Guiding wire device of electric discharge wire cutting machine tool

A technology of cutting machine tools and electric discharge wires, applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems affecting the stability of the electrode wire in the processing area, the length limit of the envelope section, etc., and achieve the role of strengthening the limit guide , Improve the stress concentration phenomenon, reduce the effect of manufacturing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

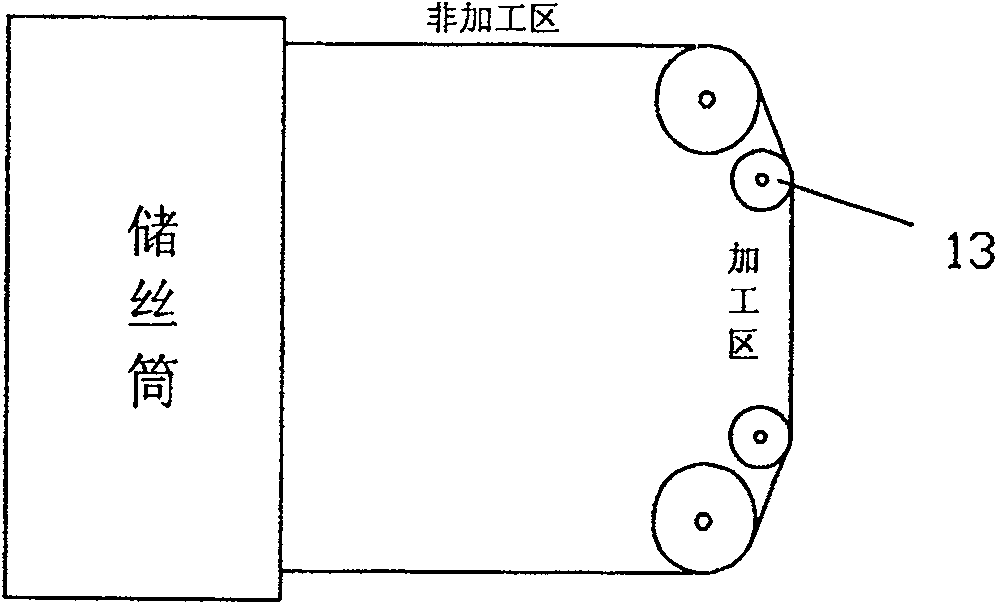

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

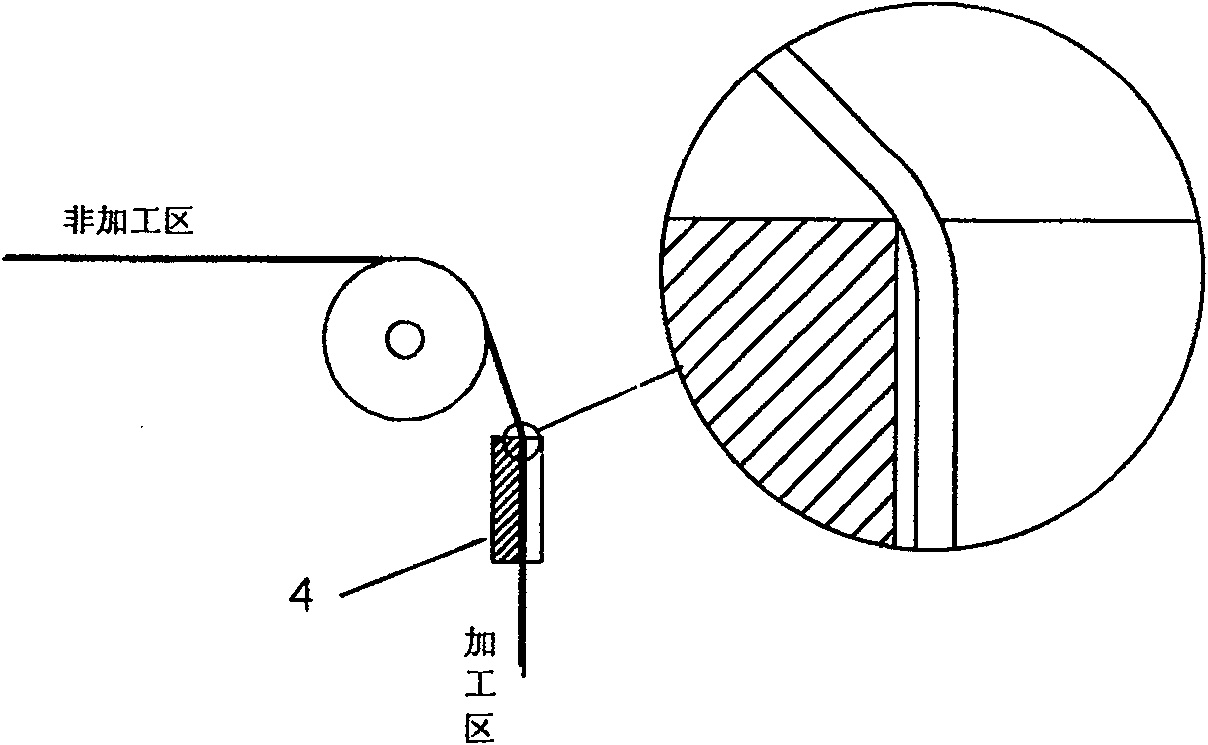

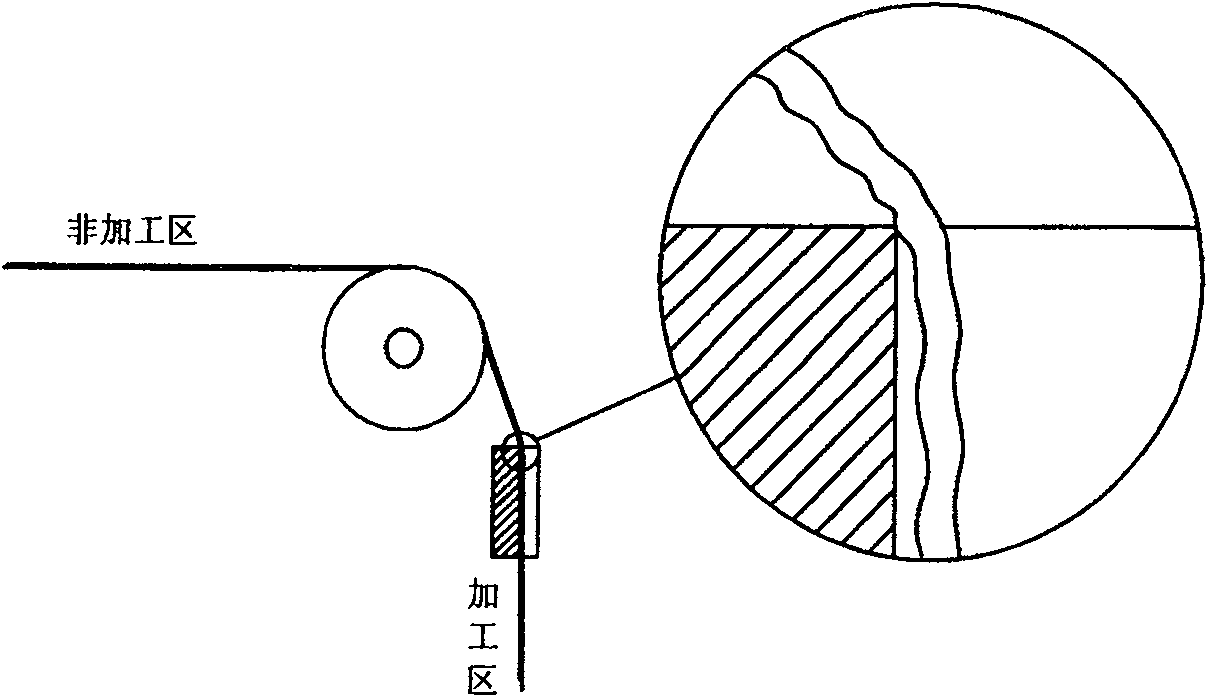

[0028] Such as Figure 5 , 6 As shown, the guide wire device is composed of a fixed base 1 and a guide wire block 2. The guide wire block 2 is installed on the fix base 1. The main body of the guide wire block 2 is a cuboid, on which there is a symmetrical curved surface 5, 6, and the curved surface 5 It intersects with the curved surface 6 at the bottom to form a V-shaped groove 7 .

[0029] Such as Figure 7 , 8 , 9, the guide wire block 2 is composed of a left cuboid 3 and a right cuboid (figure omitted) that is completely symmetrical with it, and a curved surface 5 that meets the requirements is obtained through processing, and the left cuboid 3 and the right cuboid are assembled at the surface 8. The above-mentioned guide wire block 2 is obtained.

[0030] The radius of the bottom surface of the curved surface 5 is greater than 20mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com