Coal-cutting machine

A technology of coal cutting machine and frame, which is applied in the direction of slitting machinery, earth-moving drilling and mining, etc., can solve the problems of reducing the structure size, difficult to achieve rigidity and firmness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

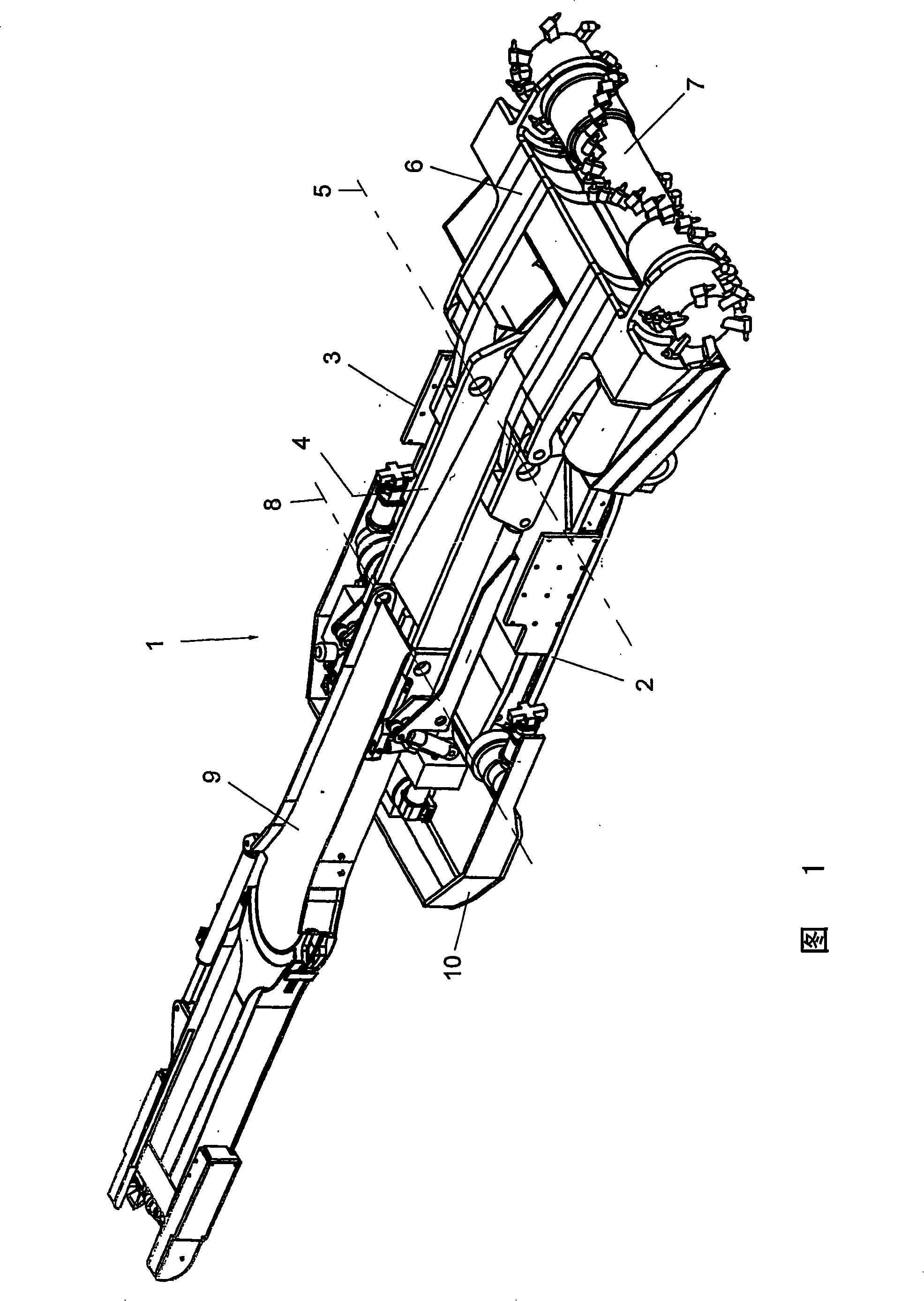

[0014] FIG. 1 shows a boring machine 1 with a crawler chassis 2 connected to a machine frame 3 . On this frame, a slide 4 is displaceable in the longitudinal direction of the machine, wherein the cantilever or cutting disc 6 with the rotatably mounted cutting drum 7 is pivotable in the height direction about a horizontal axis of rotation schematically indicated at 5 The way is hinged on the sliding seat 4.

[0015] The carriage 4 has an upwardly open groove-like contour, on the rear end of which carriage 4 a further frame part 9 is arranged so as to be deflectable about an axis of rotation 8 in the direction of height, by means of which Part 9, the conveyor belt supported in the groove, can be deflected in the height direction for adjusting the desired discharge height. On the frame 2, however, a further pivotable rear frame part 10 is arranged, which can be swiveled out sideways in curves, as will be explained in more detail in the following figures.

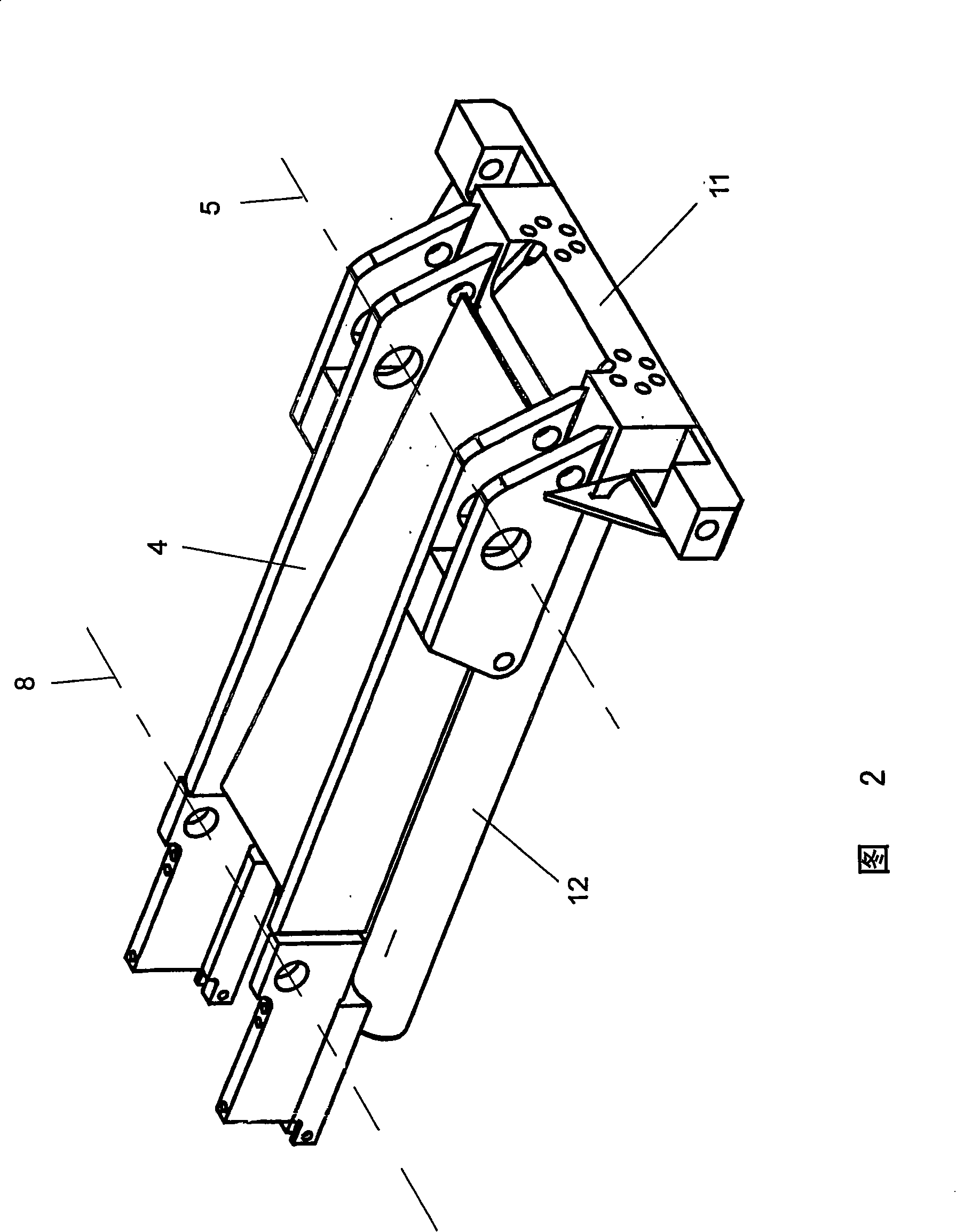

[0016] FIG. 2 shows a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com