Pipe joint

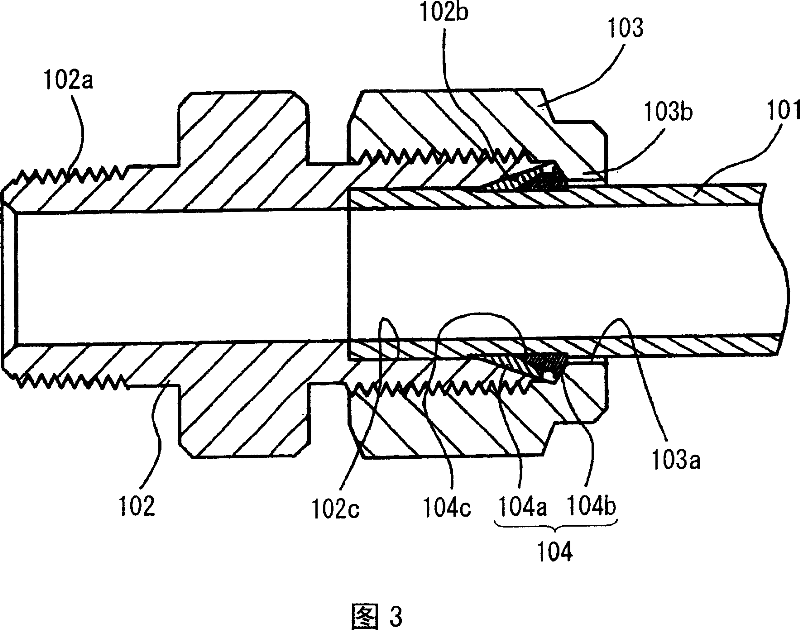

A technology for pipe joints and pipe walls, applied in the field of pipe joints, can solve problems such as difficulty in maintaining pipe holding conditions and sealing conditions, and weakening conditions of sleeve 104 biting pipe 101, etc., to achieve the effects of reducing manufacturing costs and improving efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

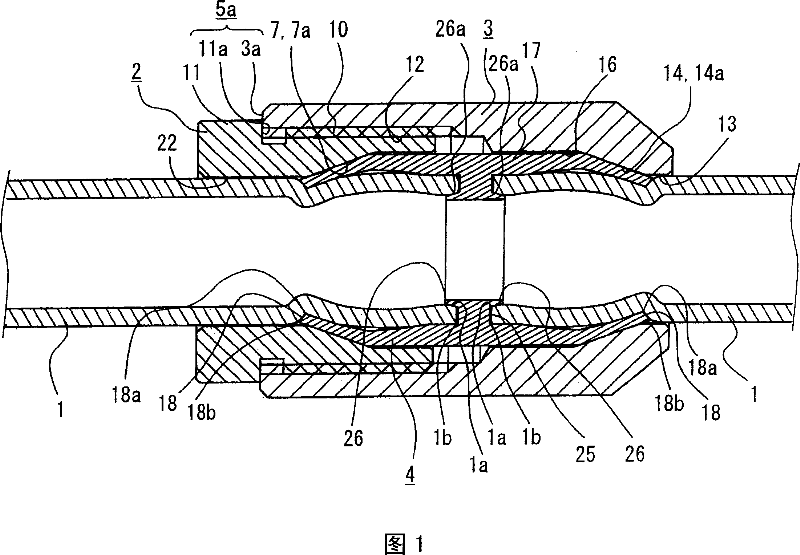

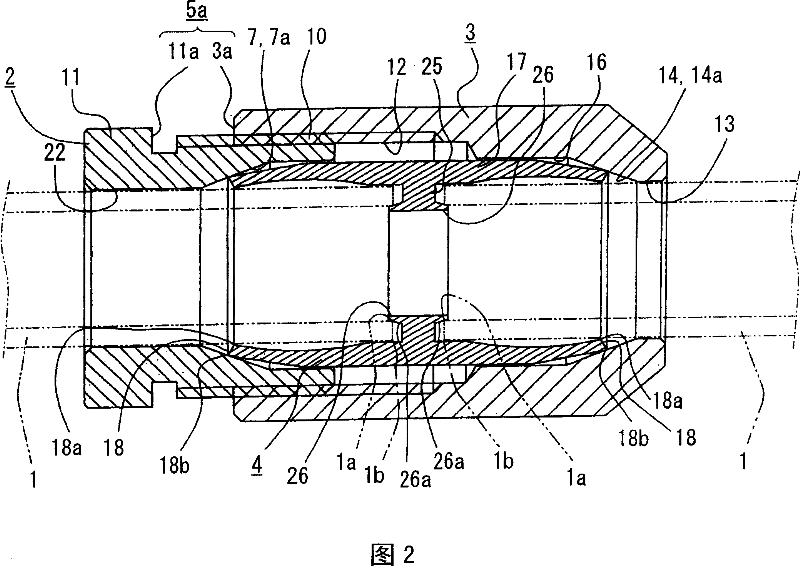

[0025] Hereinafter, an embodiment of the present invention will be described with reference to FIGS. 1 and 2 . As shown in FIG. 1 , the pipe joint is used to connect the straight ends of two pipes 1 at the same time. Hereinafter, the right tube 1 in FIGS. 1 and 2 is called the first tube 1 , and the left tube in FIGS. 1 and 2 is called the second tube 1 .

[0026] The pipe joint usually has a joint body 2, a union nut 3 screwed on the joint body 2, and a lock ring 4 on the inner circumference of the joint body 2 and the union nut 3, and the lock ring 4 is connected to the first tube 1a is joined to the second pipe 1b. In addition, the pipe joint has a tightening distance restricting portion 5 a for restricting the tightening distance or tightening amount of the union nut 3 relative to the joint main body 2 .

[0027] The joint main body 2 is made of, for example, a metal having a predetermined hardness, such as carbon steel, stainless steel, or copper alloy. The joint main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com