Current blocking element and ozone generation device

A current cutting and generating device technology, which is applied to electrical components, corona discharge devices, ozone preparation, etc., can solve the problem of fuse connection plate falling, and achieve the effect of suppressing conductor disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiment 1﹒

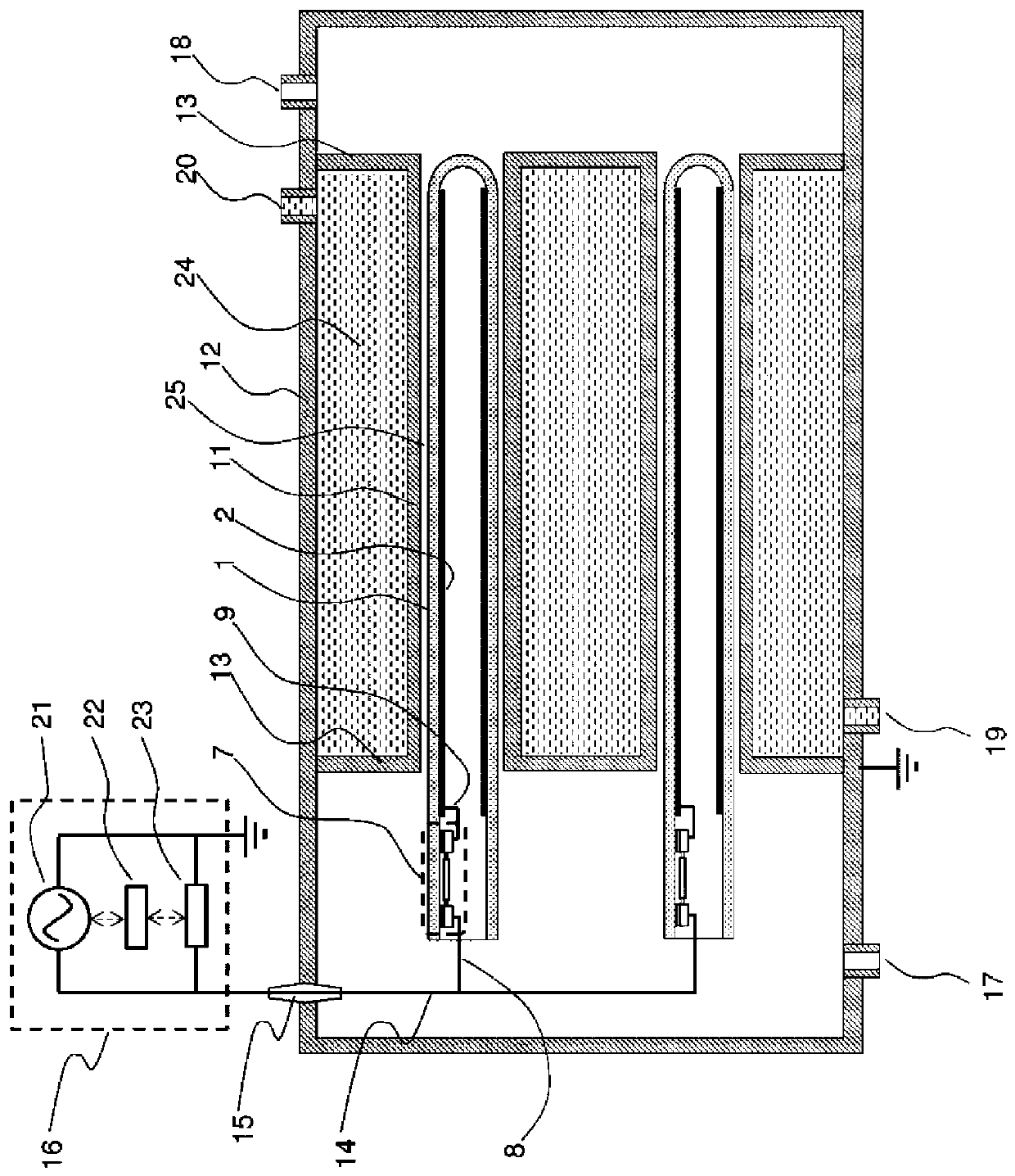

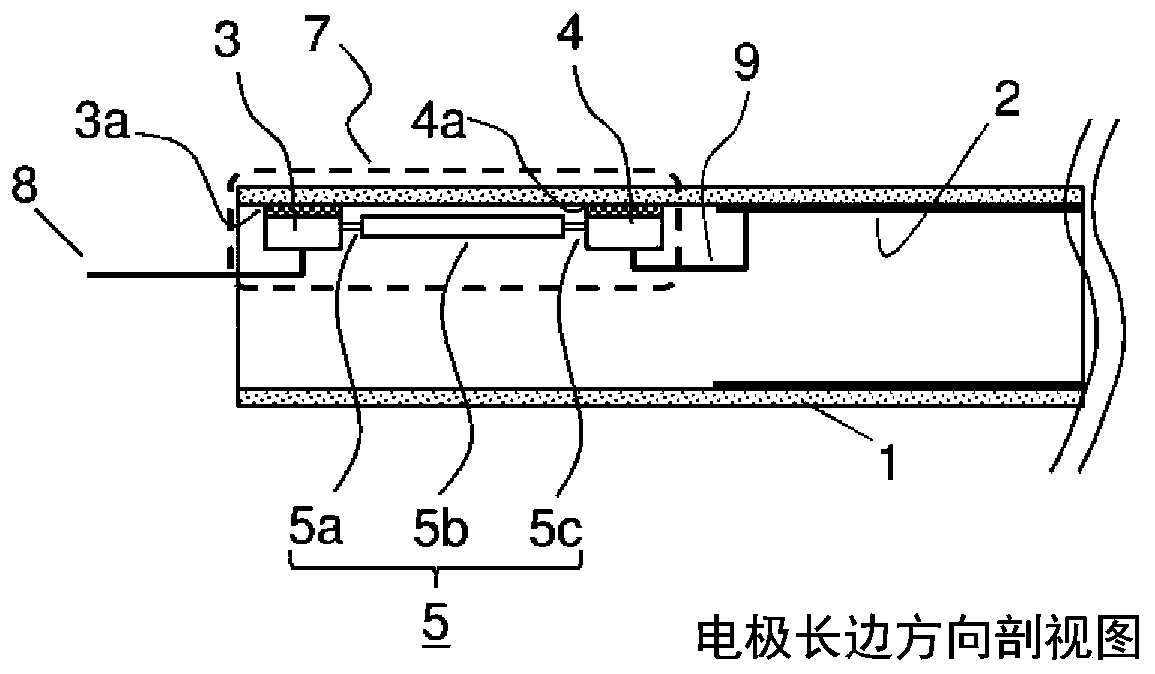

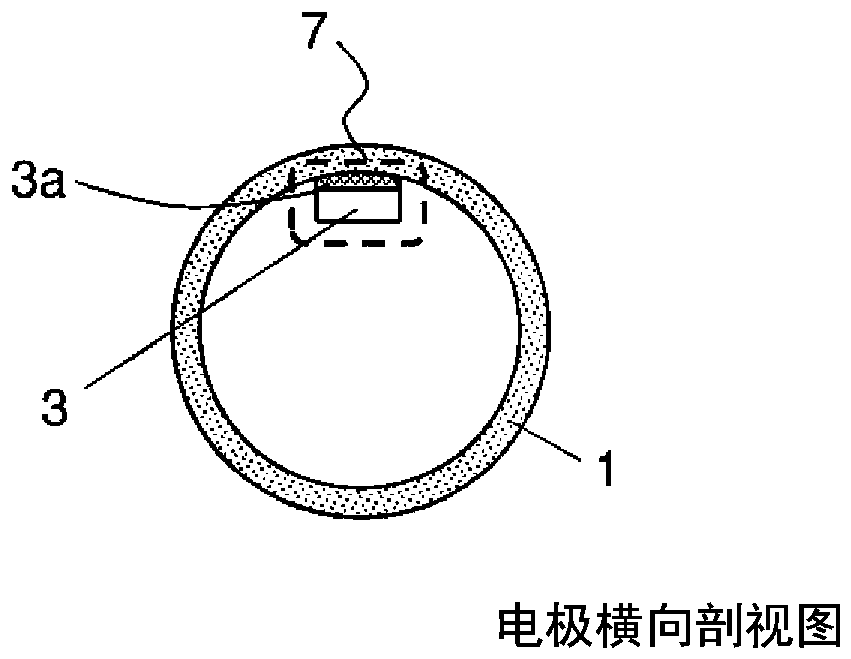

[0034] figure 1 It is a cross-sectional view showing a schematic configuration of an ozone generator according to Embodiment 1 of the present invention. figure 1 Among them, inside the ozone generator main body container 12, a cylindrical dielectric tube 1 and a ground metal electrode 11 are paired to form a single discharge tube. figure 1In order to describe the discharge tubes in detail, only two discharge tubes are shown, but in a large-capacity ozone generator, several hundreds of discharge tubes are provided inside one ozone generator main body container 12 . For example, the dielectric tube 1 is formed of a cylindrical glass tube, and the ground metal electrode 11 is formed of a pipe made of stainless steel. A narrow discharge gap 25 is formed between it and the ground metal electrode 11 . One end (right end) of the dielectric tube 1 is closed, and the other end (left end) is opened. A voltage applying electrode 2 is provided inside the diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com