Centerless grinding machine

A technology of cylindrical grinding machine and bed, which is applied in the direction of grinding machine, grinding bed, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problems of impracticability, large construction cost, and 4-axis grinding machine not suitable for through grinding, etc. problem, achieve the effect of reducing control cost and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

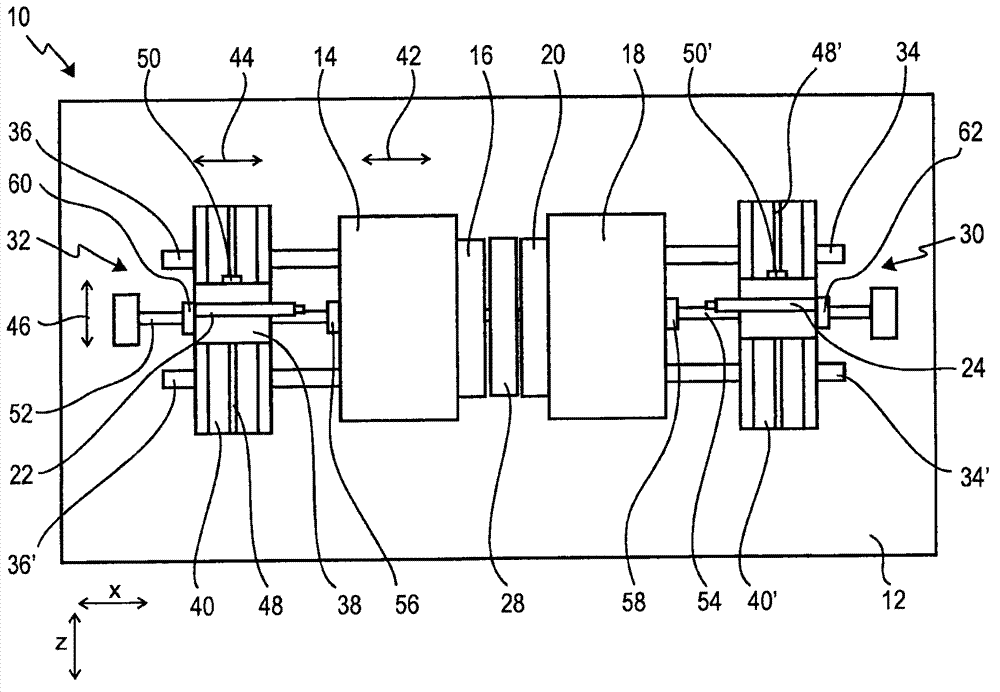

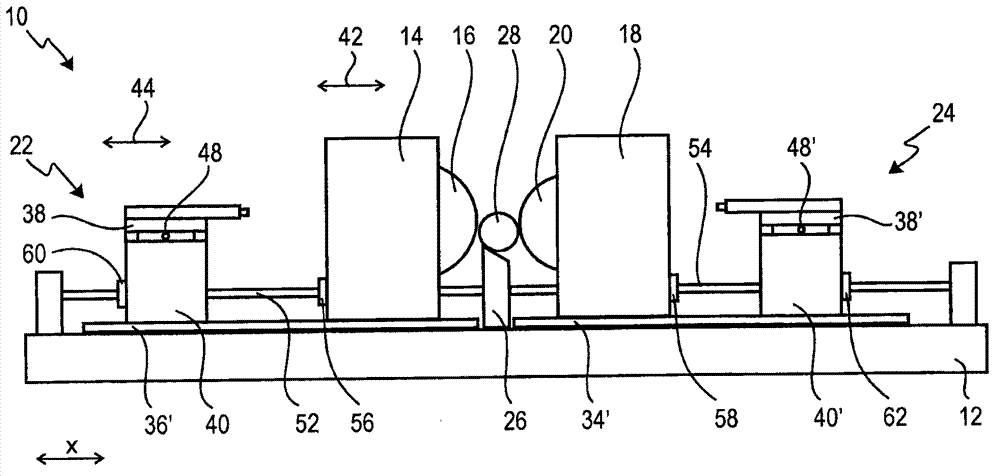

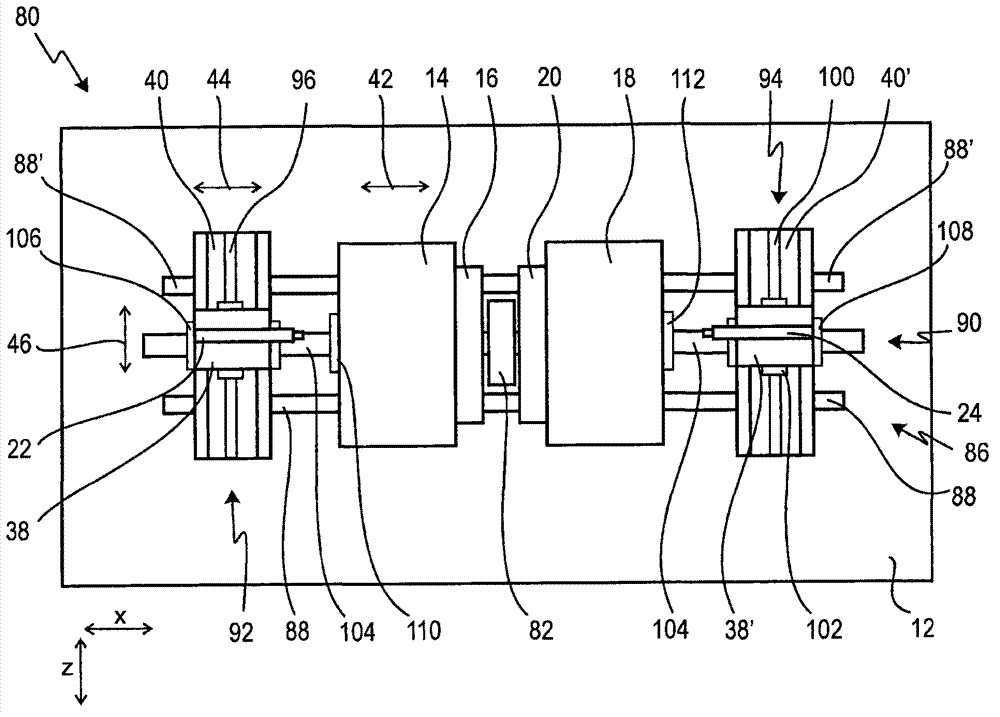

[0038] figure 1 and 2 The centerless cylindrical grinding machine shown in is marked with reference numeral 10 as a whole.

[0039] The centerless cylindrical grinding machine 10 has a bed 12 , a grinding wheel spindle 14 with a grinding wheel 16 , a control wheel spindle 18 with a control wheel 20 , and dressers 22 and 24 . Here, the first dresser 22 is used for dressing the grinding wheel 16 and the second dresser 24 is used for dressing the control wheel 20 . Between the grinding wheel spindle 14 and the control wheel spindle 18 , a workpiece support 26 is arranged on the bed 12 . In the present example, a workpiece 28 is arranged on this workpiece carrier 26 .

[0040] The grinding wheel spindle 14 and the control wheel spindle 18 are respectively arranged on linear guide mechanisms 30 and 32 . These linear guides 30 and 32 are essentially formed by corresponding guide rails 34 and 34 ′ or 36 and 36 . These guide rails 34 , 34 ′, 36 and 36 ′ are arranged on the bed 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com