Tire vulcanizer local equipment

A technology for local equipment and tire vulcanization, applied in tires, other household appliances, household appliances, etc., can solve problems such as affecting the degree of automation of equipment, reducing equipment production efficiency, affecting the quality of vulcanized tires, etc., to improve equipment production efficiency and increase storage. The amount of tire blanks and the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

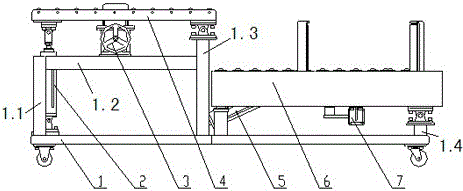

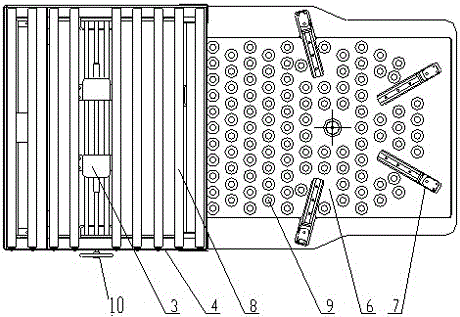

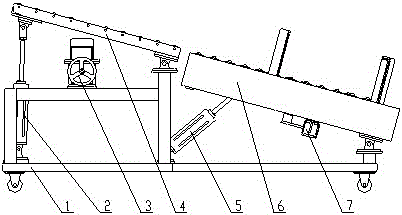

[0017] combined with Figure 1-7 , to further describe the present invention:

[0018] The partial equipment of the tire vulcanizing machine mentioned in the present invention includes a frame 1, a front turning cylinder 2, a front centering device 3, a front roller table 4, a rear turning cylinder 5, a rear roller table 6, a rear automatic centering device 7, a long Rollers 8 and universal rollers 9, the frame 1 is provided with a first longitudinal bar 1.1, an upper horizontal plate 1.2, a second longitudinal bar 1.3 and a third longitudinal bar 1.4, the top of the first longitudinal bar 1.1 is connected to the first The upper horizontal plate 1.2 is installed on the middle and upper part of the two longitudinal bars 1.3, and the upper part of the upper horizontal plate 1.2 is provided with a front centering device 3, and the left end of the front roller table 4 is connected to the left side of the frame 1 through the front turning cylinder 2, and the front roller table The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com