Polygonal barrel and protective device for space telescope lens

A technology of protection device and polygonal barrel, applied in installation, optics, instruments, etc., can solve problems such as high cost, large quality of lenses and brackets, and deformation of lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

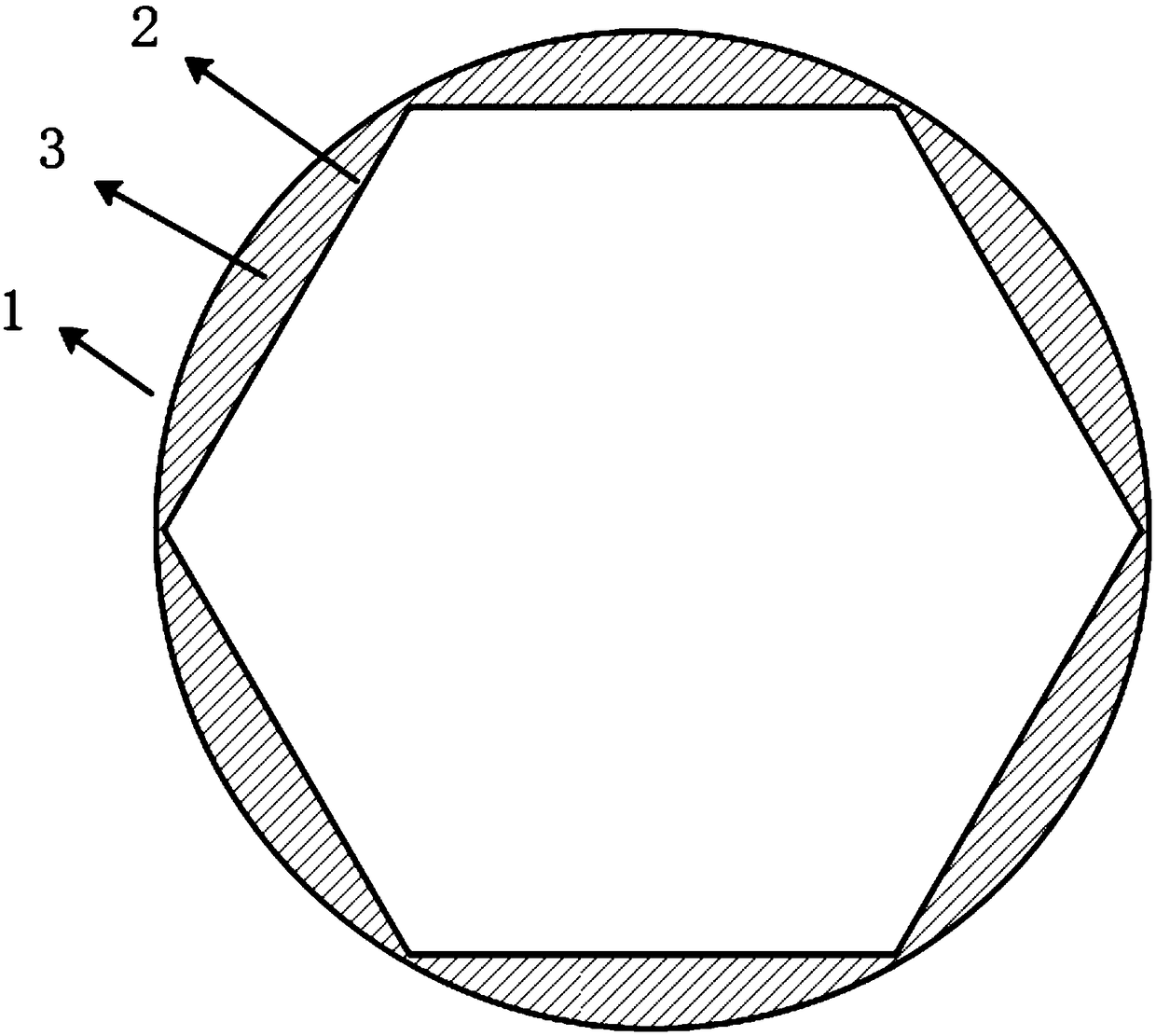

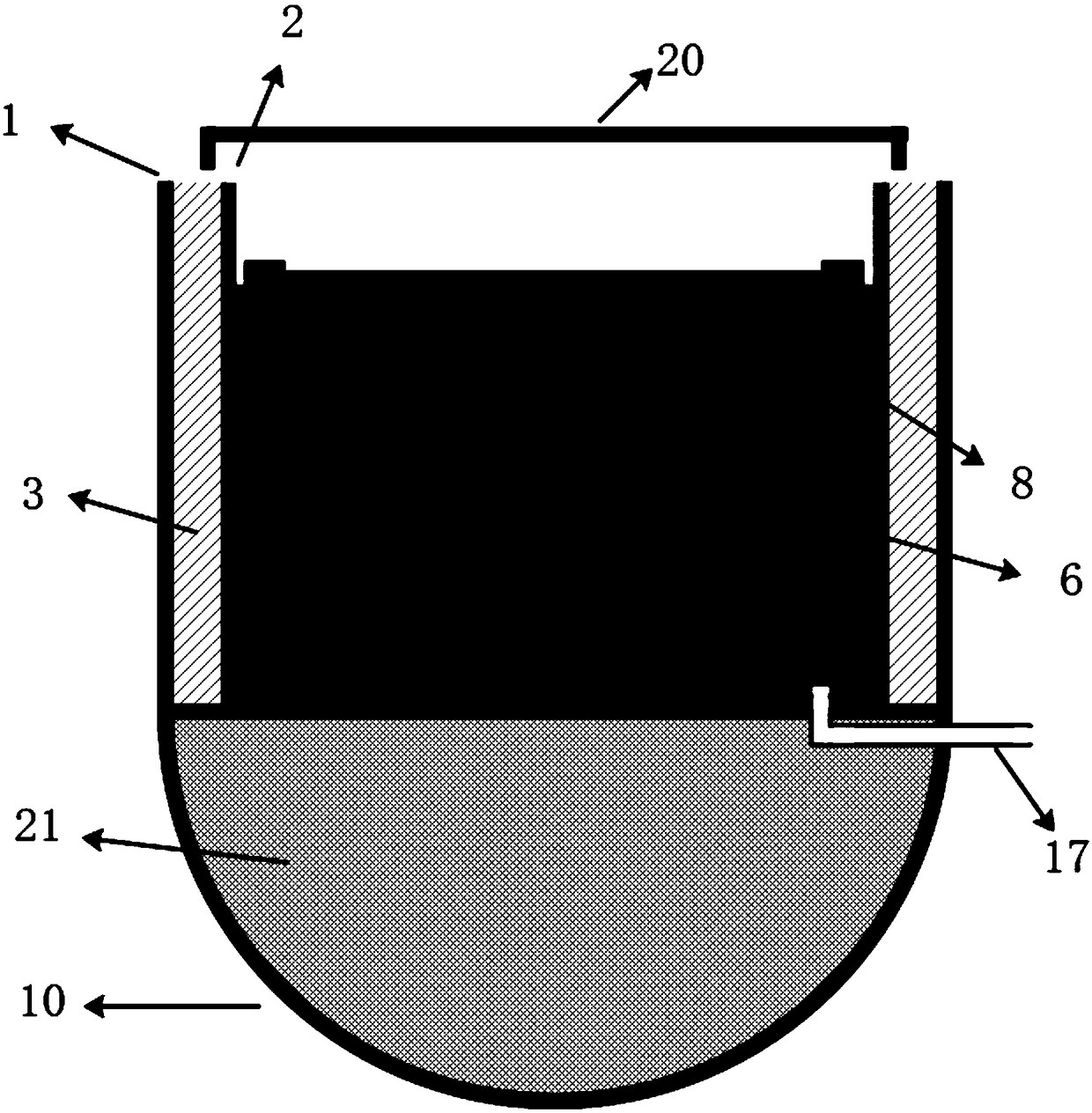

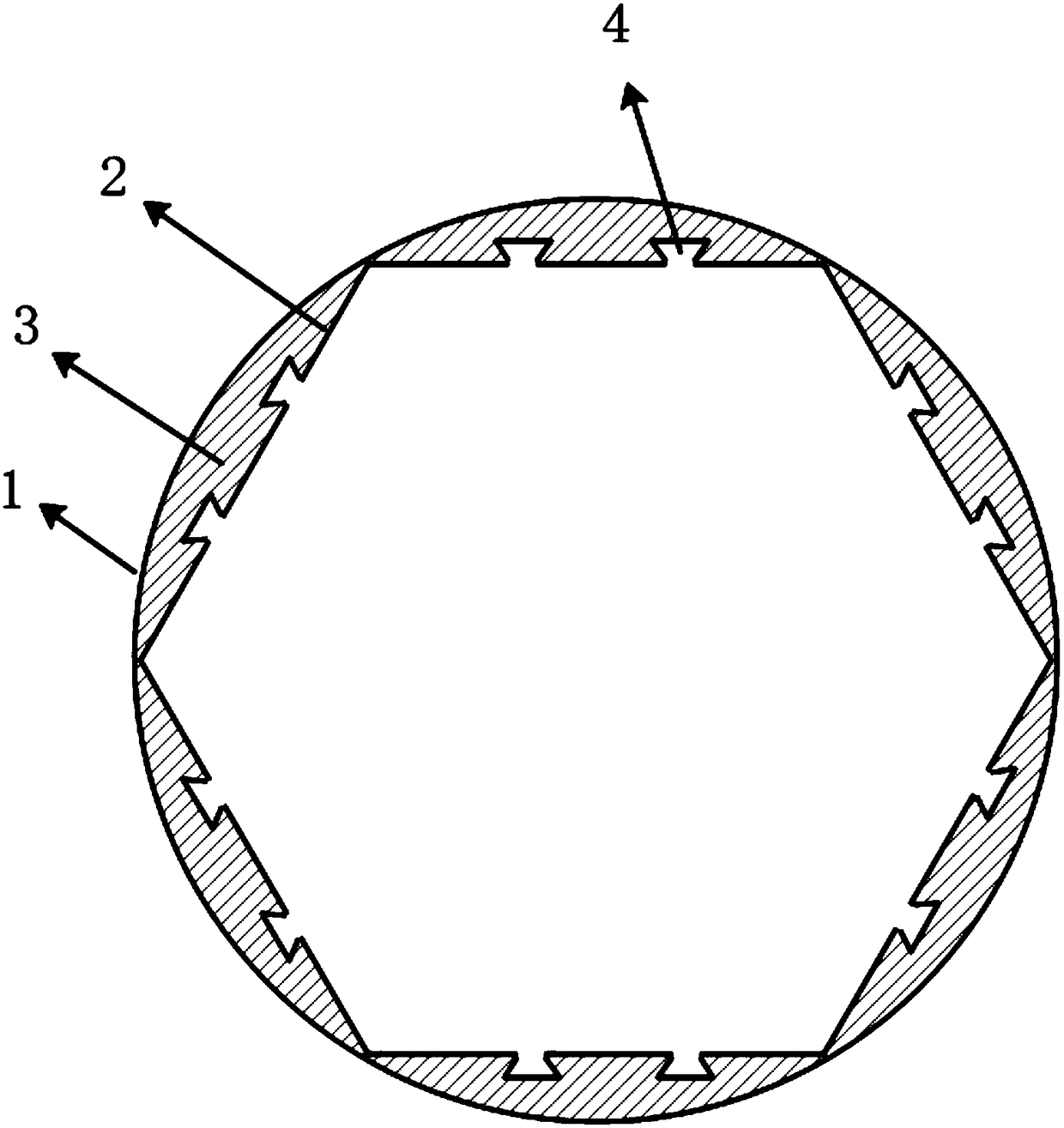

[0039] Specific embodiment one: a kind of multilateral bucket of this embodiment, the ladle body of this multilateral bucket 2, bucket bottom, bung 20 cross-sections are polygonal; There is a filler 3 between the outer barrels 1, and the filler 3 is solid.

[0040] The bottom of the outer bucket adopts a hemispherical bucket bottom 10 filled with liquid or solid matter 21 .

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the polygonal barrel is provided with piston 8, there is liquid 6 between the bottom of the barrel of the multilateral barrel 2 and the piston 8, there is pipeline at the bottom of the barrel of the multilateral barrel 2, can The liquid 6 between the piston and the bottom of the barrel flows out. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the polygonal bucket has a thermal insulation layer. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com