Forming method and clamp

一种成型方法、夹具的技术,应用在夹固、制造工具、其他制造设备/工具等方向,能够解决生产成本高、延长成型时间、降低产品良率等问题,达到减少中间运输及装夹、降低成本、提高生产效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

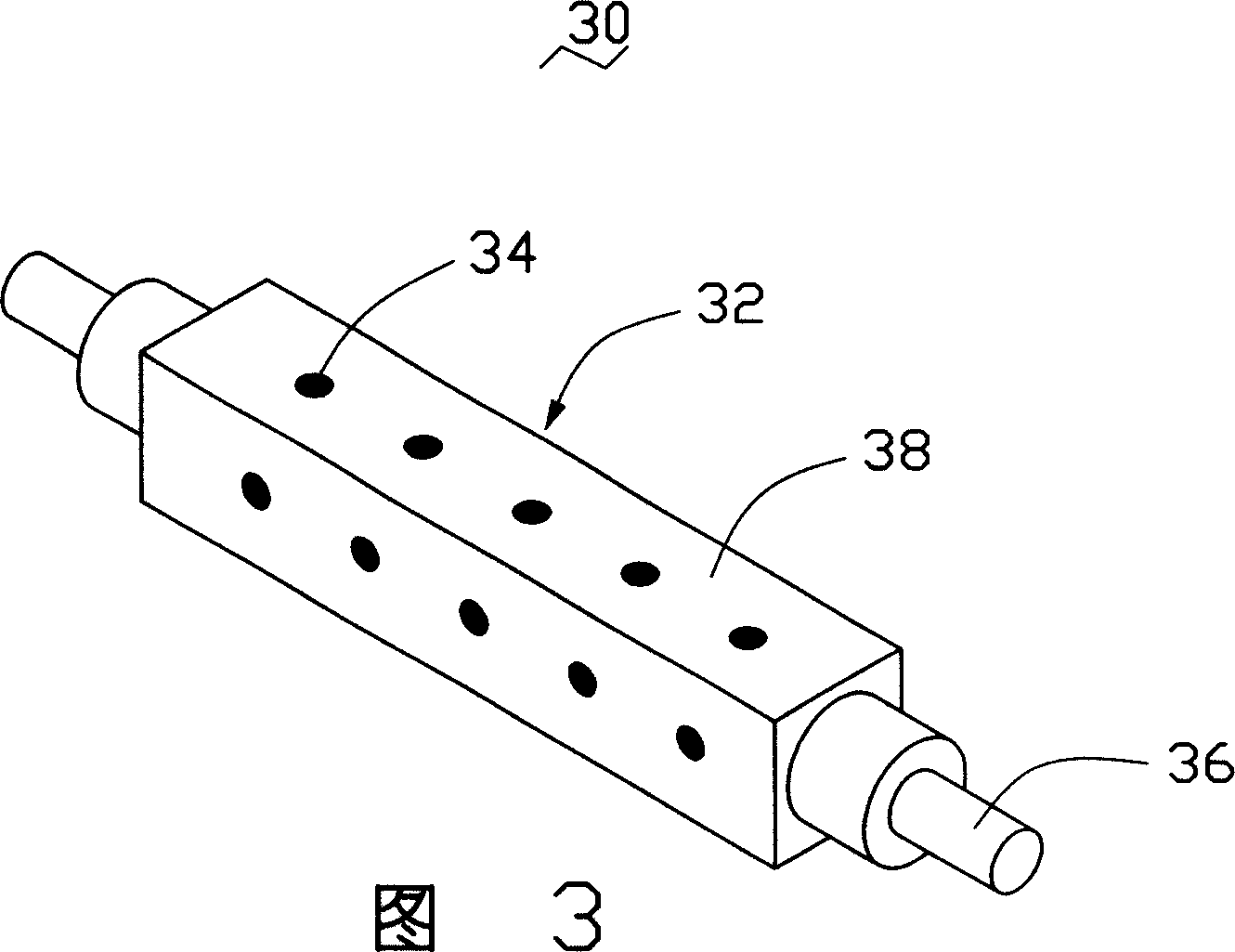

[0016] Referring to FIG. 3 , a clamp 30 according to a preferred embodiment of the present invention includes a clamping portion 32 and two mounting portions 36 respectively located at two ends of the clamping portion 32 . The clamping portion 32 is a strip-shaped prism, which is a cuboid in this preferred embodiment. The four sides of the clamping portion 32 are clamping surfaces 38, and each clamping surface 38 is provided with a A plurality of mounting holes 34 . The middle parts of both ends of the clamping part 32 extend outward to form the mounting part 36 respectively. The mounting part 36 is in the shape of a cylinder, which can be composed of one or several cylinders with different diameters. The two mounting parts 36 of the clamp 30 can be installed on a processing and forming equipment, so that the clamp 30 can be rotatably installed on the processing and forming equipment, and can be relatively locked. In this embodiment, the clamp 30 around its mounting part 36 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com