Integrated knitting technology for athleisure shoes

A technology for sports shoes and craftsmanship, which is applied in the direction of weft knitting, shoe uppers, shoes, etc., can solve the problems of affecting the size and shape of shoes, wasting leftover materials, and time-consuming cutting by laser machines, so as to improve processing efficiency and save The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

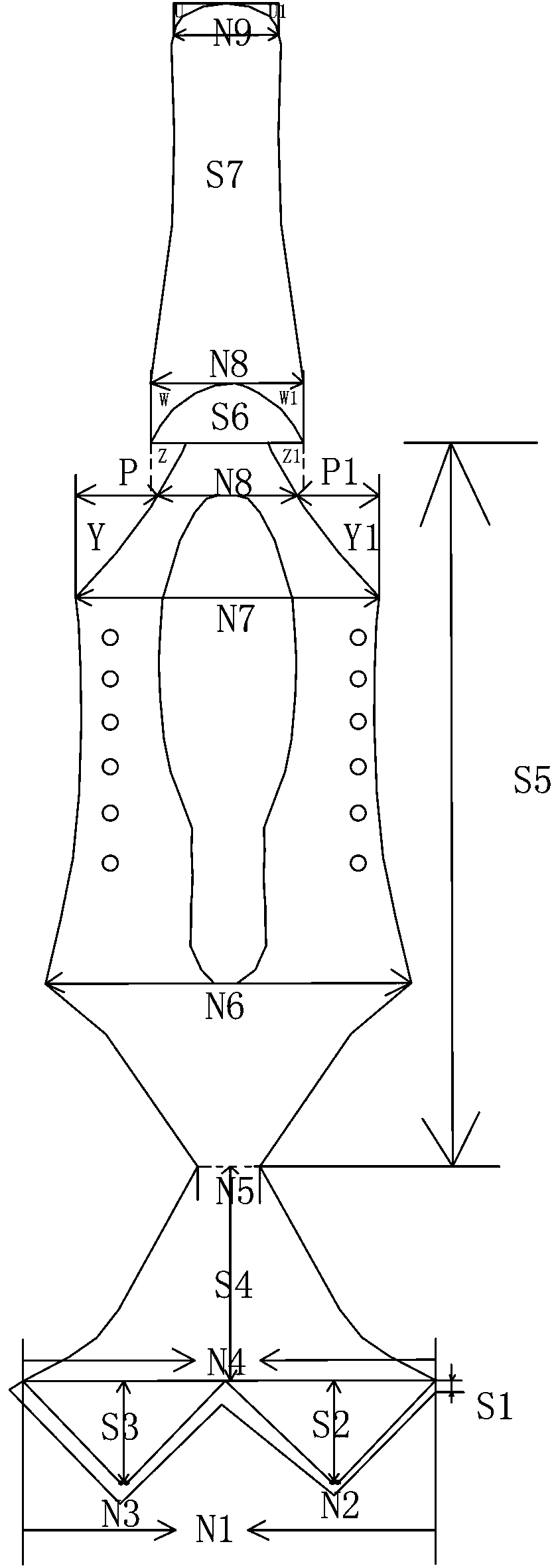

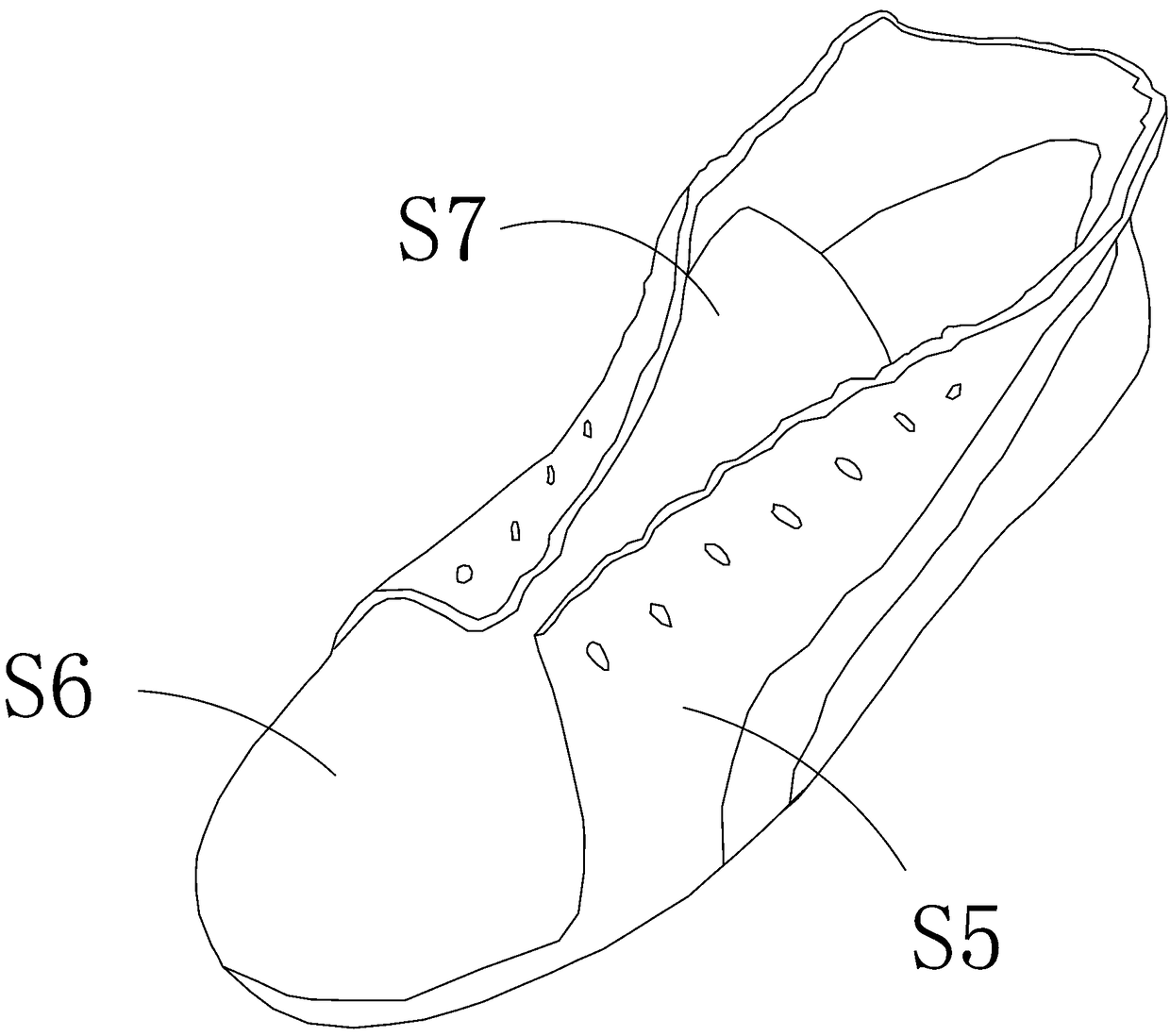

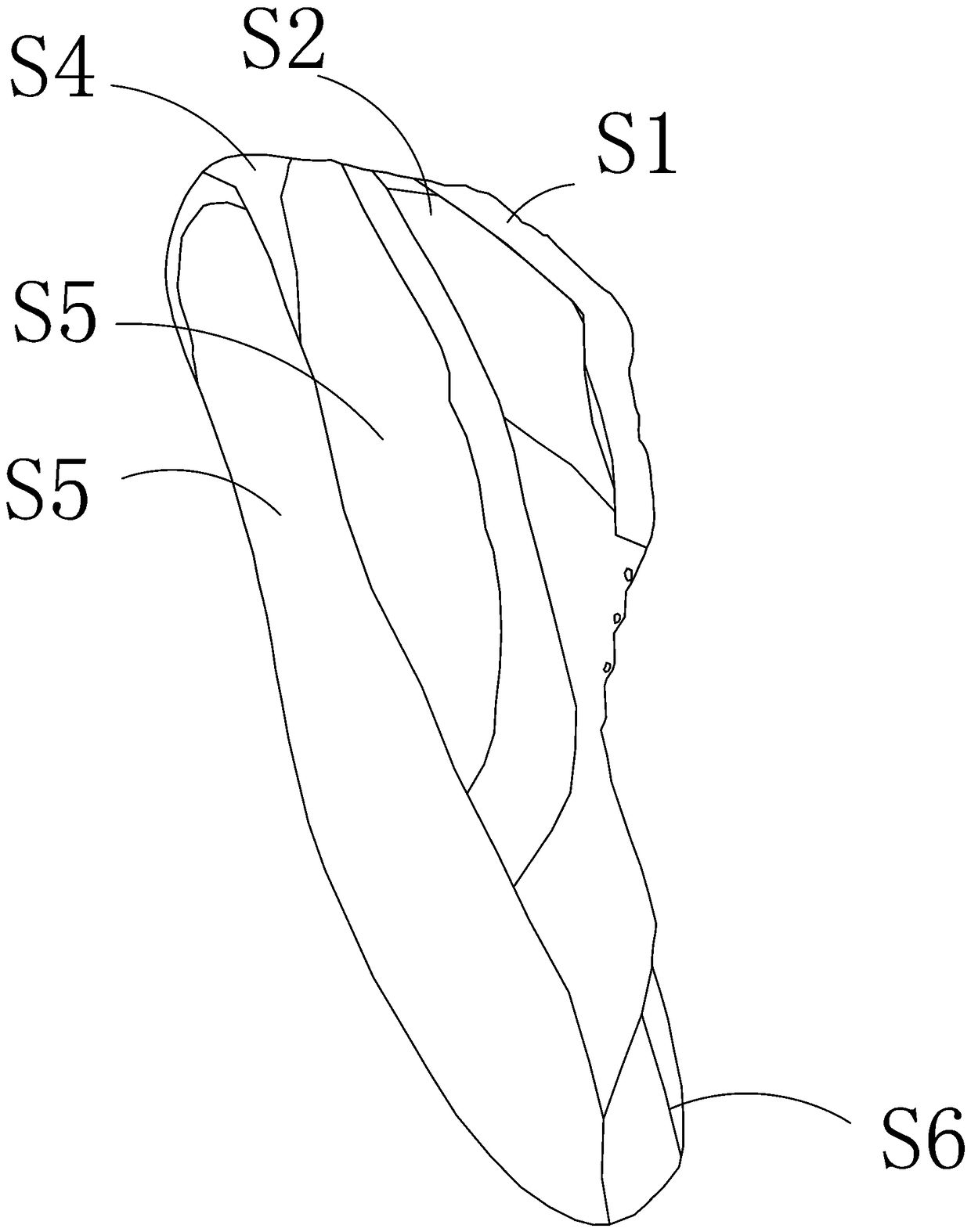

[0019] like Figure 1 to Figure 3 Shown, a kind of knitting process of casual sports shoes of one-shot molding, comprises the following steps:

[0020] (1) Weaving preparation, computerized flat knitting machine for weft knitting with one needle bed at the front and back, at least one of the needle beds of the computerized weft knitting machine can move left and right, and the needle bed has the function of transferring stitches , weft knitting computerized flat knitting machine with two or more systems, with 8 or more yarn feeders;

[0021] (2) Knitting the shoe mouth part, the knitting width of the starting needle is N1, the direction of the machine head is from left to right, and the front and rear needle beds are used to knit alternately to S1, and then the machine head is from right to left. When the knitting is completed, the machine head runs from the right Knit to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com