Electric controlled bivalve type mixer of fuel gas

A gas fuel and mixer technology, which is used in charging systems, combustion engines, machines/engines, etc., can solve the problems of natural gas engine output power change, natural gas engine use efficiency discount, and the engine cannot operate normally and safely. Long, dimensionally stable, high dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

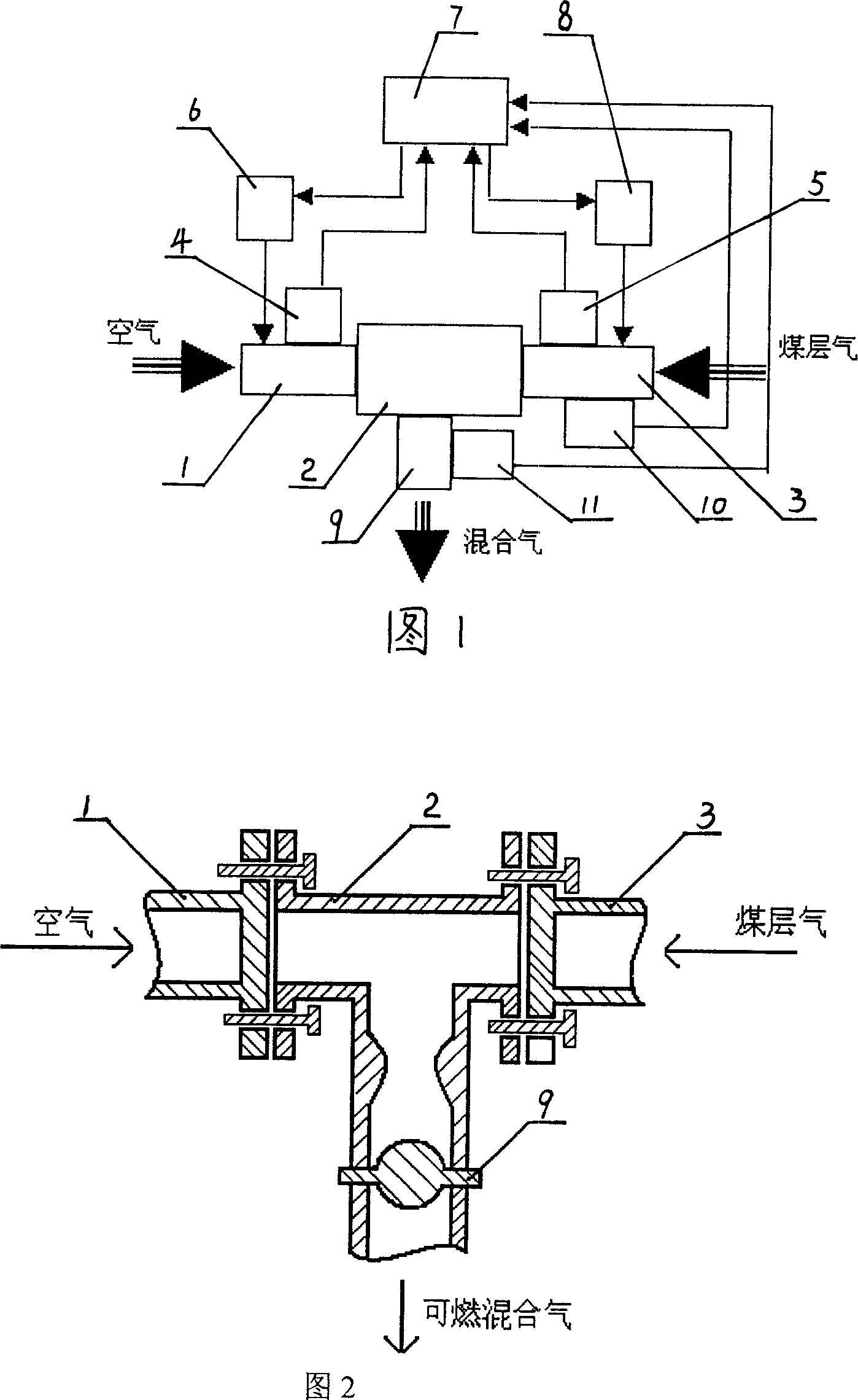

[0024] Electronically controlled double-valve gas fuel mixer, the mixing chamber casing 2 is a three-way tubular shape, and the nozzles on both sides are respectively connected to the gas valves. The gas valve on one side is the air valve 1 and the gas valve on the other side is the gas valve 3. The other side pipe of the chamber shell 2 is a Venturi throat type, and the lower part of the Venturi throat is a throttle valve 9, see Fig. 1 and Fig. 2 .

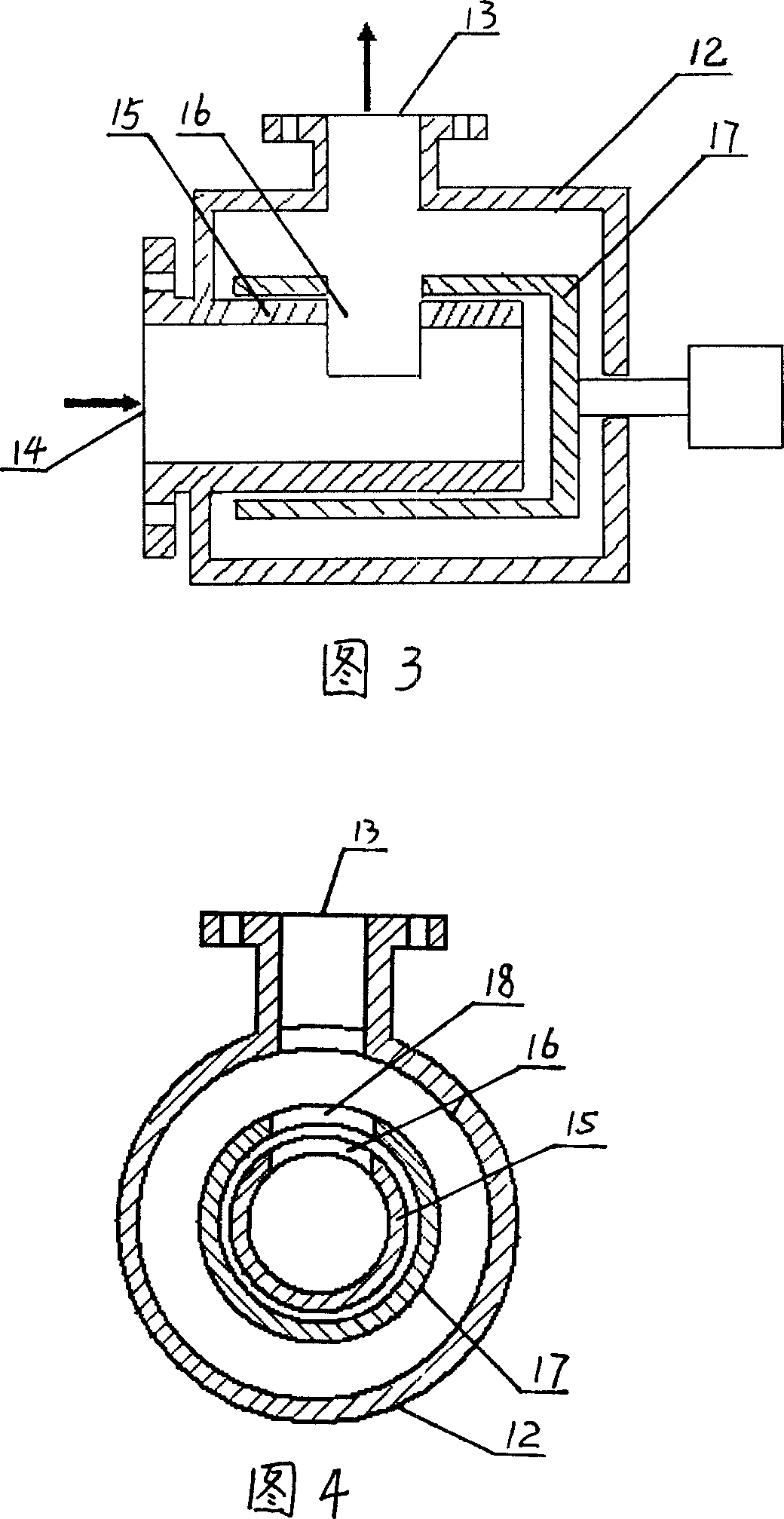

[0025] The air valve includes an outer sleeve 12. One side of the outer sleeve 12 is an outlet 13, and the other side is an inlet 14. The inlet 14 is connected to a trachea 15, and the trachea 15 extends into the outer sleeve. An air port 16 is provided, and an inner sleeve 17 is set on the air pipe 15. The inner sleeve 17 is axially connected with a stepping motor through a shaft extending to the outside of the outer sleeve 12. The stepping motor is located outside the outer sleeve 12, and the inner sleeve 17 17 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com