Open spinning machine with pipe joint

A technology for pipe joint and start spinning, which is applied to open-end spinning machines, spinning machines, spinning machines with continuous winding, etc., and can solve problems such as restarting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

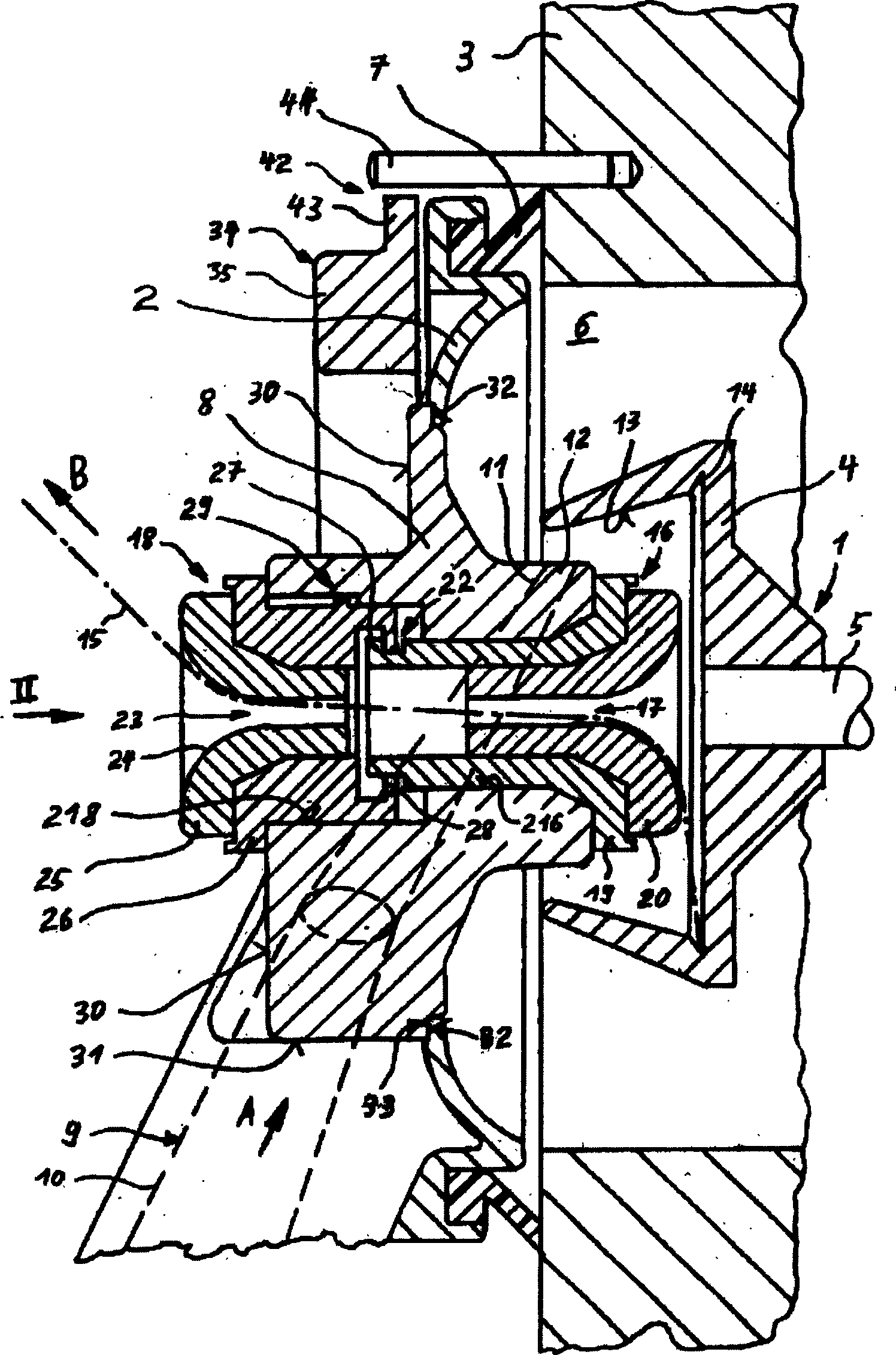

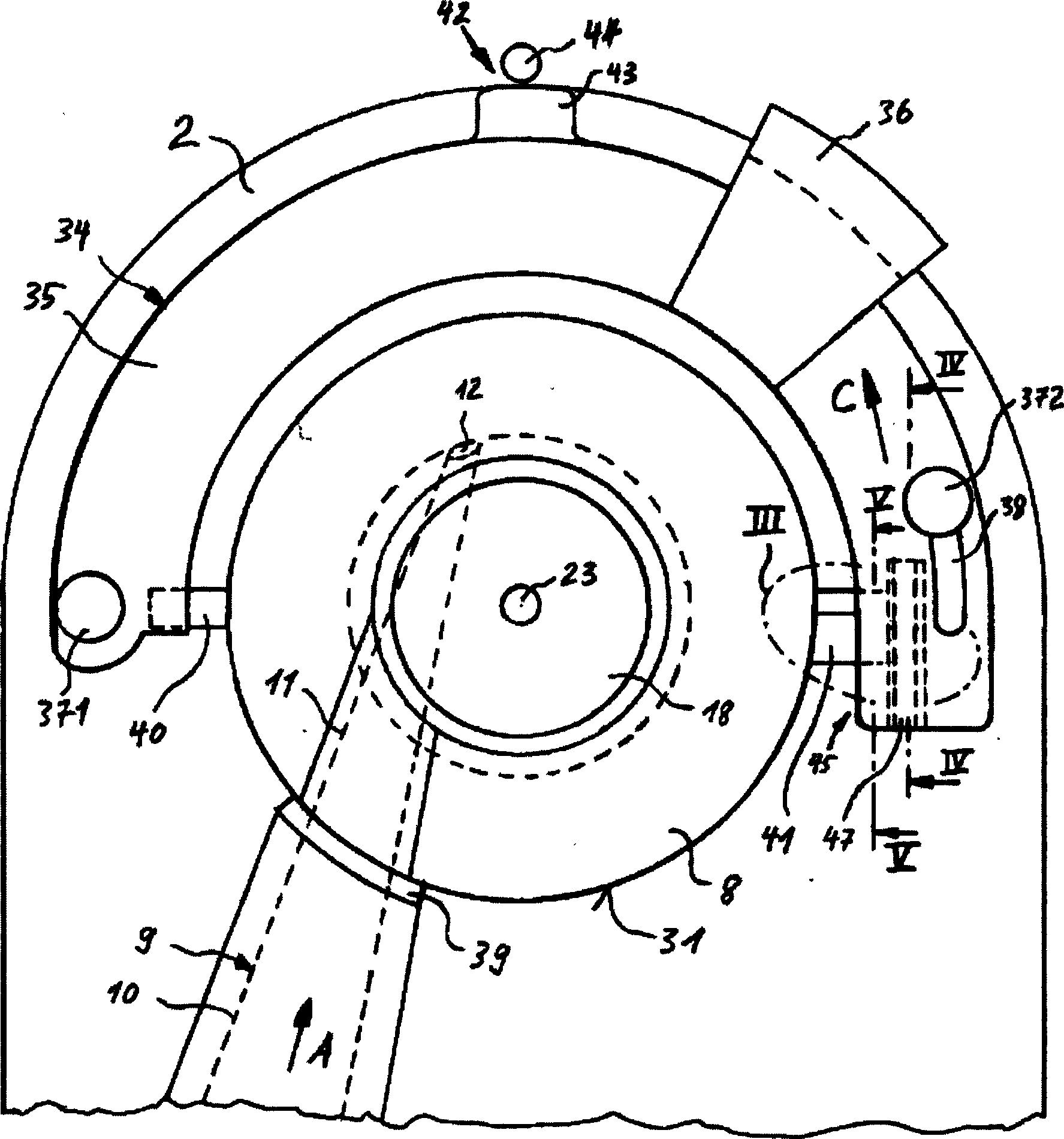

[0028] exist figure 1 and figure 2 The figure shows a rotor device 1 enclosed in a rotor housing 3 by a cover member 2 on an open-end spinning machine. The cup rotor 1 is formed in a known manner from a rotor cup 4 and a shaft 5 mounted and driven in any manner not shown in the figures.

[0029] During spinning, the rotor 4 rotates in a known manner in a negatively pressurized interior 6 formed by the rotor housing 3 . During spinning, the rotor housing 3 is closed with a cover element 2 which can be removed for maintenance purposes. The annular sealing ring 7 is used for sealing between the cover member 2 and the rotor housing 3 .

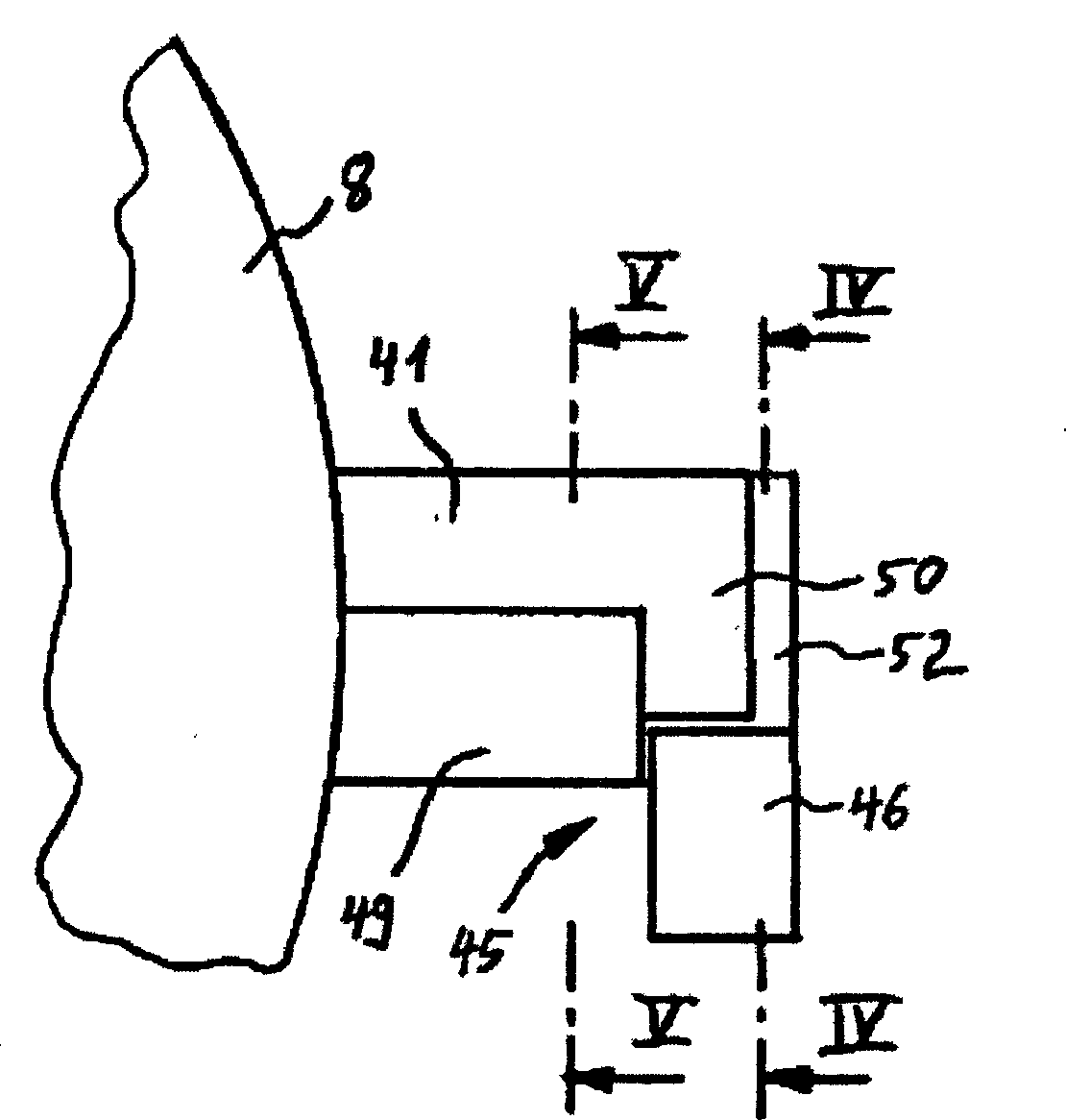

[0030]Arranged on the cover part 2 , which is often also referred to as the bezel, is an easily replaceable line connection 8 , which has a shoulder protruding into the interior of the rotor cup 4 . The fiber feed channel 9 extends in a known manner from an opening roller, not shown, to the rotor cup 4 . The fiber feed channel 9 is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com