Plane lamp source and its manufacturing method

A manufacturing method and technology of flat lamps, applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve problems such as low service life and high ignition voltage, and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

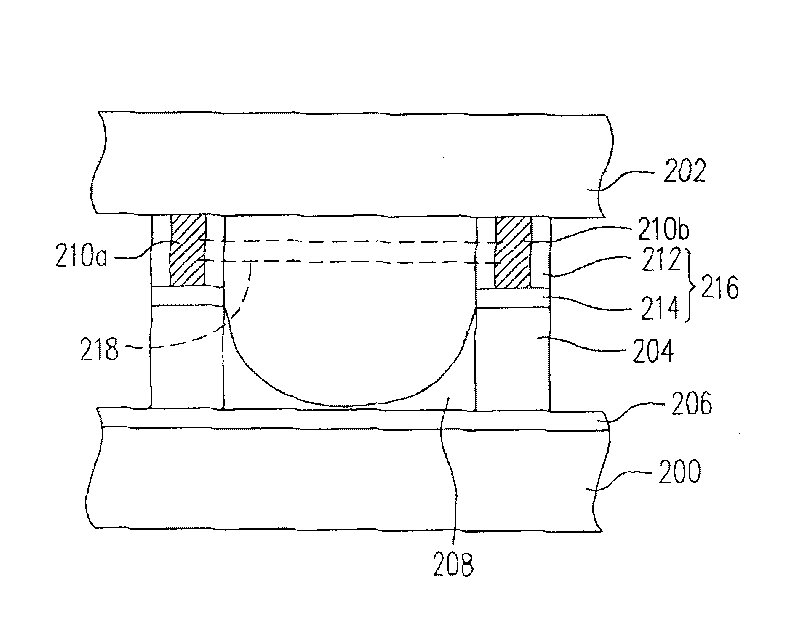

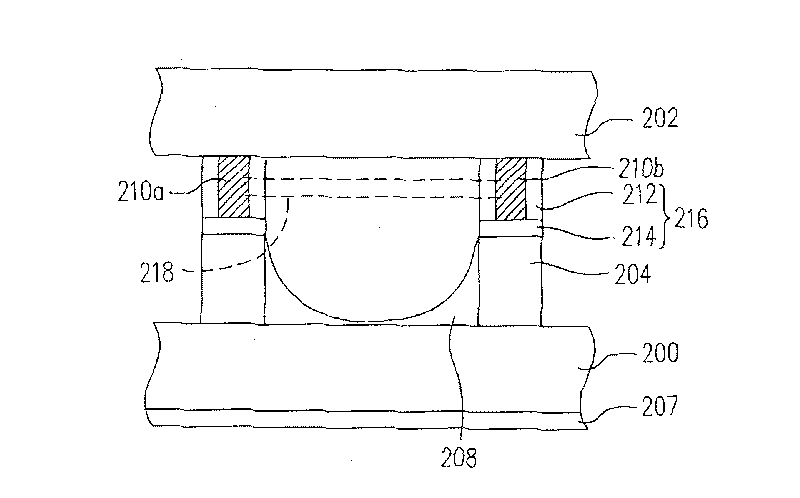

[0052] figure 2 It is a schematic diagram of a planar light source according to an embodiment of the present invention. Please refer to figure 2 The planar light source of this embodiment includes a first substrate 200 , a plurality of barrier walls 204 , a fluorescent layer 208 , a second substrate 202 , a plurality of electrode patterns 210 a , 210 b and an insulating layer 216 .

[0053]The material of the first substrate 200 and the second substrate 202 is, for example, transparent glass. The barrier wall 204 is arranged on the first substrate 200. In one embodiment, the material of the barrier wall 204 includes glass. In addition, the height of the barrier wall 204 For example, it is between 50 and 300 microns. The fluorescent layer 208 is disposed on the surface of the barrier wall 204. In another embodiment, a reflective layer 206 may also be disposed on the surface of the first substrate 200, and the reflective layer 206 may be Make the light generated by the plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com