Method for operating an injection molding machine

A technique for injection molding machines, machine tools, applied in the field of operating injection molding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

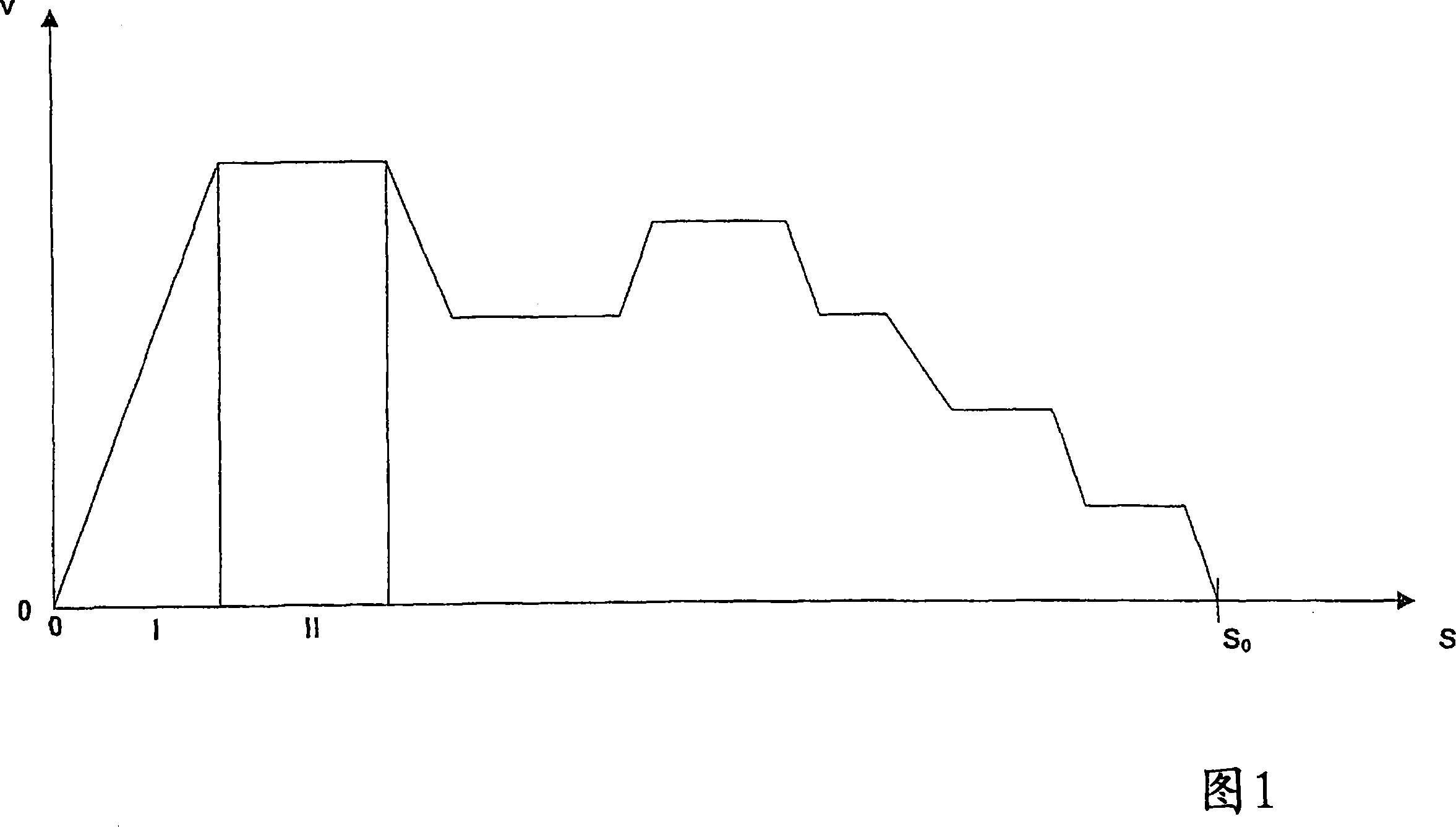

[0020] FIG. 1 shows a preliminary distribution of initial variables, on the basis of which the method according to the invention is used to automatically determine a target variable distribution for the mold protection of the mold of the injection molding machine. Figure 1 shows a moving mold half along its closing or moving distance from 0 to S 0 speed distribution. In region I the predetermined speed increases and thus the starting variable V increases to the starting speed. In zone II the mold half moves constantly at the starting speed. In other regions, the predetermined profile of the starting variable V extends in a stepwise distribution with deceleration and acceleration phases and with a constant speed phase. At the end of the travel distance, the travel speed of the mold becomes zero of course when the mold is closed. Such velocity profiles move at different velocities V along distances from 0 to S 0 Changes in are easily predictable or predictable, since the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com