described. When the user is brewing coffee, first use the above-mentioned mode switching switch 43 to select the type of brewed beverage as coffee, install the sand mesh filter (not shown in the figure) into the special filter bag 44 for coffee, and put it into the filter bag as required. Amount of coffee powder, press the start switch 42 to turn on the power, and the system starts to work. As described in Embodiment 1, the heater 10 heats the water ...

Embodiment 3

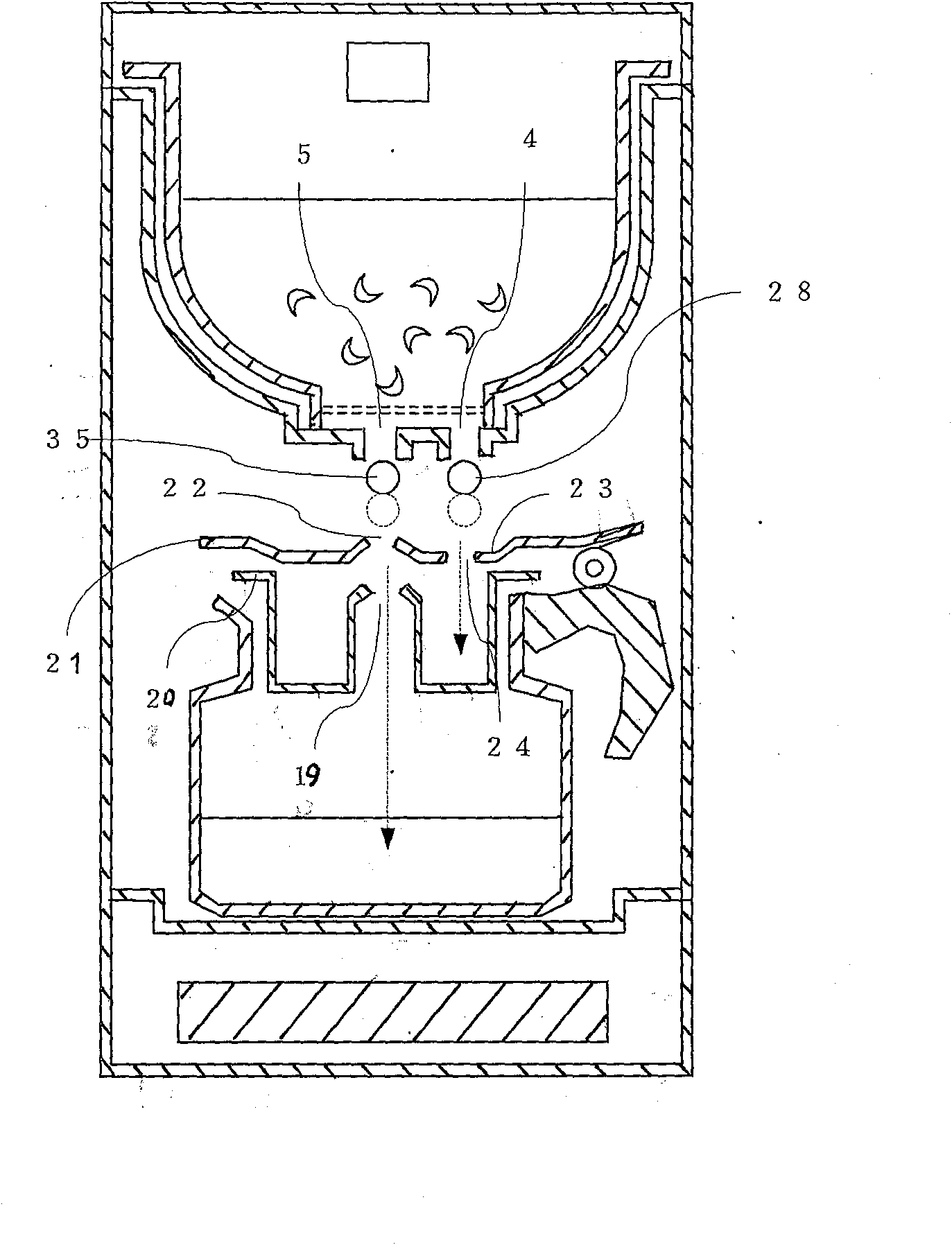

[0046] like Figure 8 , Figure 9 Shown is the schematic diagram of the design structure of the third embodiment. The host 1 of the beverage brewing device of the present invention includes a beverage brewing container 3, a first brewing control device and a second brewing control device, the first brewing control device includes a first operation control part and the first operation control part controls The first valve control part, the second brewing control device includes a second operation control part and a second valve control part controlled by the second operation control part.

[0047] Inside the beverage brewing container 3, a special filter bag 14 that can be freely installed and disassembled is designed and installed, and a mesh filter 15 that can hold tea leaves and filter drinking water is installed on the lower water outlet of the special filter bag 14. The bottom of the beverage brewing container 3 is designed with a first water outlet 4 and a second water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com