Thin film transistor and display device

A technology of thin film transistors and interlayer insulating films, applied in the field of display devices, can solve problems such as short circuit, interlayer insulating film coverage, source and drain open circuits, etc., to achieve improved reliability, high-quality display, and suppression of failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

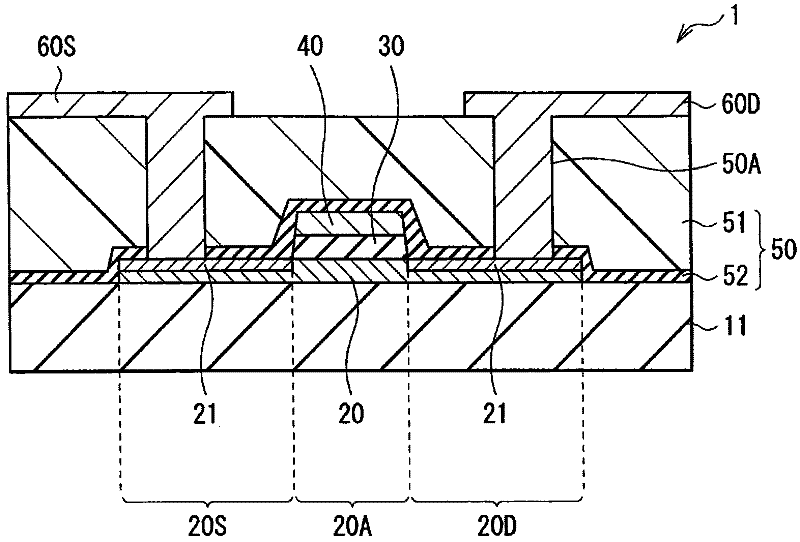

[0070] figure 1 The cross-sectional structure of the thin film transistor 1 according to the first embodiment of the present invention is illustrated. The thin film transistor 1 is used as a driving element of a liquid crystal display, an organic EL display, etc., and the thin film transistor 1 has, for example, a top-gate (staggered) structure in which an oxide semiconductor film 20 , a gate The insulating film 30, the gate electrode 40, the interlayer insulating film 50, the source electrode 60S, and the drain electrode 60D.

[0071] The substrate 11 is made of, for example, a glass substrate, a plastic film, or the like. Examples of plastic materials include PET (polyethylene terephthalate), PEN (polyethylene naphthalate), and the like. In the sputtering method described later, the oxide semiconductor film 20 is formed without heating the substrate 11, and therefore, an inexpensive plastic film can be used. In addition, the substrate 11 may be a metal substrate made of s...

example 1

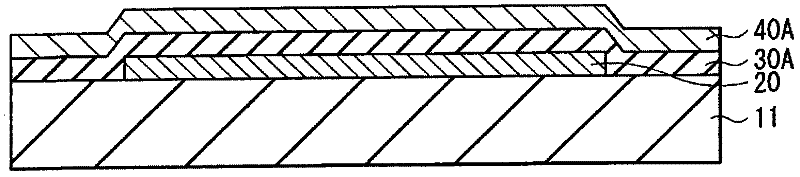

[0118] Figure 6A ~ Figure 6C as well as Figure 7 The manufacturing method of the thin film transistor 1 according to Modification 1 of the present invention is illustrated in process order. This method differs from the method of the first embodiment in that the first inorganic insulating film 52 is formed by laminating the metal film 52A and the metal oxide film 52B and oxidizing the metal film 52A. It should be noted that referring to Figure 2A ~ Figure 2C The portion overlapping with the manufacturing process of the first embodiment will be described.

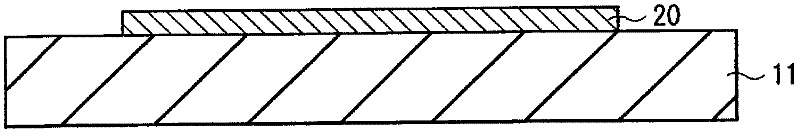

[0119] First, in a method similar to the first embodiment, by Figure 2A ~ Figure 2C In the shown process, the oxide semiconductor film 20 , the gate insulating film 30 and the gate electrode 40 are formed on the substrate 11 .

[0120] Next, if Figure 6A As shown, on the surfaces of the oxide semiconductor film 20, the gate insulating film 30, and the gate electrode 40, for example, by a sputtering method, a materia...

example 4

[0150] Figure 10 A cross-sectional configuration of a thin film transistor 1A according to Modification 4 of the present invention is illustrated. This thin film transistor 1A has a configuration similar to that of the thin film transistor 1 of the first embodiment except that the oxide semiconductor film 20 has a laminated structure including an amorphous film 22 and a crystallized film 23, and has a structure similar to that of the first embodiment. operation and effect. Accordingly, corresponding elements are given the same reference numerals as those of the first embodiment and explained.

[0151] The substrate 11 , the gate insulating film 30 , the gate electrode 40 , the interlayer insulating film 50 , the source 60S, and the drain 60D are similar to those in the first embodiment.

[0152] The oxide semiconductor film 20 has a stacked structure including an amorphous film 22 and a crystallized film 23 . The source 60S and the drain 60D are provided in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com