Hydraulic universal test machine for actively loading at two ends of test piece

A universal testing machine and active technology, applied in the field of universal testing machines, can solve the problems of the vibration cannot be eliminated or the fracture can be weakened to the middle, so as to reduce the vibration and solve the problem of the fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

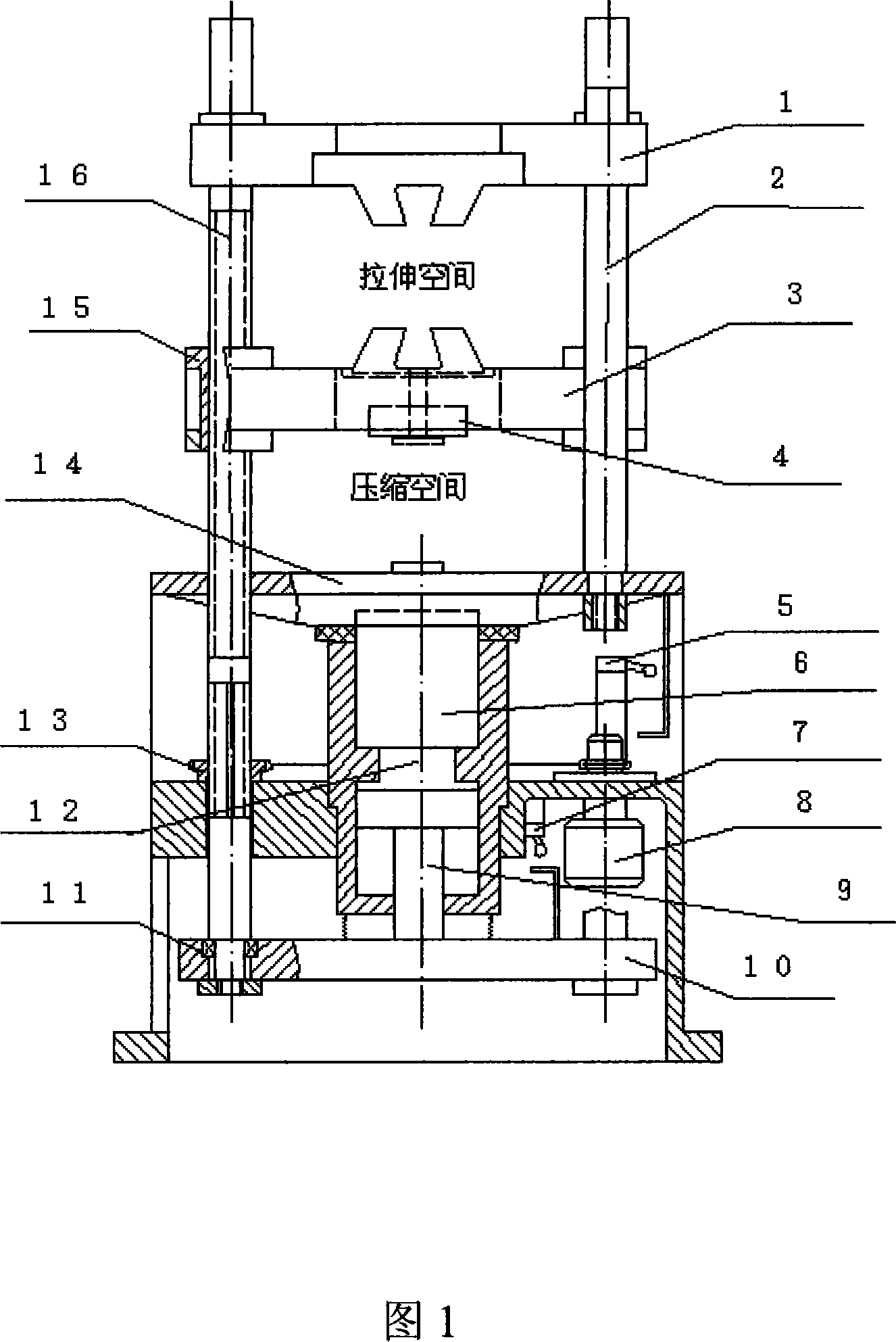

[0033] As shown in Figure 1, the best embodiment of the hydraulic universal material testing machine of the patent of the present invention comprises an upper beam 1, a moving beam 3, a lower beam 10, and an oil cylinder 12, and the moving beam 3 is set on at least two rectangular pairs. On the light rod 2 at both ends of the corner line, it engages with the threaded part of the upper part of the two lead screws 16 through the screw nut 15 at the two ends of the other diagonal line of the rectangle, and the upper beam 1 is fixedly connected with the light rod 2 , the other side is set on the lead screw 16, the lower end of the lead screw is connected with the lower beam 10 through the thrust bearing 11, the lower beam 10 is fixed with the piston 9, and the plunger 6 is supported under a test bench plate 14, the test bench The flat plate is fixedly connected with the light rod 2, and its other side is sleeved outside the leading screw 16. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com