Drop base ring clamping contour for air tubular bellow pneumatic springs

An air spring and hose type technology, which is applied in the direction of springs, spring/shock absorbers, gas shock absorbers, etc., can solve the problems of unsatisfied tensile strength and tensile strength, meet high sealing requirements, improve resistance breaking strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

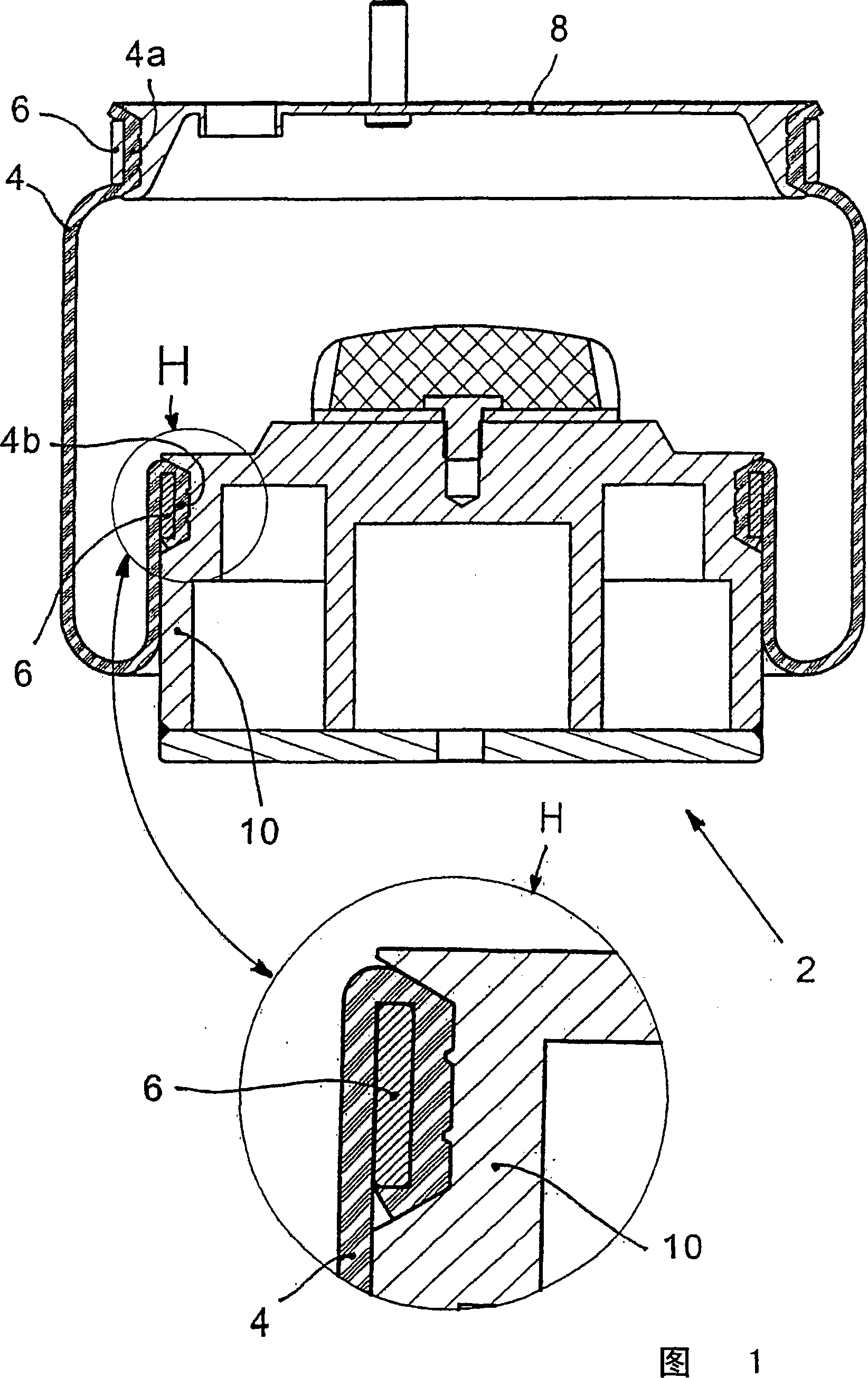

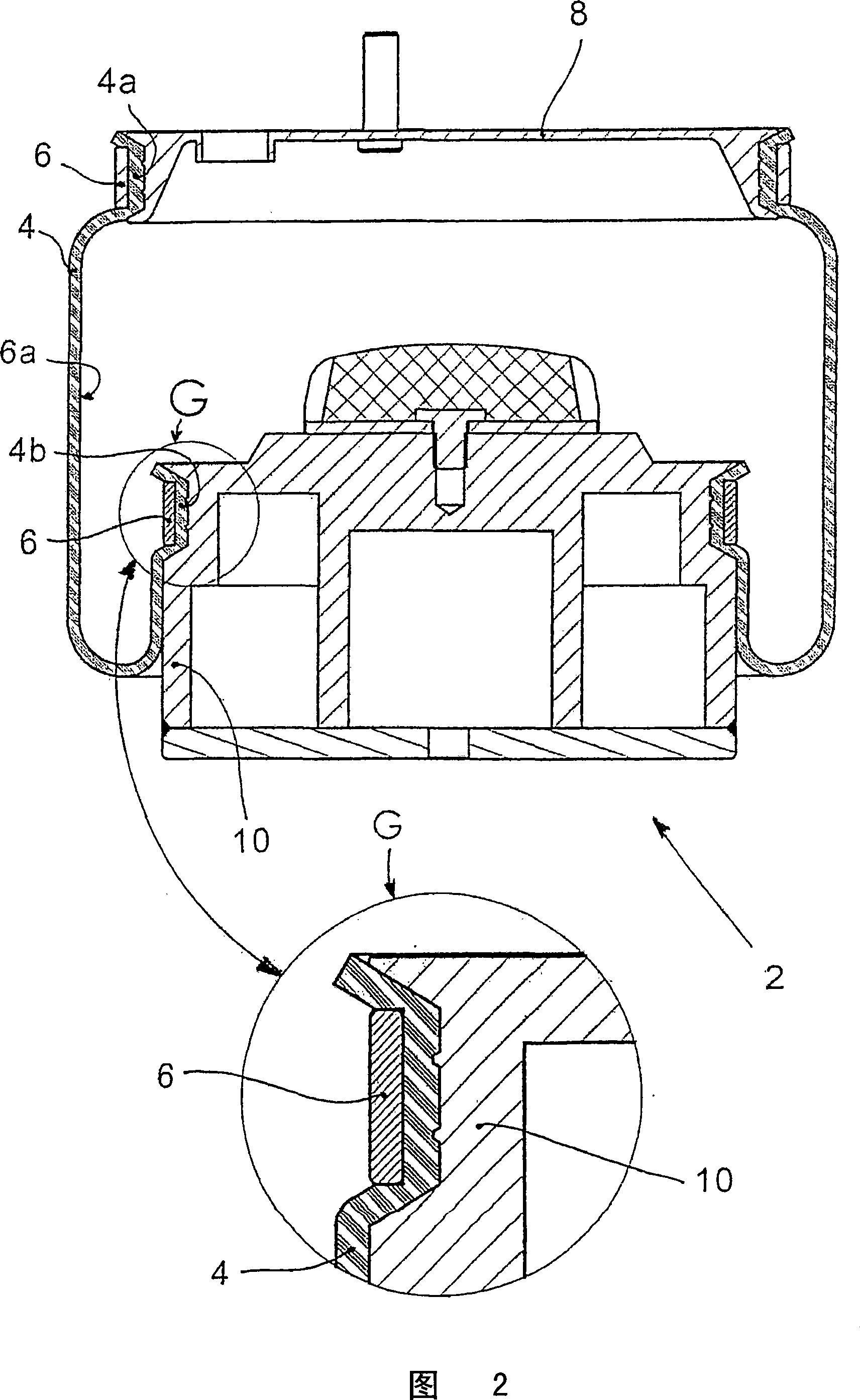

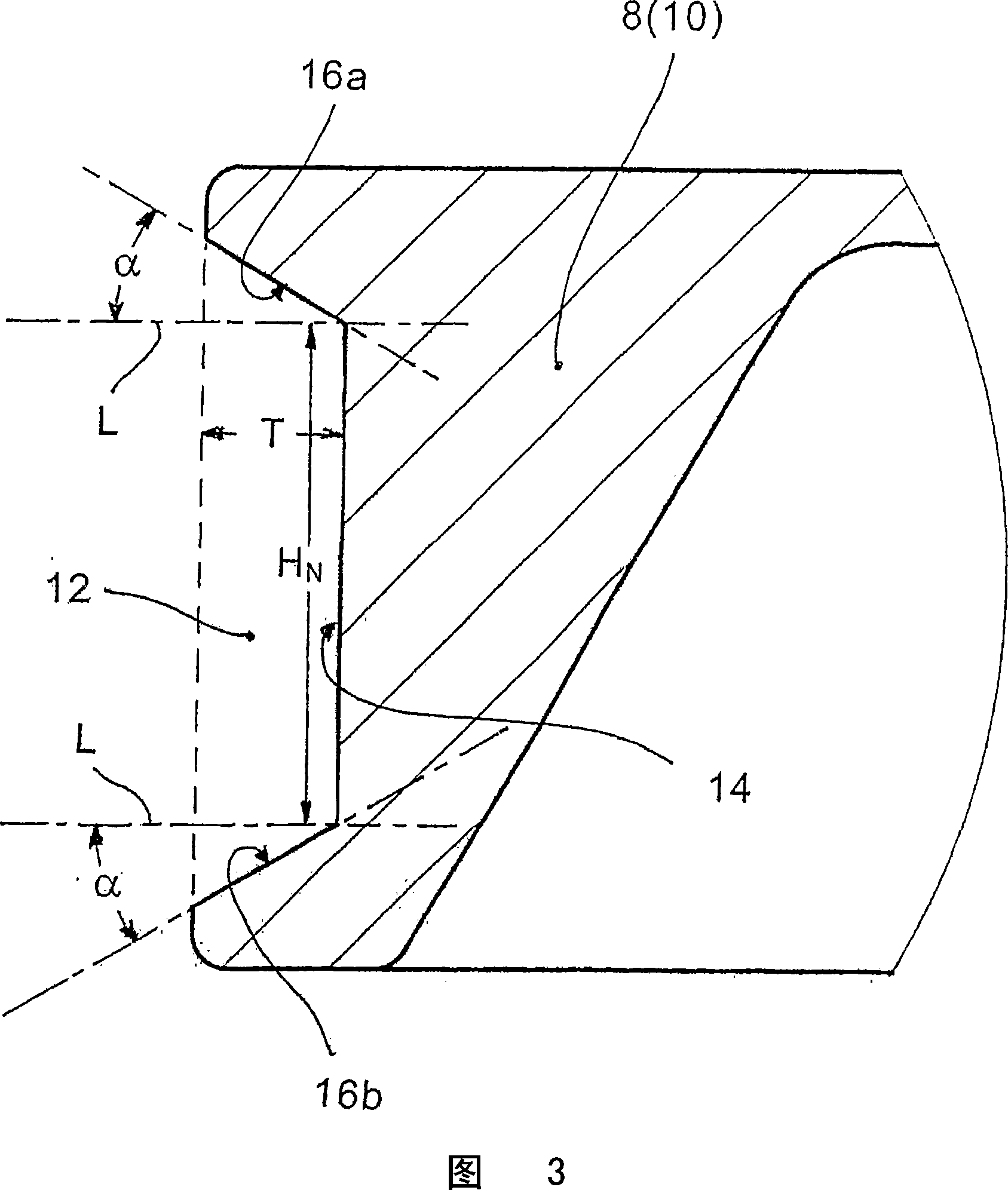

[0023] The air spring 2 shown in FIGS. 1 and 2 essentially comprises a tubular rolling film 4 , whose end sections 4 a , 4 b are positively fitted, tensile-resistant and gas-tight on the corresponding connecting piece 8 , 10 . The "upper" connecting part 8 is correspondingly an air spring cover, and the "lower" connecting part 10 is correspondingly an unwinding piston. The connecting parts 8 , 10 each have a specially formed groove 12 for fastening the tubular rolling foil ends 4 a , 4 b . An end section 4 a or 4 b of a tubular rolling film 4 is inserted into these grooves 12 and clamped in each case by means of a clamping ring 6 . As a result of the plastic deformation of the clamping ring 6 , the tubular rolling film 4 is pressed into the groove 12 formed as a “lower profile” which runs around in the respective connecting piece 8 and / or 10 .

[0024] The air spring 2 according to FIG. 2 differs from the air spring 2 shown in FIG. 1 in that here the tubular rolling film 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com