Sliding type joint angle

A connection angle and sliding technology, applied in windows/doors, building components, buildings, etc., can solve the problems of difficult use of profile frames, poor connection quality, easy to disengage, etc., and achieve simple structure, low cost, firm and safe connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

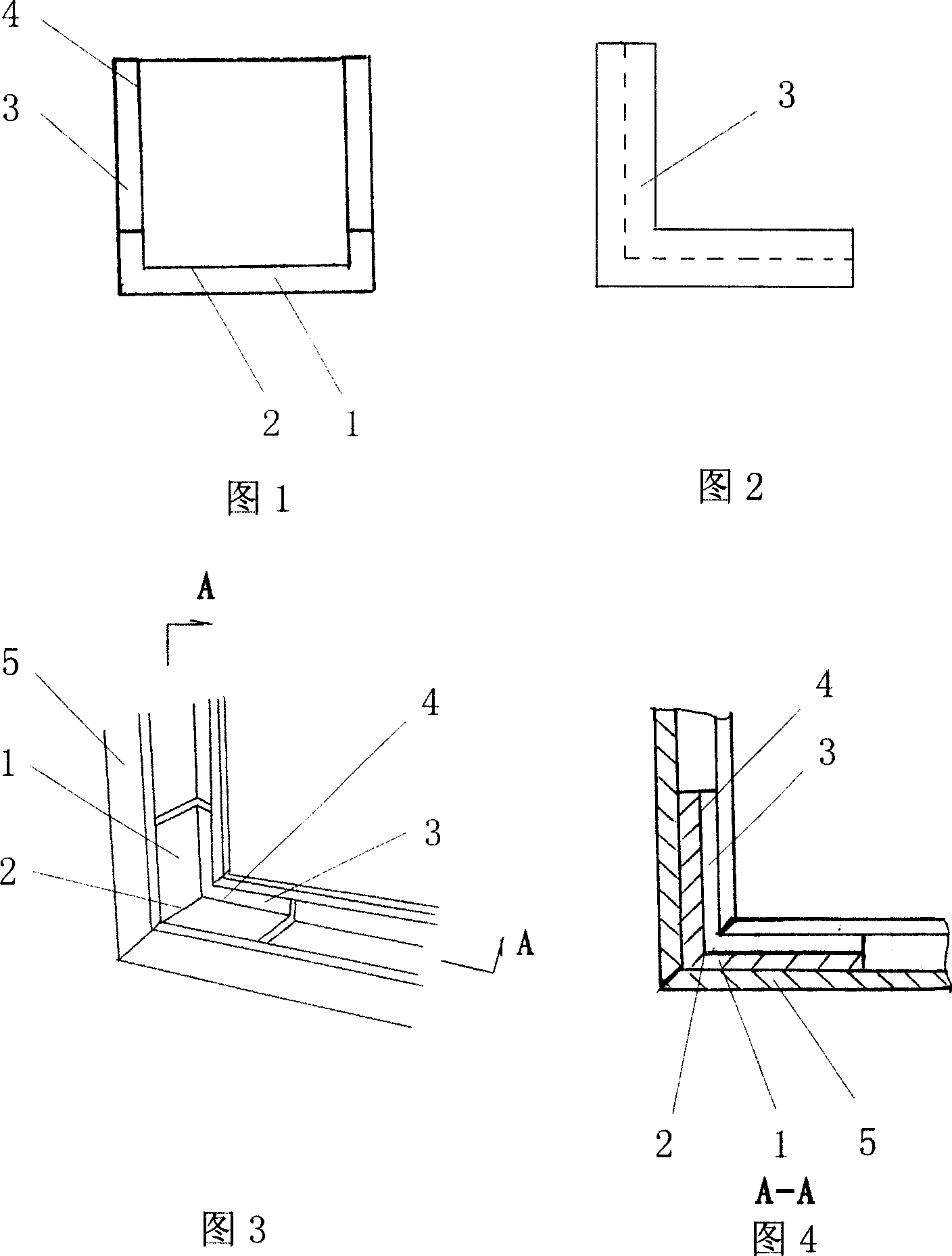

[0015] As shown in Figure 1 and Figure 2, the sliding connection angle is folded into 90 degrees by the flat rectangular body 1 and the crease line 2 at the set position in the length direction of the body 1, and the two sides of the body 1 in the width direction are respectively provided with connecting parts 3 composition.

[0016] The connecting part 3 is formed by folding 90 degrees toward the main body 1 at the crease line 4 at a set position on the main body 1 .

[0017] Each top end of the connecting portion 3 is respectively provided with rounded corners.

[0018] When specifically using the present invention to install the connected parts 5, as shown in Figure 3 and Figure 4, it is only necessary to process the butt joints of the connected parts 5 into 90-degree slopes, and then insert the connected parts 5 into 90-degree slopes. On the body 1, quick installation and positioning are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com