Multiple coaxal cable and its making method

A technology for multi-core cables and cables, which is applied in the manufacture of cables/conductors, end components of multi-core cables, cables, etc., and can solve problems such as disconnection of cable groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, specific embodiments of the present invention are explained with reference to the accompanying drawings, and the following exemplary embodiments do not limit the scope of the present invention.

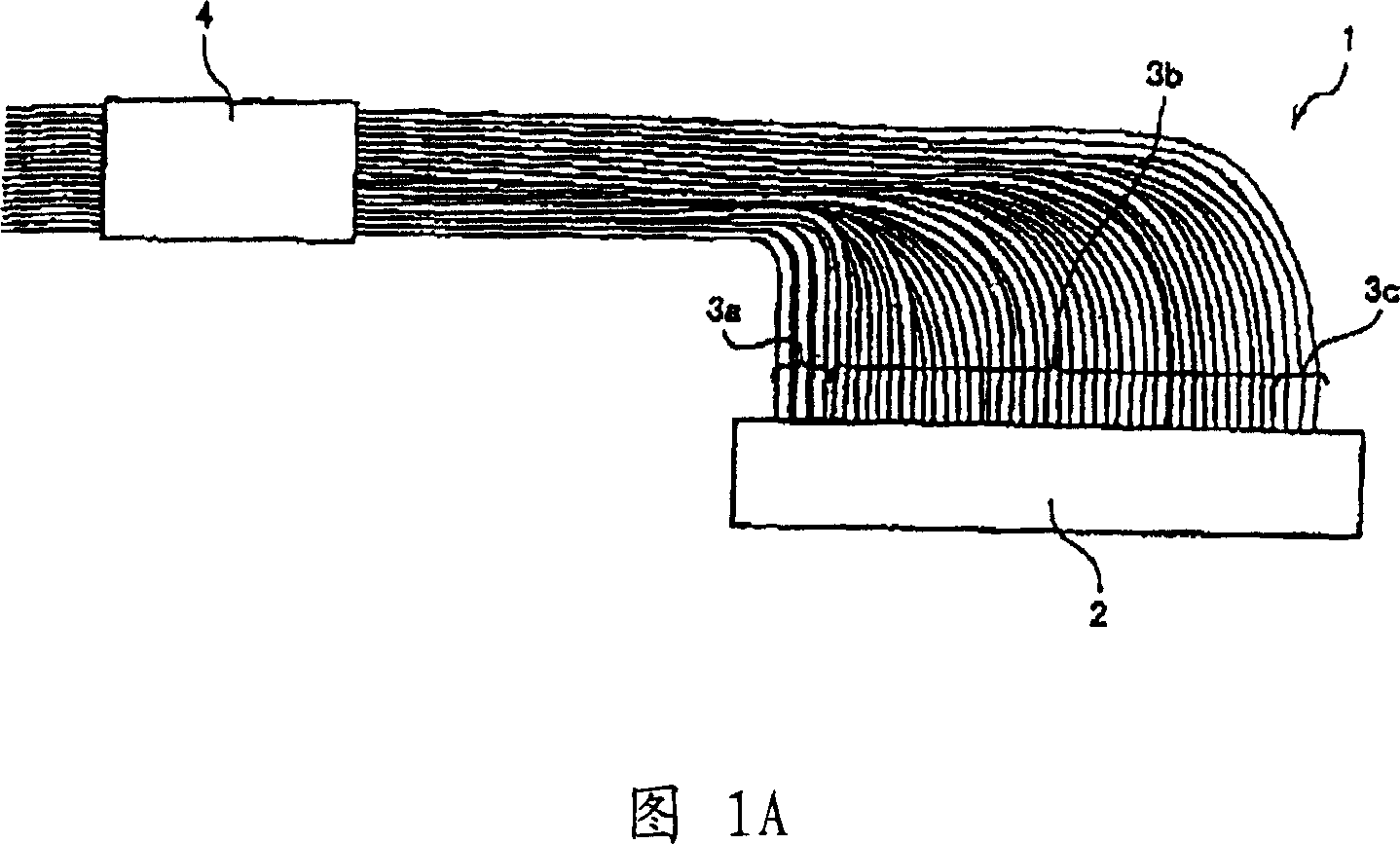

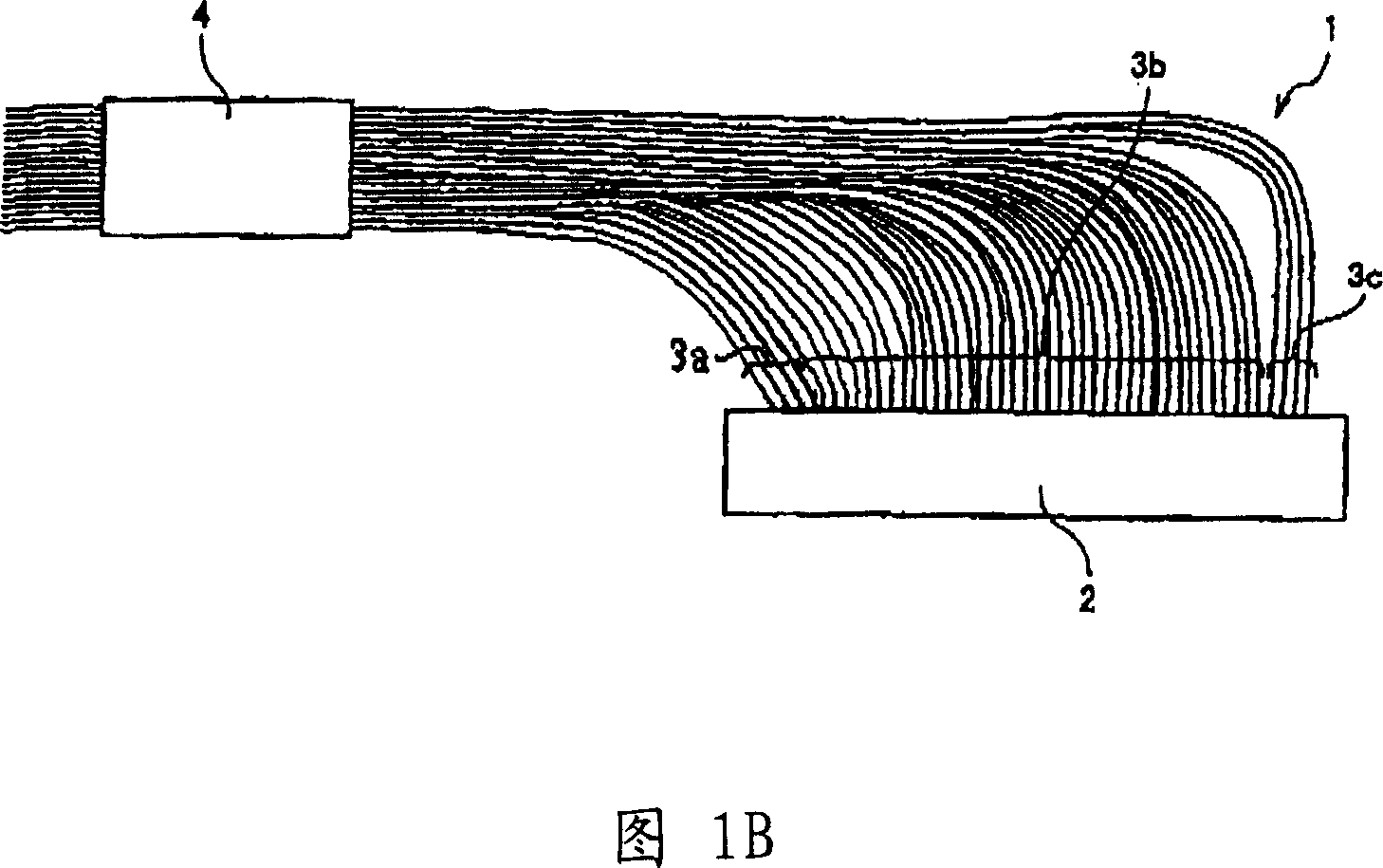

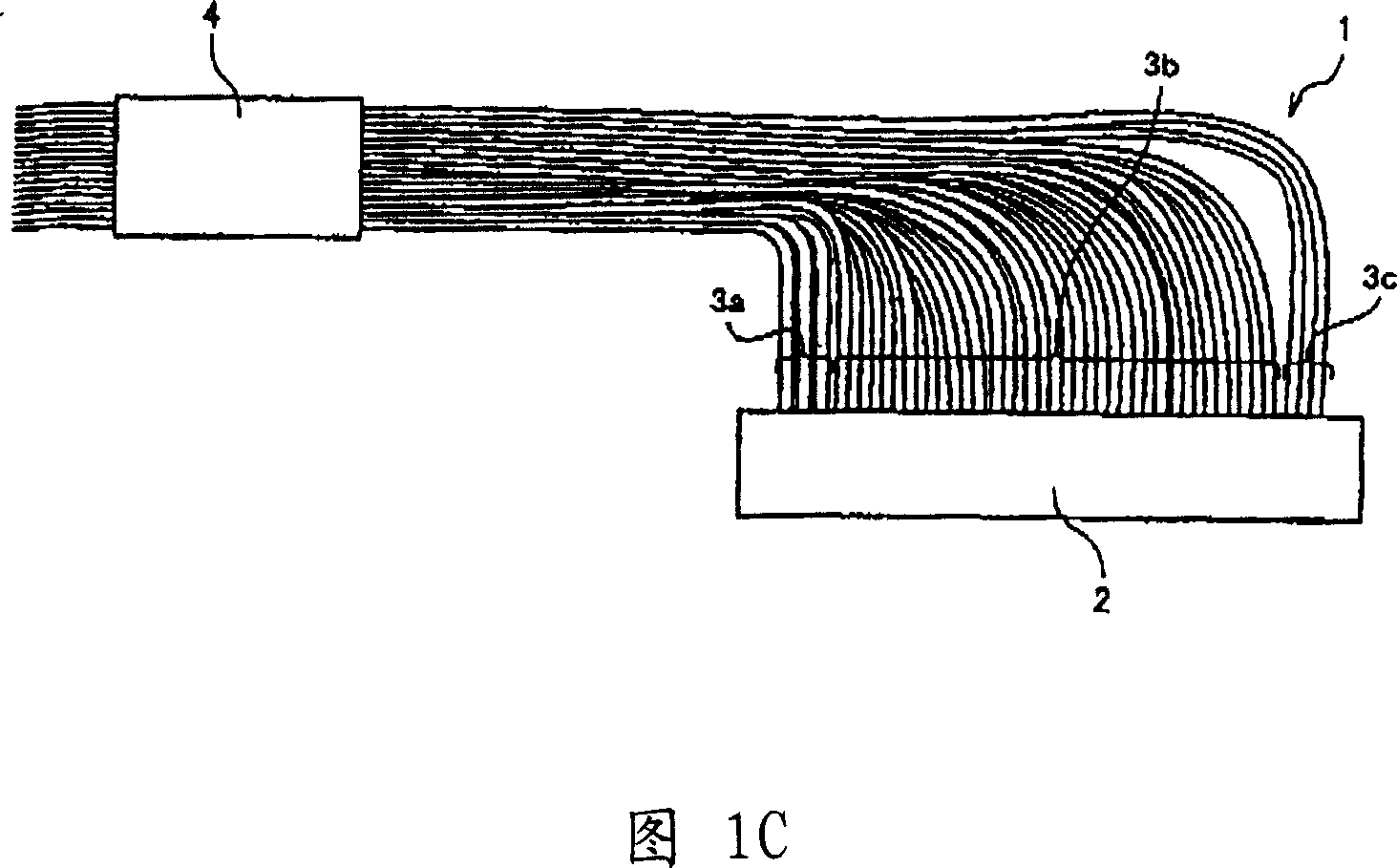

[0024] 1A to 1C are views illustrating a connector-mounted multi-coaxial cable according to an embodiment of the present invention. 2A to 2C are views showing the overall structure of the connector-mounted multi-coaxial cable shown in any one of FIGS. 1A to 1C .

[0025] A connector-mounted multi-coaxial cable 1 according to an embodiment of the present invention is a cable in which respective ends of a plurality of cables are arranged at predetermined intervals so as to be formed into a flat shape, and an electrical connector (connector) 2 Connect to each end of the cable. The cables may include coaxial cables or ultra-thin insulated cables. The middle portion of the cable of the multi-coaxial cable 1 is bundled by a band-shaped band 4 .

[0026] As shown in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com