New type automatic exhaust steam valve

An automatic exhaust valve, a new type of technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of poor sealing performance, failure to achieve the purpose of exhaust, short life, etc., to improve the exhaust capacity and facilitate the valve Sealing, the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

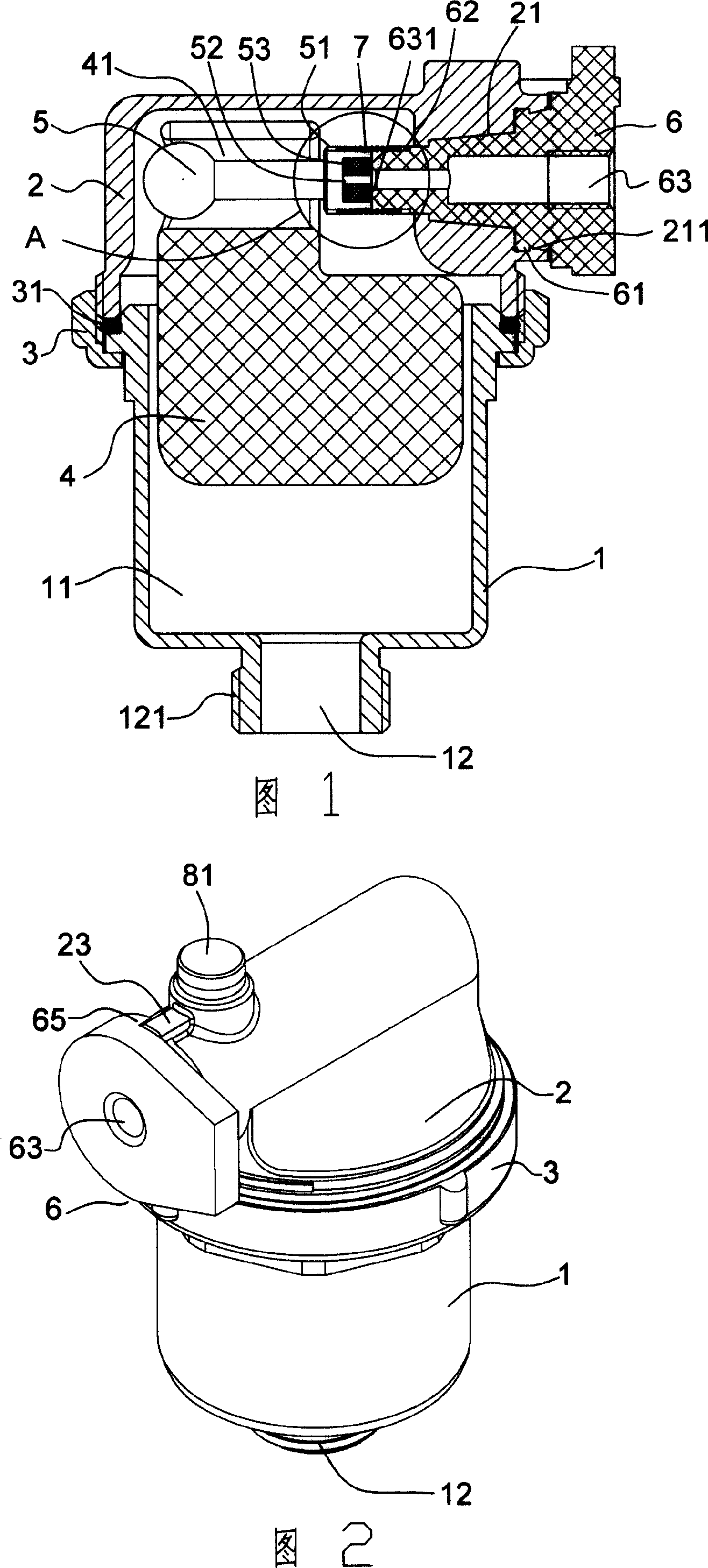

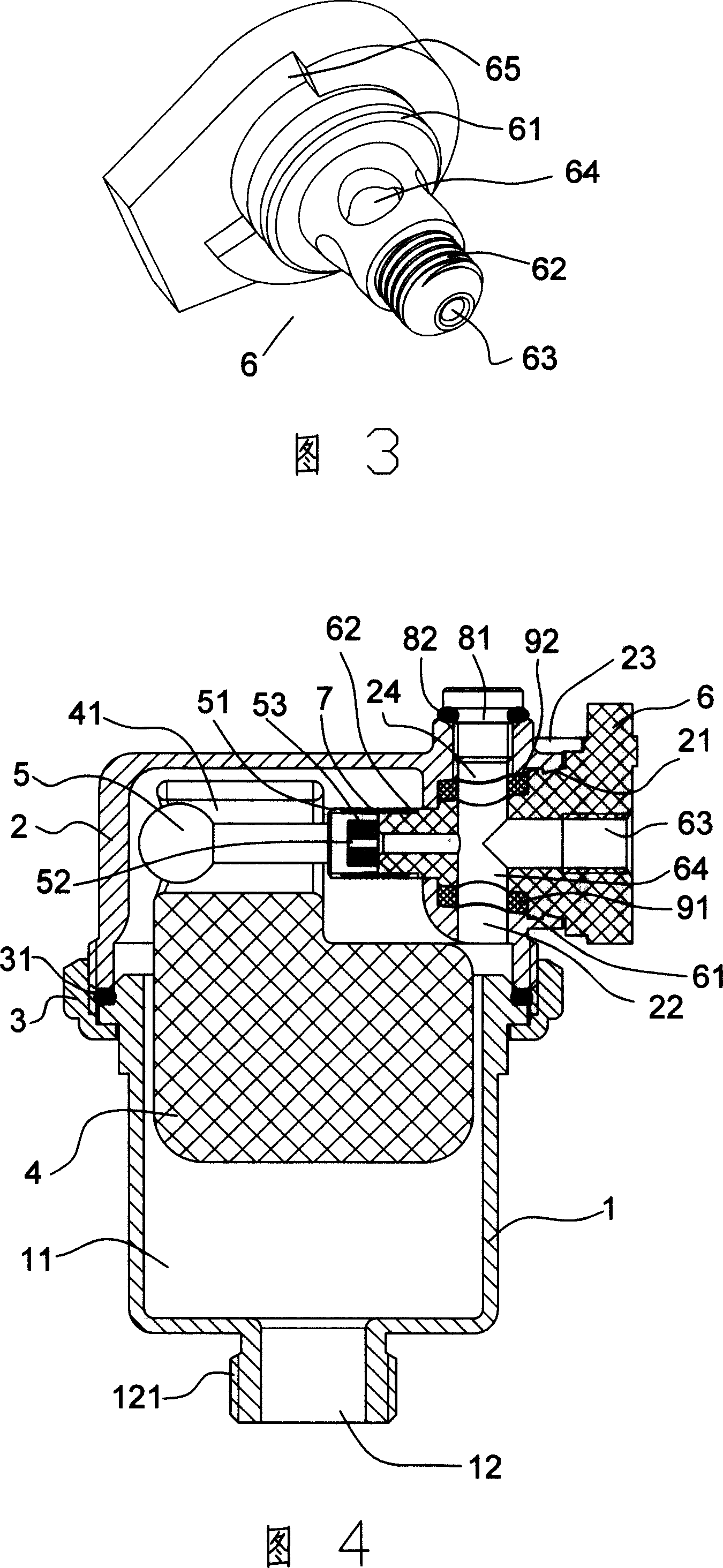

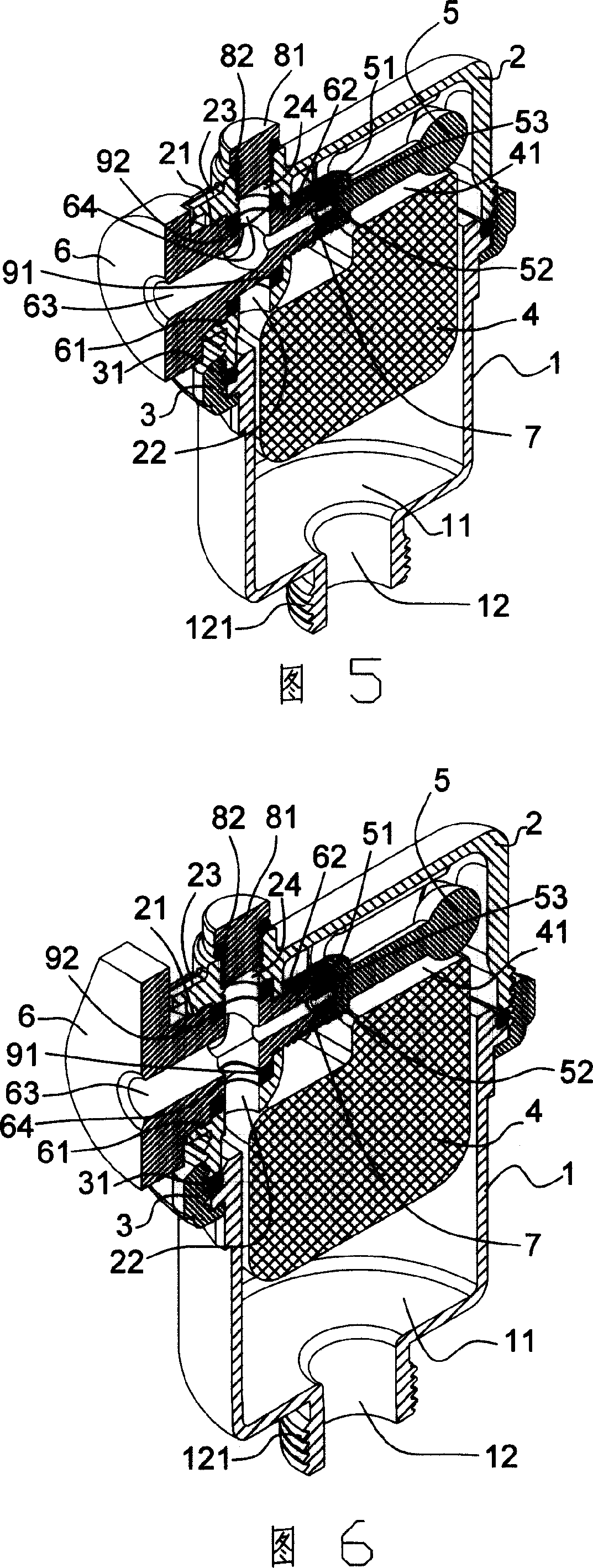

[0026] As shown in Figure 1, a new type of automatic exhaust valve includes a valve body 1 and a valve cover 2, the two are sealed and connected by a flower cap 3 to form a valve cavity 11, and an "O" is placed at the connection between the two. "Ring 31 realizes sealing, and valve body 1 lower end is provided with an air inlet 12, and the outer side of air inlet is provided with external thread or internal thread, adopts external thread 121 in the present embodiment, and it is connected with horizontal pipeline, and bonnet 2 A horizontal air outlet 21 is arranged on it.

[0027] As shown in Figure 7, a floating ball 4 is arranged inside the valve cavity 11, a slideway 41 is opened on the upper part of the floating ball 4, a connecting rod 5 is arranged inside the sliding way 41, and an engaging structure is arranged outside the end of the connecting rod. External thread 51 is adopted, a groove 52 is arranged on the end face of connecting rod 5, and a rubber washer 53 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com