Charge pump circuit

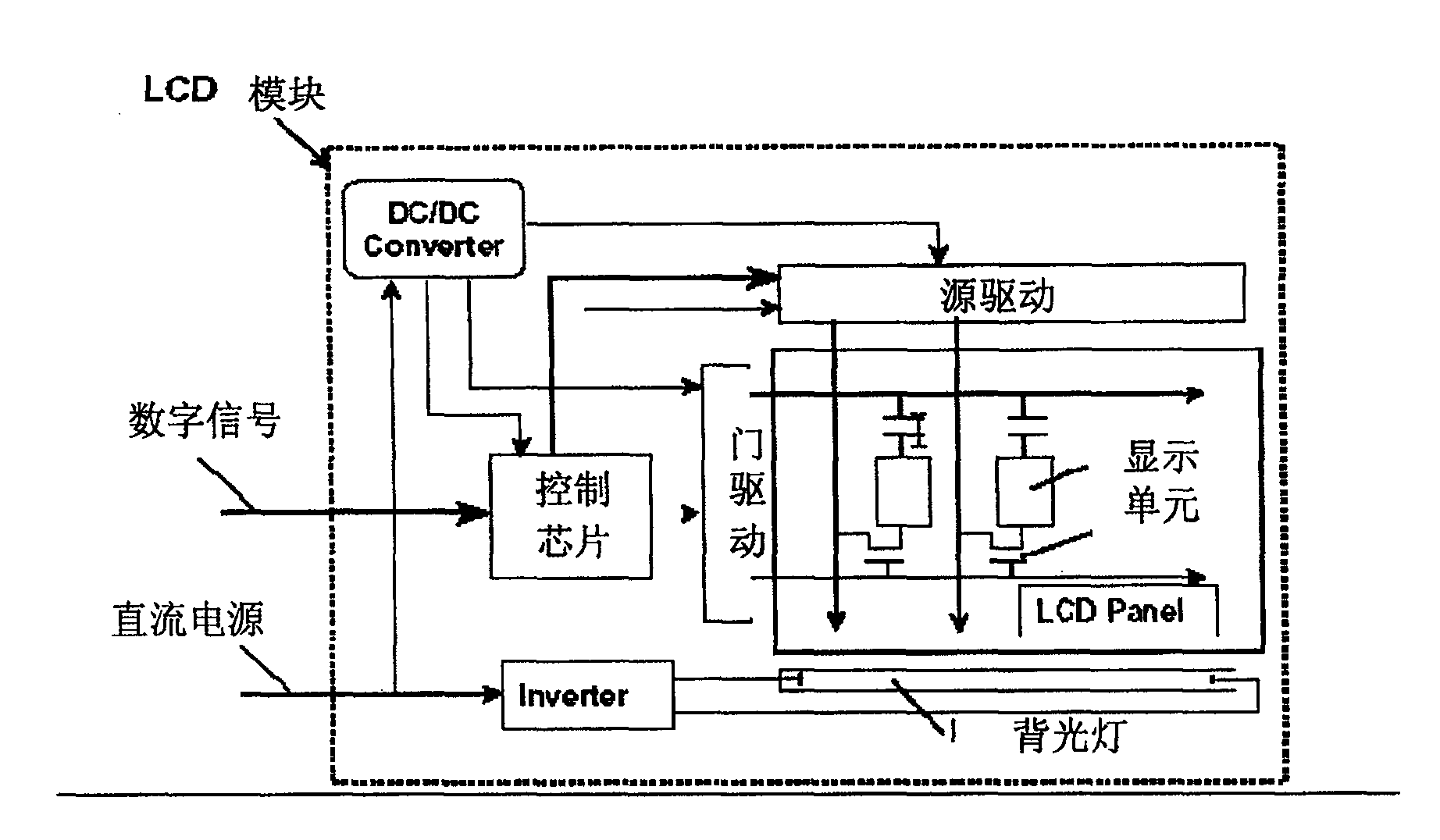

A charge pump and circuit technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve problems such as being unsuitable for low-voltage operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

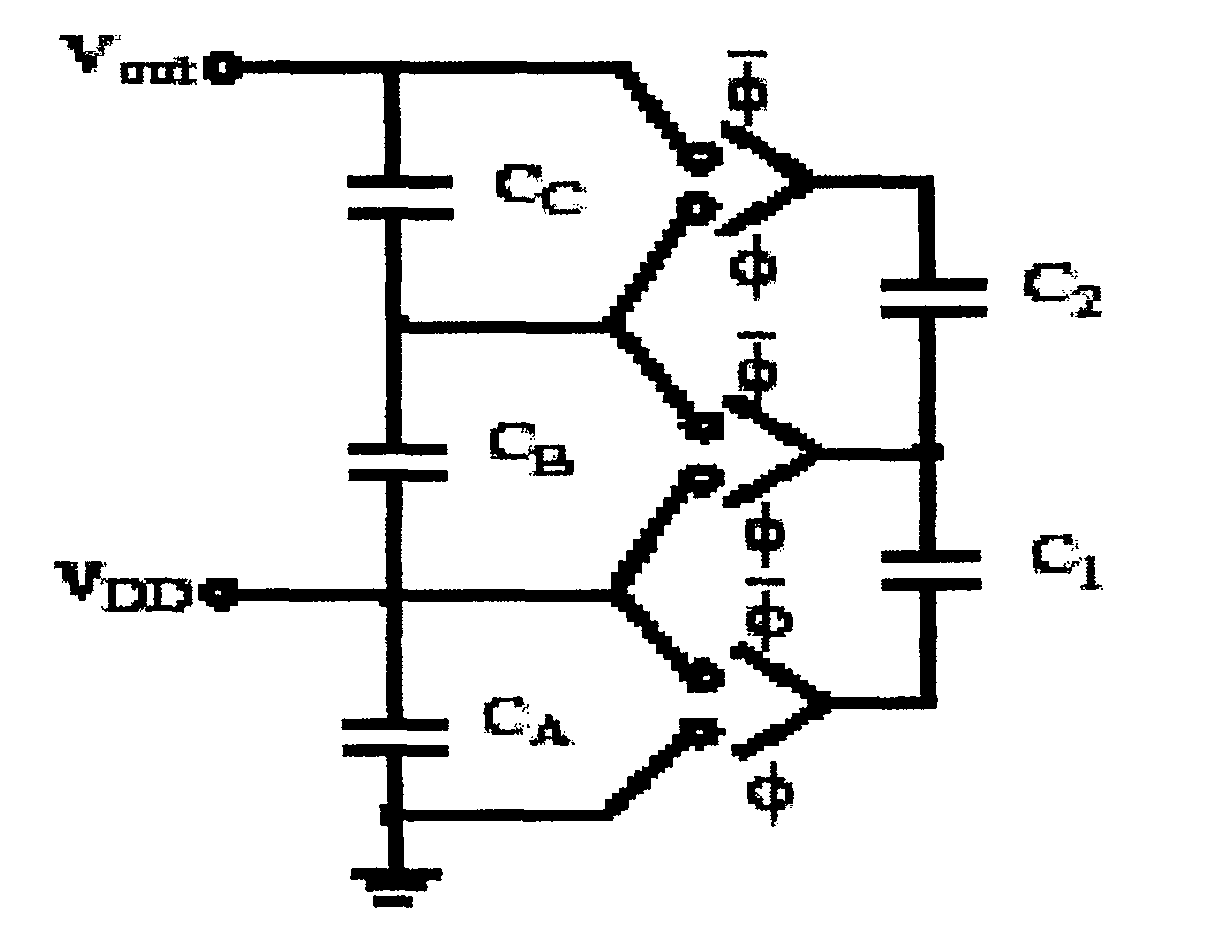

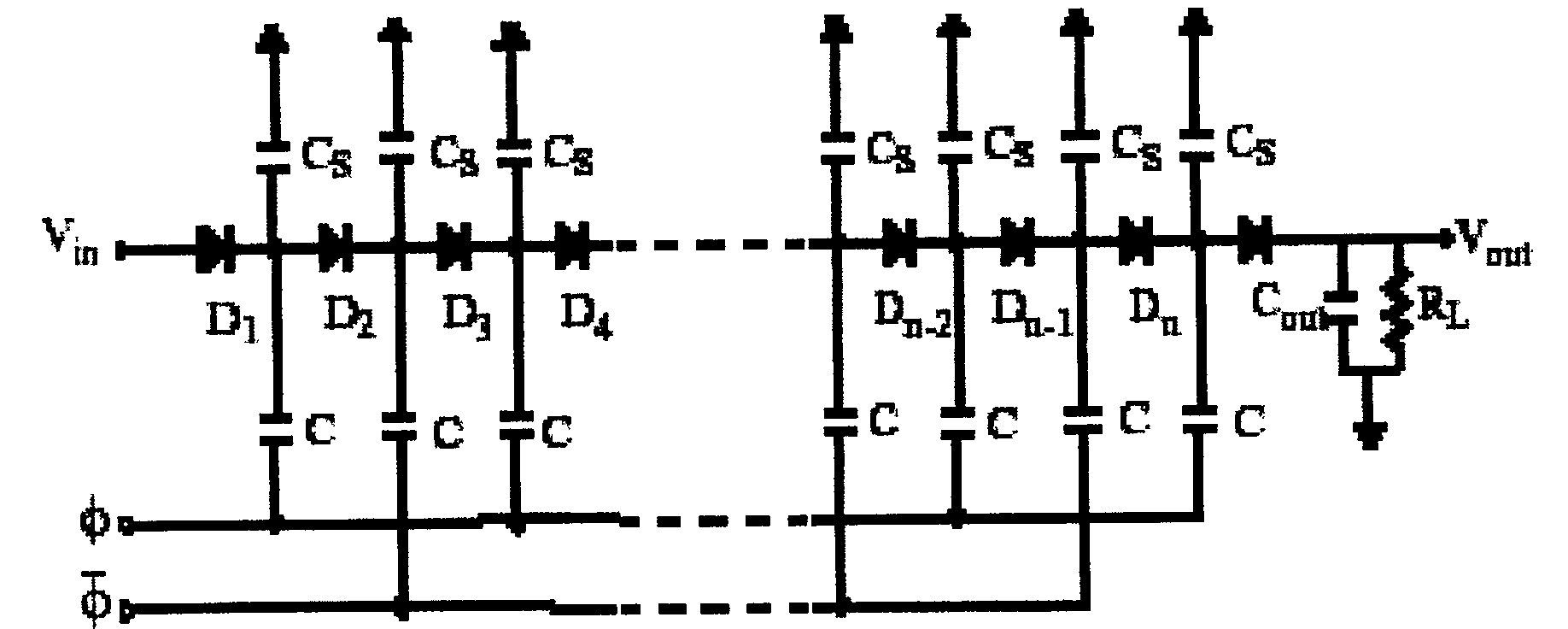

[0023] Figure 4 It is a functional module diagram of a digitally controlled charge pump, which consists of a logic control circuit and many separate analog modules with different functions (including the first-stage doubler, the second-stage tripler, the third-stage sextupler, the fourth-stage stage doubler and output stage). VDD provides the reference voltage of the charge pump and is directly input into the first-stage doubler 1, the output of the doubler 1 is connected to the input of the second-stage tripler 2, and the output of the tripler 2 is connected to the The input end of the third stage sextupler 3 is connected, the output end of the sextupler 3 is connected with the input end of the fourth stage plus doubler 4, and the output end of the doubler 4 is connected with the output stage 5 The input ends are connected, and the output ends of the logic control circuit are sequentially connected in parallel to control the first-stage doubler 1, the second-stage tripler 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com