Cutter for cutting band material, particularly textile- or steel-cord bands

A technology of cutting device and cutting belt, which is applied in the direction of shearing device, application, household appliances, etc., and can solve the problem of joint strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

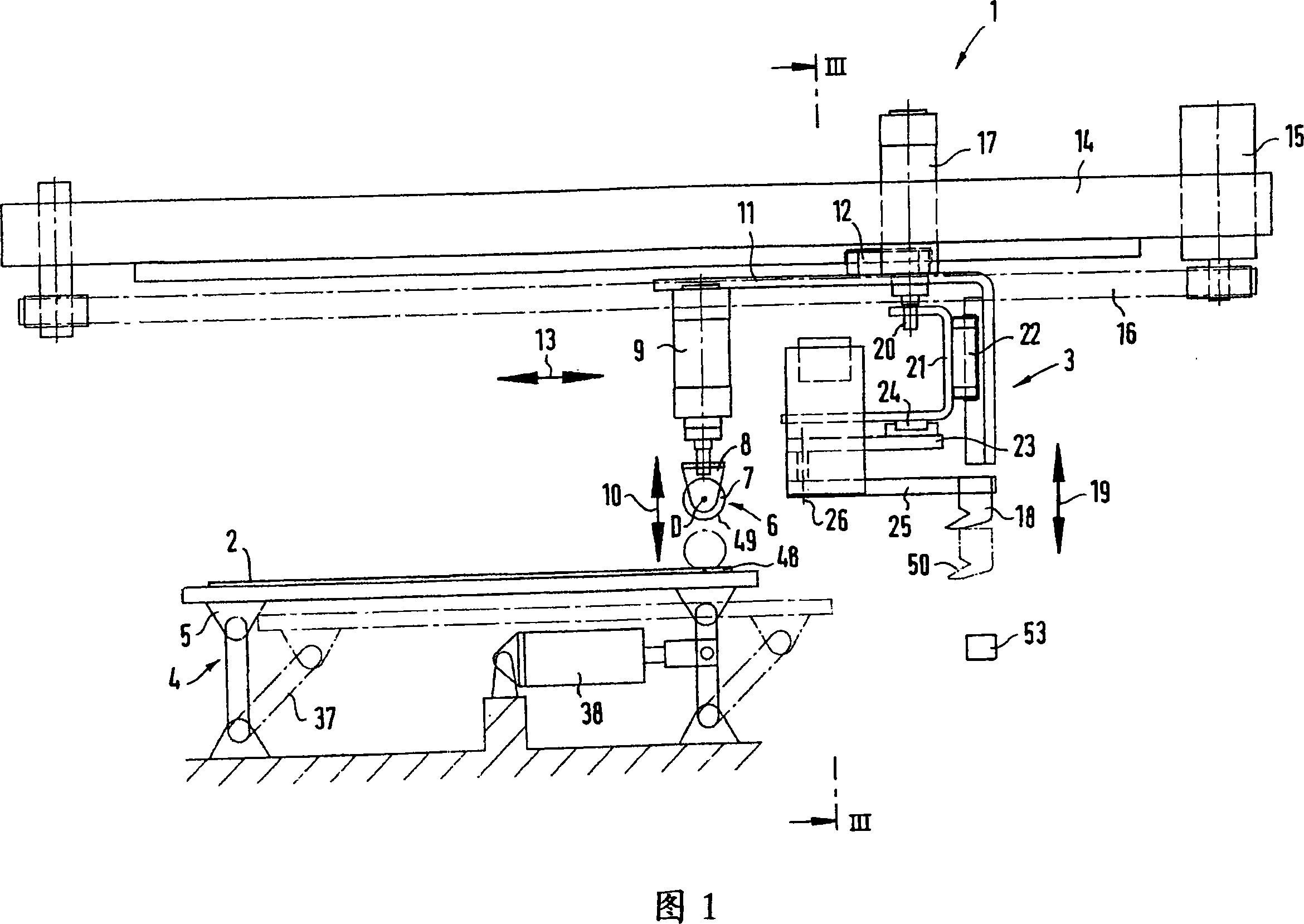

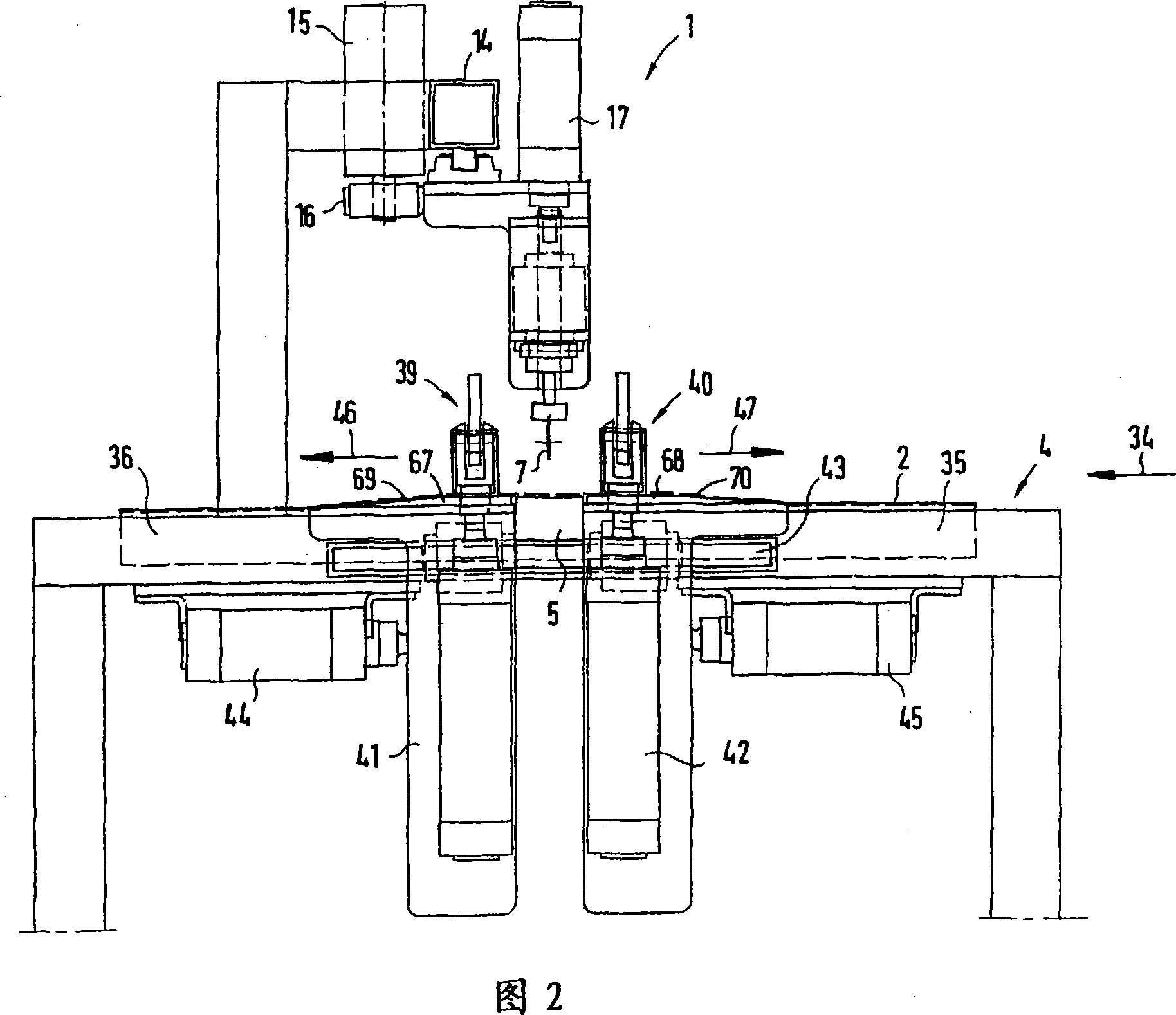

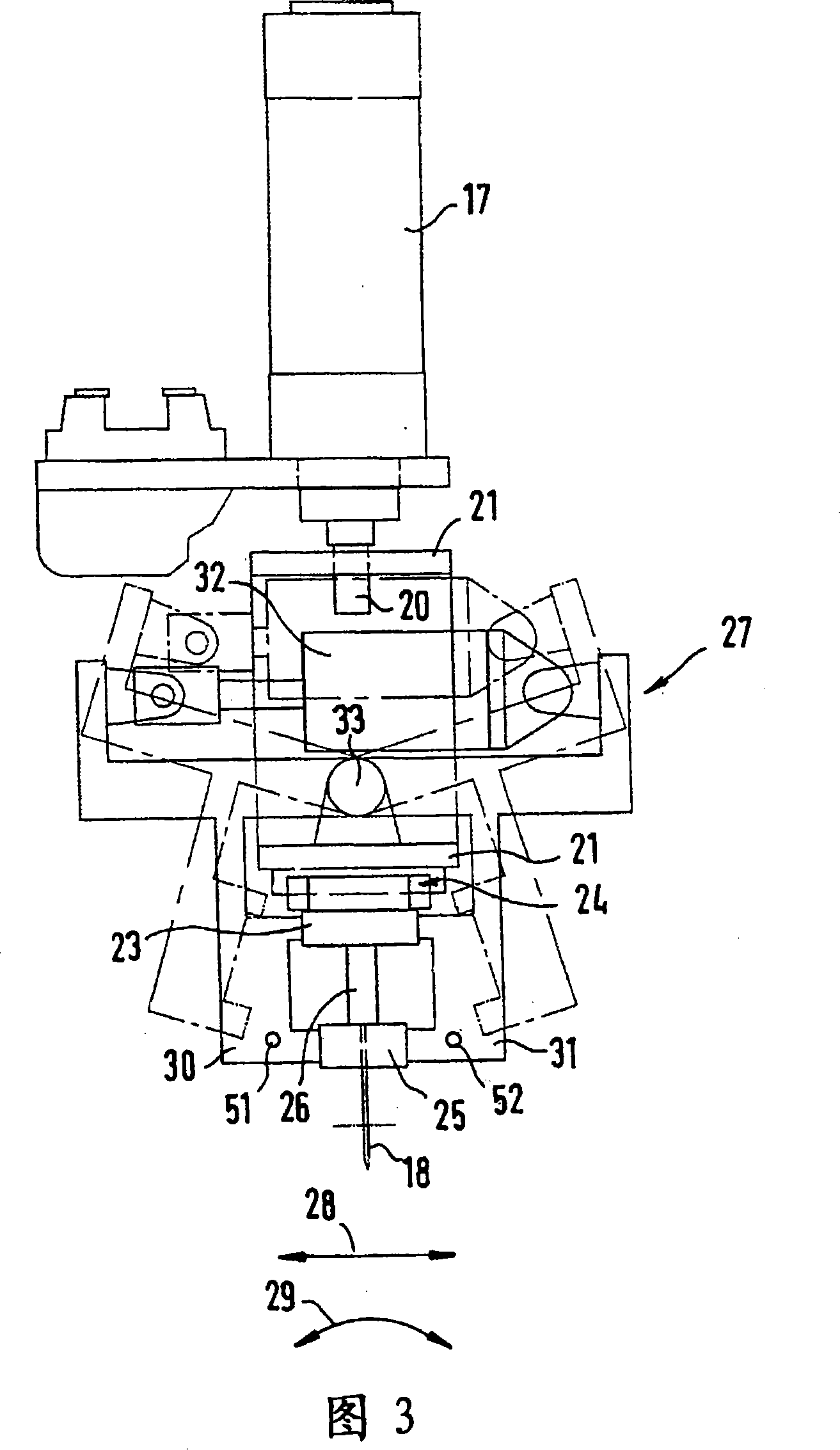

[0029] Figure 1 shows a cutting device 1 for cutting fabric or cord tape material 2 according to the invention, which comprises a cutting structure 3 and a table 4 supporting the tape material, for the sake of clarity only the said The table section 5, which can be swung by the table, will be described below. The cutting structure includes a circular knife 6 , shown here as a circular circular knife 7 . The circular knife 7 is arranged in a knife holder 8, wherein the circular knife is rotatable about an axis of rotation D and can be moved along this axis preferably against the restoring force of two tensioning springs acting laterally, so that at the same time the Axial movability perpendicular to the cutting direction is achieved. The two tensioning springs, not shown in detail, center the circular knife 7 relative to the shaft. Circular knife 7 can move vertically by a lifting device 9, as shown by double arrow 10. The lifting device 9 can be a hydraulic or pneumatic cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com