Tampon, and method for the production of a tampon

A technology of embolization and construction, applied in the field of strips connected with extraction ropes, can solve the problems of unreachable, short production time, unfavorable extraction rope and embolization, etc., and achieve short production time, high production speed, high production speed or takt time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

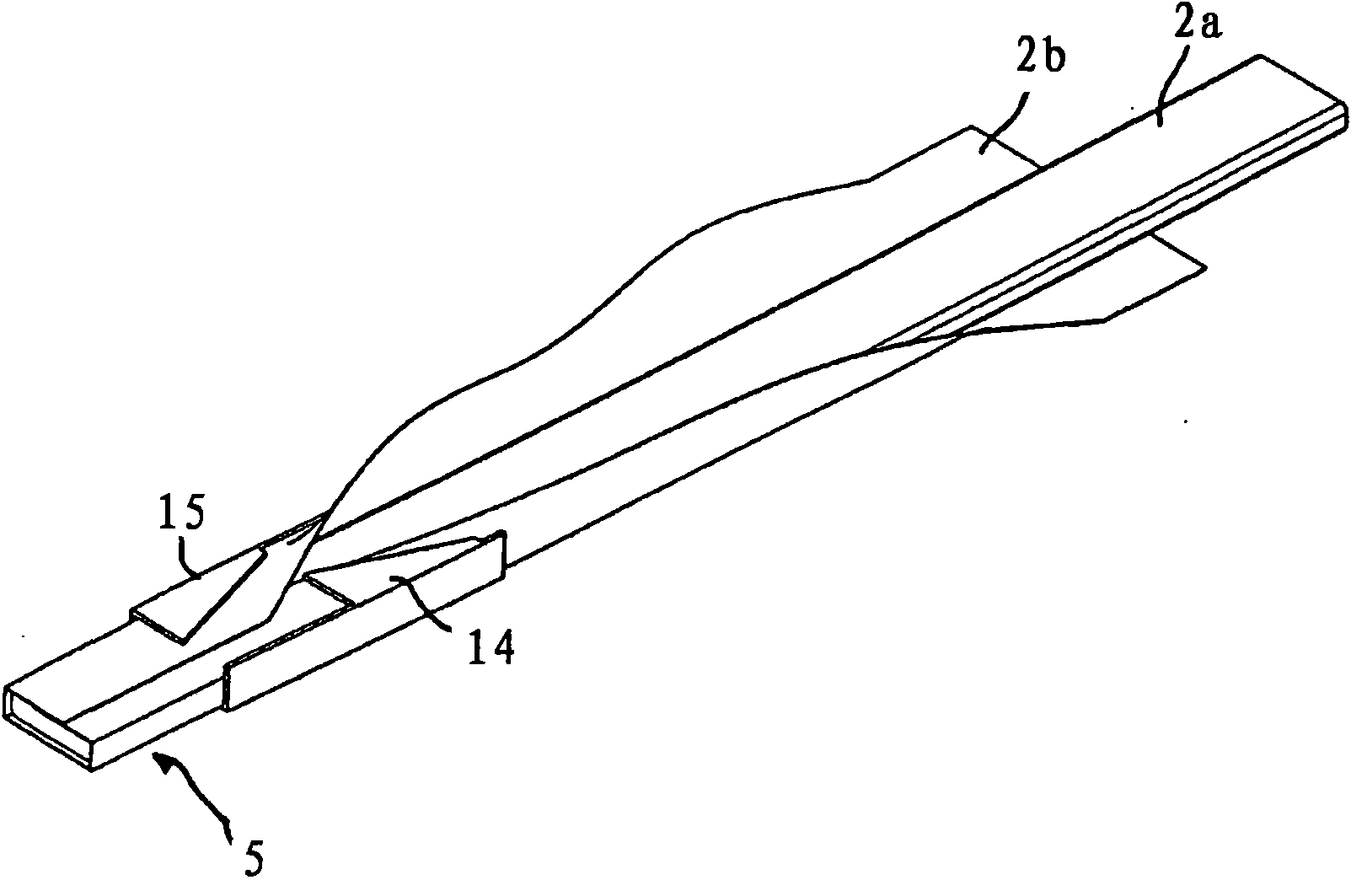

[0021] exist figure 1 1 shows first the production of a continuous material 5 from which absorbent strips 2 are cut out according to subsequent production steps in order to produce plugs 1 for insertion into plug dispensers. The continuous material 5 consists of a band 2a of liquid-absorbent fibres, or batting, and a sheath 2b surrounding the band. The fleece strip 2a has an approximately polygonal or elliptical cross-section, while the wrapping 2b is a relatively thin, liquid-permeable sheet or film. The encapsulation of the fiber strip or wool strip 2 a is effected by the relative movement of the wool strip 2 a and the film 2 b relative to the two contact jaws 14 , 15 . The wrapping 2b is similar to the tin foil of a kind of rubber candy bar wrapped around the wool wadding band 2a like this.

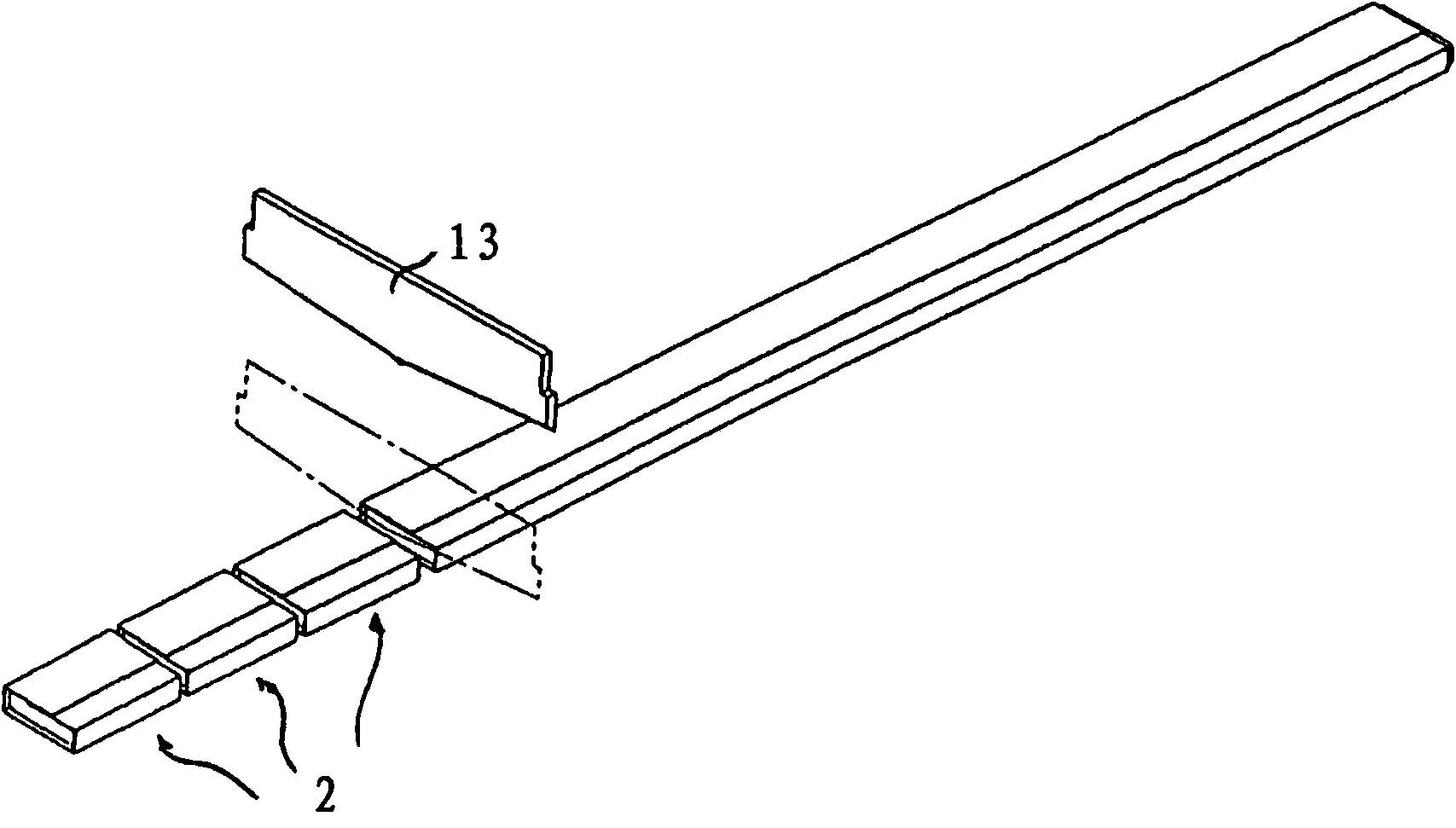

[0022] In the next production step, the continuous material 5 prepared in this way is fed to one or possibly several cutting knives 13 , which cut absorbent strips 2 from the continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com