Structure for fixing lever switch

A technology of lever switch and assembly structure, applied in the direction of electric switch, signal device, transportation and packaging, etc., can solve the problems of assembly, parts management, parts handling trouble, etc., and achieve the effect of easy assembly and restraint of the influence of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

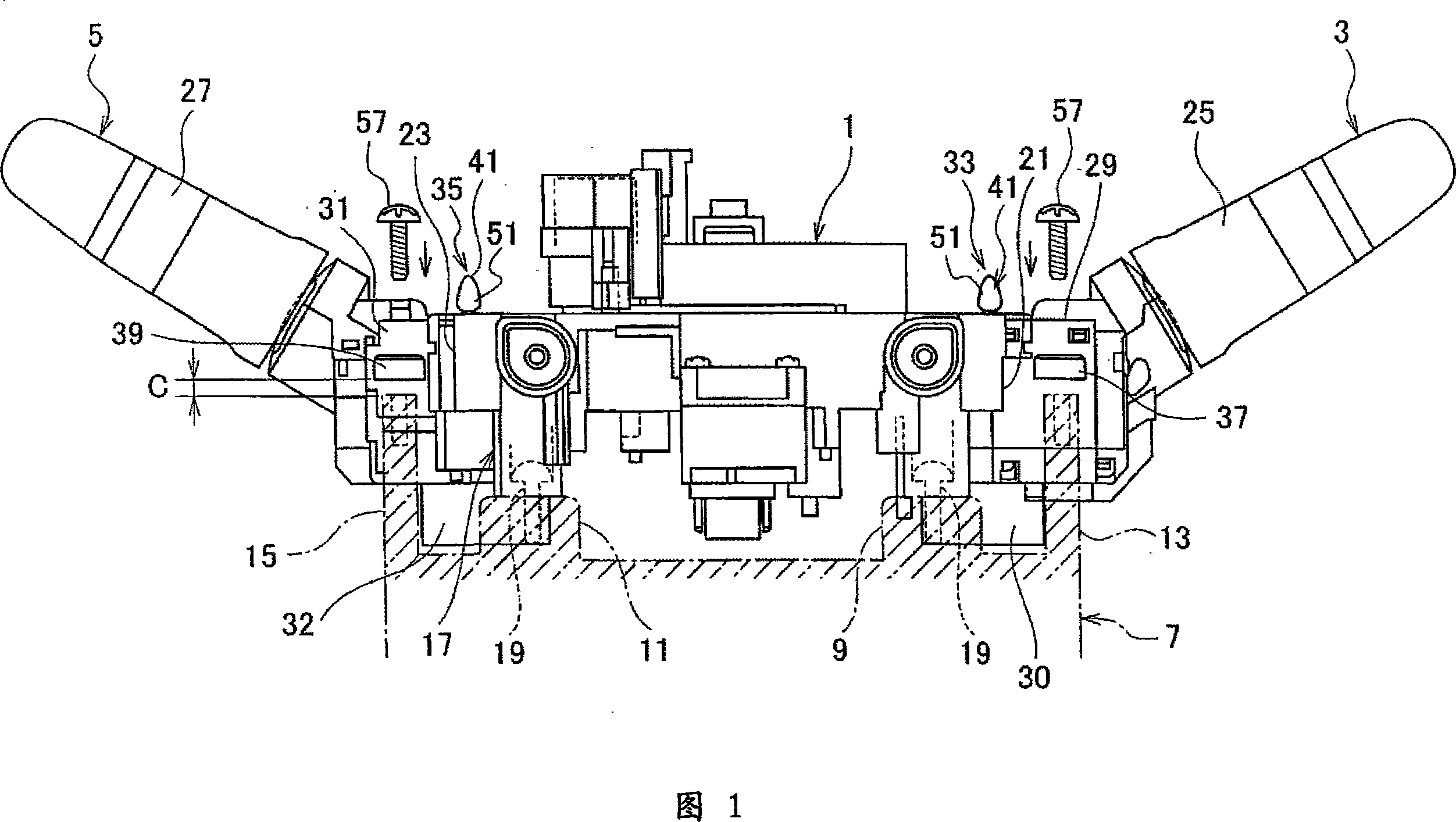

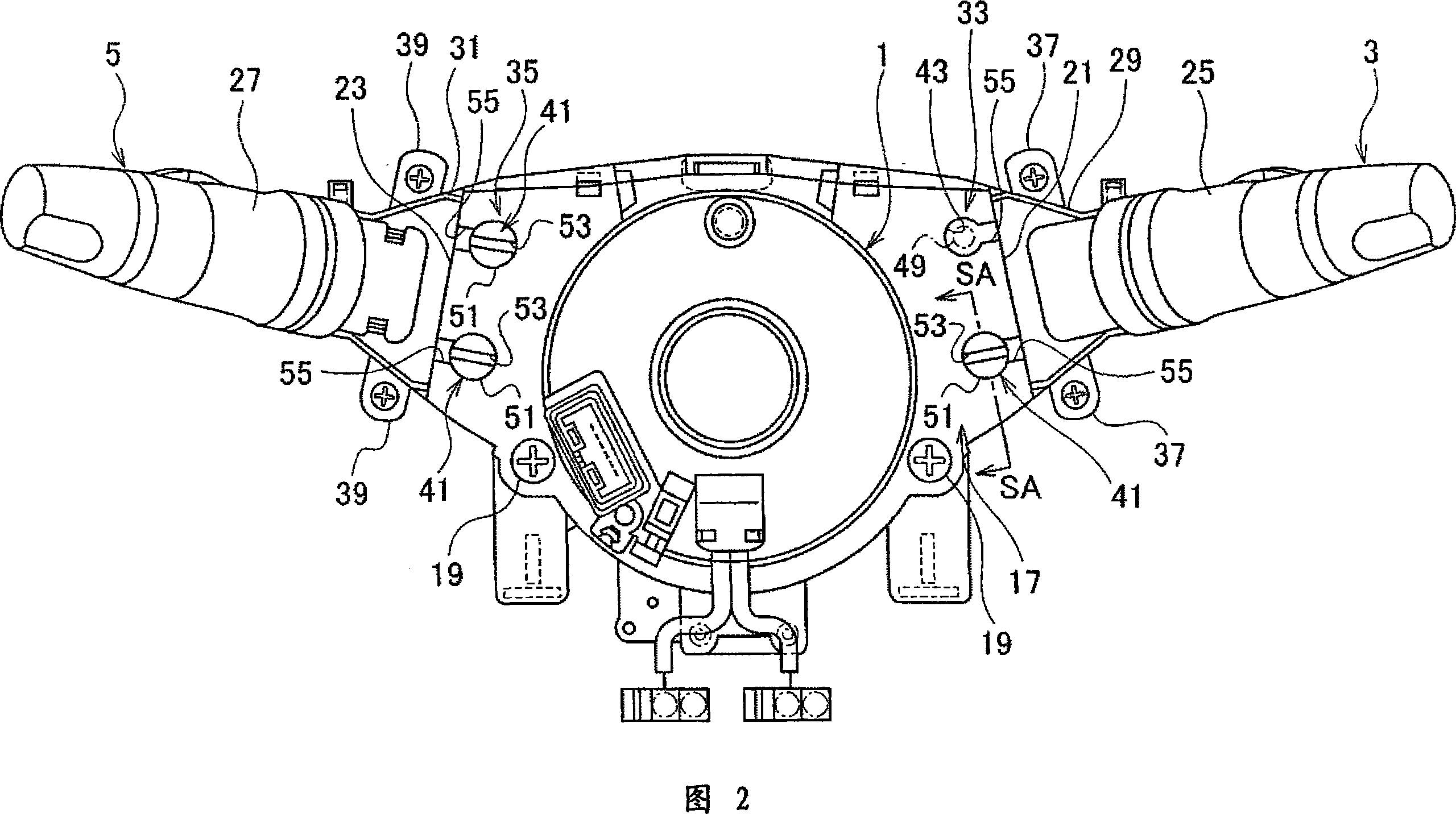

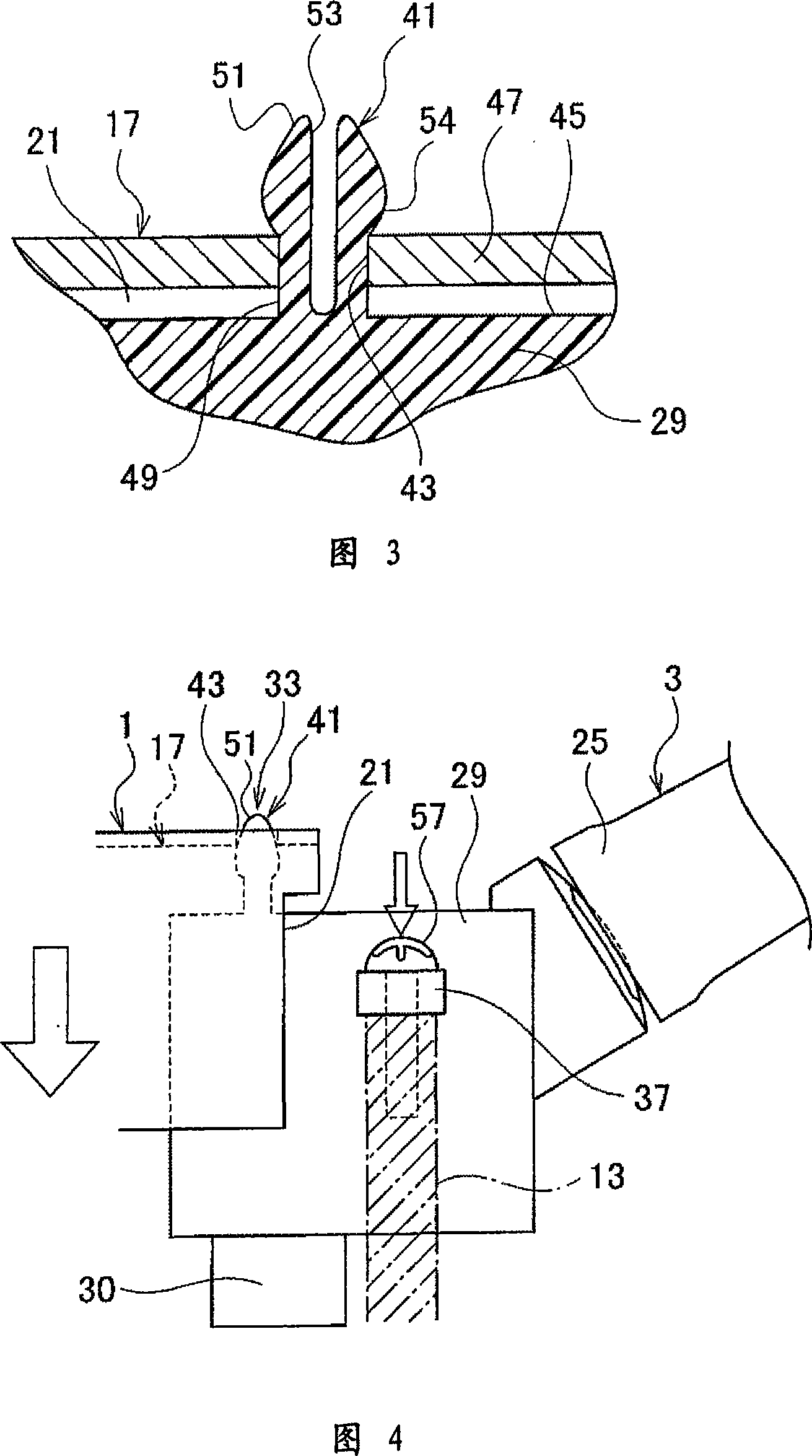

[0024] Fig. 1 and Fig. 2 are side views showing the combined switch device applicable to the relationship between the lever switch and the rotary connector in Embodiment 1 of the present invention, and Fig. 2 is its plan view. As shown in Fig. 1 and Fig. 2, the rotary connector 1, the turn signal light switch 3 as a lever switch and the wiper switch 5 are configured to be assembled on the assembly handle 7 together.

[0025] The aforementioned assembly handle 7 includes connector assembly seats 9 and 11 as connector assembly parts fixed on one side of the steering column, and switch assembly parts 13 and 15 as switch assembly parts. The connector mounts 9 and 11 are provided at, for example, two places, and the switch mounts 13 and 15 are provided at two places, for example, on the side of the lever switch 3 and the side of the wiper switch 5 , respectively.

[0026] The aforementioned rotary connector 1 is fixedly assembled on the aforementioned connector assembly seats 9 , 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com